(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000148 Intermittent Rotation Mechanism

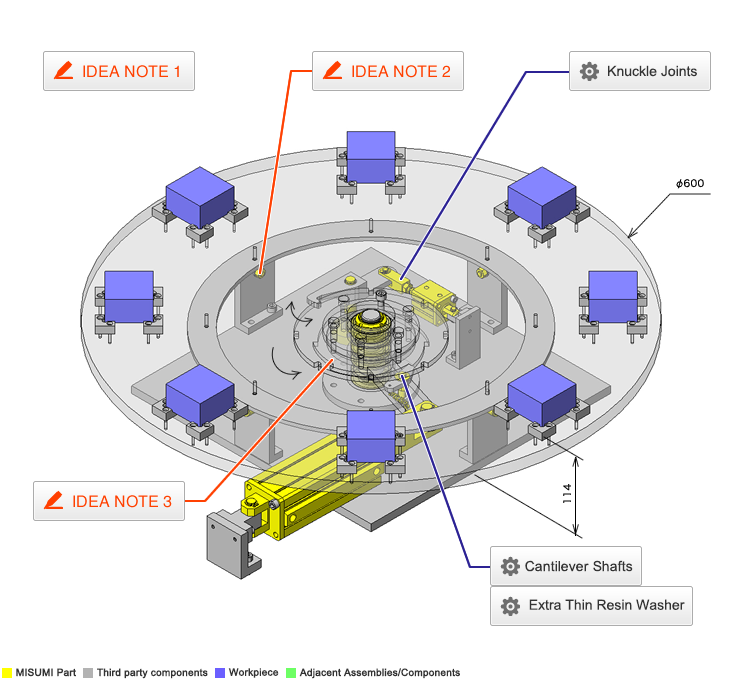

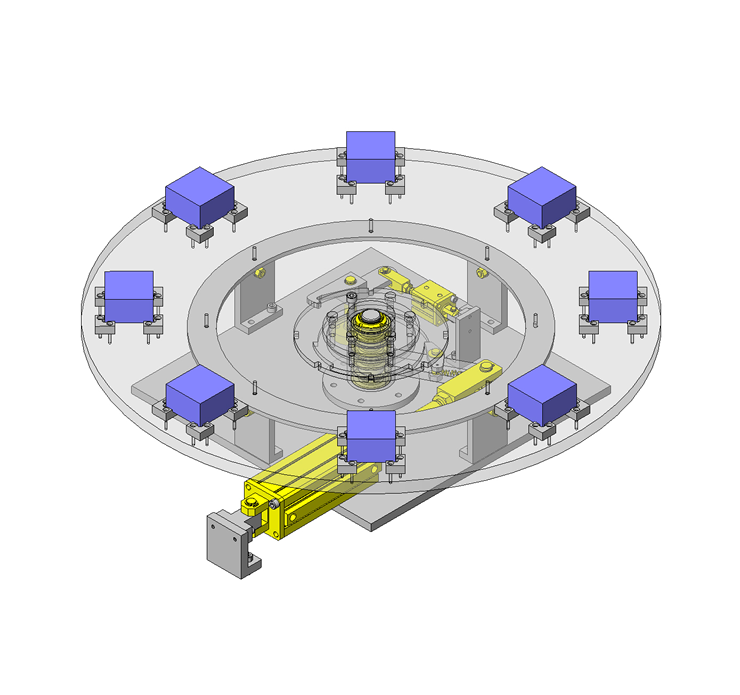

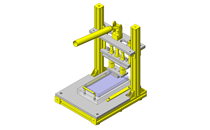

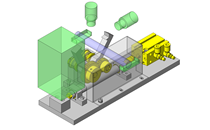

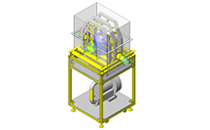

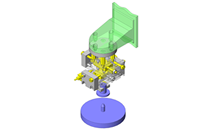

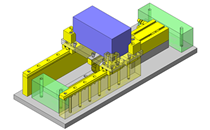

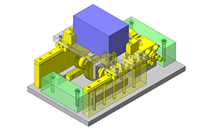

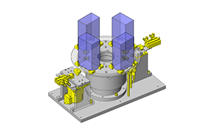

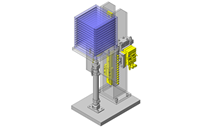

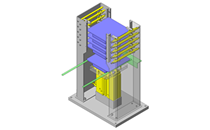

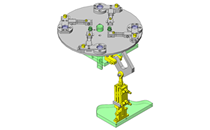

No.000148 Intermittent Rotation Mechanism

210

210

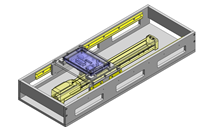

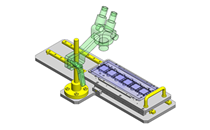

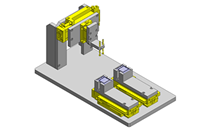

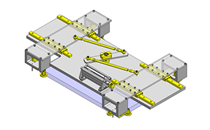

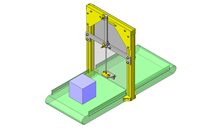

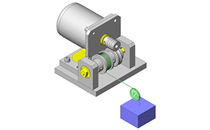

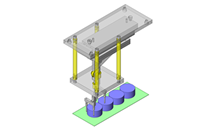

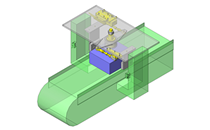

Cylinder-driven index table.

Relevant category

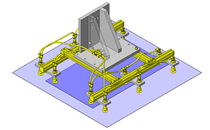

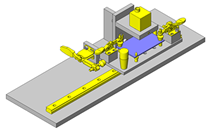

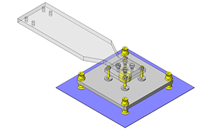

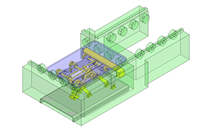

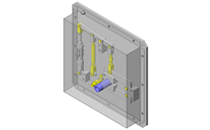

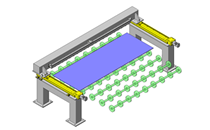

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

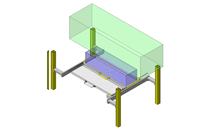

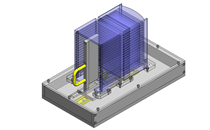

- To rotate workpieces on 8-position index table.

- Operation

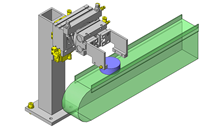

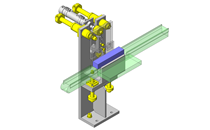

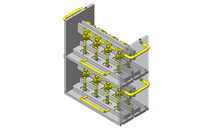

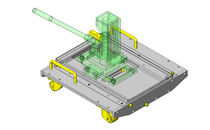

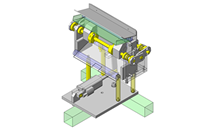

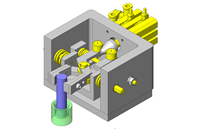

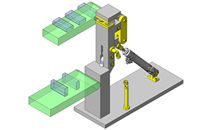

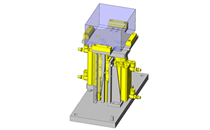

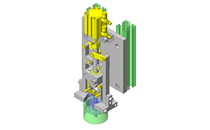

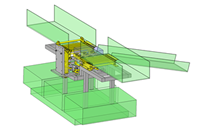

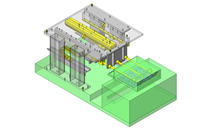

- Retracting the (indexing) cylinder, removes the finger from the groove of the indexing gear.

- When the (rotation) cylinder is extended, the claw engages the ratchet gear and the index table rotates. The tension springs keeps the claw pressed against the gear.

- When the (indexing) cylinder is extended, the finger is inserted into the groove to fix the rotational position.

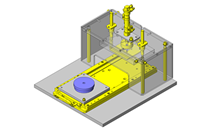

Target workpiece

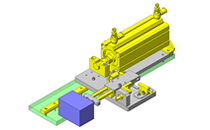

- Shape: connector

- Size: W50 x D50 x H30 mm

- Weight: 0.15 kg

Design Specifications

Operating Conditions or Design Requirements

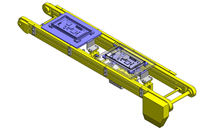

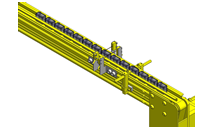

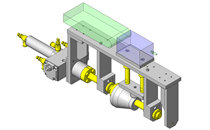

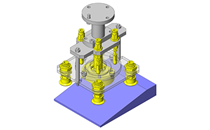

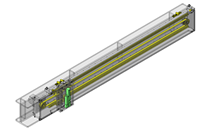

- Movement angle: 45degrees

- Cylinder stroke: 100mm

- Stopper stroke: 10mm

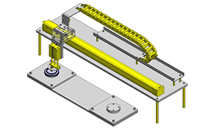

- Outer dimensions: φ600 x H114mm

Selection Criteria for Main Components

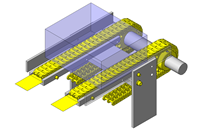

- Selected an air cylinder that has the thrust specification required to rotate the index table 45 degrees in 1 second.

Design Evaluation

Verification of main components

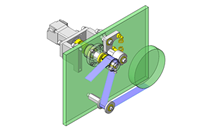

- Air Cylinder thrust calculation

- Conditional value: angle θ = 45degrees, movement time t = 1sec., link arm length L = 0.125m, moment of inertia applied to air cylinder I = 0.5492kg·m²

- As uniform acceleration motion is assumed as angular velocity here, θ: oscillating angle (rad), 45° = 2π/8rad

- Angular velocity after t seconds: ω = 2·θ/t = 2 x (2 π/8)/1 = 1.571rad/sec

- Equation of rotary motion: from I·ω = M and M = F·L, cylinder thrust F = I·ω/L = 0.5492 x 1.571/0.125 = 6.9N

- Theoretical thrust of φ40 air cylinder: 628 (N) when air pressure in use is 0.5MPa

-> As F = 6.9 (N) ≤ 628 (N), this is acceptable.

Other Design Consideration

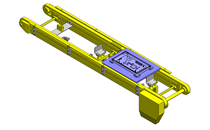

- Ensure the ratchet mechanism has sufficient strength.

The bending stress needs to be 29 (N/mm²) or less and the shearing stress needs to be 24.7 (N/mm²) or less. - Ensure the indexing positioning part is strong enough to apply the required torque.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category