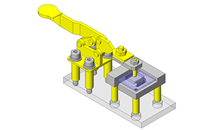

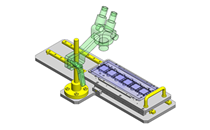

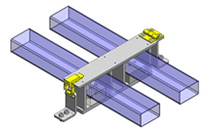

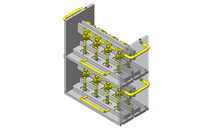

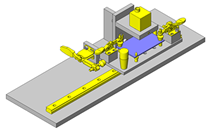

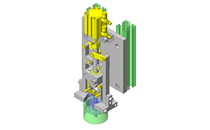

Toggle clamp

| Product name | Toggle Clamps -Horizontal Handle- |

| Part number | MC01-2 |

| Features | Hold Down, Flange Base Type. Low Profile-designed. |

* Orange colored cells in the table below indicate the part numbers used in this example.

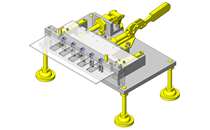

Selection criteria

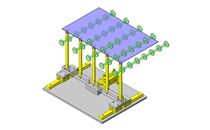

Suitable for fixture clamping with frequent change setups

Back to page top

Available sizes

Toggle clamp hold down type, Standard horizontal handle (Flange base)

| Body material | 1018 Carbon Steel | 304 Stainless Steel |

| Surface treatment | Trivalent Chromate | - |

| Clamping force(N) | 264.6 | 264.6 | 882 | 2352 | 264.6 | 264.6 | 882 | 2352 |

| Weight(g) | 30 | 35 | 130 | 265 | 30 | 35 | 130 | 265 |

| Arm open-close angle | 90° | 90° | 85° | 90° | 90° | 90° | 85° | 90° |

| Handle open/close angle | 75° | 75° | 73° | 65° | 75° | 75° | 73° | 65° |

| Overall width | 23.8 | 23.8 | 36 | 35 | 23.8 | 23.8 | 36 | 35 |

| Overall height(Clampled) | 17.3 | 17.3 | 37.8 | 47.6 | 17.3 | 17.3 | 37.8 | 47.6 |

| Overall height(Unclamped) | 48.3 | 48.3 | 96.8 | 110.2 | 48.3 | 48.3 | 96.8 | 110.2 |

| Overall length (Clamped) | 71 | 69.1 | 143.5 | 173 | 71 | 69.1 | 143.5 | 173 |

| Clamp position | Fixed | Variable | Variable | Variable | Fixed | Variable | Variable | Variable |

| Accessory | Nylon Bolt | Bolt with rubber

Material: NBR

Hardness: Shore A70 | Stainless steel bolt |

Back to page top

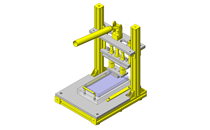

Miniature Clamp Lever

| Product name | Miniature Clamp Levers - Threaded |

| Part number | CLDMC6-12-B |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

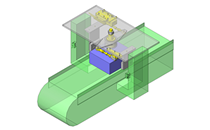

Suitable for less frequent setup changes

Back to page top

Available sizes

■Miniature Clamp Lever

Thread

Type | Lever | Screw | Spring |

| Material | Surface treatment | Pint color | Material | Surface treatment | Material |

| Threaded・Tapped | Zinc

diecast | Baked paint | Black, Silver gray, Red, Orange, Yellow | 1045 Carbon Steel | Black oxide | 304 Stainless Steel |

| 303 Stainless Steel | - |

■Sizes and Dimensions

| Screw type | Thread DIA.

(Coarse) | Handle rotating radius | Lever

height | Thread length, Tap depth |

|

| Thread | M4 | 30 | 29 | 8、12、16、20、25 |

| M5 | 8、12、16、20、25、32 |

| M6 | 8、12、16、20、25、32 |

| M8 | 42 | 40 | 8、12、16、20、25、32 |

| Tapped | M4 | 30 | 29 | 7 |

| M5 | 7 |

| M6 | 7 |

*Red and Yellow levers for M8 and M8 tap are not available

Back to page top

Performance info.

■Miniature Clamp Lever load info.

Screw DIA.

(Coarse) | Max. load Fmax.(N) | Max. clamping force Pmax.(kN) |

| 303 Stainless Steel | 1045 Carbon Steel | 303 Stainless Steel | 1045 Carbon Steel |

| M4 | 48 | 80 | 1.8 | 3 |

| M5 | 65 | 108 | 2.9 | 4.8 |

| M6 | 110 | 184 | 4.1 | 6.8 |

| M8 | 189 | 316 | 7.5 | 12.5 |

*Max. load: Maximum load that can be applied to the lever tip when clamped

*Max. clamping force: Axial force when clamped at max. load.

Back to page top

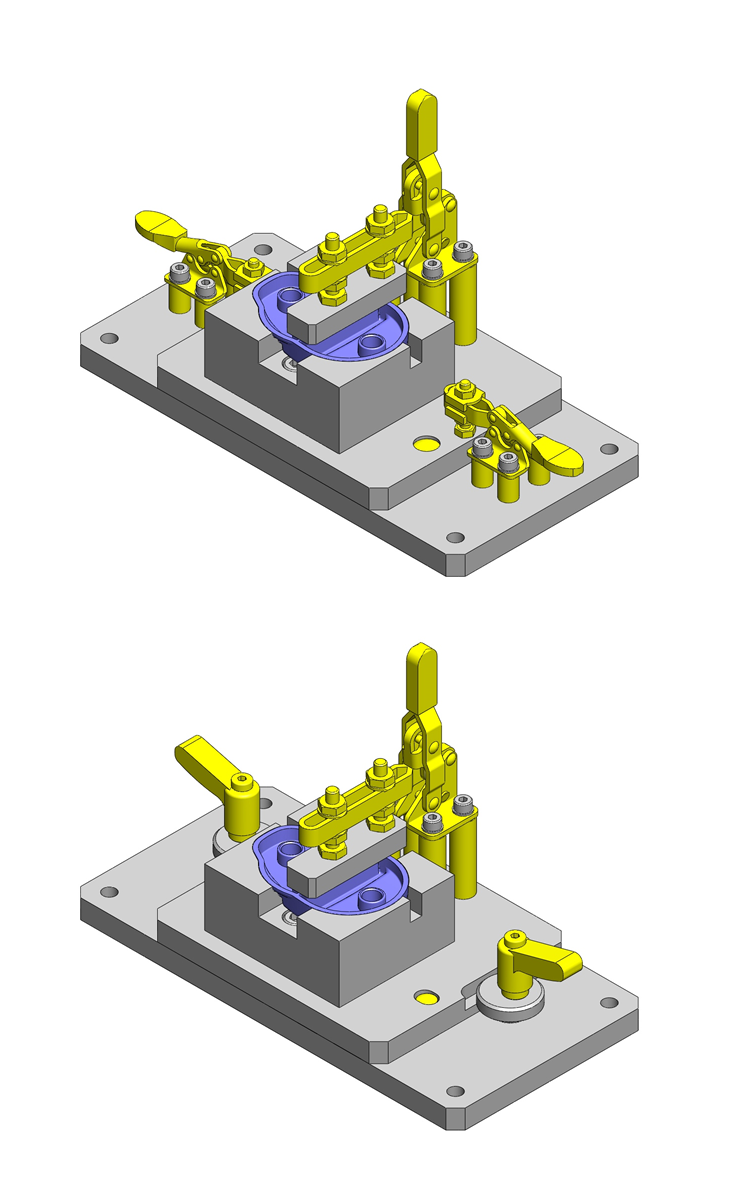

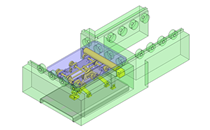

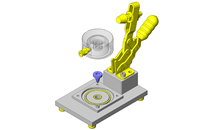

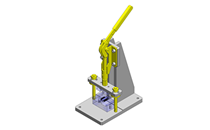

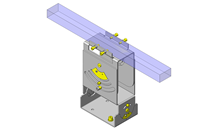

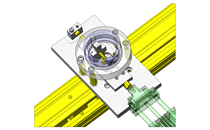

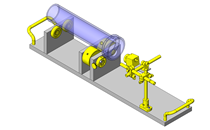

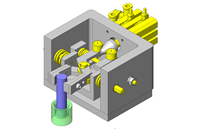

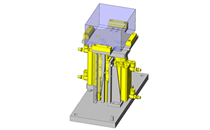

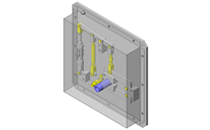

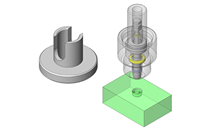

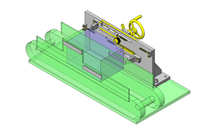

IDEA NOTE Eccentric cam for less frequent setups.

Clamping with an eccentric cam and a clamp lever for setup is labor intensive, but risk of accidental unclamping is low and suitable for less frequent setups.

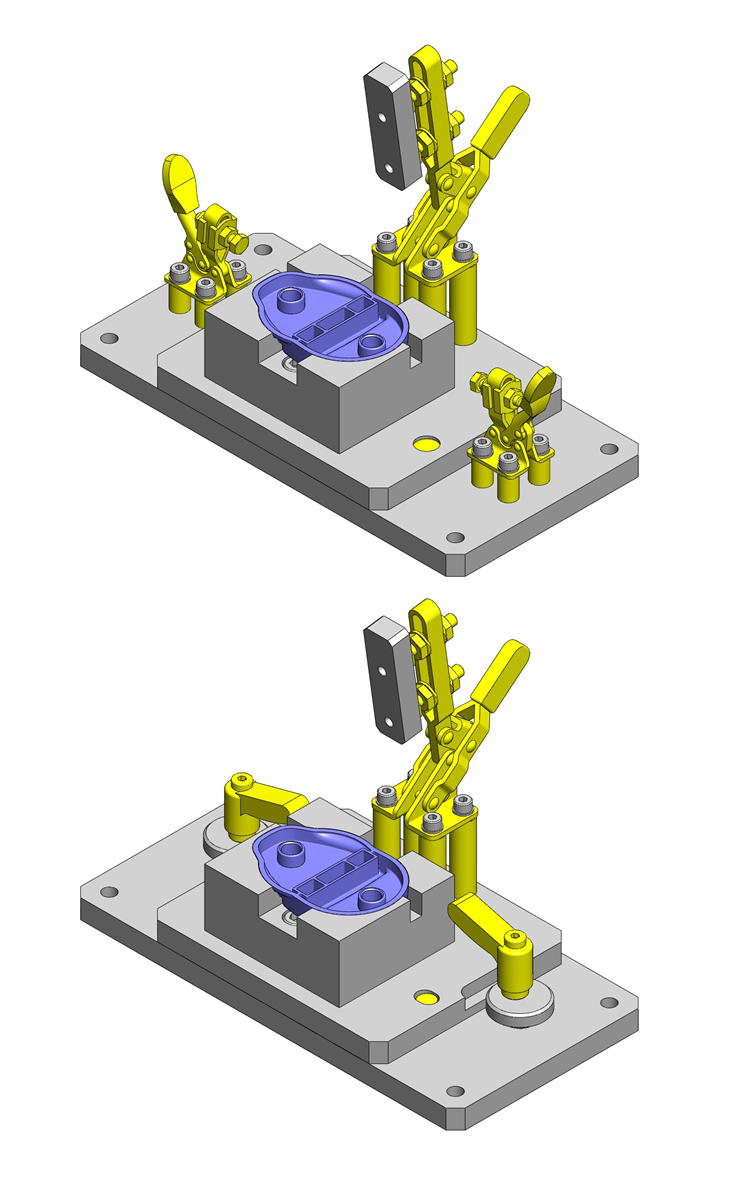

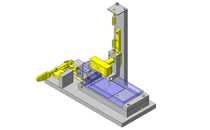

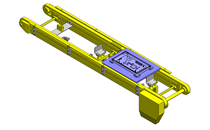

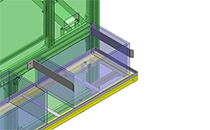

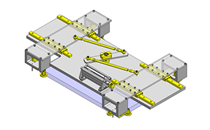

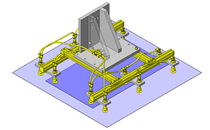

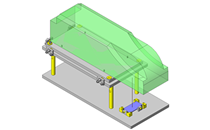

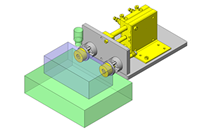

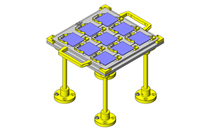

IDEA NOTE Metal collars used as toggle clamp risers.

Hold down surface for toggle clamps are generally designed to be at the same height as mounting flange seating surface. When the clamping surface is higher than the seating surface use spacers to compensate for height difference. However, if the height difference is too big,clamping force may decrease.

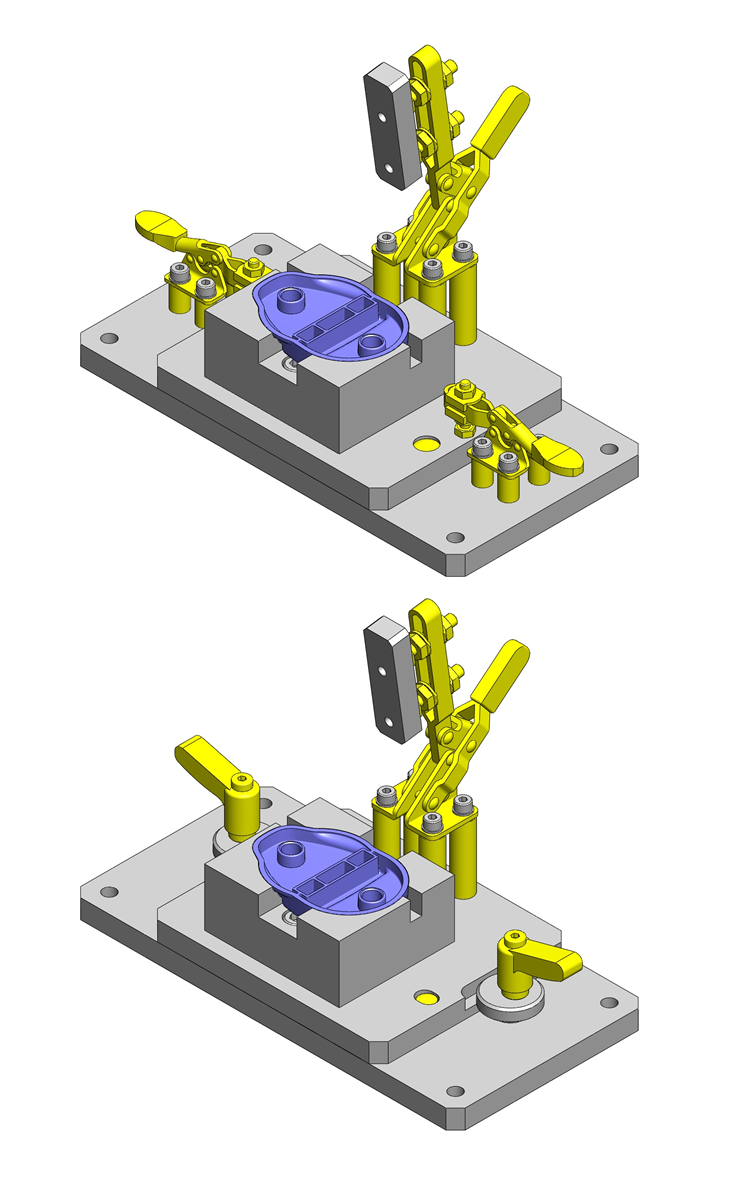

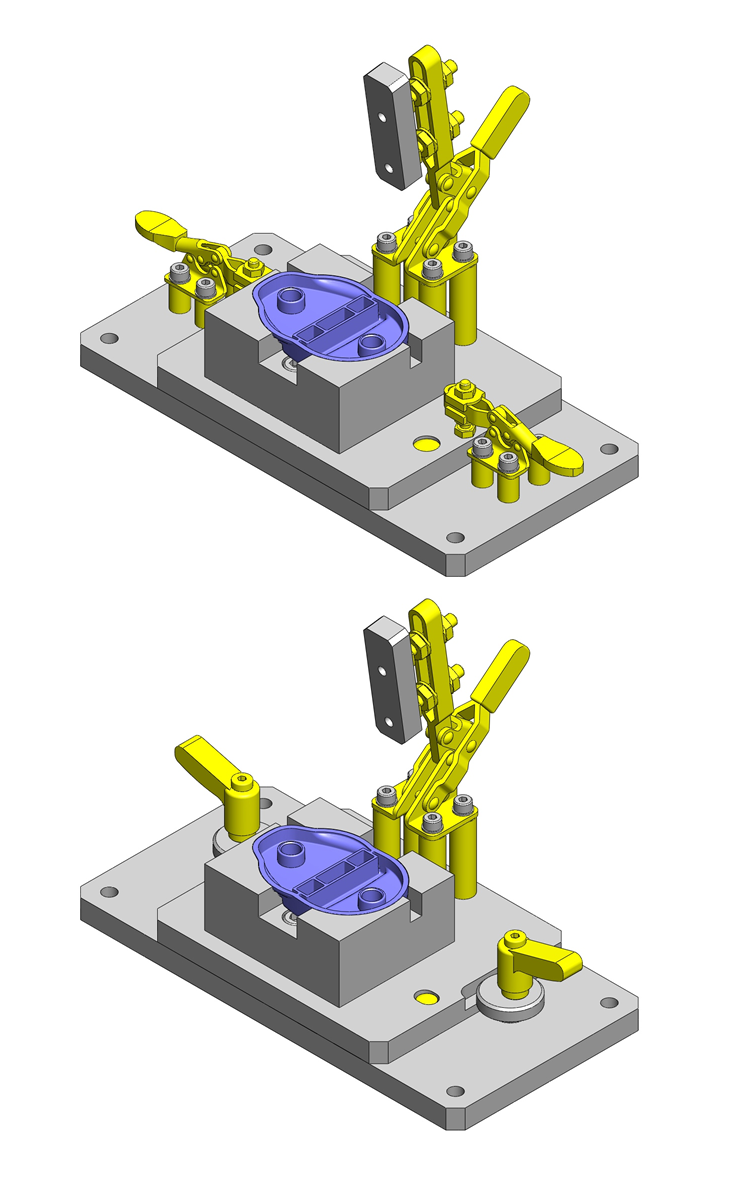

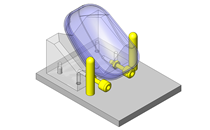

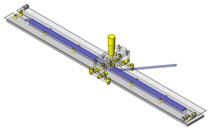

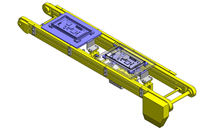

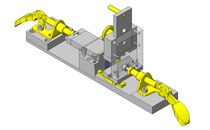

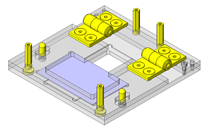

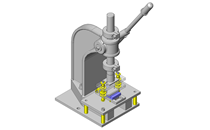

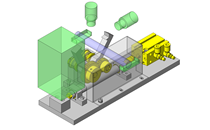

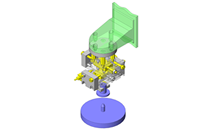

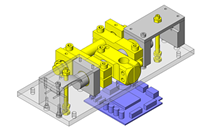

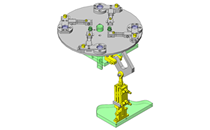

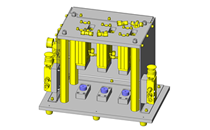

IDEA NOTE Obtaining the optimum functionality by modifying standard toggle clamps.

The workpiece holding toggle clamp (Long arm) is originally for a different purpose, but by replacing the hold down bolts with fully threaded studs and directly mounting custom press pad on them can provide optimum functionality as a workpiece hold down device.