(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

MISUMI Cable Carriers(Cable Insertion Type:Slit)

Search by specifying the lower class categoryTìm kiếm bằng cách chỉ định danh mục lớp thấp hơn

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

Recommended

You can add up to 6 items per a category to the compare list.

- On Sale Till 31/12/2024

MiSUMi Economy MiSUMi Economy

MiSUMi EconomyMISUMI

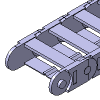

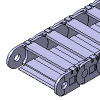

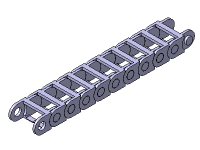

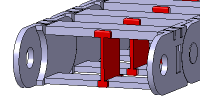

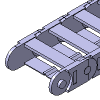

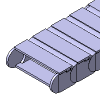

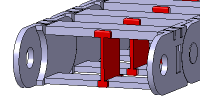

Cable Carriers With Slit Cable carriers are essential equipment used in automation machines to effectively organize and prevent the tangling and twisting of cables. They provide a wide range of sizes to choose from. [Feature] - Inner Height (mm.) : 10, 15, 20 and 32 - Inner Width (mm.) : 15, 20, 25, 30, 40 and 50 - Bending Radius (mm.) : 18, 28, 38, 48, 50, 60, 75 and 100 - Number of links (Pcs.) : can select between 10 and 65 - Pitch (mm.) : 20 and 30 - Material: PA + Glass Fiber[Application] It is used in automation machines to organize and prevent issues from the cable tangling and twisting.

- Volume Discount

Inner Height H1(mm) Inner Width W1(mm) Bending Radius R(mm) Properties Cover Type Type Pitch P(mm) Number of Divided Sections inside Carrier Cable Insertion Type Max. Cable O.D. Dp(Ø) Cable Insertion Surface Operating Speed(m/s) 10 ~ 32 15 ~ 50 18 ~ 100 - Standard Square Shape 20 ~ 30 - Slit - Outer Circumferential Surface / Inner Circumferential Surface - From: 123,467 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

MISUMI

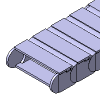

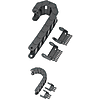

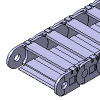

Cable Carriers suitable for being used in clean environments where particle generation is very low. The low noise level is achieved. Flaps open on either side.

Inner Height H1(mm) Inner Width W1(mm) Bending Radius R(mm) Properties Cover Type Type Pitch P(mm) Number of Divided Sections inside Carrier Cable Insertion Type Max. Cable O.D. Dp(Ø) Cable Insertion Surface Operating Speed(m/s) 14.6 ~ 32 15 ~ 50 28 ~ 100 - Standard Square Shape 20 ~ 30.5 Not Provided Slit 11 ~ 25 Outer Circumferential Surface / Inner Circumferential Surface - Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| SpecificationsĐặc điểm kĩ thuật |

| Inner Height H1(mm) |

| Inner Width W1(mm) |

| Bending Radius R(mm) |

| Properties |

| Cover Type |

| Type |

| Pitch P(mm) |

| Number of Divided Sections inside Carrier |

| Cable Insertion Type |

| Max. Cable O.D. Dp(Ø) |

| Cable Insertion Surface |

| Operating Speed(m/s) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | MISUMI |

| Product SeriesDòng sản phẩm | ||

| CADCAD |

|

|

| From | 123,467 VND Special Price On Sale Till 31/12/2024 | - |

| Days to ShipSố ngày giao hàng | Same day or more | 4 Day(s) or more |

| SpecificationsĐặc điểm kĩ thuật | ||

| Inner Height H1(mm) | 10 ~ 32 | 14.6 ~ 32 |

| Inner Width W1(mm) | 15 ~ 50 | 15 ~ 50 |

| Bending Radius R(mm) | 18 ~ 100 | 28 ~ 100 |

| Properties | - | - |

| Cover Type | Standard | Standard |

| Type | Square Shape | Square Shape |

| Pitch P(mm) | 20 ~ 30 | 20 ~ 30.5 |

| Number of Divided Sections inside Carrier | - | Not Provided |

| Cable Insertion Type | Slit | Slit |

| Max. Cable O.D. Dp(Ø) | - | 11 ~ 25 |

| Cable Insertion Surface | Outer Circumferential Surface / Inner Circumferential Surface | Outer Circumferential Surface / Inner Circumferential Surface |

| Operating Speed(m/s) | - | - |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Inner Height H1(mm)

-

Inner Width W1(mm)

-

Bending Radius R(mm)

-

Properties

- Standard

- Low Particle Generation

- Low Noise

- Low Friction

- Low Vibration

- High Endurance

-

Cover Type

-

Standard

-

Full Cover

-

One Side Cover

-

Standard

-

Type

-

Square Shape

-

Modular Type Square Shape

-

Related Components

-

Square Shape

-

Pitch P(mm)

-

Number of Divided Sections inside Carrier

-

Not Provided

-

Horizontally divided into Two

-

Not Provided

-

Cable Insertion Type

-

Max. Cable O.D. Dp(Ø)

-

Cable Insertion Surface

-

Operating Speed(m/s)

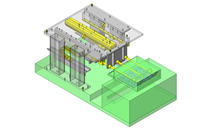

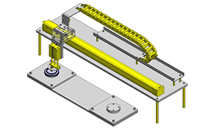

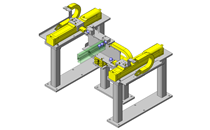

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to Cable CarriersDanh mục liên quan đến Cable Carriers

FAQ Cable Carriers

- Question: What are the advantages of using a cable carrier?

- Answer: 1. Cable Organization: Cable carriers help manage and organize cables, preventing tangling, twisting, and damage. Moreover, they also enhance workplace safety.

2. Improved Reliability: By preventing cable damage and wear, cable carriers increase the reliability and uptime of machinery and equipment.

3. Easy Maintenance: Cable carriers simplify maintenance tasks by providing easy access to cables and hoses.

4. Noise Reduction: The enclosed design dampens vibrations and reduces noise levels in a working environment.

5. Customizability: Cable carriers come in various sizes, materials, and configurations, allowing for customization based on specific application requirements of the machine - Question: How do you select the right size and type of cable carrier?

- Answer: 1. Determine cable and hose requirements: For example, how many cables are in the systems, what diameter, bending radius and types of cables and hoses

2. Check the Inner dimensions of the cable: To select the internal application area of the cable carrier We have to consider taking into account the size of the cable. Including having to allow for the distance between the cables as well

3. Consider Load Capacity: Determine the maximum weight of the cables and hoses, including any additional loads such as connectors or fittings.

4. Environmental Factors: Evaluate the operating environment for the cable carrier, such as moisture, clean room and so on. Choose a cable carrier with appropriate material and protection features to withstand these conditions.

5. Evaluate Motion Requirements: Determine the expected range of motion and dynamic behavior of the cables and hoses. Consider factors such as linear or multi-axis movement, speed and acceleration.

6. Mounting Options: Consider the available mounting methods, such as horizontal or vertical mounting, fixed or moving mounts - Question: What are some of the most important factors to consider when designing a cable carrier or drag chain system for electrical conduit protection?

- Answer: 1. Cable and Conduit Size: Ensure that the selected cable carrier has sufficient inner dimensions to accommodate the size of the electrical conduits along with any additional space required for cable movement.

2. Load Capacity: Choose a cable carrier that can handle the anticipated load without sagging or causing excessive strain.

3. Flexibility and Range of Motion: Consider factors such as linear or multi-axis movement, bending radius, and the need for torsional or lateral flexibility.

4. Environmental Conditions: Choose a cable carrier made from materials that can withstand these conditions for example high temperatures , moisture and provide adequate protection.

5. Mounting and Installation: Ensure that it is compatible with your application. Consider ease of installation, accessibility for maintenance

6. Safety and Codes Compliance: Ensure that the cable carrier system complies with relevant safety standards such as fire resistance, electrical insulation etc.

7. Maintenance: Select a cable carrier that allows for easy access and maintenance of cables moreover consider for replacements in the future. - Question: What are the different materials used to make cable carrier?

- Answer: 1. Plastic/Polymers: Cable carriers are commonly manufactured using engineering plastics such as polyamide (nylon), polypropylene, or polyethylene. These materials offer excellent resistance to chemicals, impact, and wear.

2. Steel: Steel cable carriers provide high strength and rigidity. They are often used in heavy-duty applications where there are higher loads, extreme temperatures, or exposure to harsh environments.

3. Aluminum: Aluminum cable carriers offer a balance between strength and weight.. Aluminum is corrosion-resistant and often used in applications that require reduced weight, such as robotics and automation systems.

4. Stainless Steel: Stainless steel cable carriers are highly resistant to corrosion, making them suitable for applications in harsh environments, such as marine or chemical industries. They offer excellent durability, strength, and protection against moisture, chemicals, and temperature extremes.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy