(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Hand Valves(Effective Sectional Area【classification】:~80)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

SMC

Hand Valve VH Series that allows the direction of flow to be confirmed with a glance. [Features]· The flow direction can be confirmed with just a glance at the direction of the handle.

Connecting Tube Diameter Number of Ports Switching Operation Effective Sectional Area(mm2) Main Body Shape Pipe Port Type Number of Switching Positions Plumbing Thread Nominal Plumbing Type and Direction Effective Sectional Area【classification】(mm2) How to Mount - 4-Port Manual Lever 70.11 ~ 79.34 Block Horizontal Type Rc (R) / NPT / G 3-Position Closed Center / 3-Position Exhaust Center / Others 3/8 / 1/2 Direct Side Surface ~80 Bottom / Panel Mounting Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Connecting Tube Diameter |

| Number of Ports |

| Switching Operation |

| Effective Sectional Area(mm2) |

| Main Body Shape |

| Pipe Port Type |

| Number of Switching Positions |

| Plumbing Thread Nominal |

| Plumbing Type and Direction |

| Effective Sectional Area【classification】(mm2) |

| How to Mount |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | SMC |

| Product SeriesDòng sản phẩm | |

| CADCAD |

|

| From | |

| Days to ShipSố ngày giao hàng | Same day or more |

| Connecting Tube Diameter | - |

| Number of Ports | 4-Port |

| Switching Operation | Manual Lever |

| Effective Sectional Area(mm2) | 70.11 ~ 79.34 |

| Main Body Shape | Block Horizontal Type |

| Pipe Port Type | Rc (R) / NPT / G |

| Number of Switching Positions | 3-Position Closed Center / 3-Position Exhaust Center / Others |

| Plumbing Thread Nominal | 3/8 / 1/2 |

| Plumbing Type and Direction | Direct Side Surface |

| Effective Sectional Area【classification】(mm2) | ~80 |

| How to Mount | Bottom / Panel Mounting |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Connecting Tube Diameter

- Ø4

- Ø6

- Ø8

- Ø10

- Ø12

- 1/4

- 5/16

- 3/8

- 1/2

-

Number of Ports

- 2-Port

- 3-Port

- 4-Port

- Others

-

Switching Operation

- Manual Lever

- Knob

- Others

-

Effective Sectional Area(mm2)

- 1.48

- 1.84

- 2.5

- 2.58

- 3.14

- 3.4

- 3.5

- 3.8

- 3.87

- 4

- 5.0

- 5.35

- 5.5

- 6.0

- 6.46

- 6.64

- 6.83

- 7.0

- 7.2

- 7.5

- 7.7

- 8

- 8.1

- 8.2

- 8.3

- 8.4

- 8.5

- 8.6

- 8.67

- 8.7

- 8.8

- 8.9

- 9

- 9.5

- 10.15

- 10.3

- 10.33

- 10.5

- 11

- 11.25

- 11.5

- 11.99

- 12

- 12.18

- 12.5

- 12.55

- 12.92

- 13

- 13.10

- 14.39

- 15.4

- 15.6

- 15.68

- 15.7

- 15.8

- 16

- 16.1

- 16.2

- 16.3

- 16.5

- 16.6

- 16.8

- 16.9

- 17

- 17.1

- 17.4

- 17.5

- 18

- 18.1

- 18.5

- 20

- 20.30

- 20.5

- 22

- 22.99

- 23

- 23.06

- 23.98

- 24

- 24.5

- 26

- 27.67

- 30

- 33

- 35.5

- 36

- 38.19

- 39

- 39.5

- 40

- 41

- 44

- 45.5

- 46

- 47

- 49

- 51.5

- 53.50

- 54

- 55

- 55.5

- 57.20

- 60

- 62.11

- 62.73

- 64.58

- 68.26

- 70.11

- 79.34

- 83.02

- 88

- 95

- 101.41

- 114

- 118

- 140

- 258.30

- 276.75

-

Main Body Shape

- Block Horizontal Type

- One-Touch Fitting Type

- Pin Shape

- Others

-

Pipe Port Type

- M

- Rc (R)

- NPT

- G

- One-Touch Plumbing

- Others

-

Number of Switching Positions

- 2-Position Normally Open

- 2-Position Normally Closed

- 2-Position Exhaust

- 3-Position Closed Center

- 3-Position Exhaust Center

- Selecting Valve

- 2-Position Direction Switching

- Others

-

Plumbing Thread Nominal

- M5

- 1/8

- 1/4

- 3/8

- 1/2

- 3/4

- 1

-

Plumbing Type and Direction

- Direct Side Surface

- Direct Bottom Surface

- Others

-

Effective Sectional Area【classification】(mm2)

* ~10 represents over 5, and 10 or less.

-

How to Mount

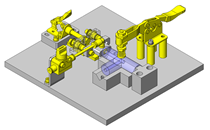

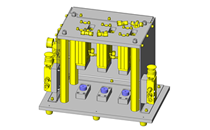

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to Hand ValvesDanh mục liên quan đến Hand Valves

FAQ Hand Valves

- Question: What is a hand valve and its functions?

- Answer: A hand valve is a manually operated device used to control the flow of fluid (liquids or gases) in a system. It consists of a handle or lever that, when turned, adjusts the position of an internal mechanism to either open or close the valve. Hand valves serve to regulate fluid flow, isolate sections of a pipeline for maintenance, and control pressure. They find application in various industries such as plumbing and industrial processes.

- Question: When should you use the hand valve?

- Answer: Use a hand valve when manual control of fluid flow is necessary. It's employed to start, stop, or adjust flow rates in systems requiring human intervention, such as emergencies, maintenance, or precise adjustments. Hand valves are useful when automation isn't feasible, during equipment servicing, or when immediate response to changes is needed. They offer a simple and reliable means of flow regulation in various industries.

- Question: What are the advantages and disadvatages of hand valves / manual valves?

- Answer: Advantages of hand valves (manual valves) include simplicity, reliability, and cost-effectiveness. They offer precise control and immediate response during emergencies or maintenance, making them suitable for small-scale applications. However, they can be slower to operate compared to automated valves, require physical presence for adjustments, and might not be suitable for large-scale or continuous processes. Additionally, potential human error in operation and limited remote control are notable disadvantages.

- Question: What are the common materials used for valves?

- Answer: Hand valves are commonly constructed from materials such as brass, stainless steel, cast iron, bronze, and plastic (such as PVC or CPVC). The choice of material depends on factors like the type of fluid being handled, pressure requirements, temperature conditions, and corrosion resistance. These materials ensure durability and compatibility with various applications across industries like plumbing, industrial processes, and water treatment.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy