(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000157 Lifter Mechanism

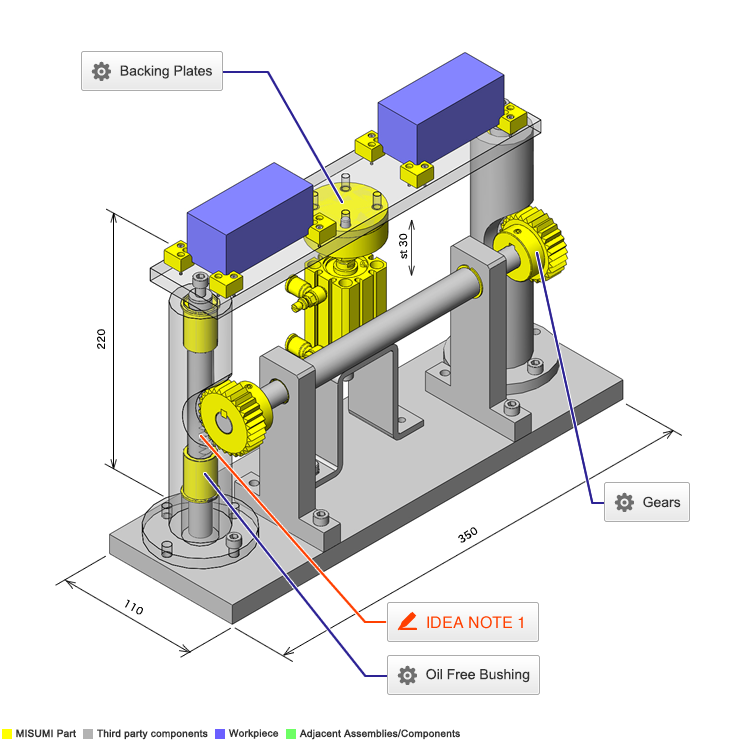

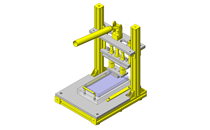

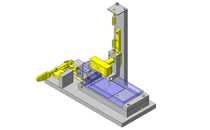

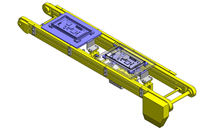

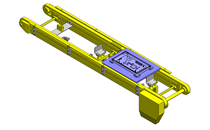

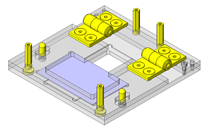

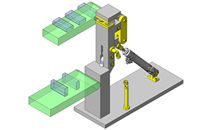

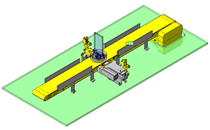

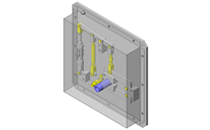

No.000157 Lifter Mechanism

16

16

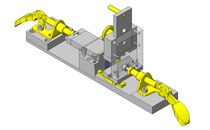

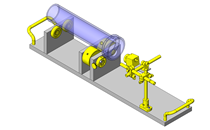

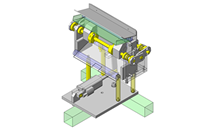

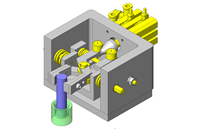

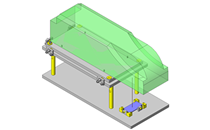

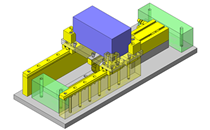

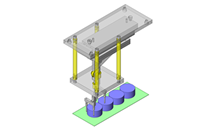

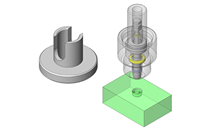

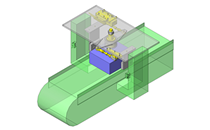

Lifting mechanism guided by interlocking gears.

Relevant category

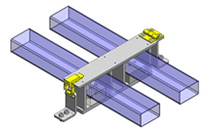

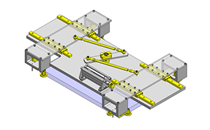

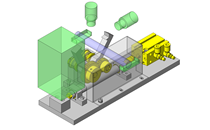

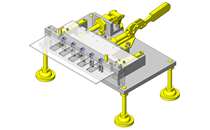

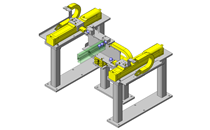

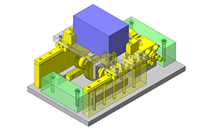

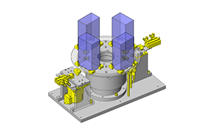

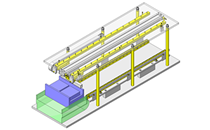

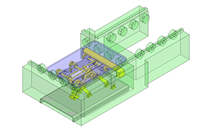

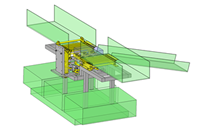

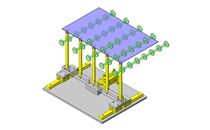

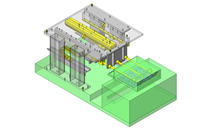

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

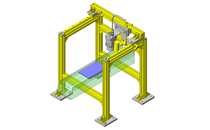

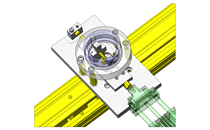

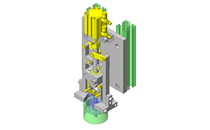

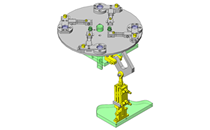

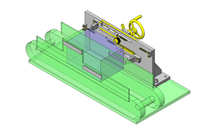

- To raise and lower workpieces with minimal abrasion on the guiding shaft's surfaces.

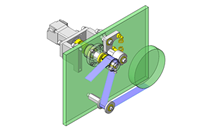

- Operation

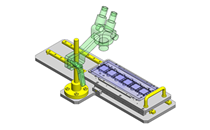

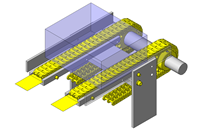

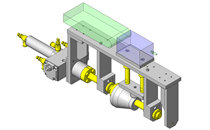

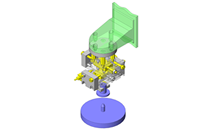

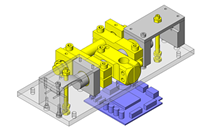

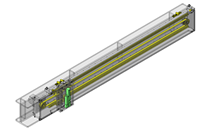

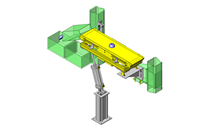

- A pneumatic cylinder provides the lifting force to raise the workpieces. The vertical movement is guided by two shafts with oil free bushings. Surface abrasion of the shafts is avoided by interconnecting them with a third shaft and a set of gears that interlocks with teeth machined on the two shafts.

Points for use

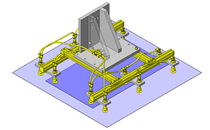

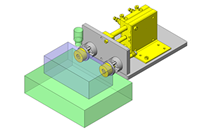

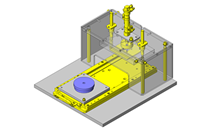

- This design is suitable for carrying unbalanced loads.

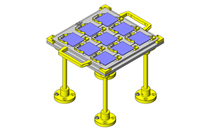

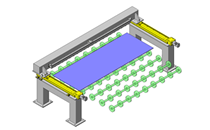

Target workpiece

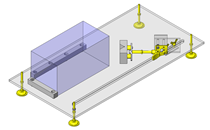

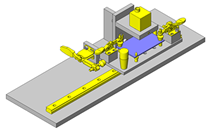

- Shape: tray, pallet

- Size: W35 x D78 x H36mm

- Weight: 4.3kg

Design Specifications

Operating Conditions or Design Requirements

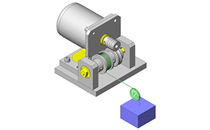

- Ascending/descending stroke: 30mm

- Outer dimensions: W110 x D350 x H210mm

Required Performance

- Load + lifting unit: 4.3 + 2.2 = 6.5kg

Selection Criteria for Main Components

- To raise and lower a workpiece load of approx. 6.5kg, a cylinder with an inner tube diameter of φ25mm is selected.

Design Evaluation

Verification of main components

- The cylinder thrust is verified based on the workpiece load.

- Selection of cylinder

- Conditional value: workpiece mass W1 = 6.5kg, gravitational acceleration g =9.8m/s²、

cylinder thrust (pulling side) F1 = 189N (operating pressure 0.5MPa) - The load F2 is

F2 = W1 x g, therefore, F2 = 6.5 x 9.8 = 63.7N < F1

⇒There is no problem.

- Conditional value: workpiece mass W1 = 6.5kg, gravitational acceleration g =9.8m/s²、

Other Design Consideration

- Oil free bushings are selected to guide the motion of the shafts and reduce friction.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category