(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000161 Workpiece Separation/Feed Mechanism

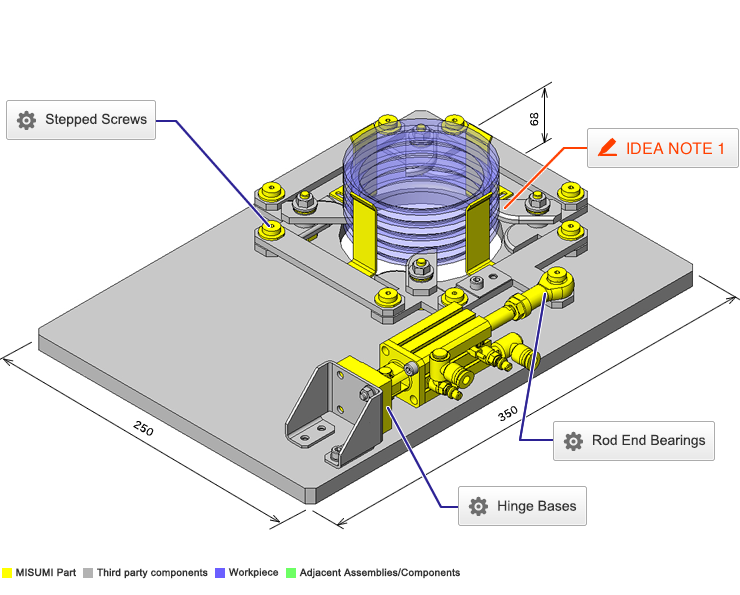

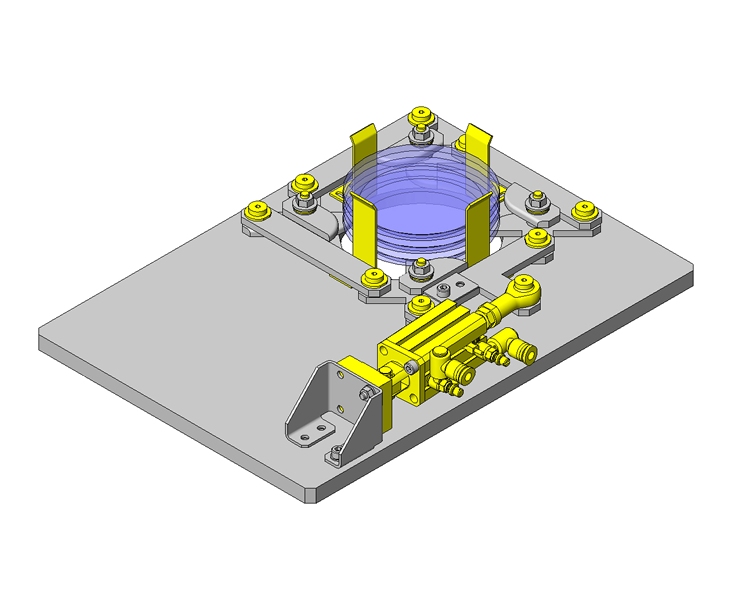

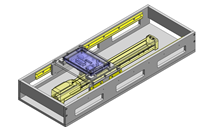

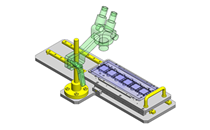

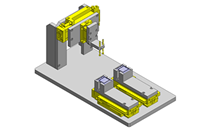

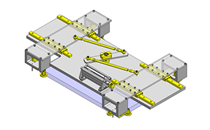

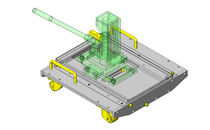

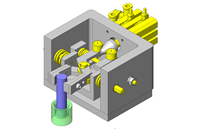

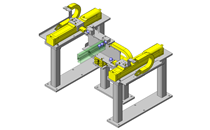

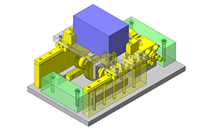

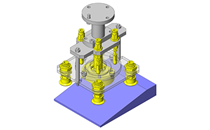

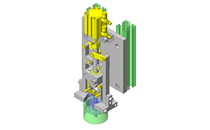

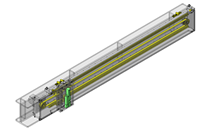

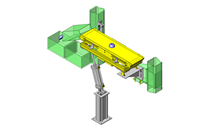

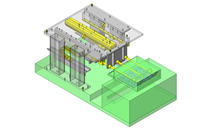

No.000161 Workpiece Separation/Feed Mechanism

32

32

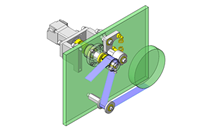

Separation and unloading of circular workpieces with a single pneumatic cylinder

Relevant category

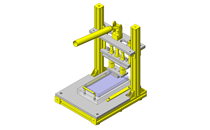

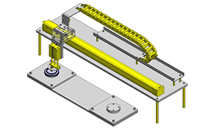

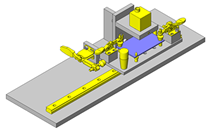

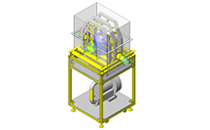

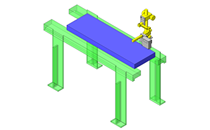

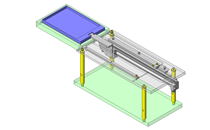

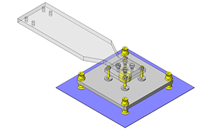

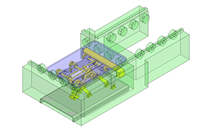

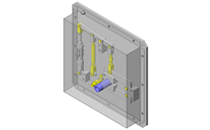

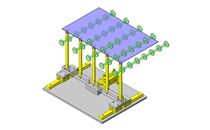

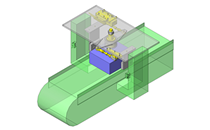

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

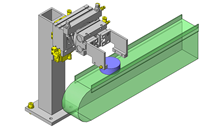

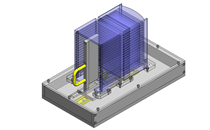

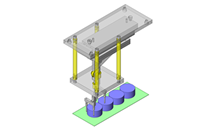

- To separate and unload stacked workpieces.

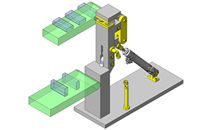

- Operation

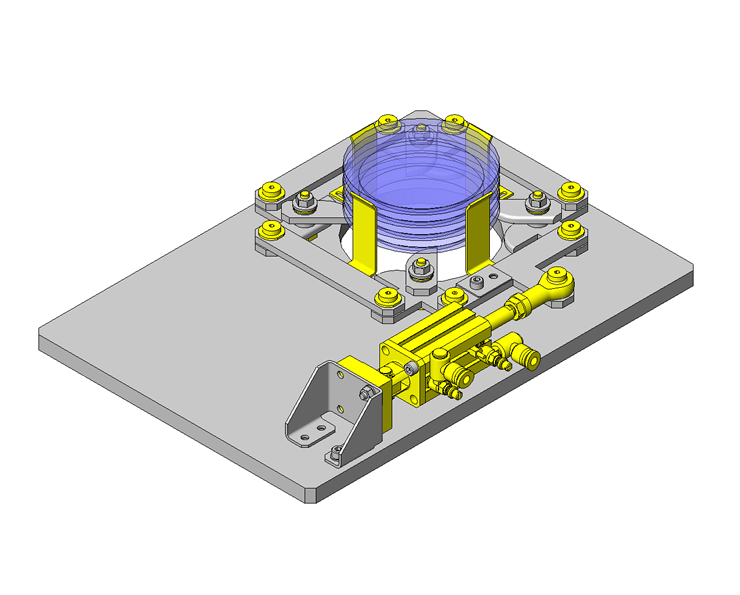

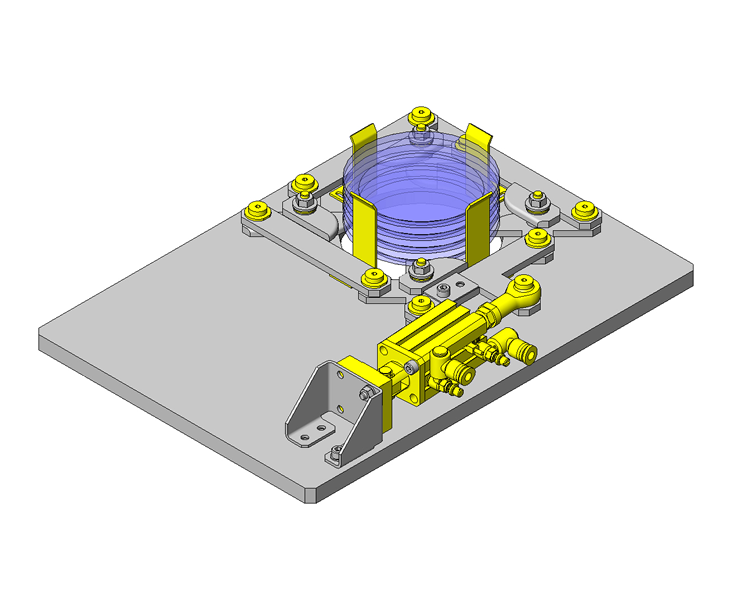

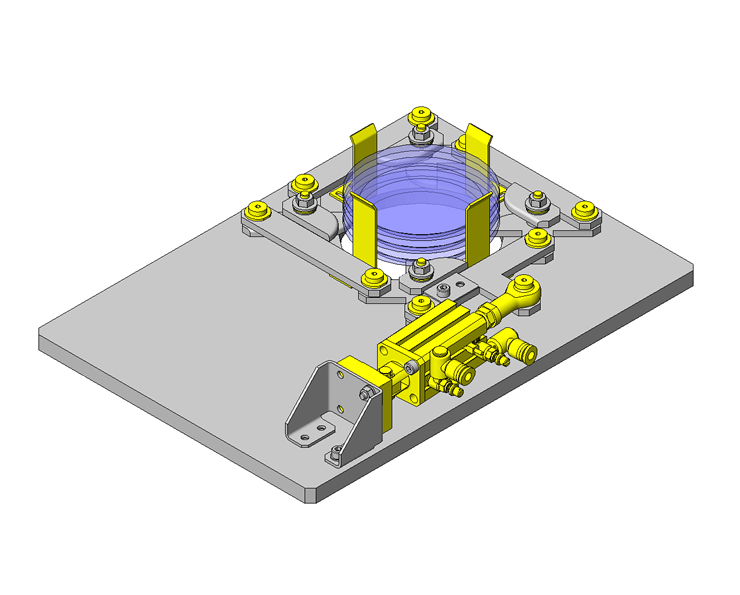

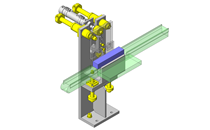

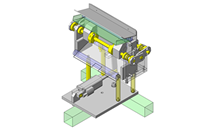

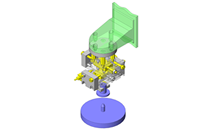

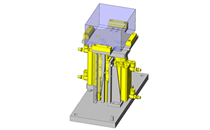

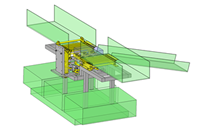

- Claws connected with links are turned by the cylinder. As the cylinder extends, the lower claws unload the workpiece at the lowermost layer. At the same time, the upper claws retain the workpiece in the second layer from the bottom. As the cylinder retracts, the workpiece is detached from the upper claws and passed downward to the lower claws that have turned.

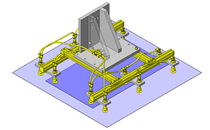

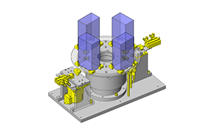

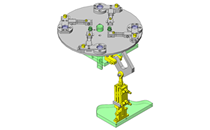

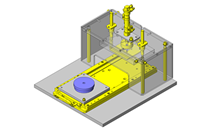

Target workpiece

- Shape: circular flanged pallet

- Size: φ100 x H10mm

- Weight: 1kg

- Maximum number of stacked workpieces: 5

Design Specifications

Operating Conditions or Design Requirements

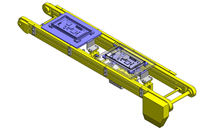

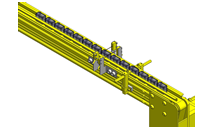

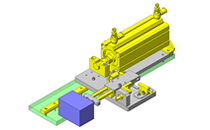

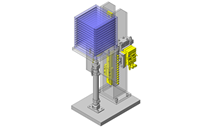

- Outer dimensions: W350 x D250 x H68mm

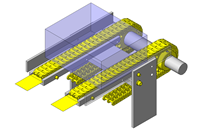

- Separation and unloading of workpiece

- Claw operation angle: 45 degrees

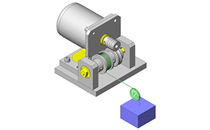

- Cylinder

- stroke length: 21mm

Required Performance

- Workpiece weight

- 50N (when stacked at maximum)

Selection Criteria for Main Components

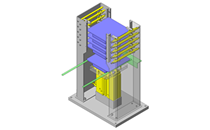

- Oil free bushing

- Environment resistance

- Low load

- Low speed

Design Evaluation

Verification of main components

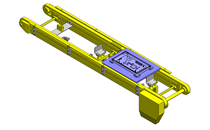

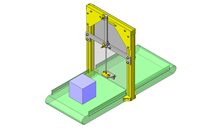

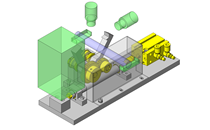

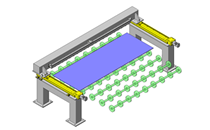

- The cylinder thrust power is verified to see whether the workpiece feed motion is possible when the workpieces are stacked at the maximum amount.

- Check of feed motion with workpieces stacked

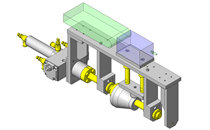

- Conditional value: workpiece m = 1kg, maximum number of stacked workpieces n = 5pieces, gravitational acceleration g = 9.8m/s², cylinder diameter = 20mm, supply pressure = 0.5MPa, link ratio (1) = cylinder-side arm:claw arm = 4:3, link ratio (2) = claw arm:claw = 6:5, cylinder thrust power = 157N, maximum angle formed by cylinder-side arm and claw arm θ = 45°, mechanical efficiency = 50%, friction coefficient μ1 = 0.2 (oil free bushing), friction coefficient μ2 = 0.2 (resin and metal)

- Claw operating force by cylinder: P = cylinder thrust power x link ratio (1) x link ratio (2) x mechanical efficiency x cos θ, therefore, P = 157 x (4/3) x (6/5) x 0.5 x cos (45°) = 88.8N

- Friction resistance due to workpiece weight: F = (μ1 + μ2) x m x n, therefore,

F = (0.2 + 0.2) x 1 x 5 = 2kg = 2 x 9.8 = 19.6N - Effective operation force P' = P - F = 88.8N - 19.6N = 69.2N

From the above, the effective operation force P' = 69.2N while the overall workpiece weight is 5kg (49N). Therefore, the feed motion is possible.

Other Design Consideration

- Optimization of workpiece height and clearance between claws.

- Link does not require maintenance because of oil free bushing.

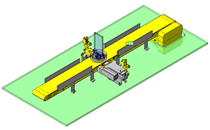

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category