(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

SMC Single Axis Robots

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

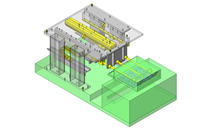

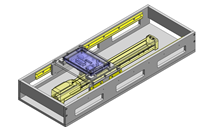

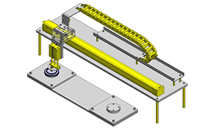

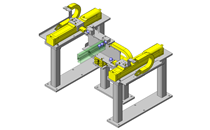

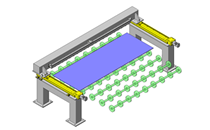

Electric Actuator Slider Type Belt Drive LEFB Series Step Motor/Servo Motor

SMC

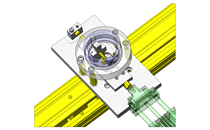

A slider-type electric actuator. [Features] · Maximum stroke: 2,000 mm (step motor [24‑V DC servo]). · Maximum speed: 2,000 mm/s (step motor [24‑V DC servo]). · Positioning repeatability: ±0.08 mm (step motor [24‑V DC servo]). · Maximum speed: 2,000 mm/s (AC servo motor). · Maximum stroke: 3,000 mm (AC servo motor). · Maximum acceleration/deceleration: 20,000 mm/S2 (AC servo motor). · Pulse input type, with absolute encoder (AC servo motor). · Positioning Repeatability: ±0.06 mm (AC servo motor).

Stroke(mm) Type Max. Transportable Mass Range (Horizontal)(kg) Max. Transportable Mass (Horizontal)(kg) Max. Transportable Mass Range (Vertical)(kg) Drive Method Max. Transportable Mass (Vertical)(kg) Main Body, Peripheral Components Lead(mm) Guide Input Power Supply Position Detection I/O Module Max. Thrust Force Range(N) Table Length L1(mm) Positioning Repeatability(µm) Maximum Velocity(mm/sec) Table Width W1(mm) Brake Operating Environment Max. Thrust Force(N) Noise Filter 1,000 ~ 900 Slider 0~2.0 / 2.1~5.0 / 5.1~10.0 / 10.1~20.0 1 ~ 19 - Belt - Main Body 48 Provided DC24V Incremental NPN / PNP / CC-Link / Not Provided - 72 ~ 122 ±80 3,000 39.4 ~ 60 Not Provided Standard - Not Provided Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Stroke(mm) |

| Type |

| Max. Transportable Mass Range (Horizontal)(kg) |

| Max. Transportable Mass (Horizontal)(kg) |

| Max. Transportable Mass Range (Vertical)(kg) |

| Drive Method |

| Max. Transportable Mass (Vertical)(kg) |

| Main Body, Peripheral Components |

| Lead(mm) |

| Guide |

| Input Power Supply |

| Position Detection |

| I/O Module |

| Max. Thrust Force Range(N) |

| Table Length L1(mm) |

| Positioning Repeatability(µm) |

| Maximum Velocity(mm/sec) |

| Table Width W1(mm) |

| Brake |

| Operating Environment |

| Max. Thrust Force(N) |

| Noise Filter |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | SMC |

| Product SeriesDòng sản phẩm | Electric Actuator Slider Type Belt Drive LEFB Series Step Motor/Servo Motor |

| CADCAD |

|

| From | - |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more |

| Stroke(mm) | 1,000 ~ 900 |

| Type | Slider |

| Max. Transportable Mass Range (Horizontal)(kg) | 0~2.0 / 2.1~5.0 / 5.1~10.0 / 10.1~20.0 |

| Max. Transportable Mass (Horizontal)(kg) | 1 ~ 19 |

| Max. Transportable Mass Range (Vertical)(kg) | - |

| Drive Method | Belt |

| Max. Transportable Mass (Vertical)(kg) | - |

| Main Body, Peripheral Components | Main Body |

| Lead(mm) | 48 |

| Guide | Provided |

| Input Power Supply | DC24V |

| Position Detection | Incremental |

| I/O Module | NPN / PNP / CC-Link / Not Provided |

| Max. Thrust Force Range(N) | - |

| Table Length L1(mm) | 72 ~ 122 |

| Positioning Repeatability(µm) | ±80 |

| Maximum Velocity(mm/sec) | 3,000 |

| Table Width W1(mm) | 39.4 ~ 60 |

| Brake | Not Provided |

| Operating Environment | Standard |

| Max. Thrust Force(N) | - |

| Noise Filter | Not Provided |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Stroke(mm)

- 1,000

- 1,100

- 1,200

- 1,500

- 1,800

- 2,000

- 20

- 30

- 40

- 50

- 75

- 100

- 125

- 150

- 200

- 250

- 300

- 350

- 400

- 450

- 500

- 550

- 600

- 650

- 700

- 750

- 800

- 850

- 900

- 950

- 1000

- 1050

- 1100

- 1150

- 1200

- 1250

- 1300

- 1350

- 1400

- 1450

- 1500

- 1550

- 1600

- 1650

- 1700

- 1750

- 1800

- 1850

- 1900

- 1950

- 2000

- 2050

- 2100

- 2150

- 2200

- 2250

- 2300

- 2350

- 2400

- 2450

- 2500

- 2550

- 2600

- 2650

- 2700

- 2750

- 2800

- 2850

- 2900

- 2950

- 3000

- 3050

- 3100

- 3150

- 3200

- 3250

- 3300

- 3350

- 3400

- 3450

- 3500

- 3550

- 3600

- 3650

- 3700

- 3750

- 3800

- 3850

- 3900

- 3950

- 4000

- 4050

-

Type

-

Slider

Slider -

Rod

Rod -

Rotary Shaft

Rotary Shaft

-

-

Max. Transportable Mass Range (Horizontal)(kg)

- 0~2.0

- 2.1~5.0

- 5.1~10.0

- 10.1~20.0

- 20.1~50.0

- 50.1~100.0

- 100.1~150.0

The calculation method differs depending on the manufacturer. For details, see the technical data provided by the relevant manufacturer.

-

Max. Transportable Mass (Horizontal)(kg)

- 1

- 2

- 3

- 4

- 5

- 5.5

- 6

- 7.5

- 8

- 10

- 11

- 12

- 13.3

- 14

- 15

- 16.6

- 19

- 20

- 25

- 30

- 35

- 40

- 43.3

- 44

- 45

- 47

- 50

- 55

- 60

- 70

- 75

- 80

- 95

- 110

- 120

- 150

The calculation method differs depending on the manufacturer. For details, see the technical data provided by the relevant manufacturer.

-

Max. Transportable Mass Range (Vertical)(kg)

- 0~2.0

- 2.1~5.0

- 5.1~10.0

- 10.1~20.0

- 20.1~50.0

- 50.1~100.0

The calculation method differs depending on the manufacturer. For details, see the technical data provided by the relevant manufacturer.

-

Drive Method

-

Rolled Ball Screw

-

Ground Ball Screw

-

Belt

-

Gear

-

Slide Screw

-

Linear Motor

- Rack and Pinion

-

Rolled Ball Screw

-

Max. Transportable Mass (Vertical)(kg)

- 0.25

- 0.4

- 0.5

- 0.8

- 1

- 1.5

- 2

- 2.5

- 3

- 3.3

- 3.5

- 4

- 4.5

- 5

- 6

- 7

- 8

- 8.3

- 8.5

- 10

- 12

- 12.5

- 14

- 15

- 17

- 18

- 18.3

- 20

- 24

- 27

- 30

- 40

- 45

- 50

- 55

The calculation method differs depending on the manufacturer. For details, see the technical data provided by the relevant manufacturer.

-

Main Body, Peripheral Components

- Main Body

- Peripheral Components

-

Lead(mm)

-

Guide

-

Not Provided

-

Provided

-

Not Provided

-

Input Power Supply

-

Position Detection

- Incremental

- Absolute

-

I/O Module

- NPN

- PNP

- CC-Link

- DeviceNet

- Not Provided

- INPOS Signal

-

Max. Thrust Force Range(N)

-

Table Length L1(mm)

-

Positioning Repeatability(µm)

-

Maximum Velocity(mm/sec)

-

Table Width W1(mm)

-

Brake

-

Operating Environment

-

Max. Thrust Force(N)

-

Noise Filter

Related Categories to Single Axis RobotsDanh mục liên quan đến Single Axis Robots

FAQ Single Axis Robots

- Question: What is a single-axis robot and what are its primary uses in industry?

- Answer: A single-axis robot is a robotic system designed to move along a single linear or rotational axis. Its primary use in industry is to automate tasks that involve simple linear movements, such as pick-and-place operations, material handling, and assembly processes.

- Question: How does a single-axis robotic arm enhance production efficiency?

- Answer: A single-axis robotic arm enhances production efficiency by automating repetitive tasks with precision and speed. It eliminates the need for manual labor in tasks that involve linear movements, leading to increased throughput, reduced cycle times, and improved overall process efficiency.

- Question: What factors should I consider when choosing a single-axis robot for my operation?

- Answer: When choosing a single-axis robot, consider factors such as payload capacity, speed, accuracy, and the specific requirements of your application. Additionally, evaluate the ease of integration to the system, compatibility with control systems, and the overall cost of ownership.

- Question: Can single-axis robots be integrated with multi-axis systems?

- Answer: Single-axis robots can be integrated into multi-axis systems to create more complex and versatile robotic solutions. Combining single-axis and multi-axis robots allows for a broader range of motion and the ability to handle intricate tasks in manufacturing and automation.

- Question: What are the benefits of using single-axis robots in a cleanroom environment?

- Answer: Single-axis robots are advantageous in cleanroom environments due to their sealed and compact designs, minimizing the risk of contamination. Their precision and reliability make them suitable for tasks like semiconductor manufacturing, electronics assembly, and medical device production that demand a controlled and sterile environment.

- Question: How do single-axis robots contribute to safety and ergonomics in the workplace?

- Answer: Single-axis robots contribute to workplace safety by taking over repetitive and potentially hazardous tasks, reducing the risk of injuries to human workers. Moreover, they enhance ergonomics by handling heavy loads and performing tasks in confined spaces, creating a safer and more comfortable working environment.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy