(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

KAYSEVEN Flexible Shaft Couplings(Body Material:Aluminum)

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

KAYSEVEN

· K-7 coupling MD series - Oldham Type. · MD series Oldham Couplings structure Consists of three parts :2 hubs and 1 torque disc. · Application: Robot, Various pumps, Blower, Printing machine, NC-MC machine tool and Conveyor. · As K-7 standard specifications, 12 MD types from MD-35 to MD-160M are available. · MD series Body material is aluminum alloy. · Torque disc material: Polyacetal resin. · Torque discs are made of resin and do not need to be lubricated. · Operating environment Temperature Range: -40 to 85 °C · Assembly and replacement of intermediate torque transmission members are easy.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham - - 35 ~ 70 54 ~ 70 Standard 5.01~10.00 ~ 20.01~50.00 Small ~ Vibration Insulation Not Provided 4001~10000 Aluminum 9.8 ~ 44 - - Coupling Main Body - 6000 ~ 10000 Polyacetal - - From: 722,134 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

KAYSEVEN

Compact, high-performance eccentricity absorbing, non-reactive force product with no backlash. Widely used in robots, medical equipment, packaging machinery, and machine tools etc.

Type Shaft Bore Dia. (machined) D1(Ø) Shaft Bore Dia. (machined) D2(Ø) Outer Dia. A(Ø) Overall Length W(mm) Application Allowable Torque Range(N•m) Features Allowable Misalignment Max. Rotational Speed Range(r/min) Body Material Allowable Torque(N•m) Allowable Angular Misalignment(deg) Allowable Lateral Misalignment(mm) Product Category Allowable Lateral Misalignment Range(mm) Max. Rotational Speed(r/min) Buffer Material Disc Material Bellows Material Oldham 3 ~ 9525 3 ~ 10 17.5 ~ 25.5 24.9 ~ 32 Standard 1.01~3.00 ~ 3.01~5.00 Low Moment of Inertia ~ Vibration Insulation Not Provided 4001~10000 ~ 10001~78000 Aluminum 1.76 ~ 3.67 - - Coupling Main Body - 10000 ~ 15000 Polyacetal - - From: 667,862 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Type |

| Shaft Bore Dia. (machined) D1(Ø) |

| Shaft Bore Dia. (machined) D2(Ø) |

| Outer Dia. A(Ø) |

| Overall Length W(mm) |

| Application |

| Allowable Torque Range(N•m) |

| Features |

| Allowable Misalignment |

| Max. Rotational Speed Range(r/min) |

| Body Material |

| Allowable Torque(N•m) |

| Allowable Angular Misalignment(deg) |

| Allowable Lateral Misalignment(mm) |

| Product Category |

| Allowable Lateral Misalignment Range(mm) |

| Max. Rotational Speed(r/min) |

| Buffer Material |

| Disc Material |

| Bellows Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | KAYSEVEN | KAYSEVEN |

| Product SeriesDòng sản phẩm | ||

| From | 722,134 VND- | 667,862 VND- |

| Days to ShipSố ngày giao hàng | 6 Day(s) or more | 4 Day(s) or more |

| Type | Oldham | Oldham |

| Shaft Bore Dia. (machined) D1(Ø) | - | 3 ~ 9525 |

| Shaft Bore Dia. (machined) D2(Ø) | - | 3 ~ 10 |

| Outer Dia. A(Ø) | 35 ~ 70 | 17.5 ~ 25.5 |

| Overall Length W(mm) | 54 ~ 70 | 24.9 ~ 32 |

| Application | Standard | Standard |

| Allowable Torque Range(N•m) | 5.01~10.00 ~ 20.01~50.00 | 1.01~3.00 ~ 3.01~5.00 |

| Features | Small ~ Vibration Insulation | Low Moment of Inertia ~ Vibration Insulation |

| Allowable Misalignment | Not Provided | Not Provided |

| Max. Rotational Speed Range(r/min) | 4001~10000 | 4001~10000 ~ 10001~78000 |

| Body Material | Aluminum | Aluminum |

| Allowable Torque(N•m) | 9.8 ~ 44 | 1.76 ~ 3.67 |

| Allowable Angular Misalignment(deg) | - | - |

| Allowable Lateral Misalignment(mm) | - | - |

| Product Category | Coupling Main Body | Coupling Main Body |

| Allowable Lateral Misalignment Range(mm) | - | - |

| Max. Rotational Speed(r/min) | 6000 ~ 10000 | 10000 ~ 15000 |

| Buffer Material | Polyacetal | Polyacetal |

| Disc Material | - | - |

| Bellows Material | - | - |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Shaft Bore Dia. (machined) D1(Ø)

-

Shaft Bore Dia. (machined) D2(Ø)

-

Outer Dia. A(Ø)

- 6

- 6.4

- 8

- 9

- 9.5

- 10

- 12

- 12.7

- 13

- 13.5

- 13.8

- 14

- 14.5

- 15

- 16

- 16.1

- 16.5

- 16.6

- 16.8

- 17

- 17.5

- 17.8

- 18

- 19

- 19.1

- 19.5

- 20

- 21

- 22

- 22.2

- 22.5

- 23.8

- 24

- 24.5

- 25

- 25.4

- 25.5

- 26

- 26.2

- 26.5

- 26.6

- 27

- 27.3

- 28

- 28.8

- 29

- 29.5

- 30

- 31.7

- 31.8

- 32

- 32.8

- 33

- 33.3

- 34

- 34.4

- 34.5

- 35

- 36

- 37.8

- 38

- 39

- 39.5

- 40

- 41.3

- 42

- 42.5

- 42.8

- 43

- 44

- 44.5

- 45

- 46

- 47

- 48

- 49

- 50

- 53

- 53.6

- 54

- 54.5

- 54.8

- 55

- 56

- 57

- 58

- 60

- 63

- 64

- 65

- 66

- 68

- 69

- 69.9

- 70

- 73

- 75

- 79

- 79.5

- 80

- 81

- 82

- 83

- 85

- 87

- 88

- 90

- 93

- 94

- 94.5

- 95

- 99

- 100

- 102

- 104

- 104.5

- 105

- 112

- 117

- 118

- 120

- 125

- 126

- 135

- 138

- 140

- 143

- 144

- 150

- 152

- 155

- 160

- 161

- 168

- 170

- 178

- 185

- 190

- 194

- 200

- 210

- 214

- 225

- 246

- 262

- 276

- 308

- 346

-

Overall Length W(mm)

- 5.1

- 7.3

- 8.4

- 9

- 9.4

- 9.6

- 10

- 10.2

- 10.5

- 11.2

- 11.4

- 11.8

- 11.9

- 12

- 12.35

- 12.4

- 12.7

- 13

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 14.7

- 14.9

- 15

- 15.4

- 15.5

- 15.6

- 15.7

- 15.8

- 15.9

- 16

- 16.2

- 16.5

- 16.6

- 16.7

- 17

- 17.4

- 17.5

- 17.6

- 17.8

- 17.9

- 18

- 18.1

- 18.4

- 18.5

- 18.7

- 18.8

- 19

- 19.1

- 19.2

- 19.35

- 19.4

- 19.6

- 19.7

- 19.8

- 20

- 20.2

- 20.4

- 20.5

- 21

- 21.1

- 21.2

- 21.3

- 21.4

- 21.5

- 21.6

- 22

- 22.1

- 22.2

- 22.4

- 22.5

- 22.8

- 23

- 23.05

- 23.1

- 23.15

- 23.2

- 23.3

- 23.4

- 23.5

- 23.6

- 23.9

- 24

- 24.1

- 24.2

- 24.4

- 24.5

- 24.9

- 25

- 25.4

- 25.45

- 25.5

- 25.6

- 25.7

- 25.9

- 26

- 26.1

- 26.2

- 26.5

- 26.6

- 27

- 27.2

- 27.3

- 27.4

- 28

- 28.1

- 28.2

- 28.3

- 28.4

- 28.5

- 28.8

- 29

- 29.4

- 29.5

- 29.8

- 30

- 30.2

- 30.4

- 30.5

- 31

- 31.2

- 31.4

- 31.5

- 31.6

- 31.7

- 31.8

- 32

- 32.2

- 32.3

- 32.5

- 32.6

- 32.7

- 32.8

- 33

- 33.2

- 33.3

- 33.5

- 33.6

- 33.8

- 34

- 34.1

- 34.2

- 34.3

- 34.4

- 34.5

- 35

- 35.5

- 35.6

- 36

- 36.1

- 36.4

- 36.5

- 36.8

- 37

- 37.2

- 37.4

- 37.8

- 38

- 38.2

- 38.4

- 38.5

- 38.6

- 39

- 39.2

- 39.4

- 39.5

- 39.7

- 39.8

- 40

- 40.5

- 41

- 41.8

- 42

- 42.2

- 43

- 43.2

- 43.4

- 43.5

- 43.6

- 43.8

- 44

- 44.2

- 44.5

- 44.7

- 44.8

- 45

- 45.1

- 45.2

- 45.3

- 45.5

- 46

- 46.1

- 46.4

- 46.6

- 47

- 47.1

- 47.2

- 47.6

- 48

- 48.4

- 49

- 49.2

- 49.4

- 50

- 50.2

- 50.5

- 50.6

- 50.8

- 51

- 51.2

- 51.3

- 51.4

- 52

- 52.8

- 53

- 53.3

- 53.4

- 53.6

- 54

- 54.1

- 54.4

- 54.5

- 54.6

- 55

- 55.5

- 56

- 56.1

- 56.2

- 56.5

- 56.6

- 56.8

- 57

- 57.5

- 58

- 58.2

- 58.5

- 58.6

- 59

- 59.4

- 59.7

- 59.8

- 59.9

- 60

- 60.4

- 60.5

- 61

- 61.2

- 62

- 63

- 63.4

- 63.5

- 63.6

- 63.7

- 63.8

- 64

- 64.8

- 65

- 65.4

- 65.6

- 66

- 66.4

- 66.6

- 66.7

- 66.8

- 67

- 67.1

- 67.5

- 68

- 68.3

- 68.5

- 68.6

- 68.7

- 68.8

- 69.2

- 69.5

- 69.6

- 69.8

- 70

- 70.5

- 70.6

- 70.9

- 71

- 71.2

- 72

- 72.4

- 73

- 73.3

- 74

- 74.4

- 74.8

- 75

- 75.5

- 75.6

- 75.9

- 76.2

- 77

- 77.2

- 77.6

- 77.8

- 78

- 78.8

- 79.5

- 79.8

- 80

- 80.8

- 81

- 81.5

- 81.8

- 82

- 82.5

- 82.6

- 83

- 83.6

- 84

- 84.7

- 85

- 85.2

- 85.5

- 85.6

- 86

- 87.6

- 88

- 89.2

- 89.3

- 89.5

- 89.6

- 89.8

- 89.9

- 90

- 90.5

- 90.8

- 91

- 92

- 93.6

- 94

- 95

- 95.6

- 96

- 96.6

- 97

- 97.2

- 98

- 98.5

- 98.6

- 98.7

- 99

- 99.2

- 99.6

- 100

- 100.2

- 101

- 101.6

- 102

- 102.5

- 104

- 104.4

- 105.8

- 106

- 107.6

- 108

- 109

- 110

- 111

- 112.8

- 113

- 113.4

- 114

- 115

- 115.6

- 117.6

- 118

- 118.4

- 118.8

- 119.6

- 120

- 120.8

- 121

- 123.6

- 124

- 125

- 126

- 127

- 129

- 129.6

- 130

- 131

- 136.4

- 137.6

- 138

- 138.7

- 140

- 141

- 144

- 144.2

- 146

- 147

- 150

- 150.6

- 153.0

- 154

- 154.6

- 156.4

- 160

- 164

- 164.6

- 170.6

- 176

- 178.4

- 182.8

- 185

- 192.4

- 193

- 200

- 208.8

- 209.2

- 210

- 216

- 217

- 218

- 223

- 238

- 241.2

- 249.4

- 260

- 286.8

- 290

- 307.0

- 335

- 337.2

- 377

- 391

- 421

- 607

-

Application

- Standard

- Servo Motor

- Stepping Motor

- Encoder

-

Allowable Torque Range(N•m)

-

Features

-

Allowable Misalignment

-

Not Provided

Not Provided -

Angular Misalignment

Angular Misalignment -

Eccentricity

Eccentricity -

Axial Misalignment

Axial Misalignment

-

-

Max. Rotational Speed Range(r/min)

-

Body Material

- Stainless Steel

- Steel

- Aluminum

- Alloy

- Plastic

- Aluminum Alloy

-

Allowable Torque(N•m)

-

Allowable Angular Misalignment(deg)

-

Allowable Lateral Misalignment(mm)

-

Product Category

- Coupling Main Body

- Maintenance Components

-

Allowable Lateral Misalignment Range(mm)

-

Max. Rotational Speed(r/min)

-

Buffer Material

-

Disc Material

-

Bellows Material

Related Categories to Flexible Shaft CouplingsDanh mục liên quan đến Flexible Shaft Couplings

FAQ Flexible Shaft Couplings

- Question: What are the different types of flexible Shaft Couplings?

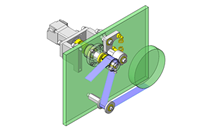

- Answer: There are several types of flexible Shaft Couplings, including beam, bellows, jaw, Oldham, disc, diaphragm, and gear couplings. Each type has unique features and benefits that make them suitable for different applications and environments. Flexible Shaft Couplings are used to connect two shafts and allow for misalignment while transmitting torque between them.

- Question: What factors should be considered when selecting a flexible Shaft Couplings?

- Answer: The factor for selecting a flexible coupling, there are several factors that should be considered, including the required torque capacity, misalignment capability, operating speed, and environmental factors such as temperature and humidity. Other considerations include the required degree of axial and radial stiffness, the space available for the coupling, and the type of equipment being connected. It is also important to consider the potential for wear and tear, maintenance requirements, and the cost of the coupling.

- Question: How is a flexible Shaft Couplings installed and maintained?

- Answer: Shaft Couplings are installed by aligning the shafts and tightening the screws or bolts. Maintenance involves regular inspections for signs of wear, damage, or misalignment. Lubrication is important to prevent excessive wear and reduce friction. Cleaning and tightening of bolts and screws are also necessary to ensure proper operation.

- Question: What is the difference between a flexible coupling and a rigid coupling?

- Answer: A flexible coupling allows for some misalignment between two connected shafts while transmitting torque, while a rigid coupling does not allow for any misalignment. Flexible Shaft Couplings are designed to absorb shock and vibration, which can help reduce wear and tear on connected equipment. Rigid couplings, on the other hand, are used in applications where precise alignment between shafts is critical, such as in high-speed rotating equipment or precision machinery.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy