(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000075 Rotate and Transfer Mechanism

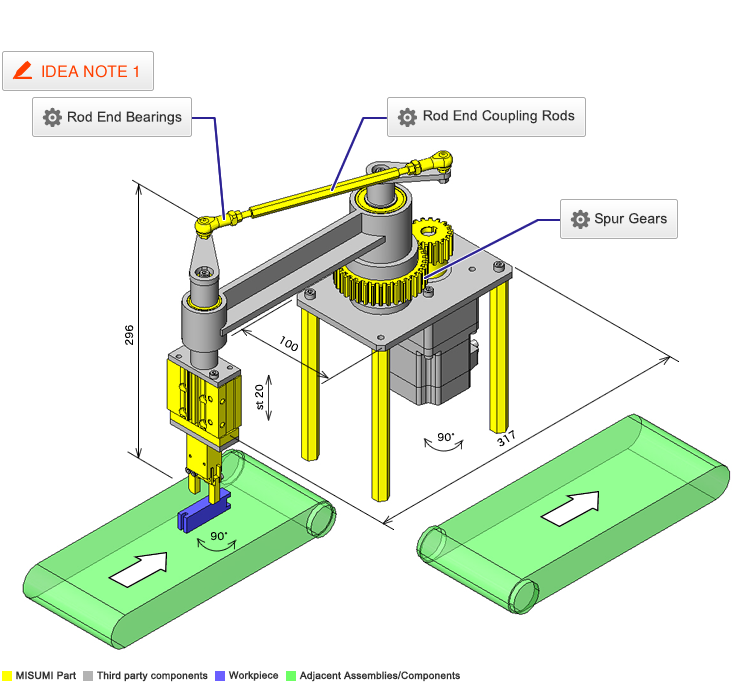

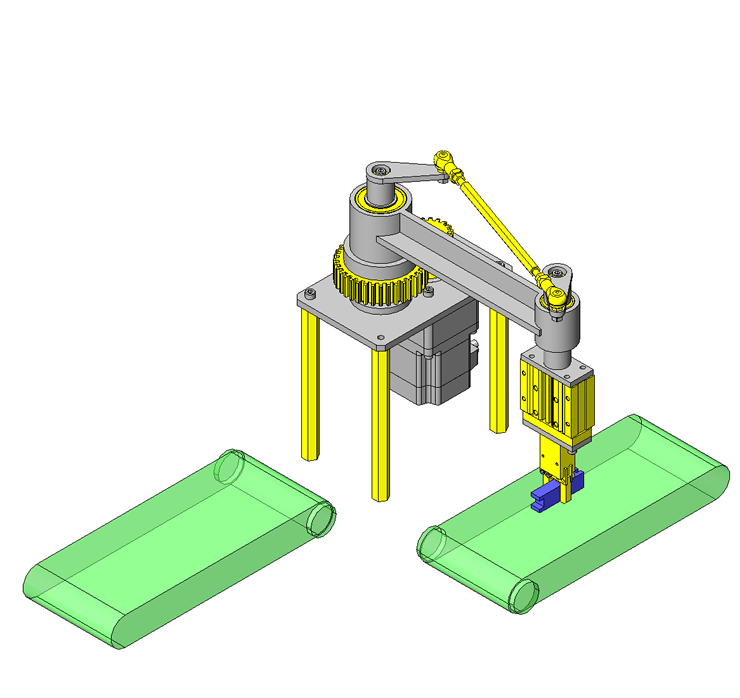

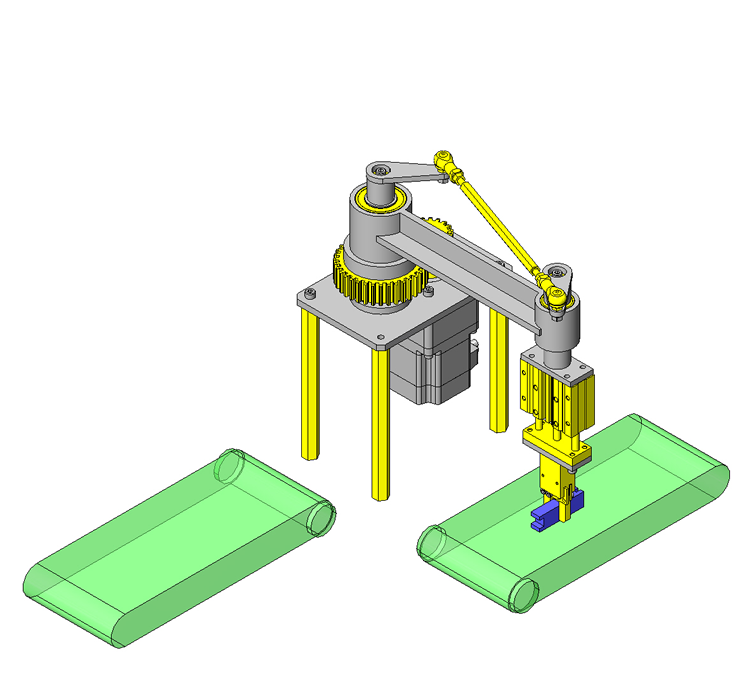

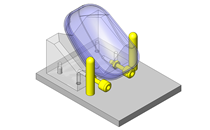

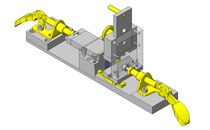

No.000075 Rotate and Transfer Mechanism

130

130

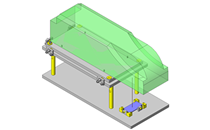

Motor and gear system rotates the arm and gripper simultaneously.

Relevant category

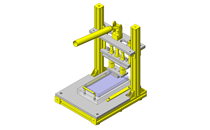

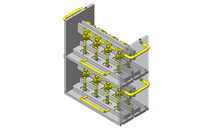

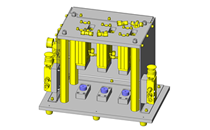

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

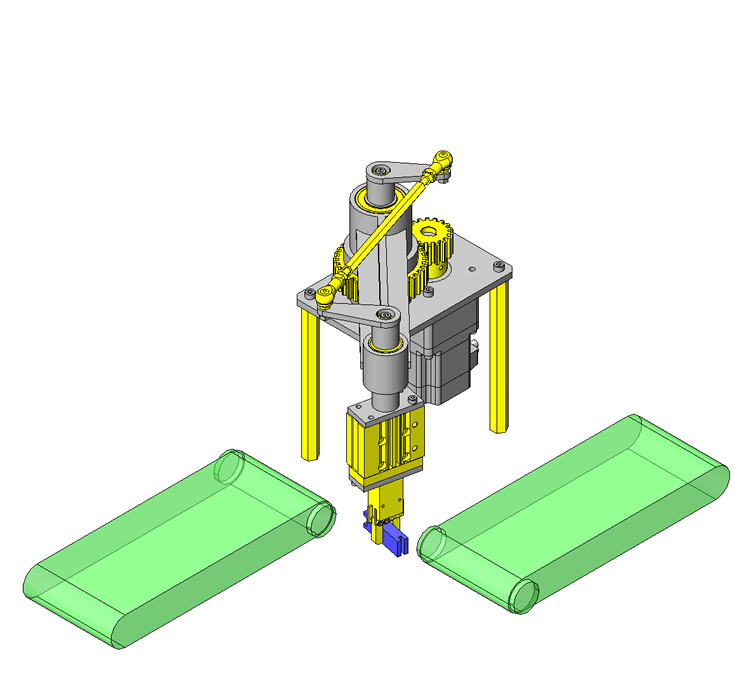

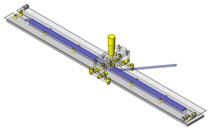

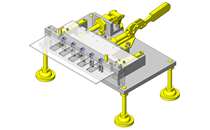

- Transfers work pieces on a conveyor to the next process by rotating the work piece 180°. The arm rotates the work piece the first 90° and the linkage rotates the gripper the second 90°.

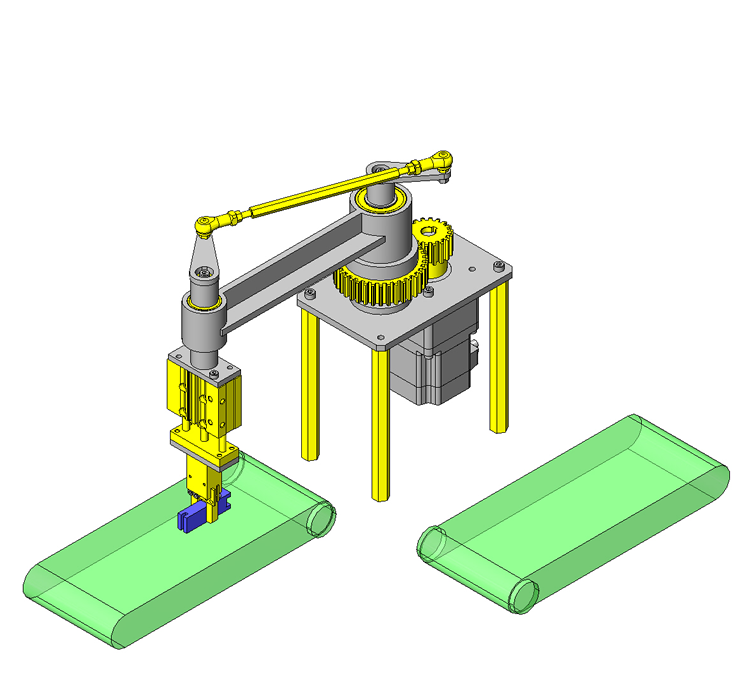

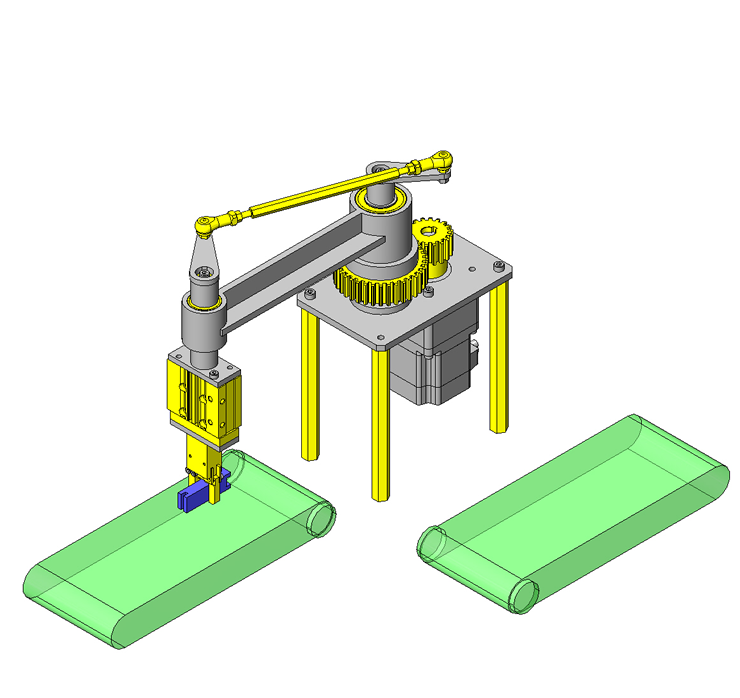

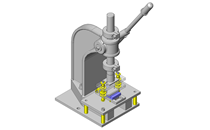

- Gripper down→Retain workpiece→Gripper up→ 90° rotate & transfer・Workpiece rotate 90°→Gripper down →Workpiece released →Gripper up.

Target workpiece

- Shape: Connector

Size: W50×D10×H15mm

Weight: 0.1 kg

Design Specifications

Operating Conditions or Design Requirements

- Transfer angle: 90 degrees

- Workpiece rotation angle: 90 degrees

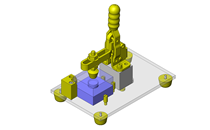

- Cylinder stroke: 20mm

- Clamp stroke: 10mm

- External dims: W100 x D317 x H269 (Before rotation)

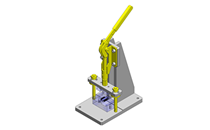

Selection Criteria for Main Components

- Ratio of fixed linkage and moving linkage ratio to be 1:1.

- Suppress inertia by reducing weight of swinging components.

- Confirm that the gear is strong enough to withstand the inertial force.

- Select the air gripper based on friction coefficient and workpiece weight.

Design Evaluation

Verification of main components

- It is important to calculate the inertia that applies to the stepper motor. The calculations are below.

- Time that takes to move 90° t 1 : 0.5sec

- Acceleration time t 0 : 0.01sec

- Swinging and rotating arm inertia moment: J 1 =4.063×10 ⁻² ㎏・㎡

- Inertia moment of a gear on the motor shaft: J 2 =3.598×10 ⁻ ⁵ ㎏・㎡

- Inertia moment applicable to motor shaft: Since it is via gear, JL = J 1 ×(Number of Teeth of sm. gear / Number of Teeth of L. gear) ² +J 2 =1.019×10 ⁻² ㎏・㎡

- Operating pulses:A=θ/θs=1250pulses

Here, the operating angle:θ=90°, Min. step angle of stepping motor:θs=0.072° - Operational pulse rate: f2 2 =A/(t 0 -t 1 )=3125Hz

- Motion speed: NM=θs/360×f 2 ×60=37.5r/min

- Inertia moment of motor's rotor: J = 0 =2.8×10 ⁻ ⁵

- Motor gear ratio: i = 10

- Acceleration torque calculation: Ta = (J 0 ・i ² +JL)/9.55×NM/t 1 =0.51N・m

- Calculation of required torque:TM=Ta×Safety margin=1.02N・m Safety ratio given: 2) Select motor from torque characteristics chart.Motor is OK

- Verifying inertia ratio: JL/ (J 0 ×i ² )=3.64≦10 is OK

Other Design Consideration

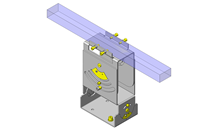

- The main shaft (center of rotation) and linkage arm to the main shaft are fixed.

- The gripper at rotation end can elevate and rotate.

Explore Similar Application Examples

Page

-

/

-