(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

NSK Roller Bearings(Raceway Ring Shape:Cone Roller)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

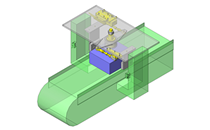

One End Cone Type Tapered Roller Bearings

NSK

Designed so the conical vertex of the raceway surfaces of the inner and outer rings and rollers converge at one point on the centerline of the bearing. Products on this page: HR model

Inner Dia. d(Ø) Outer Dia. D(Ø) Raceway Ring Shape Load Direction Width B(mm) Outer Ring Number of Raceway Ring Rows Inner/Outer Ring Material Specifications Outer Ring Type Precision (JIS) Rolling Element Material Size Standards 15 ~ 360 35 ~ 480 Cone Roller Radial 11.75 ~ 150 With Outer Ring Single Row / Double Row Steel Standard Flat / With V-Shaped Groove Class 0 Steel Metric System From: 127,170 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

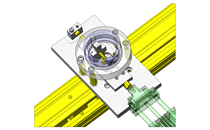

NSK

Cylindrical roller bearings are suitable for applications involving high-speed rotation because the friction between the rolling elements and the flange of the track wheel is small. Products on this page: N type

Inner Dia. d(Ø) Outer Dia. D(Ø) Raceway Ring Shape Load Direction Width B(mm) Outer Ring Number of Raceway Ring Rows Inner/Outer Ring Material Specifications Outer Ring Type Precision (JIS) Rolling Element Material Size Standards 25 ~ 280 47 ~ 420 Cone Roller Radial 16 ~ 106 With Outer Ring Double Row Steel Standard Flat Class 0 Steel Metric System From: 4,388,813 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Inner Dia. d(Ø) |

| Outer Dia. D(Ø) |

| Raceway Ring Shape |

| Load Direction |

| Width B(mm) |

| Outer Ring |

| Number of Raceway Ring Rows |

| Inner/Outer Ring Material |

| Specifications |

| Outer Ring Type |

| Precision (JIS) |

| Rolling Element Material |

| Size Standards |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | NSK | NSK |

| Product SeriesDòng sản phẩm | ||

| CADCAD |

|

|

| From | 127,170 VND Special Price On Sale Till 31/03/2025 | 4,388,813 VND- |

| Days to ShipSố ngày giao hàng | Same day or more | 6 Day(s) or more |

| Inner Dia. d(Ø) | 15 ~ 360 | 25 ~ 280 |

| Outer Dia. D(Ø) | 35 ~ 480 | 47 ~ 420 |

| Raceway Ring Shape | Cone Roller | Cone Roller |

| Load Direction | Radial | Radial |

| Width B(mm) | 11.75 ~ 150 | 16 ~ 106 |

| Outer Ring | With Outer Ring | With Outer Ring |

| Number of Raceway Ring Rows | Single Row / Double Row | Double Row |

| Inner/Outer Ring Material | Steel | Steel |

| Specifications | Standard | Standard |

| Outer Ring Type | Flat / With V-Shaped Groove | Flat |

| Precision (JIS) | Class 0 | Class 0 |

| Rolling Element Material | Steel | Steel |

| Size Standards | Metric System | Metric System |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Inner Dia. d(Ø)

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 12

- 12.7

- 12.700(1/2)

- 13

- 14

- 14.288

- 15

- 16

- 17

- 17.462

- 18

- 19

- 19.05

- 20

- 21

- 21.430

- 21.986

- 22

- 22.225

- 24

- 25

- 25.4

- 26

- 28

- 29

- 30

- 31.75

- 32

- 34.925

- 34.925(1 3/8)

- 34.988

- 35

- 37

- 38

- 38.1

- 40

- 41.275

- 42

- 43

- 45

- 47

- 48

- 50

- 50.8

- 52

- 55

- 57

- 58

- 60

- 62

- 63

- 63.5

- 65

- 67

- 68

- 70

- 72

- 73

- 75

- 77

- 80

- 82

- 85

- 87

- 90

- 92

- 95

- 100

- 102

- 105

- 110

- 112

- 115

- 120

- 122

- 125

- 130

- 132

- 135

- 140

- 145

- 150

- 155

- 160

- 162

- 165

- 170

- 175

- 180

- 190

- 195

- 200

- 205

- 220

- 225

- 240

- 245

- 260

- 265

- 280

- 285

- 290

- 300

- 320

- 330

- 340

- 360

- 380

- 400

- 420

- 440

- 460

- 480

-

Outer Dia. D(Ø)

- 6

- 6.5

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 17.462(11/16)

- 18

- 19

- 19.05

- 20

- 20.638

- 21

- 22

- 23

- 23.812

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 30.162

- 31

- 32

- 33

- 33.338

- 34

- 35

- 36

- 37

- 38

- 38.1

- 39

- 39.878

- 40

- 42

- 43

- 44

- 44.45

- 45

- 45.237

- 45.974

- 47

- 47.625(1 7/8)

- 48

- 49

- 50

- 50.005

- 50.292

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 59.131

- 59.974

- 60

- 61

- 62

- 63

- 64

- 65

- 65.088

- 66

- 66.5

- 67

- 68

- 70

- 71.5

- 72

- 73

- 73.025

- 74

- 75

- 76.2

- 77

- 78

- 80

- 81

- 82

- 83

- 85

- 86

- 88

- 89

- 90

- 92

- 93.264

- 95

- 98

- 100

- 102

- 105

- 108

- 110

- 112.712

- 115

- 117

- 120

- 125

- 127

- 130

- 135

- 137

- 140

- 145

- 150

- 153

- 155

- 160

- 165

- 170

- 173

- 175

- 178

- 180

- 188

- 190

- 200

- 210

- 215

- 220

- 225

- 230

- 240

- 250

- 260

- 270

- 280

- 290

- 300

- 310

- 320

- 340

- 360

- 370

- 380

- 400

- 420

- 440

- 460

- 480

- 500

- 520

- 540

- 560

- 580

- 600

- 620

- 650

- 680

- 700

-

Raceway Ring Shape

- Angular Contact Ball

- Cylindrical Roller

- Needle Roller

- Cone Roller

- Self-Aligning Roller

- Complex Shape Roller

- One-Way Clutch

-

Load Direction

- Radial

- Thrust

-

Width B(mm)

- 1

- 2

- 2.5

- 2.75

- 3

- 3.5

- 4

- 4.25

- 4.75

- 5

- 5.25

- 5.5

- 5.75

- 6

- 6.5

- 7

- 7.5

- 8

- 8.25

- 8.5

- 9

- 9.5

- 10

- 10.5

- 11

- 11.5

- 11.75

- 12

- 12.5

- 12.7

- 12.700(1/2)

- 13

- 13.25

- 13.5

- 14

- 14.25

- 14.605

- 14.732

- 15

- 15.25

- 15.88

- 16

- 16.25

- 16.637

- 16.764

- 17

- 17.25

- 17.462

- 18

- 18.25

- 18.288

- 19

- 19.05

- 19.25

- 19.75

- 20

- 20.75

- 21

- 21.25

- 21.75

- 22

- 22.25

- 22.75

- 23

- 23.75

- 24

- 24.25

- 24.75

- 25

- 25.25

- 25.4

- 25.40(1)

- 25.650

- 25.654

- 26

- 26.25

- 26.75

- 27

- 27.25

- 28

- 28.25

- 28.75

- 29

- 29.25

- 29.75

- 30

- 30.162

- 30.302

- 30.5

- 31

- 31.5

- 31.75

- 32

- 32.5

- 32.75

- 33

- 33.25

- 33.5

- 34

- 34.5

- 35

- 35.25

- 36

- 37

- 38

- 38.25

- 38.5

- 39

- 40

- 41

- 42

- 42.25

- 42.5

- 43

- 43.5

- 43.75

- 44.5

- 45

- 45.5

- 45.75

- 46

- 46.5

- 47

- 48

- 48.5

- 49

- 49.5

- 50

- 51

- 51.5

- 52

- 53

- 53.5

- 54

- 54.5

- 55

- 56

- 57

- 58

- 59

- 59.5

- 60

- 60.5

- 61

- 61.5

- 62

- 63

- 63.5

- 63.75

- 64

- 65

- 67

- 67.5

- 67.75

- 68

- 69

- 70

- 71.5

- 71.75

- 72

- 73

- 74

- 75

- 76

- 77

- 77.5

- 78

- 79

- 80

- 81.5

- 82

- 83

- 84

- 84.5

- 85

- 86

- 87

- 88

- 89

- 90

- 90.5

- 91

- 92

- 93

- 95

- 96

- 97

- 98

- 98.75

- 100

- 102

- 103

- 104

- 106

- 107.75

- 108

- 109

- 110

- 112

- 114

- 115

- 118

- 120

- 121

- 122

- 126

- 127

- 128

- 130

- 132

- 133

- 134

- 135

- 137

- 138

- 140

- 144

- 145

- 146

- 148

- 150

- 155

- 157

- 160

- 163

- 165

- 174

- 175

- 176

- 190

- 192

- 200

- 208

-

Outer Ring

- With Outer Ring

- W/o Outer Ring

-

Number of Raceway Ring Rows

-

Inner/Outer Ring Material

- Steel

- Stainless Steel

-

Specifications

-

Outer Ring Type

-

Precision (JIS)

- Class 0

- Class 4

- Class 5

-

Rolling Element Material

-

Size Standards

Related Categories to Roller BearingsDanh mục liên quan đến Roller Bearings

FAQ Roller Bearings

- Question: What are the different types of roller bearings?

- Answer: The different types of roller bearings are:

1. Cylindrical Roller Bearings: Suitable for moderate-speed operations with high radial-load capacity and moderate thrust loads.

2. Spherical Roller Bearings: Designed to carry heavy axial and radial loads at high speeds, even with misalignment or shaft deflection. Available with cylindrical or tapered bores.

3. Needle Roller Bearings: Feature thin, long rollers for high radial load capacities in limited space and high-speed rotational applications.

4. Tapered Roller Bearings: Support radial and thrust loads, commonly used in automotive wheel hubs, gearboxes, and industrial equipment. Available in inch and metric sizes. These bearings find applications in various industries, including heavy equipment, machinery and manufacturing. - Question: What are the advantages of using roller bearings?

- Answer: Here are some Advantages of roller bearings:

1. Reduced friction for lower starting and running friction, except at very high speeds.

2. Ability to withstand momentary shock loads.

3. Accurate shaft alignment.

4. Low manufacturing cost.

5. Moderate lubricant requirements and low friction.

6. Capability to support both radial and axial loads.

7. Long bearing life.

8. Suitable for mass production with stable quality.

9. Can support combined radial and thrust loads simultaneously. - Question: How do I choose the right roller bearing for my application?

- Answer: Here are some steps to guide you in selecting the appropriate bearing:

1. Load Requirements: Understand the magnitude and direction of the load to determine the appropriate load capacity.

2. Speed: Consider the rotational speed of the application to ensure it aligns with the bearing's capabilities.

3. Environmental Conditions: Evaluate temperature, humidity, and exposure to contaminants to select a bearing that can withstand the operating environment.

4. Bearing Type: Choose from various types like cylindrical, spherical, needle, or tapered roller bearings based on load, speed, and operating conditions.

5. Bearing Material: Select suitable materials such as stainless steel, chrome steel, ceramic, or plastic, considering load, speed, temperature, and environmental factors.

6. Lubrication Needs: Determine lubrication requirements, including type, viscosity, and replenishment intervals, to ensure smooth operation and longevity.

7. Special Features or Requirements: Consider any specific features like seals, shields, precision tolerances, or coatings needed for your application. - Question: Can roller bearings handle axial loads?

- Answer: Yes, Roller bearings can indeed handle axial loads, though most are designed primarily for radial loads. Certain designs, such as cylindrical roller bearings with flanges on both inner and outer rings, and axial spherical roller bearings, are capable of supporting axial loads. However, roller bearings generally have lower axial load capacities compared to radial loads.

- Question: How do I maintain and lubricate roller bearings?

- Answer: The guidelines for maintaining and lubricating roller bearings effectively including

1. Selection of Lubricant: Choose lubricant based on application and environment, such as mineral oil, synthetic oil, or greases like lithium soap or polyalphaolefin.

2. Lubrication Techniques: Utilize methods such as oil drip feed or grease lubrication.

3. Lubrication Schedule: Establish a schedule based on application and environmental factors and regularly inspect bearings for wear and adjust the schedule accordingly.

4. Monitoring Performance: Regularly monitor for signs of issues such as increased vibration, excessive heat, lubricant loss, or contamination and address any problems promptly to prevent premature bearing failure. - Question: What are the signs of roller bearing failure?

- Answer: Signs of roller bearing failure include excessive vibration, increased temperature, noise, lubricant contamination, and friction. Initial indicators often begin with abnormal vibration, progressing to elevated temperature and noise. Contaminated lubricants exacerbate friction, leading to heat generation and eventual failure.

- Question: How long do roller bearings typically last?

- Answer: The lifespan of roller bearings is determined by factors like rotations or operating hours, with fatigue symptoms indicating failure. The L10 life, representing the hours or rotations before 90% of bearings fail, estimates bearing life. Ratings are based on hours at a set speed, influenced by load, speed, lubrication, and conditions. Average roller bearing life is usually 4 to 5 times the L10 life, potentially longer under favorable conditions.

- Question: Can roller bearings be used in extreme temperatures?

- Answer: Roller bearings have differing temperature thresholds depending on their design, lubrication, and operational conditions. Traditional bearings can typically function in temperatures up to 149°C, while specialized high-temperature bearings can endure temperatures up to 450°C. However, excessive heat can decrease efficiency, induce wear and expansion, and compromise seals or grease. It's vital to select appropriate bearings and lubricants tailored to specific applications and environmental conditions to ensure optimal performance and longevity.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy