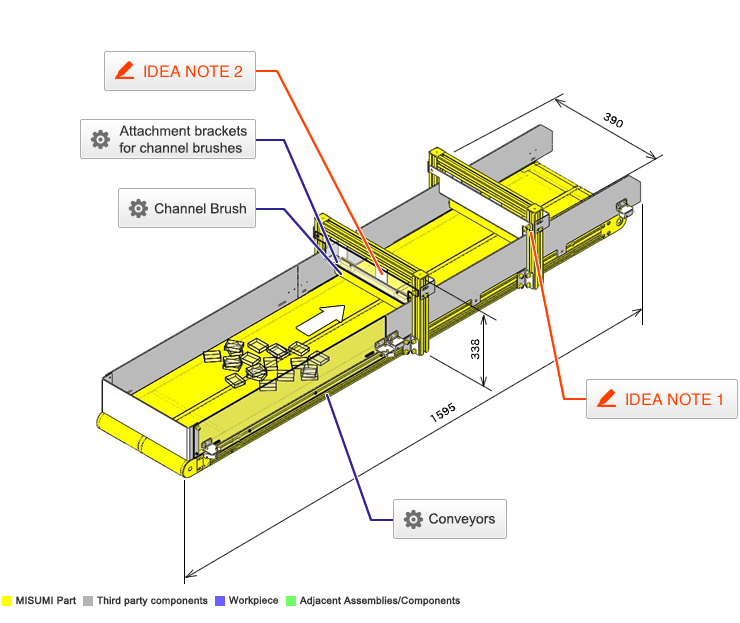

Conveyors

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

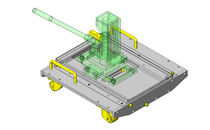

Choose this item as an completed assembly for product transfer.

Back to page top

Available sizes

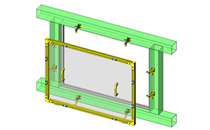

■Conveyor with full width belt, Pulley Dia. 50mm

| Part | Material | Surface Treatment |

| Frame | Aluminum | : Anodize |

| Motor Cover | Paint |

| Pulley Holder | 5052 Aluminum Alloy | : Anodize |

| 1018 Carbon Steel | Trivalent Chromate |

■Belt Specification

| Usage | Surface Material | Color Tone | Continuous Use Temperature °C |

| General Purpose | Polyurethane | Green | -10℃~80℃ |

| White |

| Sliding | Urethane Impregnated | Green |

| White |

| Electronic Parts Conveyor | Conductive Polyurethane | Black |

| Oil Resistant | Oil-Resistant Chloroethylene | Navy | 5℃~60℃ |

| Non-Adhesive | Polyurethane | White | -10℃~80℃ |

| No Belt |

■Sizes

Belt width

(10 mm increments) | Distance between pulleys

(5 mm increments) | Motor |

| Output (W) | Voltage (V) | Specifications | Gearhead Reduction Ratio |

| 80~300 | 320~2000 | 6、25、40 | * Note | 5, 7.5, 9, 12.5, 15, 18,

25, 30, 36, 50, 60, 75,

90, 100, 120, 150, 180 |

* Voltage and specification of a motor are varied with countries of sales.

Back to page top

Performance info.

■Conveying capacity (Guided belt to prevent lateral movement, single track, pulley dia. 50mm)

Back to page top

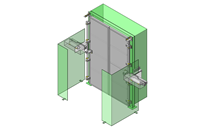

Attachment brackets for channel brushes

| Product name | Dedicated Attachment Brackets for Channel Brushes - Vertical Mount |

| Part number | BRUSAS5 |

| Features | MISUMI original design Channel Brush Attachment Brackets enabling quick brush changes are provided. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for using as a brush to even out the workpiece

Back to page top

Available sizes

■Dedicated attachment brackets for channel brushes - Vertical mount

| Body Material | Insert material | Accessory |

| MC nylon, conductive grade (black) | 304 Stainless Steel | Screw (304 Stainless Steel) |

■Sizes

Overall thickness

of the applicable brush | Applicable Channel Brush | External Dimensions | Brush fixing part | Base fixing part |

| Width | Depth | Height | Applicable screw(included) | Applicable screw |

| 3N | BRUSN3(Nylon 6) | 50 | 18 | 15 | M4 | M5 |

| BRUSM3(conductive nylon Mono-Eight®) |

| 3S | BRUSE3(conductive fiber Thunderon®) |

| 5 | BRUSN5(Nylon 6) | 20 |

| BRUSM5(conductive nylon Mono-Eight®) |

| 5K | BRUSK5(Nylon with Abrasive Grain) |

Back to page top

Channel Brush

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for using as a brush to even out the workpiece

Back to page top

Available sizes

■Channel Brush

| Brush Filament | Channel material | Color |

| Nylon 6 | 304 Stainless Steel | White |

| Conductive Fiber Thunderon® (Copper Alloy) | Silver Green |

| Conductive Nylon Mono-Eight® | Black |

| Nylon with Abrasive Grain | Gray |

■Sizes and Dimensions

| Brush Filament | Overall thickness | Wire Dia. | Filament length | Overall Width | Channel

height |

| (5 mm increments) | (5 mm increments) |

| Nylon 6 | 3 | φ0.21 | 10〜50 | 30〜800 | 3.5 |

| φ0.295 |

| 5 | φ0.21 | 10〜50 | 5.5 |

| φ0.295 |

| φ0.535 | 15〜50 |

| Conductive Fiber Thunderon® (Copper Alloy) | 3 | φ0.075 | 10〜30 | 3.5 |

| Conductive Nylon Mono-Eight® | 3 | φ0.3 | 10〜50 | 3.5 |

| 5 | 5.5 |

| Nylon with Abrasive Grain | 5 | φ0.6 | 10〜50 | 5.5 |

Back to page top

Accuracy Info

■Overall width tolerance of the channel brushes

| Overall width | Tolerance |

| 〜100 | ±1.5 |

| 101〜400 | ±2.0 |

| 401〜800 | ±2.5 |

Back to page top

IDEA NOTE Simple configuration

By using aluminum extrusion with grooves, positioning the brushes is very easy.

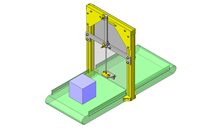

IDEA NOTE Adding a backup plate

Durability is improved by mounting a backup plate to prevent bending of brush filaments.