(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

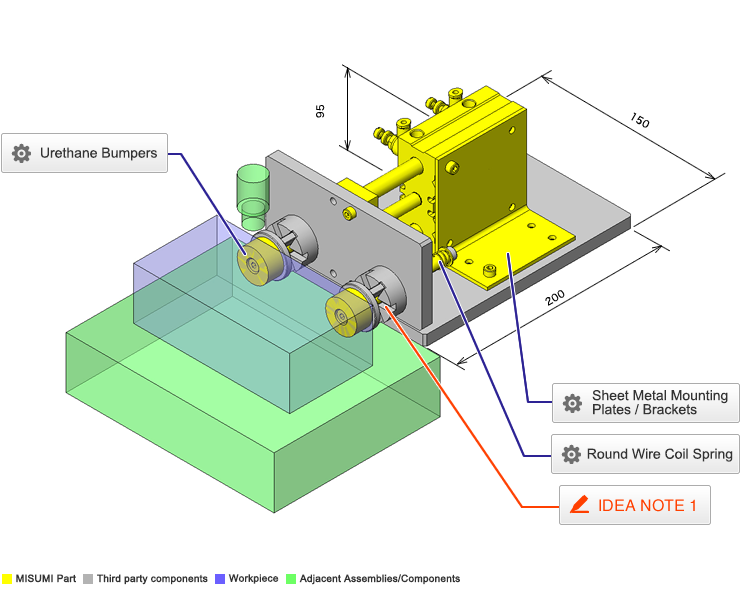

- > No.000164 Push Position Switch Mechanism

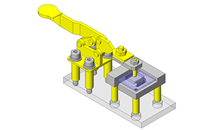

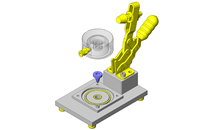

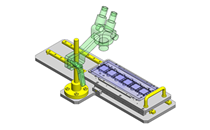

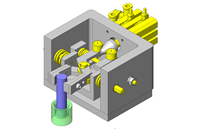

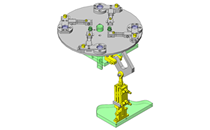

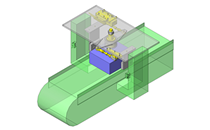

No.000164 Push Position Switch Mechanism

14

14

Easily switchable horizontal position via spring, pusher switch, and urethane bumper.

Relevant category

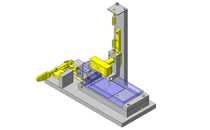

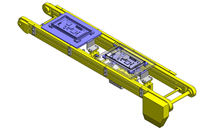

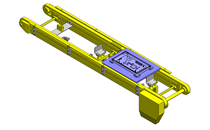

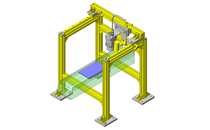

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

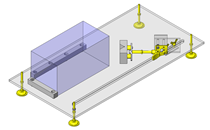

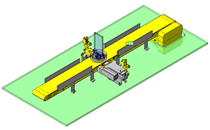

Application Overview

Purpose

- Purpose

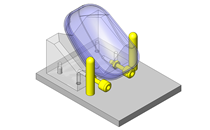

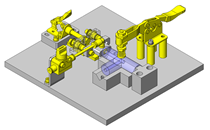

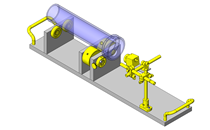

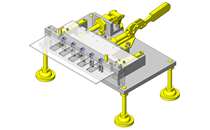

- Fixed stroke cylinder positions workpieces of different sizes.

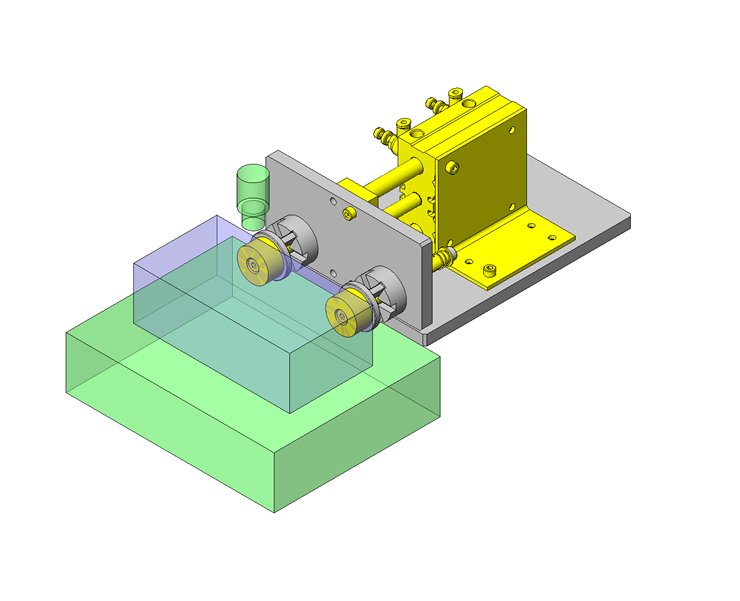

- Operation

- This mechanism is installed on both sides of the workpiece.

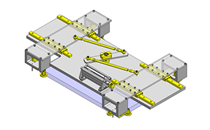

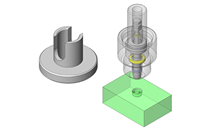

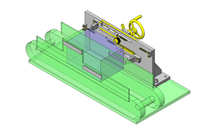

Points for use

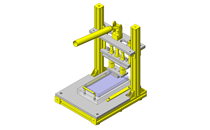

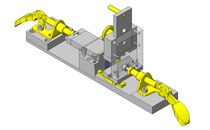

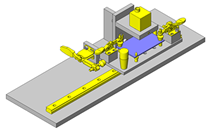

- The clamping distance can be adjusted.

The initial position is set by adjusting the height of the stopper and fixing it with a nut.

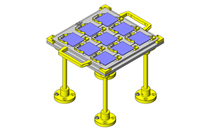

Target workpiece

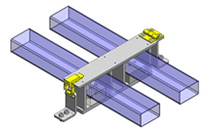

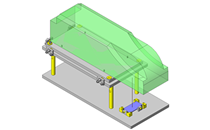

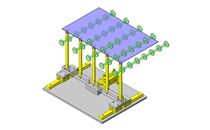

- The widths of the workpiece differ depending on the model.

Different widths: 3 positions - Width (1): W80mm

- Width (2): W86mm

- Width (3): W92mm

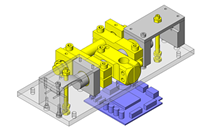

Design Specifications

Operating Conditions or Design Requirements

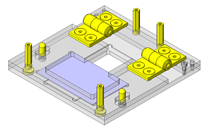

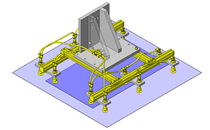

- Outer dimensions: W200 x D150 x H95mm

Required Performance

- Positioning accuracy: ±0.5mm

Selection Criteria for Main Components

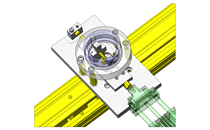

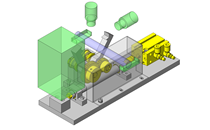

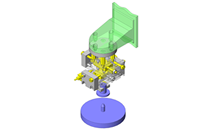

- A compression spring is chosen based on the operating force and pulling power of the stopper/knob.

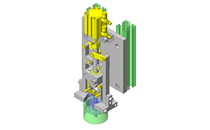

Design Evaluation

Verification of main components

- The workpiece retaining force and the operating force of the knob with a claw are verified based on the selected spring load.

- Confirmation of operating force of knob with a claw

- Conditional Value:

Different widths: 3 positions

Height (1): W80mm

Height (2): W86mm

Height (3): W92mm

Spring constant: K = 0.29N/mm

Initial spring contraction amount: L1 = 7mm

Adjustment amount: L2 = 6mm (3 steps by 3-mm increments)

Distance from the stopper end face to the tip of the claw of the knob with a claw in Height (1) state: L3 = 2mm

- Conditional Value:

- Retaining force at each step

- Spring tension in Height (3) state: P1 = K x L1, therefore, P1 = 0.29 x 7 = 2.03N

Spring tension in Height (2) state: P2 = K x (L1 + L2), therefore, P2 = 0.29 x (7 + 3) = 2.9N

Spring tension in Height (1) state: P3 = K x (L1 + L2 x 2), therefore, P3 = 0.29 x (7 + 3 x 2) = 3.77N

- Spring tension in Height (3) state: P1 = K x L1, therefore, P1 = 0.29 x 7 = 2.03N

- Operating force

- Distance needed to remove the claw of the knob with a claw from the stopper:

L4=(L1+L2×2+L3)=7+3×2+2=15mm

The operating force for step change: F1 = K x L4, therefore,

F1=0.29×15=4.35N

- Distance needed to remove the claw of the knob with a claw from the stopper:

Other Design Consideration

- The accuracy of each height is determined by the manufacturing quality of the stopper.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category