(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

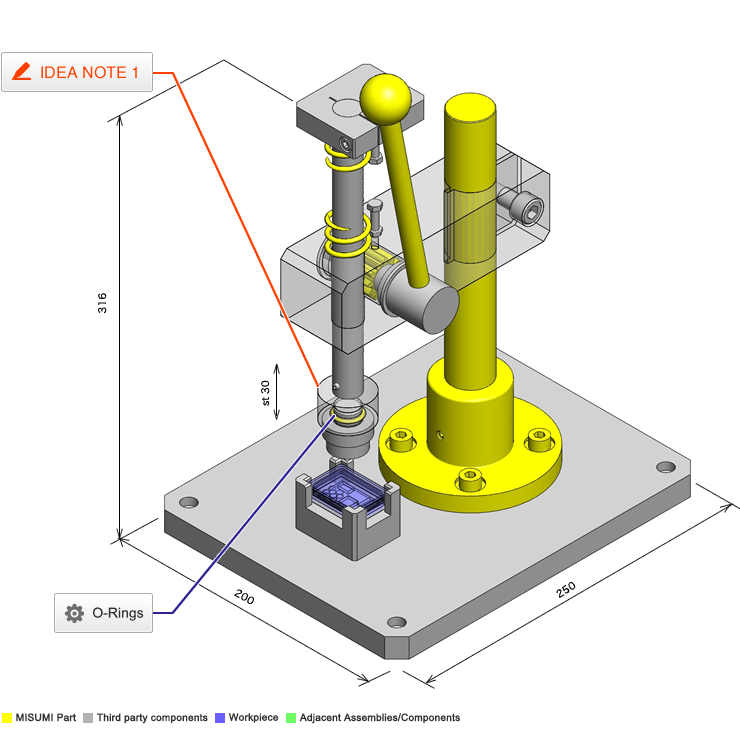

- > No.000061 Retaining Mechanism

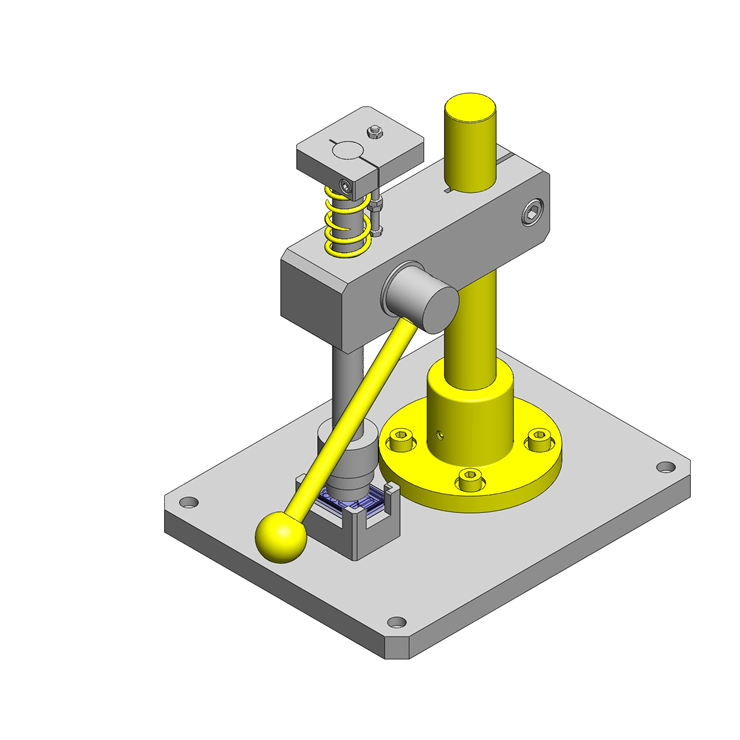

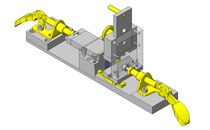

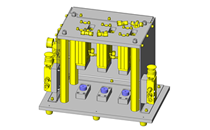

No.000061 Retaining Mechanism

52

52

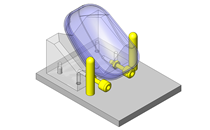

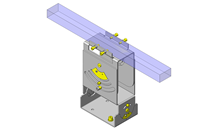

An O-ring is used for part retention.

Relevant category

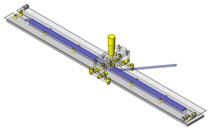

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

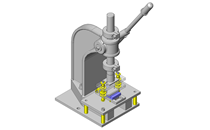

Application Overview

Purpose

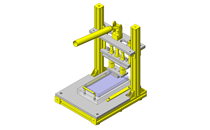

- To press-fit caps into a plastic casing.

Points for use

- Manual operation for small-quantity production.

Target workpiece

- Plastic cap

- Approximate workpiece size: 40X29X12mm

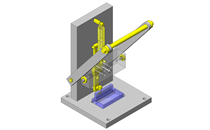

Design Specifications

Operating Conditions or Design Requirements

- External dimensions: W200XD250XH316mm

- Press fit stroke: 30mm

Required Performance

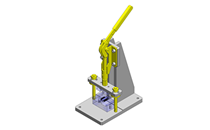

- Pushing force: 50N or more

- Operating load: 10N or less

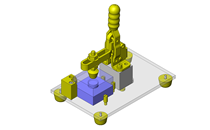

Selection Criteria for Main Components

- Device mounting stand

- Select an economical shaft with a large diameter.

Design Evaluation

Verification of main components

- Verify that the cap pressing force meets the required operating load.

- Relationship between handle operating load and pushing force

- Conditional values:

Pinion pitch circle radius rm=24mm=0.024m

Operating load Fs N

Pushing force F N = 50N

Pinion center - Operation point R m = 160mm = 0.16m - F N = Fs x R/r

Operating load Fs = F/R × r Thus, Fs = 50/0.16 x 0.024 = 7.5N

⇒Meeting "Necessary operating load of 10N or less."

- Conditional values:

Other Design Consideration

- For most O-ring applications, the groove shapes conform to JIS standards. However, different shapes are used for this application.

Explore Similar Application Examples

Page

-

/

-