(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000003 Roller Runout Inspection

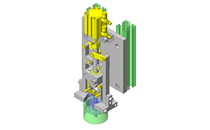

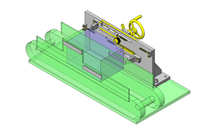

No.000003 Roller Runout Inspection

299

299

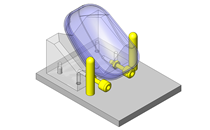

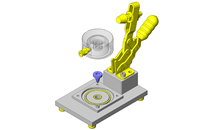

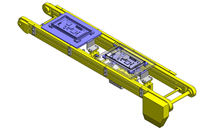

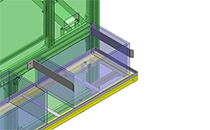

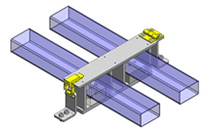

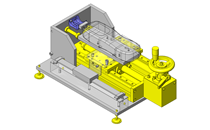

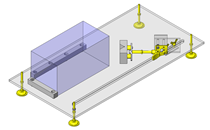

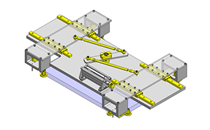

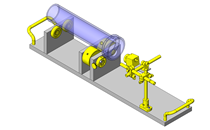

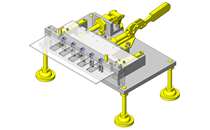

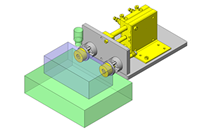

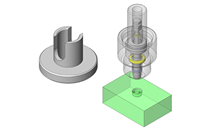

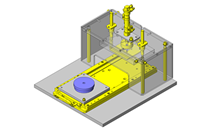

The workpiece is held with V blocks and urethane molded bearings, enabling highly accurate runout inspection.

Relevant category

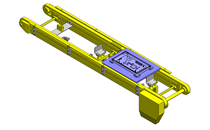

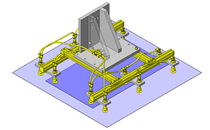

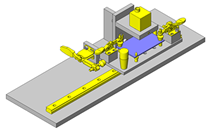

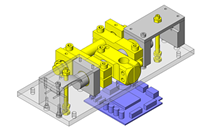

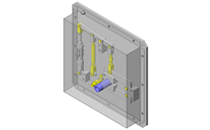

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

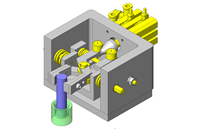

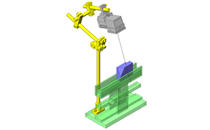

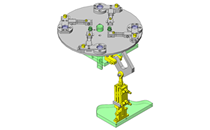

- The roller is positioned using V blocks and urethane molded bearings.

Points for use

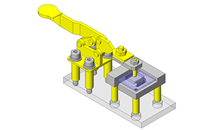

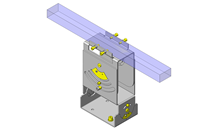

- The upper fixture with urethane molded bearings is held with toggle clamps to prevent the roller from moving in vertical direction.

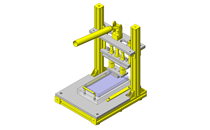

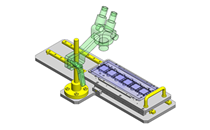

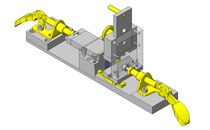

- Runout is measured with a contacting displacement sensor.

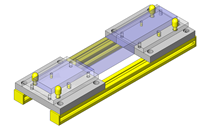

Target workpiece

- Roller

- Outer demensions: φ20xL120

- Workpiece weight: 150g

Design Specifications

Operating Conditions or Design Requirements

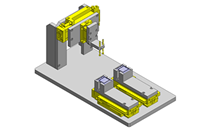

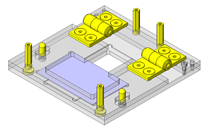

- Toggle clamp arm open/close angle: 90°

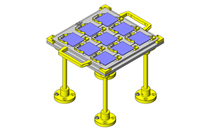

- External dimensions:

W150xD150xH107

Required Performance

- Runout measurement accuracy: 0.01mm increment

Selection Criteria for Main Components

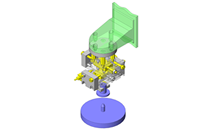

- Toggle clamp

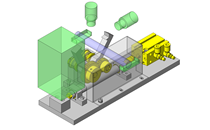

- Hold Down type is chosen since the roller is held with V blocks

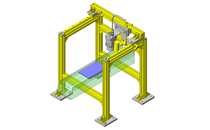

- Linear guide

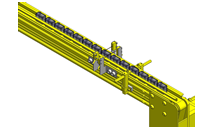

- Selected based on the unit size since the applicable moment loads are not very large.

Design Evaluation

Other Design Consideration

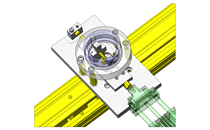

- The roller is centered with the V blocks and urethane molded bearings (3 point contact)

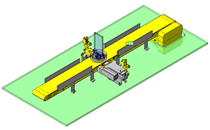

- The roller can be measured at arbitrary position within the linear guide motion range.

- The measurement sensor is fixed with a locating pin and a screw to prevent movement during measurements.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category