(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Rail Length L(mm)

- 40

- 55

- 70

- 75

- 85

- 95

- 100

- 110

- 115

- 120

- 130

- 135

- 145

- 150

- 155

- 160

- 170

- 175

- 190

- 195

- 205

- 215

- 220

- 230

- 235

- 245

- 250

- 255

- 265

- 270

- 275

- 280

- 295

- 310

- 315

- 320

- 335

- 345

- 350

- 355

- 370

- 375

- 390

- 395

- 415

- 420

- 430

- 435

- 445

- 455

- 470

- 475

- 495

- 510

- 515

- 520

- 535

- 545

- 550

- 555

- 570

- 575

- 590

- 595

- 615

- 620

- 630

- 635

- 645

- 670

- 695

- 710

- 720

- 745

- 750

- 770

- 790

- 795

- 820

- 830

- 845

- 870

- 895

- 910

- 920

- 945

- 950

- 970

- 990

[41-989/1mm Unit(s)]

-

Rail Width W1(mm)

-

Assembly Height H(mm)

-

Nominal Part Number

-

Accuracy Standards

- Standard Grade

- High Grade

-

Lubrication Type

- Filled with Lithium soap based grease

- Grease for food sector (H Type)

- Heat Resistant Grease (L Type)

- Low Dust Generation Grease (G Type)

- Lubrication Unit

-

L Dimension Type

- Configurable Type

- Selectable Type

-

type

- ES-SSECB

- ES-SSECB-MX

- ES-SSECBL

- ES-SSECBL-MX

- ES-SSECBLZ

- ES-SSECBLZ-MX

- ES-SSECBZ

- ES-SSECBZ-MX

-

Preload

- Light Preload

- Clearance

- Light Preload

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 4 Day(s) or Less

- 8 Day(s) or Less

Specify AlterationsChỉ định thay đổi

ES Miniature Linear Guides - Extra Long Blocks (Light Preload / Slight Clearance) [RoHS Compliant]

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

RoHS Compliant Miniature Linear Guides - Extra Long Blocks, Light Preload / Slight Clearance

These linear guides or linear slides are factory automation components. They offer a wide variety of sizes to choose from.

[Feature]

● Rail Length Min./Max. (mm.): 40 and 990

● Assembly Height (mm.): 8, 10, 13 and 16

● Block Type : Standard / Extra Long Block with Dowel Holes

● Material: Stainless Steel 56HRC

[Application]

It is used in a variety of machines such as CNC machines, 3D printers, measuring instruments, and so on.

Product Type(Part No.)

| Material (Hardness) 1 | Rail Length Type 2 | 1mm Increment (Specified)Number of Blocks | Preload / Precision Grade A | MX Lubrication Unit B | Assemble Height(H) C | Grease D 3 | |

|---|---|---|---|---|---|---|---|

| Light Preload | Slight Clearance | ||||||

| High | High | ||||||

| No Surface Treatment Stainless Steel [SUS440C equivalent] (56HRC~) | Standard Length (Fixed) | 1 | ES-SSECB | ES-SSECBZ | Blank : none -MX : Provided | 8 10 13 16 | Blank : Standard G : G Grease L : L Grease Y : Y Grease H : H Grease |

| 2 | ES-SSEC2B | ES-SSEC2BZ | |||||

| Standard Length (Fixed) | 1 | ES-SSECBL | ES-SSECBLZ | ||||

| 2 | ES-SSEC2BL | ES-SSEC2BLZ | |||||

| Low Temperature Black Chrome Plating Stainless Steel [SUS440C equivalent] (56HRC~) | Standard Length (Fixed) | 1 | ES-RSECB | - | none | ||

| 2 | ES-SSEC2B | ||||||

| Standard Length (Fixed) | 1 | ES-RSECBL | |||||

| 2 | ES-RSEC2BL | ||||||

1Materials of each part can be checked here>> Misumi linear guide product information

2Standard Length of selectable length type (Fixed Length) can be checked "Standard Length (Fixed Length) List or here to refer

If the require rail length is not available in the selectable length type, please select the 1mm specification (specified size).

33 blocks and 4 blocks option is available. Please compete part no. of single block type, then andd [-B3] or [-B4] as alteration.

If you request more than5 blocks, please see details here.>>Click

![NG] Blocks or Rails are can't be purchased individually (sold as SET items)

!Operating Temperature for this prodcut is −20〜80℃

!About Low Temperature Black Chrome Plating, see more details here>>click

Part No. example

ex)[Rail Length Type] 1mm Specified, [Number of Blocks] 1, [Precision Grade・Preload] Light Preload・Hight, [MX None/Proviede] Provided、[Height] 10、[Grease] Standard Grease

| Part Type(Part No.) | Rail Length(L) | ||||||

Dimensional Drawing

[!] Dimension "G" of L specified Type is not same as the value on the table below. Please refere to the chart.

[!] Blocks or Rails are can't be purchased individually (sold as SET items)

Specification

| Part No. | L 4 | Block Dimension | Rail Dimension | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | MX Lubrication Unit | H | W | L1 | B | C | S×ℓ | L2 | K | Cb | W1 | W2 | H1 | Ca | Counterbored | F | G 5 | ||

| Single Block | 2 Blocks | d1×d2×h | |||||||||||||||||

| ES-SSECB ES-SSECBL ES-SSECBZ ES-SSECBLZ ES-RSECB ES-RSECBL | ES-SSEC2B ES-SSEC2BL ES-SSEC2BZ ES-SSEC2BLZ ES-RSEC2B ES-RSEC2BL | - | 8 | 40~310 (85) | 17 | 37.5 | 12 | 20 | M2×2.5 | 27.5 | 6.5 | 0.3 | 7 | 5 | 4.7 | 0.3 | 2.4×4.2×2.3 | 15 | 5 |

| Blank : none -MX : Provided | 10 | 55~635 (115) | 20 | 49.6 | 15 | 26 | M3×3 | 38.6 | 7.8 | 0.3 | 9 | 5.5 | 5.5 | 0.3 | 3.5×6×3.5 | 20 | 7.5 | ||

| 13 | 70~970 (120) | 27 | 54.8 | 20 | 30 | M3×3.5 | 40.8 | 10 | 0.5 | 12 | 7.5 | 7.5 | 0.5 | 3.5×6×4.5 | 25 | 10 | |||

| 16 | 110~990 (150) | 32 | 70.3 | 25 | 40 | M3×4 | 55.3 | 12 | 0.5 | 15 | 8.5 | 9.5 | 0.5 | 3.5×6×4.5 | 40 | 15 | |||

4( )Dimension is the shortest Length for 2 blocks type

5Length Specified type are cut evenly on both side(left and right). In this case, G dimesnion will be different from the value in chart above. Calculation method: see below.>>click

!H8 size: Screws (M2x6) for mounting provided

!Correctly align the datum planes (the sides with the straight grooves) of both the rail and block when installation. For details, see "Installation and handling" below.

Standard Length (Fixed Length) List

The table below shows the list of selctable length.

Length which you can not find here is also available as "configurable length type" specified with 1mm increments.

| Height | Rail Length | ||||||||||||||||||||||||||||||||||||

| ( H ) | ( L ) | ||||||||||||||||||||||||||||||||||||

| 8 | 40 | 55 | 70 | 85 | 100 | 115 | 130 | 145 | 160 | 175 | 190 | 205 | 220 | 235 | 250 | 265 | 280 | 295 | 310 | ||||||||||||||||||

| 10 | 55 | 75 | 95 | 115 | 135 | 155 | 175 | 195 | 215 | 235 | 255 | 275 | 295 | 315 | 335 | 355 | 375 | 395 | 415 | 435 | 455 | 475 | 495 | 515 | 535 | 555 | 575 | 595 | 615 | 635 | |||||||

| 13 | 70 | 95 | 120 | 145 | 170 | 195 | 220 | 245 | 270 | 295 | 320 | 345 | 370 | 395 | 420 | 445 | 470 | 495 | 520 | 545 | 570 | 595 | 620 | 645 | 670 | 695 | 720 | 745 | 770 | 795 | 820 | 845 | 870 | 895 | 920 | 945 | 970 |

| 16 | 110 | 150 | 190 | 230 | 270 | 310 | 350 | 390 | 430 | 470 | 510 | 550 | 590 | 630 | 670 | 710 | 750 | 790 | 830 | 870 | 910 | 950 | 990 | ||||||||||||||

Basic Rated Load / Allowalbe Static Moment / Mass

kgf=N×0.101972

| Height (H) | Basic Rated Load6 | Static Allowable Moment | Mass | ||||

|---|---|---|---|---|---|---|---|

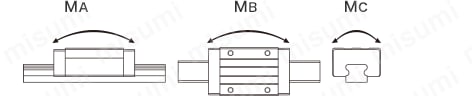

| C(Dynamic) kN | Co(Static) kN | MA N・m | MB N・m | MC N・m | Block kg | Guide Rail kg/m | |

| 8 | 1.35 | 3.3 | 10.1 | 10.1 | 12.4 | 0.02 | 0.19 |

| 10 | 2.25 | 5.0 | 18.8 | 18.8 | 23.7 | 0.04 | 0.31 |

| 13 | 3.24 | 7.6 | 34.0 | 34.0 | 47.3 | 0.07 | 0.61 |

| 16 | 6.21 | 13.5 | 80.7 | 80.7 | 104.3 | 0.12 | 1.02 |

6The basic rated load is the same for the four directions that act on the block (radial direction, reverse radial direction, and lateral direction). It can be used in any position.

- The allowable load and moment of the linear guide are determined by dividing each value (table above) by the static safety factor fs (table below).For details>>Click

ex)Under nomal operating condition: Allowalble load for H10 Type(kN) ⇒ 5.0/2=2.5 ( Approximately 255kg)

Static Safety Factor(fs lower limit)

| Condition | fs lower limit |

|---|---|

| For nomal operating condtion | 1~2 |

| When smooth running performance is required | 2~4 |

| When variatoin and impact exist | 3~5 |

Allowable load (N)≦ Co/fs

Allowable Moment (N・m)≦ (MA, MB, MC)/fs

fs:Static Safety Factor Co: Basic Static Rated Load

MA, MB, MC: Allowable Static Moment(N・m)

■Datum Side and Mounting Direction

- Datum side has Datum Plane Mark(Groove), see FigureA. Blocks and Rails must have the same datum side when use.

- Various Mounting Direction is availalbe having the same Basic Rated Load, see Figure B

| (A) | (B) |

|  |

■Precaution of use

- Although the retaining wire prevents the balls from falling off, care must be taken when attaching and detaching the block. Click here for details>>click

- If the block and rail are not used in original combination, radial clearance and accuracy cannot be guaranteed.

- It is not possible to extend the length by adding rails on the same axis.This is because the assembly accuracy between the two cut surfaces is not guaranteed.

- Dimensional Accurarcy of Linear Guides is guranteed after fixation of the rail ( Screw Mounting and pushed to the datum side).

The rail bends before are forced by fixation. so there is no probelm in using it.

■About Grease

- When shipping ES Linear Guides, Lithium Soap Grease(Kyodo Yushi Multemp PS2) is filled.

Other Brand's Grease is not reccomended to be filled. Please adopt the same brand&s grease for maintenance. - Grease can be pasted to the rail directly. Please run the blocks back and forth to blend in after pasting.

| Advantages of Lubrication Unit "MX" Buit-in porous core part impregnated with oil. Achieves long-term maintenance-free operation. Reduce maintenance costs. Ideal for locations where lubrication is not possible due to design. See more detail>>Click |

■Others

- Lifetime calculation>>Click

Alterations

| Code | Alterations | Specification | Precaution | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MC (Free of Charge) | Conterbored Hole-> Tapped Hole | ・Change Rail Mounting hole from counterbored to Tapped Hole. !Tapped Hole Specification

| !This option can't be applied with length below. H8: L 131mm or more H10: L 276mm or more H13: 471 mm or more H16: 671mm or mor | ||||||||||

| LLC RLC | LLC:Left End Cut RLC:Right End Cut  | Cut Rail End ・Rail is cut with the prodcut ID facing side( datum on other side) ・Please see cut length of each size below.

| !Overall length wll be shorter by cutting. ex)ES-SSECB13-95-LLC: LL has 90mm. !Applicable to Standard Length type only !Not applicable to H8 |

Accessories

| Height ( H ) | Linear Guide Clamper | Miniature Linear Guide Height Adjusting Block | |||

|---|---|---|---|---|---|

| S45C Equivalent Electroless Nickel Plating | Aluminum Alloy Clear Anodized | ||||

| For Standard Rail | Datum Side | Free Side | Datum Side | Free Side | |

|  | ||||

| 8 | - | GETA8 | GETE8 | AGETA8 | AGETE8 |

| 10 | - | GETA10 | GETE10 | AGETA10 | AGETE10 |

| 13 | SECK13 | GETA13 | GETE13 | AGETA13 | AGETE13 |

| 16 | SECK16 | GETA16 | GETE16 | AGETA16 | AGETE16 |

| Clamping(Block Positioning) | Rail Fixation | ||||

| ■Rail Push Plate for Fixation | ||||

| Rail Height Adjuting | |||||

| ■Linear Lock | ||||

| Block fallout prevention | |||||

■Stopper Bolt | ■Linear Guide Lock | ||||

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| ES-SSECB8-[40,55,70,85,100,115,130,145,160,175,190,205,220,235,250,265,280,295,310] |

| ES-SSECB8G-[40,55,70,85,100,115,130,145,160,175,190,205,220,235,250,265,280,295,310] |

| ES-SSECB8L-[40,55,70,85,100,115,130,145,160,175,190,205,220,235,250,265,280,295,310] |

| ES-SSECB10-[55,75,85,95,100,115,130,135,155,175,195,215,235,255,275,295,315,335,355,375,395,415,435,455,475,495,515,535,555,575,595,615,635] |

| ES-SSECB10G-[55,75,95,115,135,155,175,195,215,235,255,275,295,315,335,355,375,395,415,435,455,475,495,515,535,555,575,595,615,635] |

| ES-SSECB10L-[55,75,95,115,135,155,175,195,215,235,255,275,295,315,335,355,375,395,415,435,455,475,495,515,535,555,575,595,615,635] |

| ES-SSECB13-[70,85,95,100,115,120,130,145,170,195,220,245,270,295,320,345,370,395,420,445,470,495,520,545,570,595,620,645,670,695,720,745,770,795,820,845,870,895,920,945,970] |

| ES-SSECB13G-[70,95,120,145,170,195,220,245,270,295,320,345,370,395,420,445,470,495,520,545,570,595,620,645,670,695,720,745,770,795,820,845,870,895,920,945,970] |

| ES-SSECB13L-[70,95,120,145,170,195,220,245,270,295,320,345,370,395,420,445,470,495,520,545,570,595,620,645,670,695,720,745,770,795,820,845,870,895,920,945,970] |

| ES-SSECB16-[110,150,190,230,270,310,350,390,430,470,510,550,590,630,670,710,750,790,830,870,910,950,990] |

| ES-SSECB16G-[110,150,190,230,270,310,350,390,430,470,510,550,590,630,670,710,750,790,830,870,910,950,990] |

| ES-SSECB16L-[110,150,190,230,270,310,350,390,430,470,510,550,590,630,670,710,750,790,830,870,910,950,990] |

| ES-SSECB-MX10-[55,75,95,115,135,155,175,195,215,235,255,275] |

| ES-SSECB-MX13-[70,95,120,145,170,195,220,245,270,295,320,345,370,395,420,445,470] |

| ES-SSECB-MX16-[110,150,190,230,270,310,350,390,430,470,510,550,590,630,670] |

| ES-SSECBL8-[41-309/1] |

| ES-SSECBL8G-[41-309/1] |

| ES-SSECBL8H |

| ES-SSECBL8L-[41-309/1] |

| ES-SSECBL10-[56-634/1] |

| ES-SSECBL10G-[56-634/1] |

| ES-SSECBL10L-[56-634/1] |

| ES-SSECBL13-[71-969/1] |

| ES-SSECBL13G-[71-969/1] |

| ES-SSECBL13L-[71-969/1] |

| ES-SSECBL16-[111-989/1] |

| ES-SSECBL16G-[111-989/1] |

| ES-SSECBL16H |

| ES-SSECBL16L-[111-989/1] |

| ES-SSECBL-MX10-[56-274/1] |

| ES-SSECBL-MX13-[71-469/1] |

| ES-SSECBL-MX16-[111-669/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Rail Length L (mm) | Rail Width W1 (mm) | Assembly Height H (mm) | Nominal Part Number | Preload | Accuracy Standards | Basic Load Rating: Dynamic Load (N) | Basic Load Rating: Static Load (N) | Allowable Static Moment MA (N⋅m) | Allowable Static Moment MB (N⋅m) | Allowable Static Moment MC (N⋅m) | Lubrication Type | L Dimension Type |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 4 Day(s) | 40 ~ 310 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Filled with Lithium soap based grease | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 40 ~ 310 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Low Dust Generation Grease (G Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 40 ~ 310 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Heat Resistant Grease (L Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 55 ~ 635 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Filled with Lithium soap based grease | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 55 ~ 635 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Low Dust Generation Grease (G Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 55 ~ 635 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Heat Resistant Grease (L Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 70 ~ 970 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Filled with Lithium soap based grease | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 70 ~ 970 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Low Dust Generation Grease (G Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 70 ~ 970 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Heat Resistant Grease (L Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 110 ~ 990 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Filled with Lithium soap based grease | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 110 ~ 990 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Low Dust Generation Grease (G Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 110 ~ 990 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Heat Resistant Grease (L Type) | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 55 ~ 275 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Lubrication Unit | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 70 ~ 470 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Lubrication Unit | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 110 ~ 670 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Lubrication Unit | Selectable Type | ||

- | 1 Piece(s) | 4 Day(s) | 41 ~ 309 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Filled with Lithium soap based grease | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 41 ~ 309 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Low Dust Generation Grease (G Type) | Configurable Type | ||

- | 1 Piece(s) | 8 Day(s) | - | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Grease for food sector (H Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 41 ~ 309 | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Heat Resistant Grease (L Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 56 ~ 634 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Filled with Lithium soap based grease | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 56 ~ 634 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Low Dust Generation Grease (G Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 56 ~ 634 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Heat Resistant Grease (L Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 71 ~ 969 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Filled with Lithium soap based grease | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 71 ~ 969 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Low Dust Generation Grease (G Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 71 ~ 969 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Heat Resistant Grease (L Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 111 ~ 989 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Filled with Lithium soap based grease | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 111 ~ 989 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Low Dust Generation Grease (G Type) | Configurable Type | ||

- | 1 Piece(s) | 8 Day(s) | - | 7 | 8 | 7 | [Light Preload] Light Preload | High Grade | 1350 | 3300 | 10.1 | 10.1 | 12.4 | Grease for food sector (H Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 111 ~ 989 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Heat Resistant Grease (L Type) | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 56 ~ 274 | 9 | 10 | 9 | [Light Preload] Light Preload | High Grade | 2250 | 5000 | 18.8 | 18.8 | 23.7 | Lubrication Unit | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 71 ~ 469 | 12 | 13 | 12 | [Light Preload] Light Preload | High Grade | 3240 | 7600 | 34.0 | 34 | 47.3 | Lubrication Unit | Configurable Type | ||

- | 1 Piece(s) | 4 Day(s) | 111 ~ 669 | 15 | 16 | 15 | [Light Preload] Light Preload | High Grade | 6210 | 13500 | 80.7 | 80.7 | 104.3 | Lubrication Unit | Configurable Type |

Loading...Tải…

G Dimension

[G] Dimension of Length Specifified Type requires calculation.Please refer to the below table and formula.

*[G] Dimension of Fixed Length: Please refer to the specification table. (no calculation required)

■ ES Miniature Linear Guide -Normal Rail Dimension-

| Assemble Height H | 6・8 | 10 | 13 | 16 | 20 | # of Mounting Holes M |

| Rail Legth L | 25~35 | 35~47 | 45~57 | 70~87 | 100~139 | 2 |

| 36~50 | 48~67 | 58~82 | 88~127 | 140~199 | 3 | |

| 51~65 | 68~87 | 83~107 | 128~167 | 200~259 | 4 | |

| 66~80 | 88~107 | 108~132 | 168~207 | 240~319 | 5 | |

| 81~95 | 108~127 | 133~157 | 208~247 | 320~379 | 6 | |

| 96~110 | 128~147 | 158~182 | 248~287 | 380~439 | 7 | |

| 111~125 | 148~167 | 183~207 | 288~327 | 440~499 | 8 | |

| 126~140 | 168~187 | 208~232 | 328~367 | 500~559 | 9 | |

| 141~155 | 188~207 | 233~257 | 368~407 | 560~619 | 10 | |

| 156~170 | 208~227 | 258~282 | 408~447 | 620~679 | 11 | |

| 171~185 | 228~247 | 283~307 | 448~487 | 680~739 | 12 | |

| 186~200 | 248~267 | 308~332 | 488~527 | 740~799 | 13 | |

| 201~215 | 268~287 | 333~357 | 528~567 | 800~859 | 14 | |

| 216~230 | 288~307 | 358~382 | 568~607 | 860~919 | 15 | |

| 231~245 | 308~327 | 383~407 | 608~647 | 920~979 | 16 | |

| 246~260 | 328~347 | 408~432 | 648~687 | 980~1000 | 17 | |

| 261~275 | 348~367 | 433~457 | 688~727 | - | 18 | |

| 276~290 | 368~387 | 458~482 | 728~767 | - | 19 | |

| 291~305 | 388~407 | 483~507 | 768~807 | - | 20 | |

| 306~310 | 408~427 | 508~532 | 808~847 | - | 21 | |

| - | 428~447 | 533~557 | 848~887 | - | 22 | |

| - | 448~467 | 558~582 | 888~927 | - | 23 | |

| - | 468~487 | 583~607 | 928~967 | - | 24 | |

| - | 488~507 | 608~632 | 968~990 | - | 25 | |

| - | 508~527 | 633~657 | - | - | 26 | |

| - | 528~547 | 658~682 | - | - | 27 | |

| - | 548~567 | 683~707 | - | - | 28 | |

| - | 568~587 | 708~732 | - | - | 29 | |

| - | 588~607 | 733~757 | - | - | 30 | |

| - | 608~627 | 758~782 | - | - | 31 | |

| - | 628~635 | 783~807 | - | - | 32 | |

| - | - | 808~832 | - | - | 33 | |

| - | - | 833~857 | - | - | 34 | |

| - | - | 858~882 | - | - | 35 | |

| - | - | 883~907 | - | - | 36 | |

| - | - | 908~932 | - | - | 37 | |

| - | - | 933~957 | - | - | 38 | |

| - | - | 958~970 | - | - | 39 | |

| F Pitch of Mounting Hole | 15 | 20 | 25 | 40 | 60 |

Grease Option

| Type | Grease | Feature |

| Standard | Alvania S2 (Made by Shell) | An industrial all-purpose grease suitable for a variety of grease lubrication locations. |

| Y | AFF (Made by THK) | A grease with low dust generation, stable rolling resistance, and excellent fretting resistance. |

| G | LG2 (Made by NSK) | A grease that generates little dust and has excellent wear resistance and rust prevention properties. (Special grease for linear guides, ball screws and etc. for clean-room use) |

| L | ET-100K (Made by Kyodo Yushi) | Excels in heat resistance, oxidation stability, adhesion and adhesive power. In addition, splash or leakage is little |

| H | FGL(Lubriplate®) | Suitable for lubrication of processing and filling equipment for food, beverages, and pharmaceuticals.(NSF H-1 registration NO.043534) |

Basic InformationThông tin cơ bản

| Block Type | Super Long Block w/o Dowel Hole | Rail Type | Standard Rail | Set / Single Item | Set |

|---|---|---|---|---|---|

| Material | Stainless Steel | Ball Arrangement | Miniature Type | No. of Blocks | 1 |

| Retainer | N/A | Lubrication Type | Lubrication Applied | Rolling Element | Ball |

| Surface Treatment | none | Block Material | Stainless Steel | Material-Ball | Stainless Steel |

| Material-Return Cap | POM | Material-Retaining Wire | Stainless Steel | Material-Side Seal | Stainless Steel+Nitril Rubber(NBR) |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

![ES Miniature Linear Guides - Extra Long Blocks (Light Preload / Slight Clearance) [RoHS Compliant]](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_main/v1/p/cn/product/series/110300043340/110300043340_20201112120648.jpg?$product_main$)

![ES Miniature Linear Guides - Extra Long Blocks (Light Preload / Slight Clearance) [RoHS Compliant]](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_thum/v1/p/cn/product/series/110300043340/110300043340_20201112120649.jpg?$product_thum$)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy