(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000186 Inspection Probe Adjustment Mechanism

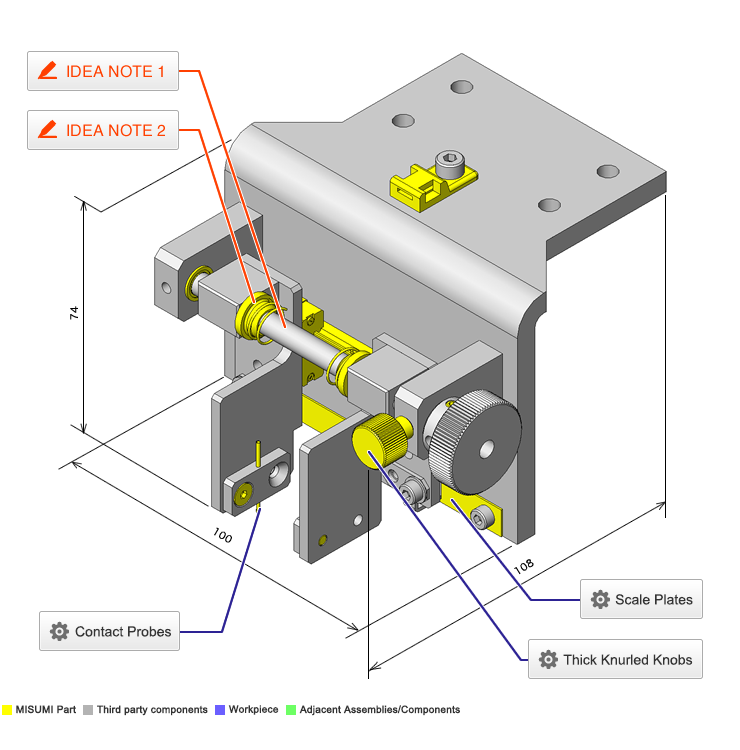

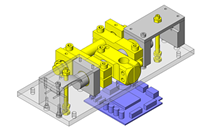

No.000186 Inspection Probe Adjustment Mechanism

18

18

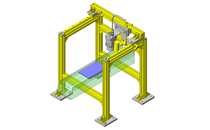

Adjustment mechanism by using the right-handed screw and left-handed screw

Relevant category

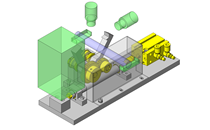

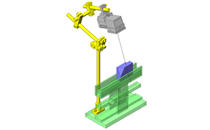

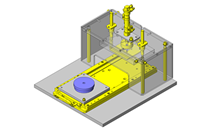

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

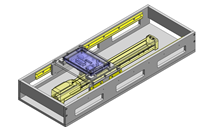

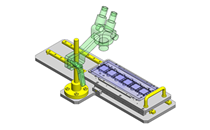

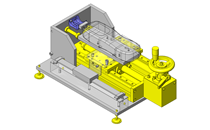

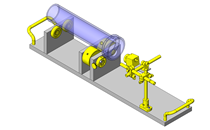

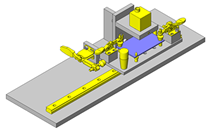

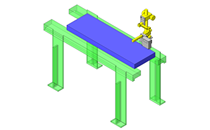

- Test unit that can handle various size workpieces by adjusting the position of inspection probes.

- Operation

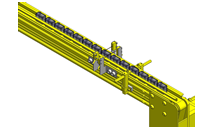

- Changes the distance between probes (probe mounting brackets) by operating right/left hand lead screws. Depending on which direction the lead screw knob is turned, the probe mounting brackets are closing in or moving out from each other.

Points for use

- Capable to adjust the probe distance from 2 mm to 22 mm.

Target workpiece

- Shape: Circuit board

- Size: W 240 x D 140 mm

Design Specifications

Operating Conditions or Design Requirements

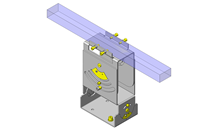

- External dimensions: W 100 x D 180 x H 74 mm

- Probe adjustment distance: 2 mm - 22 mm

Required Performance

- Accuracy: ± 0.1 mm

- Probe stroke: 2.5 mm

- Probe load: 50 gf (2/3 stroke)

Selection Criteria for Main Components

- Linear guide

- Select a linear guides that can handle the load at the probe contact (initial selection is size 10)

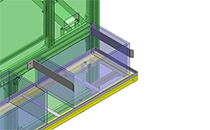

- Compression spring

- To remove any backlash when positioning inspection pins and during testing.

Design Evaluation

Verification of main components

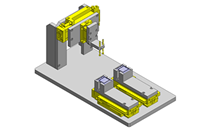

- Select motor based on load moment.

- Motor selection

- Conditional values:

- Motor shaft allowable moment of inertia: 1.25 × 10⁻⁵ kg・m² (catalogue value)

- Reduction ratio: 12.5

- Load total moment of inertia: 5.8 × 10⁻⁵ kg・m²

1.25 x 10⁻⁵ x 12.5 > 5.8 x 10⁻⁴ Thus, no problem. - t = 1.0 s, N =120 rpm (reduction ratio: 12.5), and J = 5.8 kg・cm²

Load torque T=J x N/9.55 x 10-4 x t , T= 7.3×10-3 - Allowable torque: 0.98 N・m

7.3×10⁻³ < 0.98

⇒Thus, meeting the condition.

Other Design Consideration

- Reducing operation force by adopting a fine screw thread.

- Adopting a scale with 0 at the center to read the distance value.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category