(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

AIRTAC Knuckle Joints(Thread Size M:M5)

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

3 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

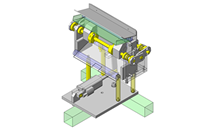

Adaptation of Auxiliary Drive (Rod Tip) Double Knuckle Joint ACQ Series Cylinder

AIRTAC

Compatible with auxiliary drive (rod tip) double knuckle joint ACQ series cylinder manufactured by AirTAC which is well known for its high quality.

Mounting Method Thread Size M(mm) Type Thread Pitch(mm) Material Accessories Included - M5 Double Notched Knuckle Joints 0.8 - - From: 80,751 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

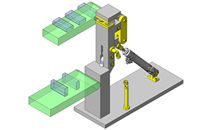

Drive Assist (Rod Tip Bracket) Double Knuckle Joint PB Series Cylinder Compatible

AIRTAC

Auxiliary drive (rod tip) double knuckle joint PB series cylinder manufactured by AirTAC which is well known overseas for its low prices and high quality is adapted. · Type: Double knuckle joint

Mounting Method Thread Size M(mm) Type Thread Pitch(mm) Material Accessories Included - M5 Double Notched Knuckle Joints 0.8 - - From: 86,728 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

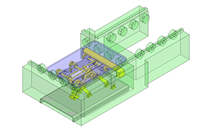

AIRTAC

Auxiliary drive (rod tip) single knuckle joint compatible with ACQ series cylinder manufactured by AirTAC, which is well-known for its high quality.

Mounting Method Thread Size M(mm) Type Thread Pitch(mm) Material Accessories Included - M5 Single Notched Knuckle Joints 0.8 - - From: 71,738 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Mounting Method |

| Thread Size M(mm) |

| Type |

| Thread Pitch(mm) |

| Material |

| Accessories Included |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | AIRTAC | AIRTAC | AIRTAC |

| Product SeriesDòng sản phẩm | Adaptation of Auxiliary Drive (Rod Tip) Double Knuckle Joint ACQ Series Cylinder | Drive Assist (Rod Tip Bracket) Double Knuckle Joint PB Series Cylinder Compatible | |

| CADCAD |

|

|

|

| From | 80,751 VND- | 86,728 VND | 71,738 VND |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more |

| Mounting Method | - | - | - |

| Thread Size M(mm) | M5 | M5 | M5 |

| Type | Double Notched Knuckle Joints | Double Notched Knuckle Joints | Single Notched Knuckle Joints |

| Thread Pitch(mm) | 0.8 | 0.8 | 0.8 |

| Material | - | - | - |

| Accessories Included | - | - | - |

Loading...Tải…

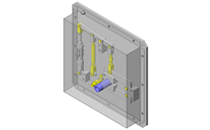

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Mounting Method

-

Tapped

Tapped -

Threaded

Threaded

-

-

Thread Size M(mm)

-

Thread Pitch(mm)

-

Material

-

Accessories Included

- Included

- Not Included

Related Categories to Knuckle JointsDanh mục liên quan đến Knuckle Joints

FAQ Knuckle Joints

- Question: In what applications are knuckle joints typically used?

- Answer: knuckle joints are commonly utilized in mechanisms requiring controlled rotational movement. They find applications in steering systems for automobiles and aircraft, allowing for precise direction control. In industrial machinery, such as cranes and robotic arms, knuckle joints facilitate movement in specific directions, enhancing versatility. Moreover, they play a vital role in construction equipment like excavators and loaders, ensuring efficient operation. Additionally, knuckle joints feature prominently in material handling systems and medical devices, providing flexibility and controlled articulation for various functions in engineering work.

- Question: What materials are commonly used for knuckle joints?

- Answer: Knuckle joints, vital for controlled rotational movement, utilize diverse materials based on specific needs. Steel, including carbon, alloy, and stainless variants, offers durability and corrosion resistance, fitting for industrial applications. Aluminum alloys balance strength and lightness, favored in aerospace and automotive sectors. Brass and bronze, prized for corrosion resistance and malleability, find use in architectural and heavy-duty contexts. Titanium's exceptional strength-to-weight ratio and corrosion resistance suit aerospace and high-performance machinery. Material selection hinges on factors like strength, weight, corrosion resistance, and environmental conditions, ensuring optimal functionality in diverse applications.

- Question: How do you maintain a knuckle joint?

- Answer: Maintaining a knuckle joint involves routine checks and actions to ensure its smooth operation and longevity. First, inspect the joint regularly for wear, damage, or misalignment. Clean the joint to remove dirt and debris that can cause friction and premature wear. Apply lubrication as recommended by the manufacturer to reduce friction and prevent corrosion. Tighten any loose fasteners to maintain structural integrity. Replace worn or damaged components promptly to prevent further issues. Finally, conduct operational tests to verify proper functionality. By following these steps, you can ensure the knuckle joint operates effectively and safely, extending its service life and minimizing downtime.

- Question: How do you determine the correct size of a knuckle joint for a specific application?

- Answer: Determining the correct size of a knuckle joint involves a comprehensive assessment of various factors. This includes analyzing the application's load requirements (static and dynamic), considering the necessary range of motion, evaluating environmental conditions, accommodating space limitations, and addressing mounting considerations. applications on industry standards, guidelines, and possibly consultations with experts to ensure the selected size can effectively withstand expected loads and movements while fitting seamlessly into the application's requirements.

- Question: Are there any limitations to using knuckle joints?

- Answer: Knuckle joints have limitations, including wear and fatigue over time, particularly under high loads or harsh conditions. They may introduce backlash or play, impacting precision, and improper maintenance or lubrication can hasten wear. The designer must carefully consider these factors when integrating knuckle joints into designs, ensuring optimal performance and longevity.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy