(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000137 Adjustable Height Clamping Mechanism

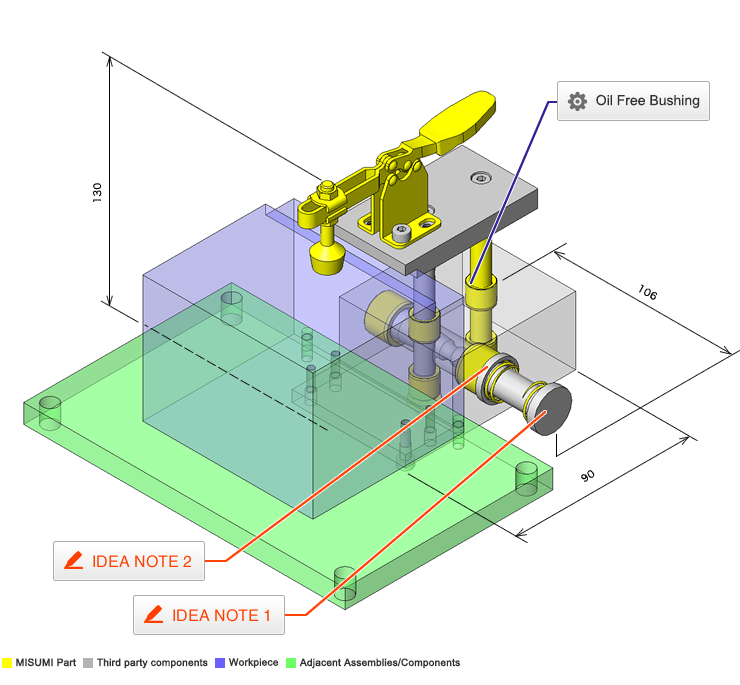

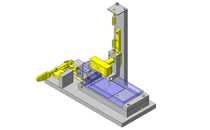

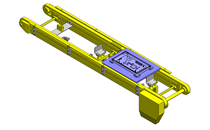

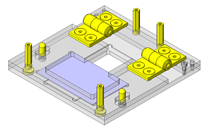

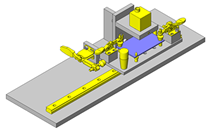

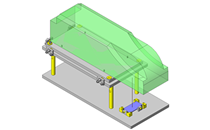

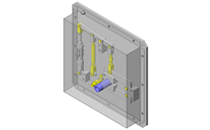

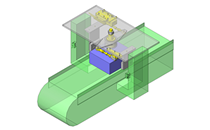

No.000137 Adjustable Height Clamping Mechanism

13

13

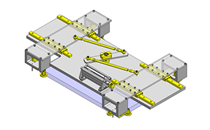

Simple height adjustment by manual operation

Relevant category

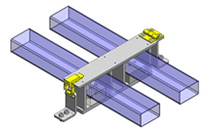

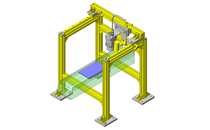

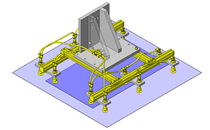

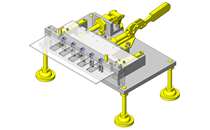

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

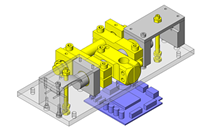

Application Overview

Purpose

- Height adjustment to clamp workpiece according to its height.

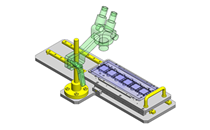

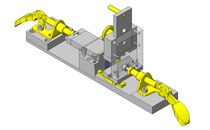

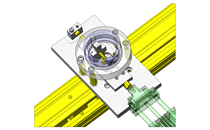

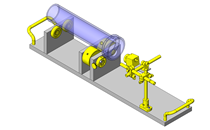

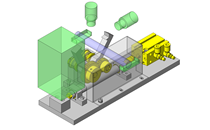

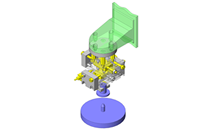

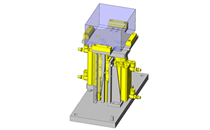

- There are three shafts in this system. Two of the vertical shafts are parallel to each other. One of the shaft acts as a linear guide, and the other shaft is tapered to fit onto a perpendicular horizontal third shaft. The third shaft perpendicular to the two parallel shafts will be spring loaded and can be position back and forth to lock and unlock the vertical tapered shaft. With this mechanism, we would have the flexibility to adjust the height of the clamp and secure position.

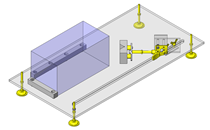

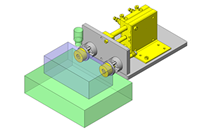

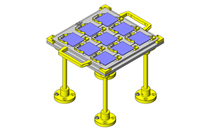

Target workpiece

- The height of resin parts differs depending on the model.

- Size (1): W80 x D90 x H67mm

Size (2): W80 x D90 x H45mm

Size (3): W80 x D90 x H30mm - Weight (1): 170g

Weight (2): 110g

Weight (3): 70g

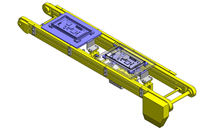

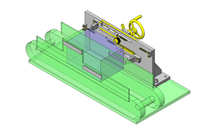

Design Specifications

Operating Conditions or Design Requirements

- Different heights: 3 positions

Height (1): H67mm

Height (2): H45mm

Height (3): H30mm

Outer dimensions: W177 x D170 x H170mm

Required Performance

- Positioning accuracy: ±0.3mm

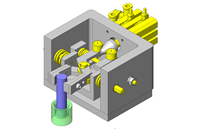

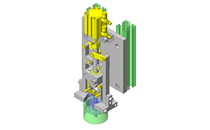

Selection Criteria for Main Components

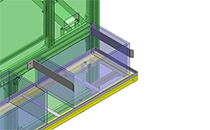

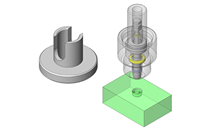

- Oil free bushings within the allowable load range of the vertical shaft of the tapered portion are selected.

Design Evaluation

Verification of main components

- Confirmation that the force applied to the oil free bushings is within the allowable range

- Conditional value: taper angle of horizontal pin: θ=5°, vertical shaft diameter = oil free bushing inner diameter: d=8mm, oil free bushing length: L=10mm, spring coefficient of the spring:k=0.3N/mm, spring free length: Lf=30mm, spring length when shaft is fixed:Ls=26mm.

- Force applied to horizontal pin by spring when shaft is fixed:F=(Lf-Ls)×k=(30-26)×0.3=1.2N.

- Force at which tapered portion of horizontal pin presses shaft in lateral direction: W=F/tanθ=1.2/tan5°=13.7N

- Force in radial direction applied to oil free bushings:P=W/(d×L)=13.7/(8×10)=0.17N/mm ²

- As two oil free bushings are arranged, the force applied to one bushing: P'=P/2=0.085N/mm ²

- As allowable maximum load on oil free bushing, copper-alloy type is980N/mm ² > P'=0.085N/mm ² , safety is secured.

Other Design Consideration

- Oil free bushings are installed on both the horizontal pins and the vertical shafts.

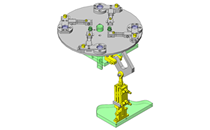

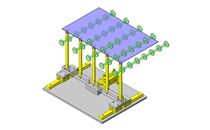

Explore Similar Application Examples

Page

-

/

-

-

Relevant category