(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Cartridge Heaters(Length L (Range):57.2~69.8)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

SAKAGUCHI

A cartridge heater from the US company WATLOW. Maximum operating temperature of 760°C. A wide range of heater diameters are available, from 1/8 inch (3.1 mm) to 3/4 inch (18.95 mm).[Features]· Carefully selected heating wires, insulation materials, and sheath materials are arranged using a unique method to minimize temperature differences between the heating element and sheath surface.· A heater with high watt density and excellent thermal efficiency.· Operating temperature of 760° CMAX.· Mechanically and thermally robust for a long service life.· Fast delivery with more than 500 types in stock.· Custom order items can also be delivered in a short time.· Support for UL/CSA/CE standards can be provided upon request.

Maximum Operating Temperature(°C) Rated Voltage(V) Diameter D (Range)(Ø) Length L (Range)(mm) Rated Capacity (Range)(W) Product Category 760 110~120 ~ 220~ ~8 ~ 8.1~9.9 57.2~69.8 ~99 ~ 300~999 Heaters From: 1,708,532 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Maximum Operating Temperature(°C) |

| Rated Voltage(V) |

| Diameter D (Range)(Ø) |

| Length L (Range)(mm) |

| Rated Capacity (Range)(W) |

| Product Category |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | SAKAGUCHI |

| Product SeriesDòng sản phẩm | |

| From | 1,708,532 VND |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more |

| Maximum Operating Temperature(°C) | 760 |

| Rated Voltage(V) | 110~120 ~ 220~ |

| Diameter D (Range)(Ø) | ~8 ~ 8.1~9.9 |

| Length L (Range)(mm) | 57.2~69.8 |

| Rated Capacity (Range)(W) | ~99 ~ 300~999 |

| Product Category | Heaters |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Maximum Operating Temperature(°C)

-

Rated Voltage(V)

-

Diameter D (Range)(Ø)

-

Length L (Range)(mm)

-

Rated Capacity (Range)(W)

-

Product Category

- Heaters

- Mounting Components

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to Cartridge HeatersDanh mục liên quan đến Cartridge Heaters

FAQ Cartridge Heaters

- Question: What is a cartridge heater and what are its general properties?

- Answer: A cartridge heater is a type of heating element commonly used in industries such as plastic molding, packaging, and sealing. It finds application in heating solids, liquids, and gases. the structure of a cartridge heater consists of a cylindrical metal tube, which is made of stainless steel, with an electrical resistance wire wound inside. The resistance wire generates heat when an electric current passes through it.

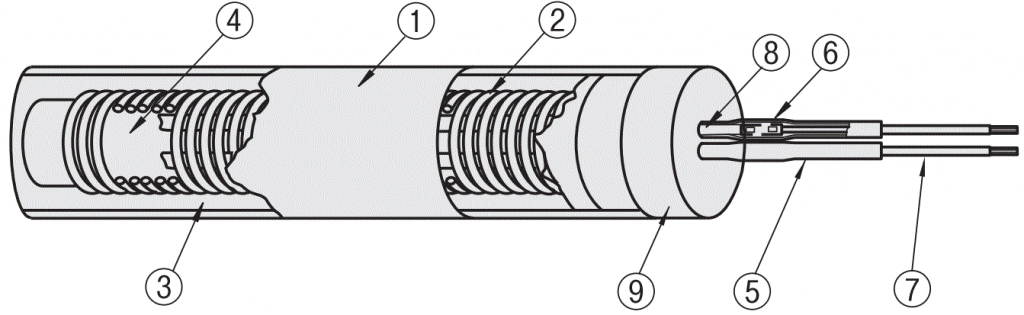

- Question: What is the structure of a cartridge heater?

- Answer: Essential component in catride heater consist of

1. Stainless steel sheath (Incoloy for High Temperature Type)

2. Heating Coil (Nickel-chrome Wire)

3. Insulation Powder (Magnesium Oxide)

4. Ceramic Core

5. Silicon (Insulation) Tube

6. Crimp Terminal

7. Lead Wire Sheath

8. Nickel Pin

9. Insulator

- Question: What are the benefits of using a cartridge heater?

- Answer: The benefits of using a cartridge heater

1. High Heating Efficiency

2. Precise Temperature Control: especially important in scientific and laboratory equipment.

3. Compact and Space-Saving: Cartridge heaters are compact and can be easily installed into equipment or systems with limited space.

4. Durability and Longevity:

5. Versatility and Customization such as diameter, length, wattage, voltage, lead wire configuration, and termination options.

6. Fast Response Time This attribute is beneficial in applications where frequent heating and cooling cycles.

7. Easy Installation and Maintenance: easy to install, often inserted into a hole or mounted using various clamping mechanisms. Their simple design and accessibility facilitate maintenance and replacement when needed.

8. Cost-Effective Solution: They minimize energy consumption, reduce downtime associated with heating processes, and require less frequent replacement compared to some other heating methods. - Question: How is a cartridge heater typically used in industrial applications?

- Answer: Cartridge heaters are typical uses in a variety of industrial applications such as

1. Plastic Molding: They are inserted into the mold to heat and maintain the desired temperature of the mold cavity

2. Packaging and Sealing: The cartridge heaters are used to heat sealing bars, platens, or dies. for sealing and bonding of materials like plastic films, laminates etc.

3. Hot Runner Systems: Cartridge heaters are an integral part of hot runner systems in injection molding.

4. Food Processing: Cartridge heaters are maintaining consistent temperatures in ovens, grills, fryers, and cooking equipment.

5. Heat Treatment: Cartridge heaters are utilized in heat treatment processes like annealing, tempering, or stress relieving of metal parts.

6. Medical Equipment: Such as sterilization chambers, incubators, and laboratory instruments. - Question: What are some common industries or applications that make use of cartridge heaters?

- Answer: Cartridge heaters are common uses in a variety of industrial applications such as

1. Plastic Molding: for example plastic injection mold

2. Packaging and Sealing: for example heat sealing bars, platens, or dies

3. Food Processing: for example in ovens, grills, fryers, and cooking equipment.

4. Heat Treatment: for example in heat treatment processes like annealing, tempering, or stress relieving of metal parts.

5. Medical Equipment: for example sterilization chambers, incubators, and laboratory instruments.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy