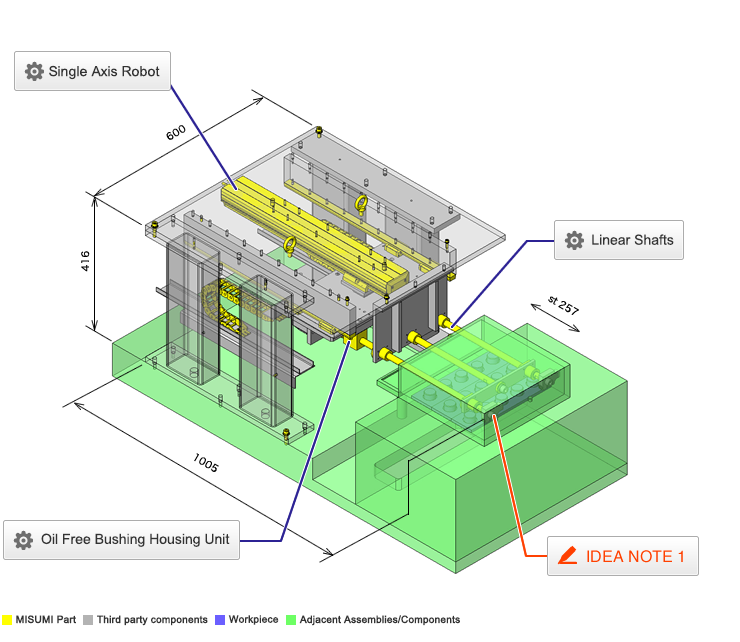

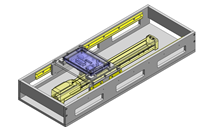

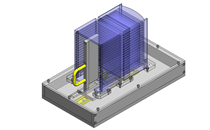

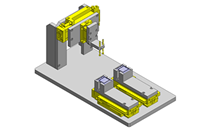

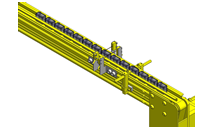

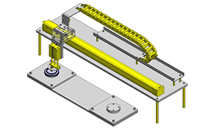

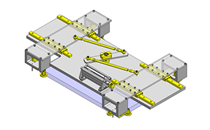

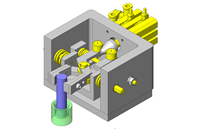

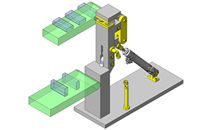

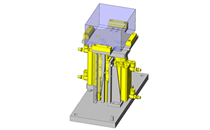

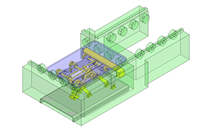

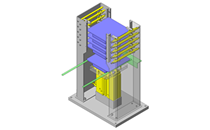

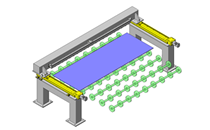

Single Axis Robot

| Product name | Single Axis Robot RSH1 |

| Part number | RSH106-C22A-C-F0-3-300 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Based on stroke, accuracy and thrust force.

Back to page top

Available sizes

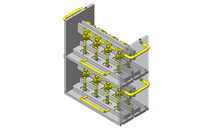

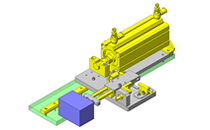

■Single Axis Robot RSH1

Height

(mm) | Type | Lead

(mm) | Stroke

(50mm Increments) |

| 65 | RSH1 | 6 | 150-800 |

| 12 |

| 20 |

| RSH2 | 5 | 150-1050 |

| 10 |

| 20 |

| 30 |

| RSH3 | 5 | 150-1050 |

| 10 |

| 20 |

Back to page top

Selection steps

■Single Axis Robot Selection Steps

Load Capacity

↓

Stroke

↓

Cycle Time or Max. Speed

↓

Check for Details

Back to page top

Accuracy Info.

Single Axis Robot Accuracy

Height

(mm) | Type | Lead

(mm) | Stroke

(50mm Increments) | Positioning Repeatability

(mm) |

| 65 | RSH1 | 6 | 150-800 | ±0.02 |

| 12 |

| 20 |

| RSH2 | 5 | 150-1050 | ±0.01 |

| 10 |

| 20 |

| 30 |

| RSH3 | 5 | 150-1050 | ±0.01 |

| 10 |

| 20 |

Back to page top

Performance info.

■Speeds / Loads (Load info.) of Single Axis Robot

| Type | Lead

(mm) | Max.

Load

Capacity

(kg) | Allowable Moment

(N・m) | Max. Velocity (mm/sec) |

| Horizontal | Vertical | Pitching | Yawing | Rolling | 150-

550st | 600

st | 650

st | 700

st | 750

st | 800

st |

| RSH1 | 6 | 40 | 8 | 95 | 70 | 110 | 360 | 324 | 270 | 234 | 216 | 180 |

| 12 | 20 | 4 | 720 | 648 | 540 | 468 | 432 | 360 |

| 20 | 12 | - | 1200 | 1080 | 900 | 780 | 720 | 600 |

| Type | Lead

(mm) | Max.

Load

Capacity

(kg) | Allowable Moment

(N・m) | Max. Velocity (mm/sec) |

| Horizontal | Vertical | Pitching | Yawing | Rolling | 150-

650st | 700

st | 750

st | 800

st | 850

st | 900

st | 950

st | 1000

st | 1050

st |

| RSH2 | 5 | 50 | 16 | 95 | 70 | 110 | 300 | 255 | 225 | 195 | 180 | 165 | 150 | 135 | 120 |

| 10 | 40 | 8 | 600 | 510 | 450 | 390 | 360 | 330 | 300 | 270 | 240 |

| 20 | 20 | 4 | 1200 | 1020 | 900 | 780 | 720 | 660 | 600 | 540 | 480 |

| 30 | 7 | - | 1800 | 1530 | 1350 | 1170 | 1080 | 990 | 900 | 810 | 720 |

| Type | Lead

(mm) | Max.

Load

Capacity

(kg) | Allowable Moment

(N・m) | Max. Velocity (mm/sec) |

| Horizontal | Pitching | Yawing | Rolling | 150-

600st | 650

st | 700

st | 750

st | 800

st | 850

st | 900

st | 950

st | 1000

st | 1050

st |

| RSH3 | 5 | 80 | 163 | 128 | 143 | 300 | 255 | 225 | 195 | 180 | 165 | 150 | 135 | 120 | 105 |

| 10 | 60 | 600 | 510 | 450 | 390 | 360 | 330 | 300 | 270 | 240 | 210 |

| 20 | 30 | 1200 | 1020 | 900 | 780 | 720 | 660 | 600 | 540 | 480 | 420 |

Back to page top

Technical Calculations

■Technical Calculation for Single Axis Robot

Selection Method of Single Axis Robot

https://vn.misumi-ec.com/maker/misumi/mech/product/rs/

Back to page top

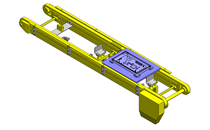

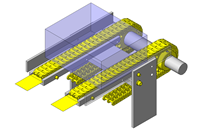

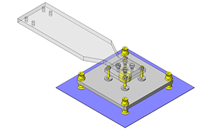

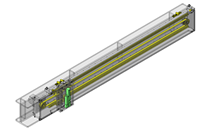

Linear Shafts

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Based on accuracy, stroke and design

Back to page top

Available sizes

■Precision Hollow Linear Shafts - Straight

| Material | Hardness | Surface Treatment |

| 52100 Bearing Steel | Induction Hardened

52100 Bearing Steel: 58HRC or More

440C Stainless Steel: 56HRC or More | - |

| 440C Stainless Steel |

| 52100 Bearing Steel | Hard Chrome Plating:

Plating Hardness HV750 -

Plating Thickness 5 µm or more |

| 52100 Bearing Steel | Low Temp. Black Chrome Plating |

■Sizes and Dimensions

| O.D. | Length

in 1 mm Increments | Thread Dia. |

| 3 | 4 | 5 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | Rc1/8 | Rc1/4 | Rc3/8 |

| 6 | 20~600 | ○ | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 8 | 20~800 | - | ○ | ○ | - | - | - | - | - | - | - | - | - | - | - |

| 10 | 20~800 | - | - | ○ | ○ | - | - | - | - | - | - | - | - | - | - |

| 12 | 20~1000 | - | - | - | - | ○ | - | - | - | - | - | - | ○ | - | - |

| 13 | 25~1000 | - | - | - | - | - | ○ | - | - | - | - | - | ○ | - | - |

| 16 | 30~1200 | - | - | - | - | - | - | ○ | - | - | - | - | - | ○ | - |

| 20 | 30~1200 | - | - | - | - | - | - | - | ○ | - | - | - | - | - | ○ |

| 25 | 35~1200 | - | - | - | - | - | - | - | - | ○ | - | - | - | - | - |

| 30 | 35~1500 | - | - | - | - | - | - | - | - | ○ | - | - | - | - | - |

| 35 | 35~1500 | - | - | - | - | - | - | - | - | - | ○ | - | - | - | - |

| 40 | 50~1500 | - | - | - | - | - | - | - | - | - | ○ | ○ | - | - | - |

| 50 | 60~1500 | - | - | - | - | - | - | - | - | - | - | ○ | - | - | - |

Back to page top

Accuracy Info.

■Accuracy of the Shafts

O.D.

(mm) | O.D. Tolerance (mm)

g6 |

|

| 6 | -0.004

-0.012 |

| 8 | -0.005

-0.014 |

| 10 |

| 12 | -0.006

-0.017 |

| 13 |

| 15 |

| 16 |

| 18 |

|

| 20 | -0.007

-0.020 |

| 25 |

| 30 |

| 35 | -0.009

-0.025 |

| 40 |

| 50 |

Back to page top

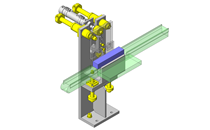

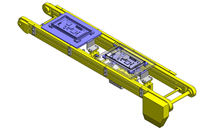

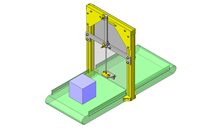

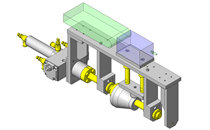

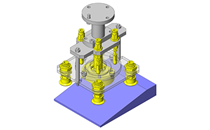

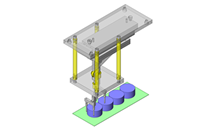

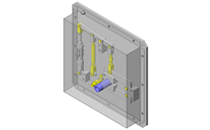

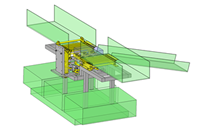

Oil Free Bushing Housing Unit

| Product name | Oil Free Bushing with Housing Units |

| Part number | JFBA16 |

| Features | Suitable for horizontal use. Reduces the time of manufacturing and assembling the housing. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Housing unit that supports both linear and rotary motion.

Back to page top

Available sizes

■Oil Free Bushing with Housing Units

| Housing | Bushing |

| Material | Surface Treatment | Material |

| Aluminum Alloy | Clear Anodize | Polyacetal |

■Sizes and Dimensions

| I.D. | Mounting Surface - Shaft Bore

Dimension | Width | Height |

| 6 | 14 | 16 | 22 |

| 8 | 16 | 20 | 26 |

| 10 | 19 | 26 | 32 |

| 12 | 20 | 26 | 34 |

| 16 | 27 | 36 | 49 |

Back to page top

Accuracy Info.

■Accuracy of oil free Bushing

| I.D.(mm) | Tolerance |

| 6 | +0.095

+0.045 |

| 8 |

| 10 |

| 12 | +0.120

+0.060 |

| 15 |

| 16 |

Back to page top

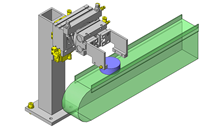

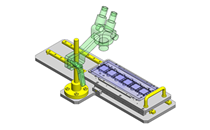

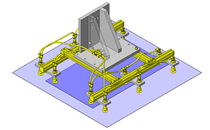

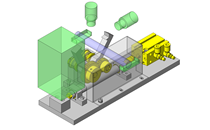

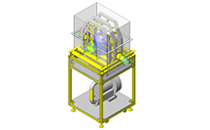

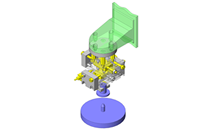

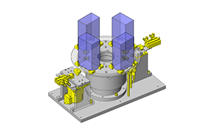

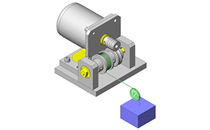

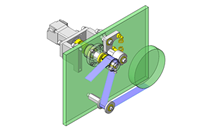

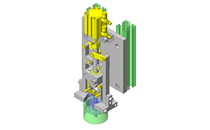

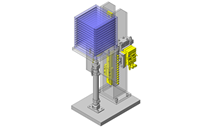

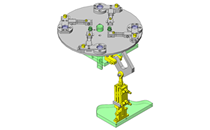

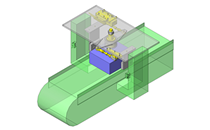

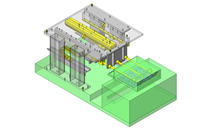

IDEA NOTE Combining linear and rotary motion units

By combining a rotary actuator with a linear actuator, the arm is able to extend and the fingers can rotate.