(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000018 Test Fixture for Product Aging

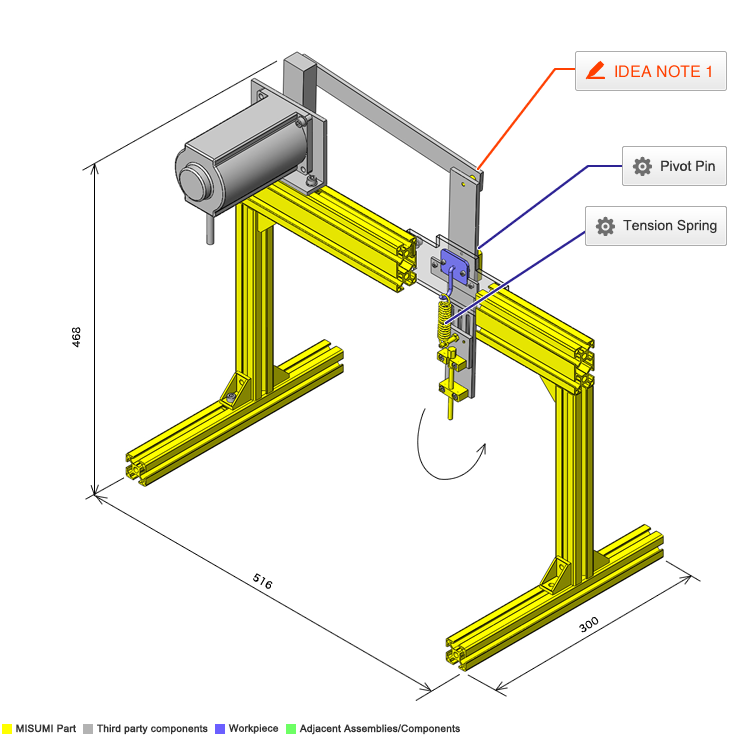

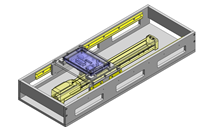

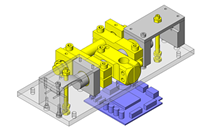

No.000018 Test Fixture for Product Aging

60

60

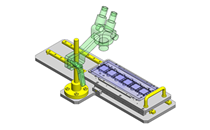

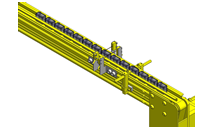

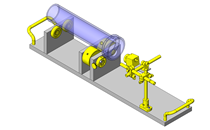

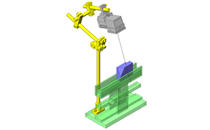

Mechanism to convert rotary motion to reciprocating motion

Relevant category

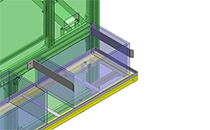

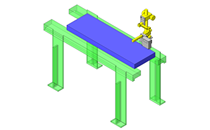

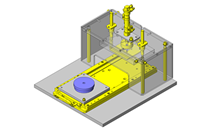

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

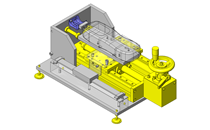

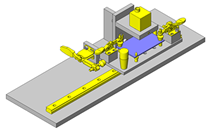

- Fixture to measure aging variations (dimensional changes over time, and cracking, etc.) by applying repeated loads. (Not to the extent of destruction)

Points for use

- Oscillating mechanism driven by a motor.

Target workpiece

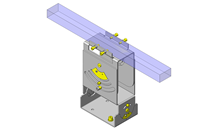

- Levered lug

External Dims.: W40 x D30 x H3 (excluding the lever)

Workpiece weight: 5g

Design Specifications

Operating Conditions or Design Requirements

- Oscillates in ± 45° range.

- External dims.: W516 x D300 x H468

Required Performance

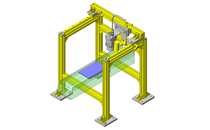

- Tensile load: 60N

Spring constant: 4.13N/mm

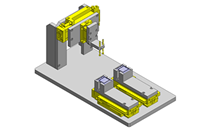

Selection Criteria for Main Components

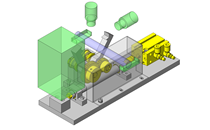

- Motor

- A motor is selected for automated oscillating motion.

- Spring

- Spring selection makes applying arbitrary loadings possible.

Design Evaluation

Verification of main components

- Select an appropriate motor for oscillating motion.

- Motor speed

- Motor RPM (Ns): 1800rpm

- Reduction ratio (i): 1/50

- Rotation pitch circle diameter (Dp): 156mm

- Link ratio: Approx. 1/3

- Speed (V)

V=Ns×(1/60)× i ×π×Dp×1/3

=1800×(1/60)×(1/50)×π×156×1/3=98 mm/s

- Torque

- Motor torque Tm=3.33N·m

- Assumed load: F=60N

- Link ratio: Approx. 1/3

- Fa=F*1/3

- Load torque TL=(Fa×Dp)/(2×1000)=60×(1/3)×156/(2×1000)=1.56 N·m

Tm>TL, OK.

- Spring load

- Formula: Reaction force F=kx

- Assumed load: F=60N

- Deflection under tension: x=14.5mm

- Spring constant: k=60/14.5=4.13N/mm selected

Other Design Consideration

- The spring load can be varied by moving the spring post slot located on the plate. And adjusting bolt is used for adjustments, making it easy to change the spring to vary tension.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category