(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000236 Lifting Mechanism

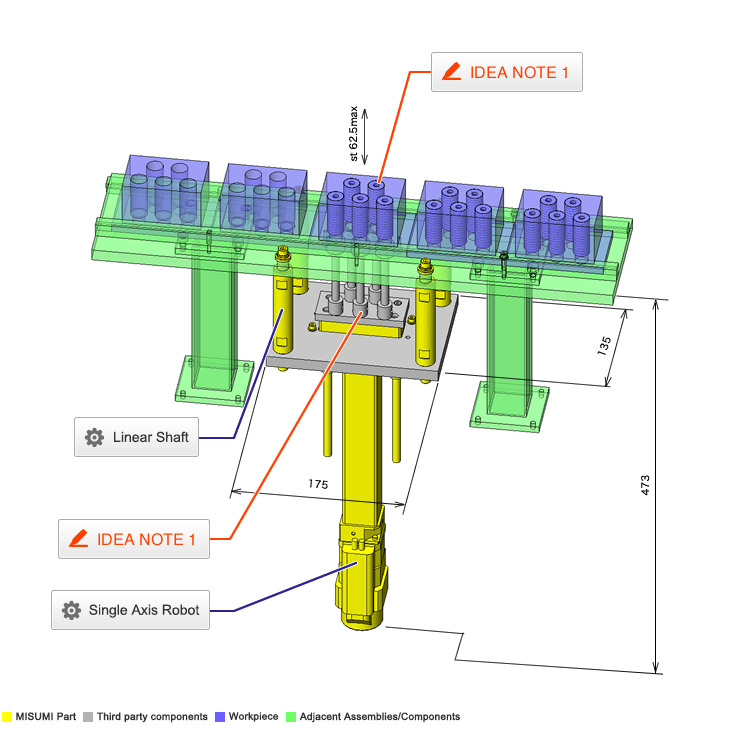

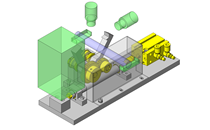

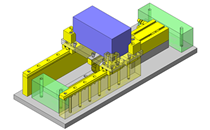

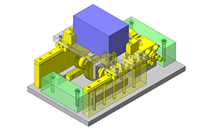

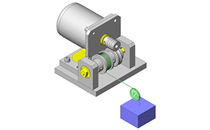

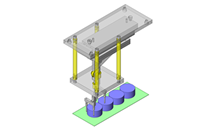

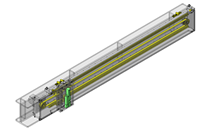

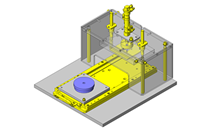

No.000236 Lifting Mechanism

Workpiece is lifted by a single axis robot

Relevant category

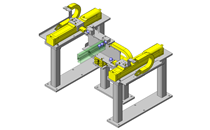

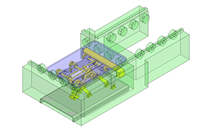

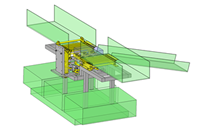

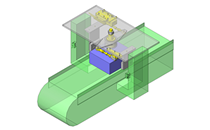

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

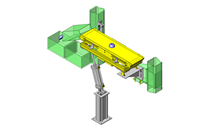

- Lifts workpiece by using a single axis linear actuator.

Points for use

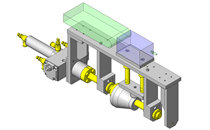

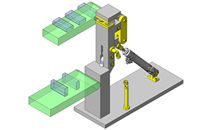

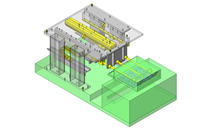

- Single axis robot is programmed for a set of predetermined movements.

Target workpiece

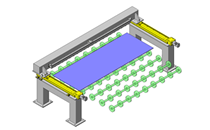

- Washer

- Exterior shape: φ16 x t 3mm

- Workpiece weight: 4g

Design Specifications

Operating Conditions or Design Requirements

- Exterior shape dimensions: W 175 x D 135 x H 473mm

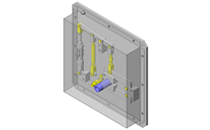

- Single axis robot stroke distance: 62.5mm

<Maximum stroke distance: 100mm.> - Single axis robot maximum transferable mass: 7.5kg

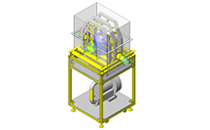

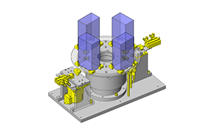

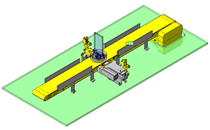

- 1 pallet contains 5 rows of 14 workpieces in a single vertical row

- A proximity switch is installed in another unit on the upstream side to detect position

Required Performance

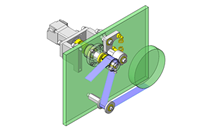

- Single axis robot positioning repeatability: +/- 0.02mm

- Single axis robot accuracy without rotation: +/- 0.05°-> +/- 0.00083mm

Selection Criteria for Main Components

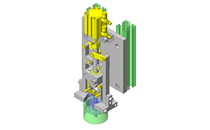

- Single Axis Robot

- A robot, for which the movable section + workpiece weight does not exceed the maximum transferable mass, is selected.

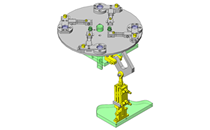

- Shaft

- A shaft with additional machining for minimizing the range of tolerance for length is selected in order to prevent tilting in the installation of the robot (tolerance: +/- 0.03 mm)

Design Evaluation

Verification of main components

- The robot transferable mass is verified for the capability to transfer the workpiece.

- Single Axis Robot Transfer Weight.

- Condition value: 4g, workpiece insert shaft weight: 44.6g, rod plate weight: 212.2g

- Maximum transferable weight of single axis robot M = workpiece weight (70 pieces) + workpiece insert shaft (5 shafts) + Rod plate weight, thus M = 4 x 70 + 44.6 x 5 + 212.2 = 715.2g ≒ 0.72kg

- Maximum transfer weight of single axis robot: 0.72kg < Maximum transferable mass of single axis robot: 7.5kg

-> Safety margin ratio of 10 is ensured.

Other Design Consideration

- A step type and a straight type are utilized for positioning of single axis robot.

- A stopper pin with urethane is used as a mechanical stopper.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category