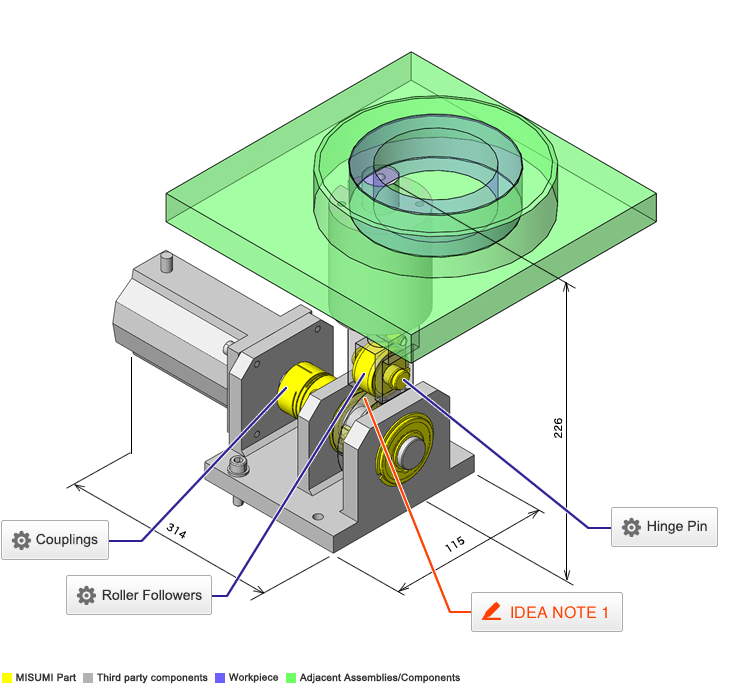

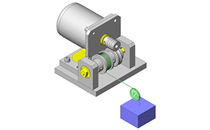

Couplings

| Product name | Couplings - Slit, Clamping |

| Part number | CPSSC32-12-14 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Shorter length and good declination performance

Back to page top

Available sizes

■Couplings - Slit, Clamping

| Material | Surface Treatment | Accessory |

| Aluminum Alloy | Anodized | Hex Socket Head Cap Screw |

| Stainless Steel | ― |

■Sizes and Dimensions

| O.D. (mm) | Shaft bore Dia. (mm),

Driving Side | Shaft bore Dia. (mm),

Driven Side | Overall Length (mm) | Set

Screw |

| Standard Type | Short |

| φ12 | *4 | *4, *5 | 18.5 | 14 | M2 |

| *5 | *5 |

| φ16 | *5 | *5, *6 | 23 | 18 | M2.5 |

| *6 | *6 |

| φ20 | *5 | *6, 6.35, *8 | 26 | 20 |

| *6 | *6, 6.35, 7, *8 |

| 6.35 | 8 |

| *8 | *8 |

| φ25 | *5 | *6 | 31 | 25 | M3 |

| *6 | *6, 6.35, *8, *10 |

| 6.35 | 8, 10 |

| *8 | *8, 9.525, *10 |

| 9.525 | 10 |

| *10 | *10 |

| φ32 | *8 | *8, 9.525, *10, 12 | 41 | 32 | M4 |

| 9.525 | 10, 12 |

| *10 | *10, 11, *12, 14 |

| *12 | *12, *14 |

| φ40 | 8 | 8, 10 | 56 | ― | M5 |

| 10 | 10 |

| 12 | 12, 14 |

| 14 | 14, 16 |

| 15 | 15 |

| 16 | 16 |

Short type is available for sizes marked with * only.

Back to page top

Accuracy Info

■Accuracy of coupling

| Type | O.D. (mm) | Shaft Bore Tolerance | Allowable Angular Misalignment

(°) | Lateral Misalignment

(mm) |

|

|

| Standard | φ12 | +0.5 for the same Dia.

Larger for different Dia.

Shaft Dia. +0.5, see | 2 | 0.10 |

| φ16 |

| φ20 |

| φ25 | 0.15 |

| φ32 |

| φ40 | 0.20 |

| Short | φ12 | 1 | ― |

| φ16 |

| φ20 |

| φ25 |

| φ32 |

The shaft Dia. tolerance represents the tolerance before slit machining.

Back to page top

Performance info.

■Load info. on coupling

| Type | O.D. | Allowable Torque

(N·m) | Max. Rotational Speed

(r/min) | Moment of Inertia

(kg·m²) |

|

Aluminum

normal | φ12 | 0.4 | 52000 | 7.8×10 -8 |

| φ16 | 0.5 | 39000 | 3.4×10 -7 |

| φ20 | 1 | 31000 | 9.1×10 -7 |

| φ25 | 2 | 25000 | 2.6×10 -6 |

| φ32 | 4 | 19000 | 9.7×10 -6 |

| φ40 | 8 | 15000 | 3.3×10 -5 |

Stainless

Steel Normal | φ12 | 0.3 | 52000 | 2.2×10 -7 |

| φ16 | 0.5 | 39000 | 9.0×10 -7 |

| φ20 | 1 | 31000 | 2.5×10 -6 |

| φ25 | 2 | 25000 | 7.1×10 6 |

| φ32 | 3.5 | 19000 | 2.7×10 -5 |

| φ40 | 8 | 15000 | 9.0×10 -5 |

Aluminum

Short | φ12 | 0.4 | 52000 | 6.4×10 -8 |

| φ16 | 0.5 | 39000 | 2.9×10 -7 |

| φ20 | 1 | 31000 | 7.5×10 -7 |

| φ25 | 2 | 25000 | 2.3×10 -6 |

| φ32 | 4 | 19000 | 8.1×10 -6 |

Stainless

Steel Short | φ12 | 0.3 | 52000 | 1.8×10 -7 |

| φ16 | 0.5 | 39000 | 7.8×10 -7 |

| φ20 | 1 | 31000 | 2.1×10 -6 |

| φ25 | 2 | 25000 | 6.3×10 -6 |

| φ32 | 3.5 | 19000 | 2.2×10 -5 |

Back to page top

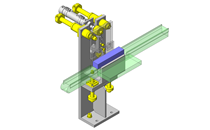

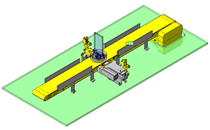

Roller Followers

| Product name | Roller Followers - Separate |

| Part number | NASTFZS12 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Effective as a cam follower to convert circular motion to linear reciprocating motion

Back to page top

Available sizes

■Roller Followers - Separate

| Grease | No Seal | With Seal | Material |

| Crowned | Flat Type | Crowned | Flat Type |

| General | ○ | ○ | ○ | ○ | 52100 Bearing Steel |

| ― | ○ | ○ | ○ | 440C Stainless Steel |

| Low Particle Generation | ― | ― | ― | ○ |

■Sizes and Dimensions

O.D.

(mm) | I.D.

(mm) | Thickness (mm) |

| No Seal | With Seal |

| 19 | 6 | 9.8 | 13.8 |

| 24 | 8 |

| 30 | 10 | 11.8 | 15.8 |

| 32 | 12 |

| 35 | 15 |

| 40 | 17 | 15.8 | 19.8 |

| 47 | 20 |

Back to page top

Accuracy Info

■In the order of accuracy information of roller followers

- Shaft Dia. Tolerance:

- 0

-0.008(mm)

- Roller Dia. Tolerance:

- 0

-0.005(mm)

Back to page top

Performance info.

■Speeds·Loads (Load info.) of roller followers

I.D.

- O.D. | Basic Dynamic Load Rating C (kN) | Basic Static Load Rating Cor (kN) | Max. Allowable Load (kN) | Track Load Capacity (kN) | Max. Rotational Speed (rpm) |

| No Seal | With Seal |

| Crowned | Flat

Type | Crowned | Flat

Type | No Seal | With Seal |

| φ6−φ19 | 4.12 | 4.55 | 0.36 | 1.37 | 3.53 | 1.37 | 3.53 | 20000 | 8000 |

| φ8−φ24 | 5.68 | 5.89 | 0.78 | 1.86 | 4.02 | 1.86 | 4.51 | 17000 | 6800 |

| φ10−φ30 | 9.7 | 9.67 | 1.42 | 2.45 | 5.59 | 2.45 | 6.86 | 15000 | 6000 |

| φ12−φ32 | 10.4 | 10.9 | 2.11 | 2.74 | 5.98 | 2.74 | 7.35 | 13000 | 5200 |

| φ15−φ35 | 12.3 | 14.3 | 4.73 | 3.14 | ― | ― | 8.04 | 10000 | 4000 |

| φ17−φ40 | 17.4 | 20.9 | 5.81 | 3.72 | 11.8 | 9500 | 3800 |

| φ20−φ47 | 19.2 | 24.5 | | 4.61 | 13.8 | 8500 | 3400 |

Back to page top

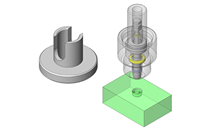

Hinge Pin

| Product name | Precision Pivot Pins - Straight, Retaining Rings |

| Part number | SCCG12-28 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Effective as the roller shaft of a cam follower

Back to page top

Available sizes

■Precision Pivot Pins - Straight, Retaining Rings

| Material | Hardness | Surface Treatment | Accessory |

|

| 1045 Carbon Steel | − | Black Oxide | Retaining Ring 2 pc. | Spring Steel |

| 40 - 45 HRC |

| − | Electroless Nickel Plating | 304 Stainless Steel |

| 40 - 45 HRC |

| Plating hardness 750 HV - | Hard Chrome Plating | Spring Steel |

| plating thickness 3 μm or more |

| 304 Stainless Steel | − | − | 304 Stainless Steel |

| 440C Stainless Steel | 45 - 50 HRC |

| 45 - 50 HRC | Hard Chrome Plating |

| Plating hardness 750 HV - | plating thickness 3 μm or more |

■Sizes and Dimensions

| Pin Dia. | Pin Section Length |

| (Configure in 0.1mm increment) |

| φ2 | 5.0- 30.0 |

| φ3 | 5.0- 50.0 |

| φ4 |

| φ5 | 10.0- 60.0 |

| φ6 | 10.0-100.0 |

| φ8 |

| φ10 | 15.0-100.0 |

| φ12 | 15.0-200.0 |

| φ13 | 25.0-200.0 |

| φ14 |

| φ15 |

| φ16 | 30.0-200.0 |

| φ17 |

| φ18 |

| φ20 |

| φ22 |

| φ25 |

Back to page top

Accuracy Info

■Pivot pin Dia. Tolerance (g6) for Hinge Pin Straight Retaining Ring Type

| Pin Dia. | Tolerance |

| φ2・φ3 | -0.002

-0.008 |

|

| φ4-φ6 | -0.004

-0.012 |

|

| φ8・φ10 | -0.005

-0.014 |

|

| φ12-φ18 | -0.006

-0.017 |

|

| φ20-φ25 | -0.007

-0.020 |

|

Back to page top

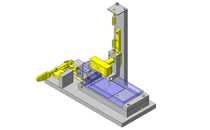

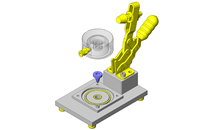

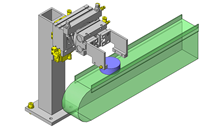

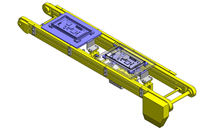

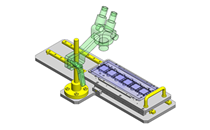

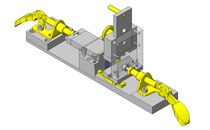

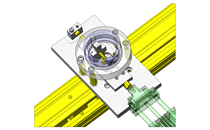

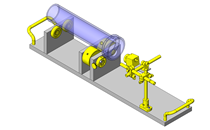

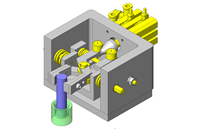

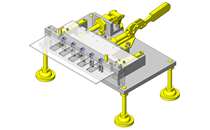

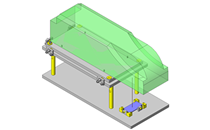

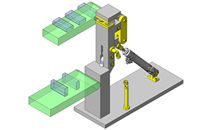

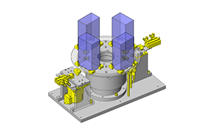

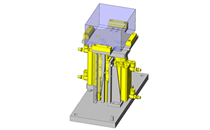

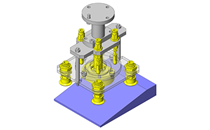

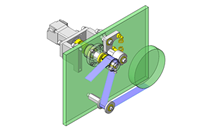

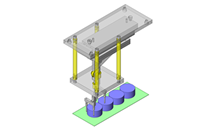

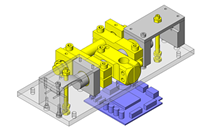

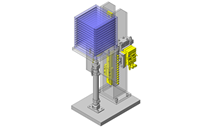

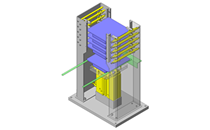

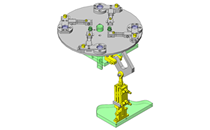

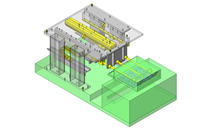

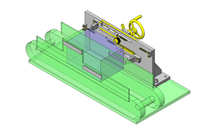

IDEA NOTE The load cell is moved up and down by a cam.

The cam causes the load cell to stroke 1.5mm. As the load is applied to the bearing of the cam shaft, the load is not applied to the vertical movement mechanism.