(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

- inCAD Library Home

- > No.000289 Removal of Static Electricity from Large Workpieces

No.000289 Removal of Static Electricity from Large Workpieces

16

16

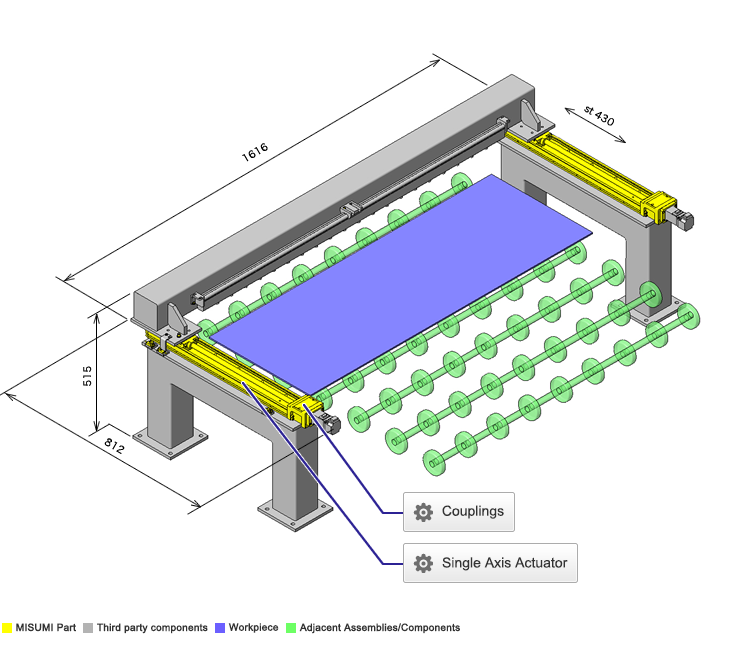

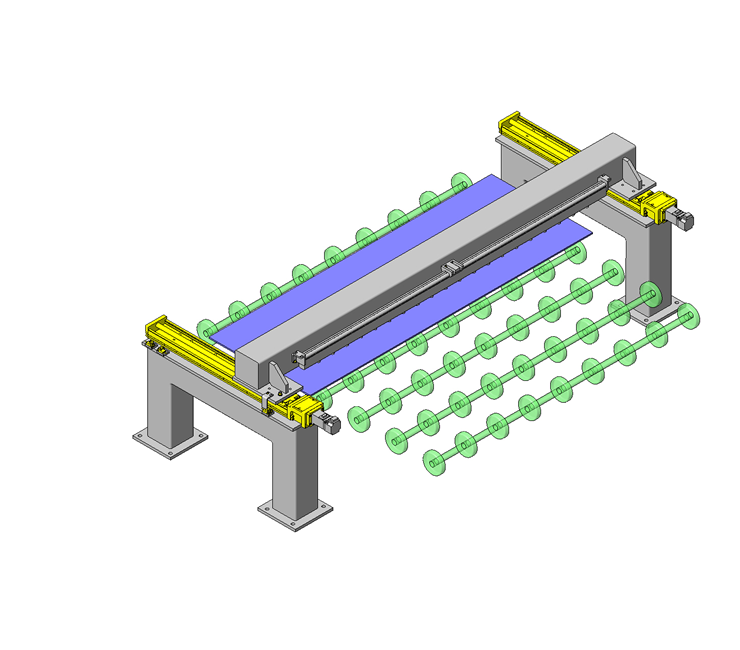

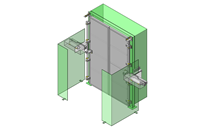

Parallel use of two single-axis actuators

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

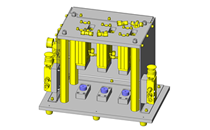

- A device to remove static electricity from resin material that is likely to create an electrical charge.

- Static electricity is removed after the workpiece is stopped.

Points for use

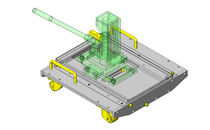

- Automatic horizontal movement enabled by single-axis actuators and servo motors.

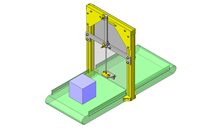

Target workpiece

- Workpiece: electrically charged resin material.

- Dimensions: W430 x D1200 x t5mm

- Mass: 3.4kg

Design Specifications

Operating Conditions or Design Requirements

- Operational Specifications

- Action stroke: 430mm

- Feed speed: 45mm/sec

- Dimensions

- Outer dimensions: W1616 x D812 x H515mm

Selection Criteria for Main Components

- Capacity of single-axis actuator.

Design Evaluation

Verification of main components

- The actuator capacity is verified based on the load condition.

- Capacity of single-axis actuator.

-

- Conditional value: stroke Ls = 430mm, feed speed V = 45mm, number of rpms n1 = 2rpm, load factor fw = 1.2 (when AC servo motor is used), operation condition "at low speed (250mm/sec (15m/min) or less)," beam [mass [kg], distances from linear block to the centers of gravity of X, Y, and Z [mm]] = [9.81, 80.18, 750, 50.17], ionizer [mass [kg], distances from linear block to centers of gravity of X, Y, and Z [mm]] = [0.73, 16.88, 750, 42.66]

→ Service life of rail part: 7 [years] * Calculated using Misumi EC Calculation Software.

→ Converted into service period assuming it is used 8 hours a day: 21 [years]

- Conditional value: stroke Ls = 430mm, feed speed V = 45mm, number of rpms n1 = 2rpm, load factor fw = 1.2 (when AC servo motor is used), operation condition "at low speed (250mm/sec (15m/min) or less)," beam [mass [kg], distances from linear block to the centers of gravity of X, Y, and Z [mm]] = [9.81, 80.18, 750, 50.17], ionizer [mass [kg], distances from linear block to centers of gravity of X, Y, and Z [mm]] = [0.73, 16.88, 750, 42.66]

Other Design Consideration

- Due to the large moment load of the removal device, two single-axis actuators are used in parallel.

- Feed mechanism are controlled by servo motors.

- To achieve synchronization, a sequencer and servo amplifier are utilized.

- Calculate the required spacing between the ionizer and the workpiece during the design stage.

- The three photo sensors mounted on the main frame detect overruns at the origin position and both ends.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category