(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

KOGANEI Air Cylinders(Cylinder Operation Method:Single-Action (Retraction))

Search by specifying the lower class categoryTìm kiếm bằng cách chỉ định danh mục lớp thấp hơn

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

3 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

KOGANEI

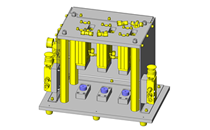

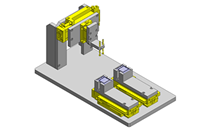

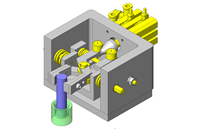

Rich series configuration available from ø 6 to ø 100. Standard non-ion specification.

Cylinder I.D: D(Ø) Stroke: L(mm) Rod Operation Method Main Body Shape Cylinder Operation Method Additional Function Environment, Applications 12 ~ 50 5 ~ 35 Single-Rod Block Shape Single-Action (Retraction) Standard Standard / Heat Resistant From: 746,959 VND Days to Ship: Số ngày giao hàng: 14 Day(s) or more  14 Day(s) or more

14 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

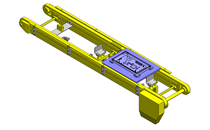

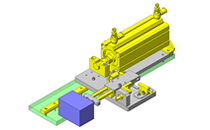

Compact Multi-Mount Cylinder, BDA/BSA/BTA/BDAV Series

KOGANEI

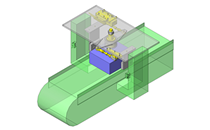

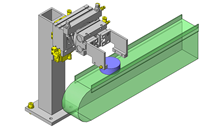

Provides multi functional support for small movements and in addition to the directly installed side mount, 3 types of mounting provide appropriate response for various mounting requirements.

Cylinder I.D: D(Ø) Stroke: L(mm) Rod Operation Method Main Body Shape Cylinder Operation Method Additional Function Environment, Applications 6 ~ 16 5 ~ 15 Single-Rod Block Shape Single-Action (Retraction) Standard / With Rod Rotation Stopper Function Standard From: 746,959 VND Days to Ship: Số ngày giao hàng: 13 Day(s) or more  13 Day(s) or more

13 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

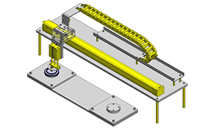

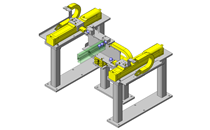

Drive equipment standard cylinder pen cylinder series

KOGANEI

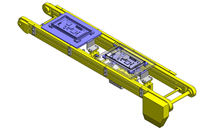

Used in wide range of industrial production lines due to its small size and ease of use.

Cylinder I.D: D(Ø) Stroke: L(mm) Rod Operation Method Main Body Shape Cylinder Operation Method Additional Function Environment, Applications 6 5 Single-Rod Standard Single-Action (Retraction) Standard No Copper, fluoropolymer Type Material (Partially Plated) From: 495,803 VND Days to Ship: Số ngày giao hàng: Same day  Same day

Same day

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Cylinder I.D: D(Ø) |

| Stroke: L(mm) |

| Rod Operation Method |

| Main Body Shape |

| Cylinder Operation Method |

| Additional Function |

| Environment, Applications |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | KOGANEI | KOGANEI | KOGANEI |

| Product SeriesDòng sản phẩm | |||

| CADCAD |

| ||

| From | 746,959 VND- | 746,959 VND- | 495,803 VND |

| Days to ShipSố ngày giao hàng | 14 Day(s) or more | 13 Day(s) or more | Same day |

| Cylinder I.D: D(Ø) | 12 ~ 50 | 6 ~ 16 | 6 |

| Stroke: L(mm) | 5 ~ 35 | 5 ~ 15 | 5 |

| Rod Operation Method | Single-Rod | Single-Rod | Single-Rod |

| Main Body Shape | Block Shape | Block Shape | Standard |

| Cylinder Operation Method | Single-Action (Retraction) | Single-Action (Retraction) | Single-Action (Retraction) |

| Additional Function | Standard | Standard / With Rod Rotation Stopper Function | Standard |

| Environment, Applications | Standard / Heat Resistant | Standard | No Copper, fluoropolymer Type Material (Partially Plated) |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Cylinder I.D: D(Ø)

-

Stroke: L(mm)

- 1

- 1,000

- 1,001

- 1,002

- 1,004

- 1,005

- 1,006

- 1,009

- 1,010

- 1,015

- 1,016

- 1,020

- 1,025

- 1,027

- 1,030

- 1,035

- 1,040

- 1,041

- 1,042

- 1,045

- 1,048

- 1,050

- 1,053

- 1,055

- 1,060

- 1,061

- 1,065

- 1,067

- 1,070

- 1,072

- 1,074

- 1,075

- 1,079

- 1,080

- 1,085

- 1,090

- 1,092

- 1,095

- 1,099

- 1,100

- 1,102

- 1,105

- 1,110

- 1,111

- 1,112

- 1,113

- 1,115

- 1,120

- 1,125

- 1,130

- 1,135

- 1,136

- 1,140

- 1,143

- 1,145

- 1,148

- 1,150

- 1,151

- 1,155

- 1,159

- 1,160

- 1,165

- 1,168

- 1,170

- 1,171

- 1,175

- 1,179

- 1,180

- 1,185

- 1,187

- 1,190

- 1,195

- 1,199

- 1,200

- 1,201

- 1,205

- 1,208

- 1,210

- 1,212

- 1,215

- 1,218

- 1,219

- 1,220

- 1,221

- 1,225

- 1,227

- 1,230

- 1,235

- 1,240

- 1,242

- 1,245

- 1,250

- 1,251

- 1,252

- 1,255

- 1,256

- 1,257

- 1,258

- 1,260

- 1,265

- 1,266

- 1,270

- 1,275

- 1,280

- 1,285

- 1,290

- 1,295

- 1,297

- 1,298

- 1,300

- 1,306

- 1,310

- 1,315

- 1,318

- 1,320

- 1,325

- 1,330

- 1,335

- 1,340

- 1,345

- 1,350

- 1,351

- 1,352

- 1,355

- 1,360

- 1,365

- 1,370

- 1,371

- 1,375

- 1,380

- 1,385

- 1,388

- 1,390

- 1,400

- 1,405

- 1,410

- 1,415

- 1,420

- 1,425

- 1,430

- 1,432

- 1,437

- 1,440

- 1,442

- 1,445

- 1,446

- 1,448

- 1,450

- 1,455

- 1,460

- 1,465

- 1,470

- 1,475

- 1,480

- 1,485

- 1,486

- 1,490

- 1,500

- 1,501

- 1,502

- 1,503

- 1,505

- 1,510

- 1,514

- 1,515

- 1,520

- 1,525

- 1,530

- 1,535

- 1,540

- 1,545

- 1,550

- 1,552

- 1,555

- 1,560

- 1,569

- 1,570

- 1,575

- 1,580

- 1,585

- 1,590

- 1,600

- 1,606

- 1,610

- 1,620

- 1,625

- 1,630

- 1,640

- 1,645

- 1,650

- 1,660

- 1,670

- 1,680

- 1,685

- 1,688

- 1,690

- 1,700

- 1,710

- 1,720

- 1,730

- 1,735

- 1,740

- 1,750

- 1,755

- 1,760

- 1,765

- 1,770

- 1,775

- 1,780

- 1,790

- 1,800

- 1,810

- 1,830

- 1,850

- 1,880

- 1,900

- 1,910

- 1,935

- 1,950

- 1,960

- 02

- 2

- 2,000

- 2,050

- 2,100

- 2,150

- 2,160

- 2,200

- 2,220

- 2,230

- 2,250

- 2,270

- 2,290

- 2,300

- 2,340

- 2,350

- 2,370

- 2,400

- 2,500

- 2,508

- 2,600

- 2,610

- 2,620

- 2,640

- 2,650

- 2,700

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 186

- 187

- 188

- 189

- 190

- 191

- 192

- 193

- 194

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 211

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 221

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 231

- 232

- 233

- 234

- 235

- 236

- 237

- 238

- 239

- 240

- 241

- 242

- 243

- 244

- 245

- 246

- 247

- 248

- 249

- 250

- 251

- 252

- 253

- 254

- 255

- 256

- 257

- 258

- 259

- 260

- 261

- 262

- 263

- 264

- 265

- 266

- 267

- 268

- 269

- 270

- 271

- 272

- 273

- 274

- 275

- 276

- 277

- 278

- 279

- 280

- 281

- 282

- 283

- 284

- 285

- 286

- 287

- 288

- 289

- 290

- 291

- 292

- 293

- 294

- 295

- 296

- 297

- 298

- 299

- 300

- 301

- 302

- 303

- 304

- 305

- 306

- 307

- 308

- 309

- 310

- 311

- 312

- 313

- 314

- 315

- 316

- 317

- 318

- 319

- 320

- 321

- 322

- 323

- 324

- 325

- 326

- 327

- 328

- 329

- 330

- 331

- 332

- 333

- 334

- 335

- 336

- 337

- 338

- 339

- 340

- 341

- 342

- 343

- 344

- 345

- 346

- 347

- 348

- 349

- 350

- 351

- 352

- 353

- 354

- 355

- 356

- 357

- 358

- 359

- 360

- 361

- 362

- 363

- 364

- 365

- 366

- 367

- 368

- 369

- 370

- 371

- 372

- 373

- 374

- 375

- 376

- 377

- 378

- 380

- 381

- 382

- 383

- 384

- 385

- 386

- 387

- 388

- 390

- 391

- 392

- 393

- 394

- 395

- 396

- 397

- 398

- 399

- 400

- 401

- 402

- 403

- 404

- 405

- 406

- 407

- 408

- 409

- 410

- 411

- 412

- 413

- 414

- 415

- 416

- 417

- 418

- 419

- 420

- 421

- 422

- 424

- 425

- 426

- 427

- 428

- 429

- 430

- 431

- 432

- 433

- 435

- 436

- 437

- 438

- 440

- 441

- 442

- 443

- 444

- 445

- 447

- 449

- 450

- 451

- 452

- 453

- 454

- 455

- 456

- 457

- 458

- 460

- 462

- 463

- 464

- 465

- 466

- 467

- 469

- 470

- 471

- 472

- 473

- 474

- 475

- 476

- 480

- 481

- 482

- 483

- 484

- 485

- 487

- 488

- 490

- 491

- 492

- 493

- 494

- 495

- 496

- 499

- 500

- 501

- 502

- 503

- 504

- 505

- 506

- 507

- 508

- 509

- 510

- 512

- 513

- 514

- 515

- 516

- 517

- 518

- 520

- 522

- 523

- 524

- 525

- 526

- 527

- 528

- 530

- 532

- 533

- 534

- 535

- 538

- 539

- 540

- 541

- 542

- 543

- 544

- 545

- 546

- 547

- 548

- 550

- 551

- 552

- 553

- 554

- 555

- 556

- 557

- 558

- 559

- 560

- 561

- 562

- 563

- 564

- 565

- 566

- 568

- 570

- 571

- 572

- 574

- 575

- 576

- 578

- 580

- 581

- 582

- 583

- 584

- 585

- 586

- 587

- 588

- 589

- 590

- 591

- 592

- 593

- 594

- 595

- 596

- 598

- 599

- 600

- 601

- 602

- 603

- 604

- 605

- 606

- 607

- 608

- 609

- 610

- 611

- 612

- 613

- 615

- 616

- 619

- 620

- 621

- 622

- 623

- 624

- 625

- 626

- 627

- 630

- 632

- 634

- 635

- 638

- 640

- 641

- 642

- 644

- 645

- 646

- 647

- 648

- 650

- 652

- 653

- 654

- 655

- 656

- 657

- 658

- 659

- 660

- 662

- 663

- 664

- 665

- 666

- 667

- 668

- 670

- 672

- 673

- 675

- 677

- 678

- 680

- 685

- 686

- 688

- 690

- 691

- 692

- 693

- 694

- 695

- 696

- 699

- 700

- 701

- 704

- 705

- 706

- 707

- 708

- 710

- 711

- 715

- 716

- 719

- 720

- 722

- 724

- 725

- 727

- 730

- 735

- 736

- 737

- 738

- 740

- 742

- 744

- 745

- 747

- 748

- 749

- 750

- 752

- 753

- 754

- 755

- 756

- 757

- 758

- 760

- 762

- 764

- 765

- 768

- 769

- 770

- 771

- 772

- 773

- 775

- 777

- 779

- 780

- 783

- 785

- 787

- 788

- 789

- 790

- 791

- 792

- 794

- 795

- 800

- 801

- 802

- 803

- 805

- 806

- 807

- 808

- 810

- 811

- 812

- 813

- 814

- 815

- 816

- 819

- 820

- 821

- 823

- 825

- 827

- 830

- 831

- 832

- 833

- 834

- 835

- 838

- 839

- 840

- 843

- 844

- 845

- 849

- 850

- 851

- 853

- 854

- 855

- 856

- 858

- 860

- 863

- 864

- 865

- 870

- 872

- 873

- 874

- 875

- 880

- 885

- 886

- 888

- 890

- 892

- 895

- 898

- 900

- 901

- 903

- 905

- 906

- 908

- 910

- 914

- 915

- 920

- 921

- 922

- 923

- 925

- 926

- 928

- 930

- 931

- 932

- 933

- 934

- 935

- 938

- 939

- 940

- 942

- 943

- 944

- 945

- 947

- 950

- 951

- 952

- 954

- 955

- 956

- 957

- 958

- 959

- 960

- 962

- 963

- 964

- 965

- 970

- 974

- 975

- 976

- 978

- 979

- 980

- 985

- 988

- 989

- 990

- 994

- 995

- 997

- 998

- 999

- 1000

- 1172

- 1254

- 1305

- 1395

- 1435

- 1452

-

Rod Operation Method

-

Single-Rod

-

Dual-Rod

-

Single-Rod

-

Main Body Shape

-

Standard

-

Block Shape

-

With Guide

-

Others

-

Standard

-

Cylinder Operation Method

-

Double Acting

-

Single Acting (Extension)

-

Single-Action (Retraction)

-

Double Acting

-

Additional Function

- Standard

- High Rigidity, High Precision, High-Grade Guide

- With Rod Rotation Stopper

- With Fall Prevention Mechanism

- With Brake

- With Intermediate Stop Function

- With Rod Rotation Stopper Function

- With Speed Adjustment Function

- With Cylinder Thrust Force Doubling Function

- With Stroke Adjustment Function

- Dual Stroke

-

Environment, Applications

- Standard

- Low Friction (Internal Resistance)

- High Speed, High Frequency

- Slow Speed

- Heat Resistant

- No Copper, fluoropolymer Type Material (Partially Plated)

- Clean Room

- Non-use of Copper-zinc Material

- Vacuum

Related Categories to Air CylindersDanh mục liên quan đến Air Cylinders

FAQ Air Cylinders

- Question: What are the key specifications of general purpose cylinders?

- Answer: General purpose cylinders come with critical specifications that define their performance. Bore size, representing the internal diameter, directly influences the force output — a larger bore delivers more force but may impact speed. Stroke length, indicating the distance the cylinder travels, is pivotal for ensuring the cylinder can execute the required motion. Operating pressure, the force generated at a specific pressure, is crucial for determining the cylinder's capability.

- Question: How do I select the right cylinder model?

- Answer: Choosing the appropriate cylinder model involves a nuanced assessment. Understanding force requirements is paramount; the cylinder must deliver the necessary force for the application. Environmental factors, such as temperature and exposure to contaminants, should guide the selection. Additionally, considering space constraints ensures the chosen cylinder fits seamlessly into the designated area, with compact models being advantageous in confined spaces.

- Question: What applications do general purpose cylinders serve?

- Answer: General purpose cylinders find versatile applications across industries. In material handling, they play a pivotal role in conveyor systems and robotic arms for efficient movement of items. In clamping applications, these cylinders secure workpieces in fixtures, ensuring stability during various manufacturing processes. Their versatility extends to tasks requiring linear force, making them indispensable in pushing and pulling applications.

- Question: What materials are these cylinders made from?

- Answer: The materials used in general purpose cylinders impact their performance and longevity. Aluminum cylinders, owing to their lightweight nature and corrosion resistance, are ideal when weight is a critical consideration. Stainless steel cylinders, on the other hand, offer durability and corrosion resistance, making them suitable for applications in harsh environments where resilience is paramount.

- Question: What is the importance of cylinder I.D. and stroke length?

- Answer: Cylinder I.D. (Internal Diameter) and stroke length are pivotal considerations in the selection process. A larger I.D. results in more force output, but engineers must balance this with available pressure in system. Stroke length is equally crucial, determining the range of motion the cylinder can achieve. Engineers must ensure that both parameters align with the specific requirements of the task at hand to optimize the cylinder's functionality in the given application.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy