(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Standard Linear Guides(Accuracy:NLE)

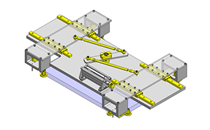

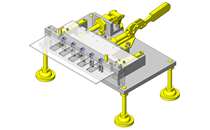

Thanh trượt dẫn hướng là thành phần rất quan trọng trong lĩnh vực máy móc, cho phép tạo ra các chuyển động trơn tru, chính xác và có kiểm soát dọc theo trục dẫn hoặc đường ray cố định. Các nhà sản xuất khác nhau gọi chúng với những cái tên khác nhau, ví dụ như Thanh trượt dẫn hướng bởi MISUMI, thanh dẫn hướng LM bởi THK, Thanh trượt dẫn hướng NSK bởi NSK, đường dẫn tuyến tính bởi IKO, và thanh trượt bởi NB. Một đặc điểm chính của Thanh trượt dẫn hướng là khả năng duy trì chuyển động ổn định mà không bị ảnh hưởng bởi rung lắc, do đó giảm đáng kể các sai số cơ học và tăng hiệu quả vận hành tổng thể. Thanh trượt dẫn hướng của MISUMI, được sản xuất bởi Suruga Production Plalform, nổi tiếng về chất lượng và tính đa dạng. Họ cung cấp danh mục sản phẩm phong phú, từ thanh dẫn hướng nhỏ phù hợp cho yêu cầu tải nhẹ đến những loại có tải trọng trung bình và nặng được thiết kế để xử lý các ứng dụng công nghiệp khắt khe hơn.

Các sản phẩm Thanh trượt dẫn hướng đa dạng về kích thước, vật liệu, độ chính xác, được thiết kế riêng để phù hợp với từng nhu cầu cụ thể.

Ngoài ra, khối trượt là bề mặt ổn định để lắp đặt các bộ phận khác, và tấm chắn cung cấp khả năng chống lại bụi và các chất ô nhiễm bên ngoài. Nếu bạn cần một Thanh trượt dẫn hướng chính xác tải nhẹ hay một thanh dẫn hướng độ bền cao cho các nhiệm vụ quy mô lớn, hãy xem xét đến các sản phẩm đa dạng, nhiều tính năng tùy chọn và có chất lượng hàng đầu của MISUMI, thứ sẽ giúp nâng cao tính hiệu quả và hiệu suất trong các dự án của bạn.

Các loại Thanh trượt, Thanh Trượt Tiêu Chuẩn, thanh trượt dẫn hướng, ray trượt cơ khí và sản phẩm liên quan phổ biến: Thanh trượt vuông, thanh trượt vuông mini, thanh ray trượt chịu lực, thanh ray con trượt, thanh trượt con trượt, thanh trượt mini, Ray trượt vuông 12, ray trượt vuông 15, ray trượt vuông 20, ray trượt vuông 25, ray trượt vuông 30, thanh trượt vuông 12, thanh trượt vuông 15, thanh trượt vuông 25, ray trượt vuông, thanh ray trượt vuông, ray trượt chịu lực, ray trượt chịu tải, thanh trượt chịu lực, Thanh ray trượt, thanh dẫn hướng, thanh ray dẫn hướng, ray trượt dẫn hướng, thanh trượt tuyến tính, bộ thanh ray trượt, thanh trượt TBI, thanh trượt có đế, thanh trượt vuông Hiwin, thanh trượt THK, ray trượt Hiwin, thanh trượt bi, thanh trượt Hiwin, thanh trượt dẫn hướng, con trượt Hiwin.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

![[Short Delivery Size] Caged Ball LM Guide, International Standard, SHS Type](//vn.misumi-ec.com/linked/material/mech/THK1/PHOTO/SHS25C.jpg?$product_view_b$)

[Short Delivery Size] Caged Ball LM Guide, International Standard, SHS Type

THK

A best selling THK product. The SHS series can be used in any position.*When ordering multiple shaft types, input multiples of the number of required shafts as the order quantity.(Example) required shafts: 2(-II)⇒ Order quantity: "2, 4, 6..."Required shafts: 3 3(-III)⇒ Order quantity: "3, 6, 9..."Please place your orders in this manner.

Rail Length L(mm) Block Type Rail Width(mm) Mounting Height H(mm) Nominal Part Number Rail Type Set / Single Item Preload Accuracy Material Ball Arrangement No. of Blocks Retainer Block Mounting Hole Pitch (Width Direction)(mm) Block Mounting Hole Pitch (Length Direction)(mm) Block Mounting Hole Diameter Rail Mounting Hole Pitch(mm) Rail Mounting Hole Diameter 86 ~ 2920 Standard 15 24 15 Standard Set NLC NLE Carbon Steel 4-Row, Circular 1 / 2 / 3 / 4 Available 26 34 4 60 4.5 Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Rail Length L(mm) |

| Block Type |

| Rail Width(mm) |

| Mounting Height H(mm) |

| Nominal Part Number |

| Rail Type |

| Set / Single Item |

| Preload |

| Accuracy |

| Material |

| Ball Arrangement |

| No. of Blocks |

| Retainer |

| Block Mounting Hole Pitch (Width Direction)(mm) |

| Block Mounting Hole Pitch (Length Direction)(mm) |

| Block Mounting Hole Diameter |

| Rail Mounting Hole Pitch(mm) |

| Rail Mounting Hole Diameter |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | THK |

| Product SeriesDòng sản phẩm | [Short Delivery Size] Caged Ball LM Guide, International Standard, SHS Type |

| CADCAD |

|

| From | |

| Days to ShipSố ngày giao hàng | 7 Day(s) or more |

| Rail Length L(mm) | 86 ~ 2920 |

| Block Type | Standard |

| Rail Width(mm) | 15 |

| Mounting Height H(mm) | 24 |

| Nominal Part Number | 15 |

| Rail Type | Standard |

| Set / Single Item | Set |

| Preload | NLC |

| Accuracy | NLE |

| Material | Carbon Steel |

| Ball Arrangement | 4-Row, Circular |

| No. of Blocks | 1 / 2 / 3 / 4 |

| Retainer | Available |

| Block Mounting Hole Pitch (Width Direction)(mm) | 26 |

| Block Mounting Hole Pitch (Length Direction)(mm) | 34 |

| Block Mounting Hole Diameter | 4 |

| Rail Mounting Hole Pitch(mm) | 60 |

| Rail Mounting Hole Diameter | 4.5 |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Rail Length L(mm)

- 25

- 35

- 39

- 40

- 45

- 50

- 55

- 70

- 75

- 76

- 80

- 85

- 90

- 95

- 100

- 110

- 115

- 120

- 130

- 131

- 135

- 140

- 145

- 146

- 150

- 155

- 160

- 161

- 170

- 175

- 176

- 190

- 191

- 195

- 200

- 205

- 206

- 215

- 220

- 221

- 230

- 235

- 236

- 245

- 250

- 251

- 255

- 260

- 265

- 270

- 275

- 276

- 280

- 281

- 290

- 295

- 296

- 310

- 315

- 316

- 320

- 335

- 336

- 340

- 345

- 350

- 355

- 360

- 370

- 375

- 380

- 390

- 395

- 400

- 410

- 415

- 420

- 430

- 435

- 440

- 445

- 455

- 460

- 470

- 471

- 475

- 495

- 496

- 500

- 510

- 515

- 520

- 521

- 530

- 535

- 545

- 546

- 550

- 555

- 560

- 570

- 571

- 575

- 580

- 590

- 595

- 596

- 600

- 615

- 620

- 621

- 630

- 635

- 640

- 645

- 646

- 670

- 671

- 680

- 695

- 696

- 700

- 710

- 720

- 745

- 750

- 760

- 770

- 790

- 795

- 820

- 830

- 840

- 845

- 870

- 880

- 895

- 910

- 920

- 940

- 945

- 950

- 970

- 990

- 1000

- 1060

- 1080

- 1120

- 1160

- 1180

- 1240

- 1300

- 1320

- 1360

- 1400

- 1420

- 1480

- 1540

- 1560

- 1600

- 1640

- 1660

- 1720

- 1780

- 1800

- 1840

- 1880

- 1900

- 1960

- 9400

[86-2920/1mm Unit(s)]

-

Block Type

-

Standard

Standard -

Short

Short -

Wide

Wide -

Wide Long

Wide Long -

Long

Long -

Extra Long

Extra Long -

Wide Short

Wide Short

-

-

Rail Width(mm)

-

Mounting Height H(mm)

-

Nominal Part Number

-

Rail Type

-

Standard

Standard -

Wide

Wide

-

-

Set / Single Item

- Set

- Block Only

- Rail Only

-

Preload

- Standard

- Light Preload

- Medium Preload

- Clearance

- Heavy Preload

- NLC

See the accuracy standard of each manufacturer.

-

Accuracy

- Standard Grade

- High Grade

- Precision Grade

- High Precision Grade

- Ultra Precision Grade

- NLE

See the accuracy standard of each manufacturer.

-

Material

- Carbon Steel

- Stainless Steel

In the case of Set, the block and rail use the same materials.

-

Ball Arrangement

-

No. of Blocks

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

-

Retainer

-

Block Mounting Hole Pitch (Width Direction)(mm)

-

Block Mounting Hole Pitch (Length Direction)(mm)

-

Block Mounting Hole Diameter

-

Rail Mounting Hole Pitch(mm)

-

Rail Mounting Hole Diameter

Related Categories to Standard Linear GuidesDanh mục liên quan đến Standard Linear Guides

FAQ linear guide

- Question: What are standard linear guides?

- Answer: Standard linear guides come in different configurations, such as:

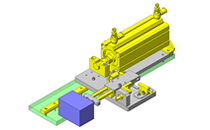

1. Profiled Rail Guides: These linear guides have a rectangular-shaped rail with a corresponding carriage. They provide high load capacity and stiffness, making them suitable for applications that require precision and rigidity.

2. Round Rail Guides: These linear guides feature a round rail and a carriage with circular-shaped rolling elements. They offer smooth and quiet motion and are commonly used in applications with lower load capacities.

3. Compact Linear Guides: These linear guides are designed to have a smaller footprint and are suitable for applications with limited space. They often feature ball bearing-based systems and are used in various industries, including automation and robotics - Question: How do standard linear guides work?

- Answer: Standard linear guides, also known as linear motion systems are mechanical devices used to provide smooth and precise linear motion in various applications. Here's a short explanation of how they work

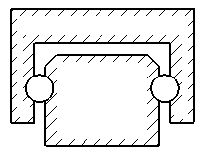

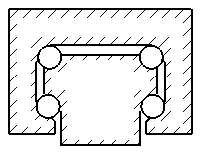

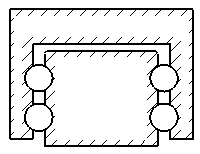

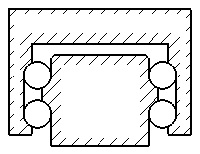

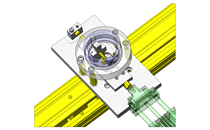

1. Rail and Slide block: A standard linear guide consists of two main components: a rail and a slide block. The rail is a long, straight and rigid structure that serves as a guide for the linear motion. The slide block is a movable component that rides along the rail.

2. Rolling Elements: Inside the slide block, there are ball rolling. These elements reduce friction, enable smooth motion along the rail and distribute the load evenly across the rail,

3. Lubrication: Some linear guides require lubrication to further reduce friction and ensure smooth operation. Lubricants can be applied to the bearing surfaces or be pre-lubricated within the slide block.

4. Mounting: Linear guides are usually mounted to a stationary base or structure, and the slide block is connected to the moving part or load that needs linear motion. - Question: What industries use standard linear guides?

- Answer: Standard linear guides, which provide precise linear motion control, are utilized in several industries such as

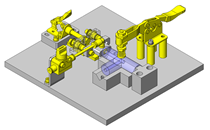

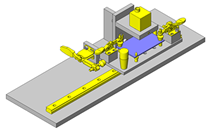

1. Manufacturing and Automation: These kinds of industries widely employ standard linear guides for accurate linear motion control in machine tools, assembly lines, conveyors, and robotic systems

2. Electronics and Semiconductor Industries: The semiconductor and electronics industries rely on linear guides for precise linear motion in equipment such as wafer handling systems, semiconductor manufacturing machines, electronic assembly lines, and so on

3. Medical Industries: Linear guides are used in medical and laboratory equipment for precise linear motion control in kinds of these machines such as surgical robots, measurement tools, and laboratory automation.

4. Printing industry: The printing industry utilizes linear guides to facilitate precise linear motion control in printing machinery systems such as paper handling systems, and paper converting equipment, ensuring high-quality printing and accurate paper handling. - Question: What are the benefits of using standard linear guides?

- Answer: By using standard linear guides offers several benefits in applications requiring precise linear motion control.

1. Precise Linear Motion Control

2. Smooth and Low-Friction Operation

3. High Load-Carrying Capacity

4. Repeatability and Positioning Accuracy

5. Enhanced System Stability

6. Durability and Longevity

7. Versatile and Customizable

8. Wide Range of Applications By utilizing standard linear guides, users can achieve precise, smooth, and reliable linear motion control in their designs, enhancing system performance, accuracy, and overall productivity in numerous applications. - Question: How to select the right standard linear guide for a specific application?

- Answer: Selecting the right standard linear guide for a specific application involves considering various factors. Here's a short step by step for selecting the linear guide

1. Load Capacity: Determine the maximum load the linear guide needs to support in the application. Consider both static and dynamic loads to ensure the guide can handle the required weight.

2. Travel Distance: Evaluate the required travel distance or stroke length of the linear motion and range of motion without exceeding its limits.

3. Precision Requirements: Assess the level of precision needed for the application. Consider factors such as positioning accuracy, repeatability, and smoothness of motion.

4. Speed and Acceleration: Determine the desired speed and acceleration of the linear motion.

5. Environmental Factors: Consider factors such as temperature, humidity, dust, and exposure to chemicals.

6. Mounting and Integration: Consider the mounting options and requirements for integrating the linear guide into the application.

7. Maintenance and Lubrication: Consider factors such as ease of maintenance, lubrication intervals, and access to lubrication points.

8. Budget and Cost Considerations: Evaluate the budget available for the linear guide

9. Consult Manufacturer's Recommendations: Review the manufacturer's specifications, guidelines, and recommendations for the specific linear guide models.

- Câu hỏi: Thanh trượt dẫn hướng tiêu chuẩn là gì?

- Trả lời: Thanh trượt dẫn hướng tiêu chuẩn có nhiều tùy chọn khác nhau, ví dụ:

1. Thanh trượt dẫn hướng định hình: Các thanh trượt dẫn hướng này có thanh ray hình chữ nhật với con trượt tương ứng. Chúng cung cấp khả năng chịu tải và độ cứng cao, phù hợp với các ứng dụng đòi hỏi độ chính xác và cứng vững.

2. Thanh trượt dẫn hướng có ray tròn: Các thanh trượt dẫn hướng này có thanh ray hình tròn và cụm con trượt với các bộ phận lăn có hình tròn. Chúng chuyển động trơn tru và yên tĩnh, thường được sử dụng trong các ứng dụng đòi hỏi khả năng chịu tải thấp hơn.

3. Thanh trượt dẫn hướng nhỏ gọn: Các thanh trượt dẫn hướng này được thiết kế với diện tích nhỏ hơn để phù hợp với các ứng dụng có không gian hạn chế. Chúng thường có các hệ thống ổ bi và được sử dụng trong nhiều ngành công nghiệp, bao gồm tự động hóa và robot. - Câu hỏi: Thanh trượt dẫn hướng tiêu chuẩn hoạt động như thế nào?

- Trả lời: Thanh trượt dẫn hướng tiêu chuẩn, hay hệ thống chuyển động tuyến tính, là các thiết bị cơ học được sử dụng để cung cấp các chuyển động thẳng một cách trơn tru và chính xác trong nhiều ứng dụng khác nhau. Sau đây là giải thích ngắn gọn về cách chúng hoạt động

1. Thanh ray và khối trượt: Thanh trượt dẫn hướng tiêu chuẩn bao gồm hai thành phần chính: Thanh ray và Khối trượt. Thanh ray là một cấu trúc dài, thẳng và cứng, có chức năng bộ phận dẫn hướng cho chuyển động thẳng. Khối trượt là một bộ phận chuyển động chạy dọc theo thanh trượt.

2. Các bộ phận lăn: Bên trong khối trượt, có các bi lăn. Các bộ phận này làm giảm ma sát, cho phép chuyển động trơn tru dọc theo đường ray và phân bổ tải đều trên thanh ray.

3. Bôi trơn: Một số thanh trượt dẫn hướng tuyến tính cần được bôi trơn để giảm ma sát và đảm bảo hoạt động trơn tru.Mỡ bôi trơn có thể được bôi trơn lên bề mặt ổ trục hoặc được bôi trơn trước bên trong khối trượt.

4. Lắp đặt: Thanh trượt dẫn hướng tuyến tính thường được lắp vào đế hoặc bề mặt cố định và khối trượt được lắp với bộ phận chuyển động hoặc tải có chuyển động thẳng. - Câu hỏi: Những ngành nào cần sử dụng thanh trượt dẫn hướng ?

- Trả lời: Các thanh trượt dẫn hướng tiêu chuẩn, cung cấp chuyển động tuyến tính một cách chính xác, được sử dụng trong một số ngành công nghiệp như:

1. Sản xuất và Tự động hóa: Các ngành công nghiệp này sử dụng rộng rãi các thanh trượt dẫn hướng tiêu chuẩn dùng cho chi tiết chính xác trong máy công cụ, dây chuyền lắp ráp, băng tải và hệ thống rô bốt

2. Ngành công nghiệp điện tử và bán dẫn: Các ngành công nghiệp này sử dụng thanh trượt dẫn hướng tuyến tính để đảm bảo chuyển động tuyến tính chính xác trong các thiết bị như hệ thống xử lý wafer, máy sản xuất bán dẫn, dây chuyền lắp ráp điện tử, và các ứng dụng tương tự.

3. Ngành công nghiệp y tế: Các thanh trượt dẫn hướng tuyến tính được sử dụng trong thiết bị y tế và phòng thí nghiệm để kiểm soát chuyển động tuyến tính chính xác trong các loại máy như robot phẫu thuật, dụng cụ đo lường, và hệ thống tự động hóa trong phòng thí nghiệm.

4. Ngành công nghiệp in ấn: Ngành công nghiệp in ấn sử dụng các thanh trượt dẫn hướng trong chuyển động tuyến tính chính xác của các hệ thống máy móc in ấn như hệ thống xử lý giấy và thiết bị chuyển đổi giấy, đảm bảo chất lượng in cao và chính xác. - Câu hỏi: Những lợi ích của việc sử dụng các thanh trượt dẫn hướng tiêu chuẩn là gì?

- Trả lời: Việc sử dụng các thanh trượt dẫn hướng tiêu chuẩn mang lại một số lợi ích trong các ứng dụng yêu cầu điều khiển chuyển động tuyến tính một cách chính xác.

1. Kiểm soát chính xác chuyển động

2. Hoạt động trơn tru và ma sát thấp

3. Khả năng chịu tải trọng cao

4. Độ chính xác lặp lại và định vị

5. Cải thiện độ ổn định hệ thống

6. Độ bền và tuổi thọ

7.Khả năng tùy chỉnh

8. Phạm vi ứng dụng rộng rãi Bằng cách sử dụng các thanh trượt dẫn hướng tiêu chuẩn, người dùng có thể kiểm soát chuyển động tuyến tính chính xác, trơn tru và đáng tin cậy trong các thiết kế của họ, giúp nâng cao hiệu suất, độ chính xác và năng suất tổng thể của hệ thống trong nhiều ứng dụng. - Câu hỏi: Làm thế nào để chọn thanh trượt dẫn hướng tiêu chuẩn phù hợp cho một ứng dụng cụ thể?

- Trả lời: Để lựa chọn đúng thanh trượt dẫn hướng tiêu chuẩn cho một ứng dụng cụ thể thì cần xem xét nhiều yếu tố khác nhau. Sau đây là hướng dẫn ngắn gọn giúp lựa chọn thanh trượt dẫn hướng tuyến tính:

1. Khả năng chịu tải: Xác định tải trọng tối đa mà thanh trượt dẫn hướng tuyến tính phải chịu. Xem xét cả tải trọng tĩnh và tải trọng động để đảm bảo thanh trượt dẫn hướng có thể chịu được trọng lượng yêu cầu.

2. Hành trình di chuyển: Đánh giá hành trình di chuyển hoặc độ dài hành trình cần thiết của chuyển động tuyến tính và phạm vi chuyển động mà không vượt quá giới hạn của thanh trượt.

3. Yêu cầu về độ chính xác: Đánh giá mức độ chính xác cần thiết cho ứng dụng. Xem xét các yếu tố như độ chính xác định vị, sai số lặp lại và tính trơn tru của chuyển động.

4. Tốc độ và Gia tốc: Xác định tốc độ và gia tốc mong muốn của chuyển động tuyến tính.

5. Các yếu tố về môi trường: Xem xét các yếu tố như nhiệt độ, độ ẩm, bụi và sự tiếp xúc với hóa chất.

6. Lắp ráp và Tích hợp: Xem xét các tùy chọn lắp ráp và yêu cầu để tích hợp thanh trượt dẫn hướng tuyến tính vào ứng dụng.

7. Bảo trì và Bôi trơn: Xem xét các yếu tố như tính dễ dàng bảo trì, chu kì bôi trơn và khả năng tiếp cận các điểm bôi trơn.

8. Cân nhắc về Ngân sách và Chi phí: Đánh giá ngân sách hiện có cho thanh trượt tuyến tính.

9. Tham khảo ý kiến nhà sản xuất: Xem xét các thông số kỹ thuật, hướng dẫn và khuyến nghị của nhà cung cấp cho từng mẫu thanh trượt dẫn hướng tuyến tính cụ thể. - Misumi Việt Nam cung cấp các loại Thanh trượt, Thanh Trượt Tiêu Chuẩn, thanh trượt dẫn hướng, ray trượt cơ khí chất lượng, giá tốt, giao hàng nhanh. Nhiều dòng sản phẩm thông dụng, thường thấy trong các giải pháp sản xuất: Thanh trượt vuông, thanh trượt vuông mini, thanh ray trượt chịu lực, thanh ray con trượt, thanh trượt con trượt, thanh trượt mini, Ray trượt vuông 12, ray trượt vuông 15, ray trượt vuông 20, ray trượt vuông 25, ray trượt vuông 30, thanh trượt vuông 12, thanh trượt vuông 15, thanh trượt vuông 25, ray trượt vuông, thanh ray trượt vuông, ray trượt chịu lực,, ray trượt chịu tải, thanh trượt chịu lực, Thanh ray trượt, thanh dẫn hướng, thanh ray dẫn hướng, ray trượt dẫn hướng, thanh trượt tuyến tính, bộ thanh ray trượt, thanh trượt TBI, thanh trượt có đế, thanh trượt vuông Hiwin, thanh trượt THK, ray trượt Hiwin, thanh trượt bi, thanh trượt Hiwin, thanh trượt dẫn hướng, con trượt Hiwin.

![[Short Delivery Size] Caged Ball LM Guide, International Standard, SHS Type](http://vn.misumi-ec.com/linked/material/mech/THK1/PHOTO/SHS25C.jpg?$product_view_b$)

![[Short Delivery Size] Caged Ball LM Guide, International Standard, SHS Type](http://vn.misumi-ec.com/linked/material/mech/THK1/PHOTO/SHS25C.jpg?$product_view_c$)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy