(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Flexible Shaft Couplings(Features:Small)

Take advantage of the convenience of FREE SHIPPING and NO MINIMUM ORDER on couplings. If you have any doubts or require assistance in choosing the right product, our experts are readily available to provide.

|

Type

|

|

|---|---|

Brand |

|

Filter By |

|

| CAD |

|

| Days to Ship |

|

52 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

![Jaw-Shaped Coupling - Clamping Type - [SJCM]](//vn.misumi-ec.com/linked/material/mech/SGL1/PHOTO/221005341075.jpg?$product_view_b$)

Jaw-Shaped Coupling - Clamping Type - [SJCM]

SUNGIL

Simple structure comprising of two hubs and one insert, with the insert relieving shock when the inertial load starts and stops. Easy installation and removal type product. SUNGIL The company is a Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 20 ~ 30 24 ~ 60 104 94 Servo Motor 100 < 500 High Torsional Rigidity ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 2001~4000 Aluminum 300 ~ 600 1 0.1 ~ 0.15 Coupling Main Body 0.02~0.2 3000 - - - From: 4,065,913 VND Days to Ship: Số ngày giao hàng: 6 Day(s)  6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

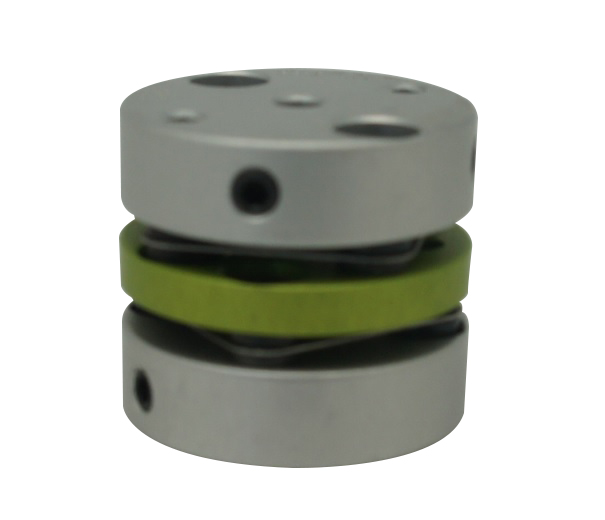

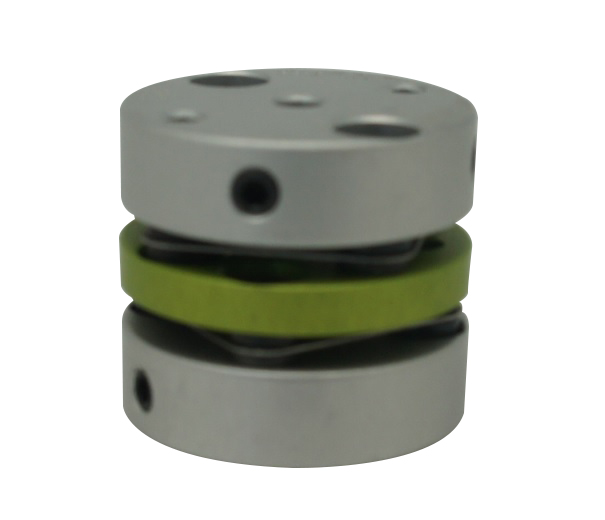

Disc Type Coupling (SD Series)

SUNGIL

[Features] ・High torsional rigidity, excellent positioning power ・Used for high precision position control system ・Low moment of inertia ・Semi-permanent life ・Deflection, eccentricity accepted ・The characteristics of positive / reverse are the same ・Single disc, double disc type (can not accommodate eccentric type in case of single type) •Related Keywords: Sungil Machinery, Standard Coupling, Coupling / Shaft Joint

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 16 ~ 64 11.9 ~ 90.5 Servo Motor / Stepping Motor / Encoder 0.05~1.00 ~ 20.01~50.00 Clean Environment ~ Vacuum Environment Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum / Aluminum Alloy 0.5 ~ 31 1 ~ 3 0 ~ 0.8 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 9,000 ~ 16000 Aluminum Bronze / Others Stainless Steel - From: 443,638 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

SUNGIL

[Features] ・Structure assembled by applying preload to sleeve ・Zero backlash (low operating otok environment) ・Excellent durability, high torsional stiffness ・Sleeve for eccentricity, declination and vibration ・The same positive / reverse characteristics ・Oil resistance, electric insulation ・Use temperature: -30°C to -120°C

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 3 ~ 28 3 ~ 28 14 ~ 55 22 ~ 78 Servo Motor 1.01~3.00 ~ 20.01~50.00 High Torsional Rigidity ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 1.2 ~ 35 1 0.1 ~ 0.15 Coupling Main Body 0.02~0.2 7500 ~ 27000 Others Aluminum - From: 530,660 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Slit Type Coupling (SRB Series)

SUNGIL

[Features] ・Zero backlash ・Eccentricity, declination, complete end-play absorption (spring of Radical Beam Sit) ・High rigidity aluminum alloy (AL 7075-T6) ・High torsional stiffness and allowable torque ・Low moment of inertia, stability at high rotational speed ・ Static reversal is the same ・Oil resistance, chemical resistance •Related keywords: Sungil Machinery, Standard Coupling, Coupling / Shaft Joint

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Slit 3 ~ 25 3 ~ 25 12.7 ~ 60 13 ~ 88 Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small - 2001~4000 ~ 10001~78000 Stainless Steel / Aluminum Alloy 0.2 ~ 30 1 ~ 2.5 0 ~ 0.3 - 0.02~0.2 ~ 0.21~0.40 12,000 ~ 40000 - - - From: 373,870 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

OLDHAM Type Coupling (SOH Series)

SUNGIL

[Features] ・Electrical insulation effect, non-magnetic ・Absorption of excellent eccentricity and declination (slip phenomenon of middle disc and rounding effect of hub) ・Easy to assemble and replace ・ Minimization of axial load during unalignment ・Free flow, low bearing load •Related Keywords: Sungil Machinery, Standard Coupling, Coupling / Shaft Joint

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 25 3 ~ 25 16 ~ 53 21 ~ 58 Standard / Stepping Motor 1.01~3.00 ~ 20.01~50.00 No Backlash ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 2001~4000 ~ 4001~10000 Aluminum / Aluminum Alloy 1 ~ 25 1.5 ~ 2 1 ~ 3.2 Coupling Main Body 0.41~1.0 ~ 3.1~5.0 3400 ~ 8000 Polyacetal Aluminum - From: 407,683 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

MIKI PULLEY

· SFC Model for Servo Coupling · Application: Servo Motor / Stepping Motor / Encoder. · Body material: Using aluminum clad in a clear anodized finish. · Disc members are made of 304 stainless steels. · Single and double element configurations are available. · Bores can be configured with clamp, taper-lock, or keyed styles. · Maximum Rotational Speed Range: 4001 ~ 10000 (r/min). · Maximum allowable torque: 250 Nm. · Bore size range: 3 mm to 45mm. · Backlash: Zero. · Operating Temperature Range: -30 to 100 °C · Couplings are precisely assembled using high strength, corrosion resistant fasteners.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 45 3 ~ 45 12 ~ 104 12.35 ~ 101.6 Servo Motor / Stepping Motor / Encoder 0.05~1.00 ~ 100 < 500 High Accuracy ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 0.25 ~ 250 0.5 ~ 2 0.01 ~ 0.63 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 10000 - Stainless Steel - From: 1,229,300 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Helical Coupling, Set-Screw Type, Short Type HC-SS

JIT COUPLING

[Features]· The HC-SS Series are couplings with a shorter design.· Helical Coupling has a relief shape machined on the inner diameter portion where beam is located to prevent coupling damage due to shaft interference caused by eccentricity and declination.· The tightening angle of the fixing bolt is set to 120° and the force that is fixed to the shaft is dispersed.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Slit 3 ~ 30 3 ~ 30 16 ~ 48 18 ~ 48 Standard / Servo Motor / Stepping Motor / Encoder - High Accuracy ~ Vibration Insulation - - Aluminum - 3 0.1 ~ 0.2 - - 4000 ~ 10000 - - - From: 276,690 VND Days to Ship: Số ngày giao hàng: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![Jaw-Shaped Coupling - Clamping Type - [SJC, SJCA, and SJCB]](//vn.misumi-ec.com/linked/material/mech/SGL1/PHOTO/221005341064_001.jpg?$product_view_b$)

Jaw-Shaped Coupling - Clamping Type - [SJC, SJCA, and SJCB]

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

- Volume Discount

- CAD :

- 2D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 3 ~ 18 3 ~ 18 14 ~ 40 22 ~ 66 Servo Motor 1.01~3.00 ~ 10.01~20.00 High Torsional Rigidity ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum 1.2 ~ 17 1 0.1 ~ 0.15 Coupling Main Body 0.02~0.2 8500 ~ 22000 Others Aluminum - From: 408,120 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

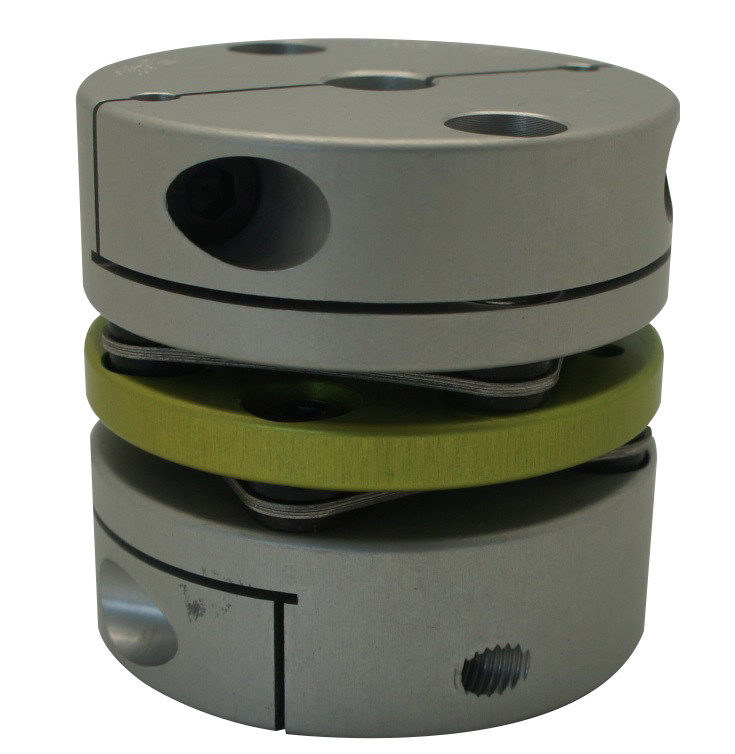

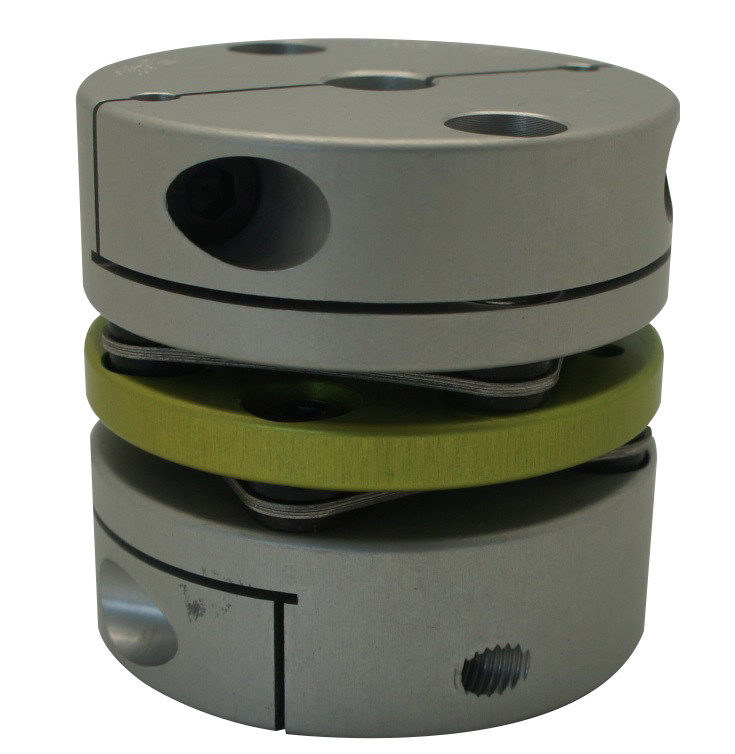

Disc type coupling Set screw type (double disc) Body aluminum

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 16 ~ 64 15.6 ~ 74 Servo Motor / Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum 0.5 ~ 31 3 0.2 ~ 0.3 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 7000 ~ 12000 Aluminum Bronze / Others Stainless Steel - From: 507,272 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disc Coupling Single Disc Type DC-SA

JIT COUPLING

[Features] · The DC-SA Type Coupling is a type with a single disk plate. · Its shorter size makes it suitable for small spaces. · Because the fluidity of the disk is low, the two axes in particular must be lined up accurately. · The surface is hard-anodized and has excellent corrosion resistance, oil resistance and chemical resistance.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 4 ~ 25 4 ~ 25 32 ~ 68 28.1 ~ 50.5 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 1 ~ 2 0.1 ~ 0.2 - - 2800 ~ 6500 - Stainless Steel - From: 490,440 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc Coupling Clamping Type (Double Disc) SDWA

SUNGIL

Structure that adjusts axis misalignment by deflection of a thin metal disc. Large torque transmission, even at high-speeds. Simple structure that is easy to remove. Clamping type product. SUNGIL The company is a Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 16 ~ 64 21 ~ 74 Servo Motor / Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum 0.5 ~ 31 3 0.2 ~ 0.3 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 6500 ~ 14000 Aluminum Bronze / Others Stainless Steel - From: 460,392 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

![Oldham Coupling -Clamping Short Type - [SOHM-16C]](//vn.misumi-ec.com/linked/material/mech/SGL1/PHOTO/221005200822_003.jpg?$product_view_b$)

Oldham Coupling -Clamping Short Type - [SOHM-16C]

SUNGIL

Coupling with a relatively large misalignment tolerance. Clamping type product. SUNGIL The company is a Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 25 3 ~ 25 16 ~ 53 21 ~ 53 Standard / Stepping Motor 1.01~3.00 ~ 20.01~50.00 No Backlash ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 2001~4000 ~ 4001~10000 Aluminum / Aluminum Alloy 1 ~ 25 2 1 ~ 3.2 Coupling Main Body 1.1~3.0 ~ 3.1~5.0 3400 ~ 8000 - - - From: 407,683 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc-Shaped Coupling - Clamping Type (Single Disc)

SUNGIL

Structure that adjusts axis misalignment by deflection of a thin metal disc. Large torque transmission, even at high-speeds. Simple structure that is easy to remove. Clamping type product. SUNGIL The company is a Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 16 ~ 64 17.4 ~ 58 Servo Motor / Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 0.5 ~ 31 1 ~ 1.5 0 Coupling Main Body 0.41~1.0 6500 ~ 10000 Aluminum Bronze / Others Stainless Steel - From: 531,733 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Jaw Coupling, Set-Screw Type JC-S

JIT COUPLING

[Features]· Divided into two hubs to facilitate processing of the key-way; the tightening angle of the fixing bolt is set to 120° intervals, enabling it to be mounted safely.[Usage]· Can be used for a wide range of general industrial machines, such as compact geared motors and compact DC motor-powered pumps.· Suitable for machines that are often assembled and disassembled, or those subject to frequent forward / reverse movements.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 3 ~ 22 3 ~ 22 16 ~ 42 23.6 ~ 55 Standard / Servo Motor / Stepping Motor - High Durability ~ Vibration Insulation - - Aluminum - 1 0.1 ~ 0.2 - - 3000 ~ 9000 Polyurethane - - From: 265,100 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc Coupling Clamping Type (Double Disc) SDWC

SUNGIL

Disc type coupling with low moment of inertia and stable even at high speed.[Features]·It has a shape with high torsional rigidity and is excellent in oil and chemical resistance.·Semi-permanent life with zero backlash.·Absorbs declination, eccentricity, and end play misalignment.・ The characteristics of forward/reverse rotation are the same and no repair is required.[Applications]·It can be used for servo motors, stepping motors, precision motors, etc.·Ideal for high-precision encoders, dynamometer drivers, high-speed, high-precision position control systems, centrifuges, copiers, etc.

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 5 ~ 25 5 ~ 25 39 ~ 54 44.8 ~ 58 Servo Motor / Stepping Motor 3.01~5.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 5 ~ 22 3 0.3 ~ 0.4 Coupling Main Body 0.21~0.40 ~ 0.41~1.0 6000 ~ 8000 Aluminum Bronze / Others Stainless Steel - From: 714,915 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Jaw Coupling, Clamping Screw / Set Screw Combined Type JC-CS

JIT COUPLING

[Features]· The JC-CS Type Coupling uses a clamp-type on one side and a set screw on the other side to facilitate mounting.· The main body is made of highly rigid aluminum (AL705-6T).· Highly elastic polyurethane is adopted for the ring gear used as an intermediate medium.· The surface is anodized and has excellent corrosion resistance.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 3 ~ 22 3 ~ 22 16 ~ 42 23.6 ~ 55 Standard / Servo Motor / Stepping Motor - High Durability ~ Vibration Insulation - - Aluminum - 1 0.1 ~ 0.2 - - 3000 ~ 9000 Polyurethane - - From: 298,010 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Oldham Coupling, Clamping-Screw Type OC-C

JIT COUPLING

[Features]· In oldham coupling, a slot groove on the tip of the cylindrical aluminum material is processed, the polyacetal disk with superior lubrication performance is inserted between the groove, and mechanical part is proceesed and the tightening errors is corrected, and to transmit rotational force.· Ideal coupling.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 30 3 ~ 30 16 ~ 54 22 ~ 58 Standard - Low Moment of Inertia ~ Vibration Insulation - - Aluminum - 2 1 ~ 3.5 - - 2700 ~ 8000 Polyacetal - - From: 275,440 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Oldham Coupling - Clamping Type -

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

- Volume Discount

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 25 3 ~ 25 16 ~ 53 23.6 ~ 58 Standard / Stepping Motor 1.01~3.00 ~ 20.01~50.00 No Backlash ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 2001~4000 ~ 4001~10000 Aluminum - 1.5 1 ~ 3.2 Coupling Main Body 0.41~1.0 ~ 3.1~5.0 3400 ~ 8000 Polyacetal Aluminum - From: 463,658 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Helical Coupling, Clamping-Screw Type HC-C

JIT COUPLING

[Features]· The Helical Coupling uses a cylindrical material and has two spiral-twisted beams for flexible elasticity in the axial direction.· It has excellent torsional rigidity, low moment of inertia and excellent responsiveness.[Usage]· A coupling suitable for a place high-speed response is required.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Slit 3 ~ 26 3 ~ 26 16 ~ 48 22 ~ 54 Standard / Servo Motor / Stepping Motor / Encoder - High Accuracy ~ Vibration Insulation - - Aluminum - 3 0.1 ~ 0.15 - - 4000 ~ 10000 - - - From: 289,490 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disk Coupling Double-Disk Type DC-C

JIT COUPLING

[Features]· This Disk Coupling is made from ideal materials into the ideal structure to realize zero backlash, while giving it the power to withstand repeated stress.· There is a need to accurately line up the two axes due to small eccentricity..· Maintenance is not required and it features excellent oil resistance and heat resistance.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 48 3 ~ 48 20 ~ 81 22.8 ~ 82 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 1 ~ 2 0.1 ~ 0.2 - - 2800 ~ 15000 - Stainless Steel - From: 363,470 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Helical Coupling Set-Screw Type, Normal Type HC-S

JIT COUPLING

[Features]· The Helical Coupling is made from highly rigid duralumin (AL075-6T) and features excellent torsional rigidity in addition to a high deflection angle and end play absorption rate.· The surface is rigid anodized and has excellent wear resistance.[Usage]· Used for X-Y robots, medical equipment, coil winding machines, optical devices and measuring equipment.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Slit 3 ~ 30 3 ~ 30 16 ~ 48 22 ~ 54 Standard / Servo Motor / Stepping Motor / Encoder - High Accuracy ~ Vibration Insulation - - Aluminum - 3 0.1 ~ 0.15 - - 4000 ~ 10000 - - - From: 259,570 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

XSTS/XWSS Clean, Vacuum, Heat-Resistance Support Coupling - Slit Type (SUS316L)

NABEYA BI-TECH

Low particle. Chemical resistant SUS316L made. Backlash "0"

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Slit 5 ~ 14 5 ~ 14 25 ~ 32 25 ~ 32 Stepping Motor 1.01~3.00 ~ 3.01~5.00 Clean Environment ~ Vacuum Environment Angular Misalignment / Axial Misalignment 10001~78000 - 2 ~ 3.5 1 - Coupling Main Body - 19000 ~ 25000 - - - From: 2,829,417 VND Days to Ship: Số ngày giao hàng: 14 Day(s) or more  14 Day(s) or more

14 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Oldham Coupling, Clamping Screw / Set Screw Combined Type OC-CS

JIT COUPLING

[Features]· The OC-CS Type coupling uses a clamp-type on one side and a set screw on the other side to facilitate mounting.· Used high rigidity aluminum (AL705-6T) for the main body, and used acetal resin for the disk used as an intermediate medium.· The surface is anodized and features excellent abrasion-resistance and wear resistance.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 22 3 ~ 22 16 ~ 42 21 ~ 45 Standard - Low Moment of Inertia ~ Vibration Insulation - - Aluminum - 2 1 ~ 3 - - 3000 ~ 8000 Polyacetal - - From: 234,660 VND Days to Ship: Số ngày giao hàng: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disk Coupling, Clamping Screw Double-Disk Type DC-A

JIT COUPLING

[Features]· The Disk Coupling is a coupling in which a high elasticity metal disk is assembled with bolts between the hubs that fix the shaft.The disk diameter of the DC-A Type is larger than its shaft diameter, enabling a higher regular-use torque can be selected.[Usage]· Since only metal materials are used, this coupling can be used in areas where high levels of heat is generated.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 4 ~ 25 4 ~ 25 32 ~ 68 38 ~ 66.4 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 1 ~ 2 0.1 ~ 0.2 - - 2800 ~ 6500 - Stainless Steel - From: 511,570 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disk Coupling, Single-Disk Type DC-SC

JIT COUPLING

[Features]· Disk coupling is a metal laminated plate spring type and as there is no contact part to move, there is no abrasion and expected lifespan is long.· The hub body is made of highly rigid aluminum and its moment of inertia is small.· The product is also back-lash free and highly rigid.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 48 3 ~ 48 20 ~ 81 17.9 ~ 65.4 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 0.15 ~ 2 0.1 ~ 0.2 - - 2800 ~ 15000 - Stainless Steel - From: 295,510 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc-Shaped Coupling - Clamping Type (Single Disc)

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 6 ~ 25 6 ~ 25 42.5 ~ 54 31.4 ~ 42 Servo Motor / Stepping Motor 5.01~10.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 6 ~ 22 1 0 Coupling Main Body - 6000 ~ 8000 Aluminum Bronze / Others Stainless Steel - From: 883,033 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![Disc-Shaped Coupling - Set Screw Long Type (Double Disc) - [SDWB]](//vn.misumi-ec.com/linked/material/mech/SGL1/PHOTO/221005340580.jpg?$product_view_b$)

Disc-Shaped Coupling - Set Screw Long Type (Double Disc) - [SDWB]

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 19 3 ~ 19 16 ~ 47 17.6 ~ 46 Servo Motor / Stepping Motor 0.05~1.00 ~ 5.01~10.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum 0.5 ~ 10 3 0.2 ~ 0.4 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 8000 ~ 12000 Aluminum Bronze / Others Stainless Steel - From: 507,623 VND Days to Ship: Số ngày giao hàng: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disc-Shaped Coupling - Set Screw Type (Single Disc) -

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 16 ~ 64 11.9 ~ 58 Servo Motor / Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 ~ 10001~78000 Aluminum 0.5 ~ 31 1 ~ 1.5 0 Coupling Main Body - 7000 ~ 16000 Aluminum Bronze / Others Stainless Steel - From: 443,638 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Super zero Oldham coupling series MCZ type aluminum alloy products

NIHON MINIATURE

Type that fixes the shaft with tightening of a set screw and clamp. Larger shaft hole diameters can be selected.[Features]· Super zero Oldham coupling achieves zero backlash, with improved machining accuracy· Stronger and more compact design, that can now be used with high precision equipment impossible until now.· Stainless steel series added, becoming 4 series, with further improvements.· Materials used are, engineering plastic for spacer, and stainless steel SUS303 for hubs, aluminum series uses aluminum alloy (alumite surface treatment).· Easy to handle coupling, with low moment of inertia, large swing rigidity, good electrical insulation, and maintenance-free, easy assembly.· Two types of super zero Oldham coupling, with set screw or collet shaft fixing methods both available, that can be freely combined.· Stainless steel has no. 4 model number, and the aluminum series has no. 10 model number.· Stocking stainless steel series from ø4 to ø28, aluminum series from ø3 to ø40 in millimeter and inch system of inner diameter finish.

- CAD :

- 2D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 25 3 ~ 35 18 ~ 70 25 ~ 53 Standard 1.01~3.00 ~ 100 < 500 High Torque ~ Small Angular Misalignment / Eccentricity 4001~10000 ~ 10001~78000 Aluminum 2.452 ~ 176.52 1 1.5 ~ 2.5 Coupling Main Body 1.1~3.0 10000 ~ 25000 Others - - From: 997,090 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc Coupling Clamping Type (Double Disc) SDA

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 22.2 ~ 64 33 ~ 89.5 Servo Motor / Stepping Motor 1.01~3.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 1.1 ~ 31 3 0.4 ~ 0.5 Coupling Main Body 0.21~0.40 ~ 0.41~1.0 6500 ~ 10000 Aluminum Bronze / Others Stainless Steel - From: 738,525 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disk Coupling, Single-Disk Type DC-SB

JIT COUPLING

[Features]· When a shaft with large diameter of a servo motor reduction drive is connected to a shaft with small diameter at the tip of ball screw, DC-SB type coupling can be used to couple ideally.· High elasticity disk is made of stainless steel and has long lifespan.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 4 ~ 25 6 ~ 40 32 ~ 68 28.1 ~ 53.3 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 1 ~ 2 0.1 ~ 0.2 - - 2800 ~ 6500 - Stainless Steel - From: 405,300 VND Days to Ship: Số ngày giao hàng: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![Jaw Coupling -Set Screw Type- [SJC-14-GR]](//vn.misumi-ec.com/linked/material/mech/SGL1/PHOTO/221005200844.jpg?$product_view_b$)

Jaw Coupling -Set Screw Type- [SJC-14-GR]

SUNGIL

Jaw type coupling with excellent backlash durability and high torsional rigidity.[Features]·No maintenance, no lubrication, elastic spider is Pitload's shock-reducing shaft coupling.·Same forward/reverse rotation characteristics, good oil resistance and electrical insulation.·Balancing is optimized by machining the inner diameter of the hub.[Applications]·Ideal for transmission equipment, position control/positioning tables, robot systems, medical equipment, and servo motors.

- CAD :

- 2D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Jaw 4 ~ 15 4 ~ 15 20 ~ 40 30 ~ 55 Servo Motor 3.01~5.00 ~ 10.01~20.00 High Torsional Rigidity ~ Vibration Insulation Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 5 ~ 12.5 1 0.1 ~ 0.15 Coupling Main Body 0.02~0.2 9600 ~ 19000 Others Aluminum - From: 381,796 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disc-Shaped Coupling - Set Screw Type (Double Disc) -

SUNGIL

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 30 3 ~ 30 22.2 ~ 64 28.3 ~ 89.9 Servo Motor / Stepping Motor / Encoder 1.01~3.00 ~ 20.01~50.00 Clean Environment ~ Vacuum Environment Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum / Aluminum Alloy 1.1 ~ 31 1.5 ~ 3 0.12 ~ 0.5 Coupling Main Body 0.21~0.40 ~ 0.41~1.0 7000 ~ 12000 Aluminum Bronze / Others Stainless Steel - From: 550,809 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disc-Shaped Coupling, Clamping Long Type (Double Disc)

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 3 ~ 25 3 ~ 25 16 ~ 54 23 ~ 52 Servo Motor / Stepping Motor 0.05~1.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 0.5 ~ 22 3 0.2 ~ 0.4 Coupling Main Body 0.02~0.2 ~ 0.41~1.0 6000 ~ 10000 Aluminum Bronze / Others Stainless Steel - From: 511,797 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc Coupling Clamping Type (Double Disc) SDAA

SUNGIL

Disc coupling clamping type (double disc).[Features]·Shape with high torsional rigidity. Semi-permanent life with zero backlash.·Absorbs declination, eccentricity, and end play misalignment.·Stable even at high rotation with a low moment of inertia. The characteristics of forward/reverse rotation are the same and no repair is required.·Excellent oil and chemical resistance.[Applications]·Servo motors, stepping motors, precision motors, etc.·High-precision encoder, dynamometer driver, high-speed, high-precision position control system.·Centrifuge, copier.

- CAD :

- 3D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 6 ~ 20 6 ~ 20 42.5 ~ 54 50 ~ 75.6 Servo Motor / Stepping Motor 5.01~10.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 6 ~ 22 3 0.4 ~ 0.5 Coupling Main Body 0.21~0.40 ~ 0.41~1.0 7000 ~ 8000 Aluminum Bronze Stainless Steel - From: 1,205,935 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Long Disc-Shaped Coupling, Set Screw Type (Double Disc)

SUNGIL

Brand-name products provided by MISUMI-VONA are offered based on customers' needs that selected from products of Asian manufacturers carefully. Please select an item according to the user's various usage scenes. A Korean manufacturer established in 1991. Korean coupling market share is 70%, with over 3,000 customers. No1 maker. Rich selection, and short lead-times.

- CAD :

- 3D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 6 ~ 20 6 ~ 20 42.5 ~ 54 58 ~ 85 Servo Motor / Stepping Motor 5.01~10.00 ~ 20.01~50.00 Heat Resistant ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Aluminum 6 ~ 22 3 0.5 ~ 0.8 Coupling Main Body 0.41~1.0 7500 ~ 8000 Aluminum Bronze Stainless Steel - From: 1,206,632 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Oldham Coupling, Set-Screw Type OC-S

JIT COUPLING

[Features]· Extends through the inside of an oldham disk and is free of shaft interference.· The product is designed that acetal disk receives compressive force and generation of damage in disk is minimal.· The oldham disk is a near-perfect insulator and blocks electrical noise.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 22 3 ~ 22 16 ~ 42 20 ~ 42 Standard - Low Moment of Inertia ~ Vibration Insulation - - Aluminum - 2 1 ~ 3 - - 3000 ~ 8000 Polyacetal - - From: 191,500 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

ADVANCED

· Small but strong coupling with excellent durability· A wide selection of products that can be selected based on the ideal external size· Combination of SUS sintered hub and carbon FRP slider

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 1 ~ 20 1 ~ 20 6 ~ 38 8.4 ~ 118.8 Standard 0.05~1.00 ~ 20.01~50.00 High Durability ~ Vibration Insulation Angular Misalignment / Eccentricity 4001~10000 ~ 10001~78000 Stainless Steel 0.3 ~ 28 1.5 ~ 2 0.3 ~ 0.7 Coupling Main Body 0.21~0.40 ~ 1.1~3.0 5800 ~ 12000 Carbon Reinforced Resin - - From: 374,408 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

KAYSEVEN

· K-7 coupling MD series - Oldham Type. · MD series Oldham Couplings structure Consists of three parts :2 hubs and 1 torque disc. · Application: Robot, Various pumps, Blower, Printing machine, NC-MC machine tool and Conveyor. · As K-7 standard specifications, 12 MD types from MD-35 to MD-160M are available. · MD series Body material is aluminum alloy. · Torque disc material: Polyacetal resin. · Torque discs are made of resin and do not need to be lubricated. · Operating environment Temperature Range: -40 to 85 °C · Assembly and replacement of intermediate torque transmission members are easy.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham - - 35 ~ 160 54 ~ 164 Standard 5.01~10.00 ~ 100 < 500 Small ~ Vibration Insulation Not Provided 2001~4000 ~ 4001~10000 Steel / Aluminum / Plastic 9.8 ~ 294 - - Coupling Main Body - 4000 ~ 10000 Polyacetal - - From: 146,953 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ADVANCED

· Miniature coupling making full use of engineered plastic fatigue resistance· It has excellent resistance to bending fatigue as compared with metals such as aluminum alloys, realizing light and smooth rotation transmission· For light load transmission such as those from rotary switches, encoders, or small motors· For rotation transmission parts that require electric insulation

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 2 ~ 8 2 ~ 8 8 ~ 18 9 ~ 18 Standard / Encoder 0.05~1.00 No Backlash ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 2001~4000 ~ 4001~10000 Plastic 0.1 ~ 0.9 3 ~ 5 0.05 ~ 0.2 Coupling Main Body 0.02~0.2 4000 ~ 6000 - Glass Fiber Reinforced Resin / Polyacetal - From: 174,680 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Disc Couplings - High Rigidity (O.D. 40) / Keyless Clamping, Keywayed Bore, for Servo Motors

MISUMI

[Features]·It has a compact size, and the high stiffness surface pressure and keyway can be selected.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 10 ~ 16 10 ~ 16 40 39.4 ~ 53 Servo Motor 5.01~10.00 High Torque ~ Small Angular Misalignment / Eccentricity / Axial Misalignment 4001~10000 Steel / Aluminum 6 ~ 8 1 0.2 Coupling Main Body 0.02~0.2 10000 - Stainless Steel - Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Super zero Oldham coupling series CCZ type aluminum alloy products

NIHON MINIATURE

Clamp type, aluminum made Oldham coupling. Prevent slippage by tightening the entire shaft.[Features]· Super zero Oldham coupling achieves zero backlash, with improved machining accuracy· Stronger and more compact design, that can now be used with high precision equipment impossible until now.· Stainless steel series added, becoming 4 series, with further improvements.· Materials used are, engineering plastic for spacer, and stainless steel SUS303 for hubs, aluminum series uses aluminum alloy (alumite surface treatment).· Easy to handle coupling, with low moment of inertia, large swing rigidity, good electrical insulation, and maintenance-free, easy assembly.· Two types of super zero Oldham coupling, with set screw or collet shaft fixing methods both available, that can be freely combined.· Stainless steel has no. 4 model number, and the aluminum series has no. 10 model number.· Stocking stainless steel series from ø4 to ø28, aluminum series from ø3 to ø40 in millimeter and inch system of inner diameter finish.

- CAD :

- 2D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 1 ~ 40 3 ~ 40 16 ~ 80 20 ~ 61 Standard 1.01~3.00 ~ 100 < 500 High Torque ~ Small Angular Misalignment / Eccentricity 10001~78000 Aluminum 1.961 ~ 215.746 1 1.5 ~ 2.5 Coupling Main Body 1.1~3.0 15000 ~ 25000 Others - - From: 597,154 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Disk Coupling, Double-Disk Type DC-B

JIT COUPLING

[Features]· When a shaft with large diameter of a servo motor reduction drive is connected to a shaft with small diameter at the tip of ball screw, DC-SB type coupling can be used to couple ideally.· High elasticity disk is made of stainless steel and has long lifespan.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Disc 4 ~ 25 6 ~ 40 32 ~ 68 38 ~ 69.2 Standard / Servo Motor / Stepping Motor / Encoder - Heat Resistant ~ Small - - Aluminum - 1 ~ 2 0.1 ~ 0.2 - - 2800 ~ 6500 - Stainless Steel - From: 511,640 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

Super zero Oldham couplings series SCZ type stainless steel.

NIHON MINIATURE

Stainless steel hub (boss part), with zero backlash. Stronger and more compact coupling.[Features]· Super zero Oldham coupling achieves zero backlash, with improved machining accuracy· Stronger and more compact design, that can now be used with high precision equipment impossible until now.· Stainless steel series added, becoming 4 series, with further improvements.· Materials used are, engineering plastic for spacer, and stainless steel SUS303 for hubs, aluminum series uses aluminum alloy (alumite surface treatment).· Easy to handle coupling, with low moment of inertia, large swing rigidity, good electrical insulation, and maintenance-free, easy assembly.· Two types of super zero Oldham coupling, with set screw or collet shaft fixing methods both available, that can be freely combined.· Stainless steel has no. 4 model number, and the aluminum series has no. 10 model number.· Stocking stainless steel series from ø4 to ø28, aluminum series from ø3 to ø40 in millimeter and inch system of inner diameter finish.

- CAD :

- 2D

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 4 ~ 28 4 ~ 28 20 ~ 60 33 ~ 65 Standard 3.01~5.00 ~ 50.01~100.00 High Torque ~ Small Angular Misalignment / Eccentricity 4001~10000 Stainless Steel 3.432 ~ 98.067 1 1.5 ~ 2 Coupling Main Body 1.1~3.0 5000 ~ 6000 Others - - From: 1,721,474 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

KAYSEVEN

Compact, high-performance eccentricity absorbing, non-reactive force product with no backlash. Widely used in robots, medical equipment, packaging machinery, and machine tools etc.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 9525 3 ~ 10 17.5 ~ 25.5 24.9 ~ 32 Standard 1.01~3.00 ~ 3.01~5.00 Low Moment of Inertia ~ Vibration Insulation Not Provided 4001~10000 ~ 10001~78000 Aluminum 1.76 ~ 3.67 - - Coupling Main Body - 10000 ~ 15000 Polyacetal - - From: 667,862 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Type |

| Shaft Bore Dia. (machined) D1(Ø) |

| Shaft Bore Dia. (machined) D2(Ø) |

| Outer Dia. A(Ø) |

| Overall Length W(mm) |

| Application |

| Allowable Torque Range(N•m) |

| Features |

| Allowable Misalignment |

| Max. Rotational Speed Range(r/min) |

| Body Material |

| Allowable Torque(N•m) |

| Allowable Angular Misalignment(deg) |

| Allowable Lateral Misalignment(mm) |

| Product Category |

| Allowable Lateral Misalignment Range(mm) |

| Max. Rotational Speed(r/min) |

| Buffer Material |

| Disc Material |

| Bellows Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | SUNGIL | SUNGIL | SUNGIL | SUNGIL | SUNGIL | MIKI PULLEY | JIT COUPLING | SUNGIL | SUNGIL | JIT COUPLING | SUNGIL | SUNGIL | SUNGIL | JIT COUPLING | SUNGIL | JIT COUPLING | JIT COUPLING | SUNGIL | JIT COUPLING | JIT COUPLING | JIT COUPLING | NABEYA BI-TECH | JIT COUPLING | JIT COUPLING | JIT COUPLING | SUNGIL | SUNGIL | SUNGIL | NIHON MINIATURE | SUNGIL | JIT COUPLING | SUNGIL | SUNGIL | SUNGIL | SUNGIL | SUNGIL | JIT COUPLING | ADVANCED | KAYSEVEN | ADVANCED | MISUMI | NIHON MINIATURE | JIT COUPLING | NIHON MINIATURE | KAYSEVEN |

| Product SeriesDòng sản phẩm | Disc type coupling Set screw type (double disc) Body aluminum | Jaw Coupling, Clamping Screw / Set Screw Combined Type JC-CS | XSTS/XWSS Clean, Vacuum, Heat-Resistance Support Coupling - Slit Type (SUS316L) | Oldham Coupling, Clamping Screw / Set Screw Combined Type OC-CS | Disc-Shaped Coupling - Set Screw Long Type (Double Disc) - [SDWB] | Super zero Oldham coupling series MCZ type aluminum alloy products | Disc Couplings - High Rigidity (O.D. 40) / Keyless Clamping, Keywayed Bore, for Servo Motors | Super zero Oldham coupling series CCZ type aluminum alloy products | Super zero Oldham couplings series SCZ type stainless steel. | ||||||||||||||||||||||||||||||||||||

| CADCAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| From | 4,065,913 VND | 443,638 VND Special Price On Sale Till 31/03/2025 | 530,660 VND | 373,870 VND Special Price On Sale Till 31/03/2025 | 407,683 VND | 1,229,300 VND | 276,690 VND | 408,120 VND | 507,272 VND | 490,440 VND | 460,392 VND Special Price On Sale Till 31/03/2025 | 407,683 VND | 531,733 VND | 265,100 VND Special Price On Sale Till 31/03/2025 | 714,915 VND | 298,010 VND | 275,440 VND | 463,658 VND | 289,490 VND | 363,470 VND Special Price On Sale Till 31/03/2025 | 259,570 VND | 2,829,417 VND | 234,660 VND | 511,570 VND | 295,510 VND | 883,033 VND | 507,623 VND | 443,638 VND | 997,090 VND | 738,525 VND | 405,300 VND | 381,796 VND | 550,809 VND | 511,797 VND | 1,205,935 VND | 1,206,632 VND | 191,500 VND | 374,408 VND | 146,953 VND | 174,680 VND | 597,154 VND | 511,640 VND | 1,721,474 VND | 667,862 VND | |

| Days to ShipSố ngày giao hàng | 6 Day(s) | Same day or more | 4 Day(s) or more | Same day or more | Same day or more | Same day or more | 5 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | Same day or more | Same day or more | Same day or more | 4 Day(s) or more | Same day or more | 4 Day(s) or more | Same day or more | Same day or more | 4 Day(s) or more | Same day or more | Same day or more | Same day or more | 14 Day(s) or more | 5 Day(s) or more | Same day or more | Same day or more | 4 Day(s) or more | 5 Day(s) or more | 4 Day(s) or more | Same day or more | 4 Day(s) or more | 5 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | Same day or more | 6 Day(s) or more | 6 Day(s) or more | Same day or more | 8 Day(s) or more | 6 Day(s) or more | Same day or more | 6 Day(s) or more | 4 Day(s) or more | Same day or more | 6 Day(s) or more | 4 Day(s) or more |

| Type | Jaw | Disc | Jaw | Slit | Oldham | Disc | Slit | Jaw | Disc | Disc | Disc | Oldham | Disc | Jaw | Disc | Jaw | Oldham | Oldham | Slit | Disc | Slit | Slit | Oldham | Disc | Disc | Disc | Disc | Disc | Oldham | Disc | Disc | Jaw | Disc | Disc | Disc | Disc | Oldham | Oldham | Oldham | Disc | Disc | Oldham | Disc | Oldham | Oldham |

| Shaft Bore Dia. (machined) D1(Ø) | 20 ~ 30 | 3 ~ 30 | 3 ~ 28 | 3 ~ 25 | 3 ~ 25 | 3 ~ 45 | 3 ~ 30 | 3 ~ 18 | 3 ~ 30 | 4 ~ 25 | 3 ~ 30 | 3 ~ 25 | 3 ~ 30 | 3 ~ 22 | 5 ~ 25 | 3 ~ 22 | 3 ~ 30 | 3 ~ 25 | 3 ~ 26 | 3 ~ 48 | 3 ~ 30 | 5 ~ 14 | 3 ~ 22 | 4 ~ 25 | 3 ~ 48 | 6 ~ 25 | 3 ~ 19 | 3 ~ 30 | 3 ~ 25 | 3 ~ 30 | 4 ~ 25 | 4 ~ 15 | 3 ~ 30 | 3 ~ 25 | 6 ~ 20 | 6 ~ 20 | 3 ~ 22 | 1 ~ 20 | - | 2 ~ 8 | 10 ~ 16 | 1 ~ 40 | 4 ~ 25 | 4 ~ 28 | 3 ~ 9525 |

| Shaft Bore Dia. (machined) D2(Ø) | 24 ~ 60 | 3 ~ 30 | 3 ~ 28 | 3 ~ 25 | 3 ~ 25 | 3 ~ 45 | 3 ~ 30 | 3 ~ 18 | 3 ~ 30 | 4 ~ 25 | 3 ~ 30 | 3 ~ 25 | 3 ~ 30 | 3 ~ 22 | 5 ~ 25 | 3 ~ 22 | 3 ~ 30 | 3 ~ 25 | 3 ~ 26 | 3 ~ 48 | 3 ~ 30 | 5 ~ 14 | 3 ~ 22 | 4 ~ 25 | 3 ~ 48 | 6 ~ 25 | 3 ~ 19 | 3 ~ 30 | 3 ~ 35 | 3 ~ 30 | 6 ~ 40 | 4 ~ 15 | 3 ~ 30 | 3 ~ 25 | 6 ~ 20 | 6 ~ 20 | 3 ~ 22 | 1 ~ 20 | - | 2 ~ 8 | 10 ~ 16 | 3 ~ 40 | 6 ~ 40 | 4 ~ 28 | 3 ~ 10 |

| Outer Dia. A(Ø) | 104 | 16 ~ 64 | 14 ~ 55 | 12.7 ~ 60 | 16 ~ 53 | 12 ~ 104 | 16 ~ 48 | 14 ~ 40 | 16 ~ 64 | 32 ~ 68 | 16 ~ 64 | 16 ~ 53 | 16 ~ 64 | 16 ~ 42 | 39 ~ 54 | 16 ~ 42 | 16 ~ 54 | 16 ~ 53 | 16 ~ 48 | 20 ~ 81 | 16 ~ 48 | 25 ~ 32 | 16 ~ 42 | 32 ~ 68 | 20 ~ 81 | 42.5 ~ 54 | 16 ~ 47 | 16 ~ 64 | 18 ~ 70 | 22.2 ~ 64 | 32 ~ 68 | 20 ~ 40 | 22.2 ~ 64 | 16 ~ 54 | 42.5 ~ 54 | 42.5 ~ 54 | 16 ~ 42 | 6 ~ 38 | 35 ~ 160 | 8 ~ 18 | 40 | 16 ~ 80 | 32 ~ 68 | 20 ~ 60 | 17.5 ~ 25.5 |

| Overall Length W(mm) | 94 | 11.9 ~ 90.5 | 22 ~ 78 | 13 ~ 88 | 21 ~ 58 | 12.35 ~ 101.6 | 18 ~ 48 | 22 ~ 66 | 15.6 ~ 74 | 28.1 ~ 50.5 | 21 ~ 74 | 21 ~ 53 | 17.4 ~ 58 | 23.6 ~ 55 | 44.8 ~ 58 | 23.6 ~ 55 | 22 ~ 58 | 23.6 ~ 58 | 22 ~ 54 | 22.8 ~ 82 | 22 ~ 54 | 25 ~ 32 | 21 ~ 45 | 38 ~ 66.4 | 17.9 ~ 65.4 | 31.4 ~ 42 | 17.6 ~ 46 | 11.9 ~ 58 | 25 ~ 53 | 33 ~ 89.5 | 28.1 ~ 53.3 | 30 ~ 55 | 28.3 ~ 89.9 | 23 ~ 52 | 50 ~ 75.6 | 58 ~ 85 | 20 ~ 42 | 8.4 ~ 118.8 | 54 ~ 164 | 9 ~ 18 | 39.4 ~ 53 | 20 ~ 61 | 38 ~ 69.2 | 33 ~ 65 | 24.9 ~ 32 |

| Application | Servo Motor | Servo Motor / Stepping Motor / Encoder | Servo Motor | Stepping Motor | Standard / Stepping Motor | Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor / Encoder | Servo Motor | Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor / Encoder | Servo Motor / Stepping Motor | Standard / Stepping Motor | Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor | Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor | Standard | Standard / Stepping Motor | Standard / Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor / Encoder | Stepping Motor | Standard | Standard / Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor / Encoder | Servo Motor / Stepping Motor | Servo Motor / Stepping Motor | Servo Motor / Stepping Motor | Standard | Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor / Encoder | Servo Motor | Servo Motor / Stepping Motor / Encoder | Servo Motor / Stepping Motor | Servo Motor / Stepping Motor | Servo Motor / Stepping Motor | Standard | Standard | Standard | Standard / Encoder | Servo Motor | Standard | Standard / Servo Motor / Stepping Motor / Encoder | Standard | Standard |

| Allowable Torque Range(N•m) | 100 < 500 | 0.05~1.00 ~ 20.01~50.00 | 1.01~3.00 ~ 20.01~50.00 | 0.05~1.00 ~ 20.01~50.00 | 1.01~3.00 ~ 20.01~50.00 | 0.05~1.00 ~ 100 < 500 | - | 1.01~3.00 ~ 10.01~20.00 | 0.05~1.00 ~ 20.01~50.00 | - | 0.05~1.00 ~ 20.01~50.00 | 1.01~3.00 ~ 20.01~50.00 | 0.05~1.00 ~ 20.01~50.00 | - | 3.01~5.00 ~ 20.01~50.00 | - | - | 1.01~3.00 ~ 20.01~50.00 | - | - | - | 1.01~3.00 ~ 3.01~5.00 | - | - | - | 5.01~10.00 ~ 20.01~50.00 | 0.05~1.00 ~ 5.01~10.00 | 0.05~1.00 ~ 20.01~50.00 | 1.01~3.00 ~ 100 < 500 | 1.01~3.00 ~ 20.01~50.00 | - | 3.01~5.00 ~ 10.01~20.00 | 1.01~3.00 ~ 20.01~50.00 | 0.05~1.00 ~ 20.01~50.00 | 5.01~10.00 ~ 20.01~50.00 | 5.01~10.00 ~ 20.01~50.00 | - | 0.05~1.00 ~ 20.01~50.00 | 5.01~10.00 ~ 100 < 500 | 0.05~1.00 | 5.01~10.00 | 1.01~3.00 ~ 100 < 500 | - | 3.01~5.00 ~ 50.01~100.00 | 1.01~3.00 ~ 3.01~5.00 |

| Features | High Torsional Rigidity ~ Vibration Insulation | Clean Environment ~ Vacuum Environment | High Torsional Rigidity ~ Vibration Insulation | Heat Resistant ~ Small | No Backlash ~ Vibration Insulation | High Accuracy ~ Small | High Accuracy ~ Vibration Insulation | High Torsional Rigidity ~ Vibration Insulation | Heat Resistant ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | No Backlash ~ Vibration Insulation | Heat Resistant ~ Small | High Durability ~ Vibration Insulation | Heat Resistant ~ Small | High Durability ~ Vibration Insulation | Low Moment of Inertia ~ Vibration Insulation | No Backlash ~ Vibration Insulation | High Accuracy ~ Vibration Insulation | Heat Resistant ~ Small | High Accuracy ~ Vibration Insulation | Clean Environment ~ Vacuum Environment | Low Moment of Inertia ~ Vibration Insulation | Heat Resistant ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | High Torque ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | High Torsional Rigidity ~ Vibration Insulation | Clean Environment ~ Vacuum Environment | Heat Resistant ~ Small | Heat Resistant ~ Small | Heat Resistant ~ Small | Low Moment of Inertia ~ Vibration Insulation | High Durability ~ Vibration Insulation | Small ~ Vibration Insulation | No Backlash ~ Small | High Torque ~ Small | High Torque ~ Small | Heat Resistant ~ Small | High Torque ~ Small | Low Moment of Inertia ~ Vibration Insulation |

| Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity / Axial Misalignment | - | - | Angular Misalignment / Eccentricity / Axial Misalignment | - | - | - | Angular Misalignment / Axial Misalignment | - | - | - | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | - | Angular Misalignment / Eccentricity | Not Provided | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Angular Misalignment / Eccentricity | - | Angular Misalignment / Eccentricity | Not Provided |

| Max. Rotational Speed Range(r/min) | 2001~4000 | 4001~10000 ~ 10001~78000 | 4001~10000 | 2001~4000 ~ 10001~78000 | 2001~4000 ~ 4001~10000 | 4001~10000 | - | 4001~10000 ~ 10001~78000 | 4001~10000 ~ 10001~78000 | - | 4001~10000 ~ 10001~78000 | 2001~4000 ~ 4001~10000 | 4001~10000 | - | 4001~10000 | - | - | 2001~4000 ~ 4001~10000 | - | - | - | 10001~78000 | - | - | - | 4001~10000 | 4001~10000 ~ 10001~78000 | 4001~10000 ~ 10001~78000 | 4001~10000 ~ 10001~78000 | 4001~10000 | - | 4001~10000 | 4001~10000 | 4001~10000 | 4001~10000 | 4001~10000 | - | 4001~10000 ~ 10001~78000 | 2001~4000 ~ 4001~10000 | 2001~4000 ~ 4001~10000 | 4001~10000 | 10001~78000 | - | 4001~10000 | 4001~10000 ~ 10001~78000 |

| Body Material | Aluminum | Aluminum / Aluminum Alloy | Aluminum | Stainless Steel / Aluminum Alloy | Aluminum / Aluminum Alloy | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum / Aluminum Alloy | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | - | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum / Aluminum Alloy | Aluminum | Aluminum | Aluminum | Aluminum | Stainless Steel | Steel / Aluminum / Plastic | Plastic | Steel / Aluminum | Aluminum | Aluminum | Stainless Steel | Aluminum |

| Allowable Torque(N•m) | 300 ~ 600 | 0.5 ~ 31 | 1.2 ~ 35 | 0.2 ~ 30 | 1 ~ 25 | 0.25 ~ 250 | - | 1.2 ~ 17 | 0.5 ~ 31 | - | 0.5 ~ 31 | 1 ~ 25 | 0.5 ~ 31 | - | 5 ~ 22 | - | - | - | - | - | - | 2 ~ 3.5 | - | - | - | 6 ~ 22 | 0.5 ~ 10 | 0.5 ~ 31 | 2.452 ~ 176.52 | 1.1 ~ 31 | - | 5 ~ 12.5 | 1.1 ~ 31 | 0.5 ~ 22 | 6 ~ 22 | 6 ~ 22 | - | 0.3 ~ 28 | 9.8 ~ 294 | 0.1 ~ 0.9 | 6 ~ 8 | 1.961 ~ 215.746 | - | 3.432 ~ 98.067 | 1.76 ~ 3.67 |