(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

MISUMI Photomicrosensors(Shape:Type T)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

Recommended

You can add up to 6 items per a category to the compare list.

MiSUMi Economy

MiSUMi EconomyPhoto Microsensors, Cable Length 2M

MiSUMi EconomyMISUMI

- Volume Discount

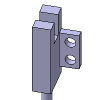

Shape Slit Width(mm) Max. Head Size Width W(mm) Max. Head Size Height H(mm) Max. Head Size Length L(mm) Type T 5 26 14 26.2 From: 87,783 VND Days to Ship: Số ngày giao hàng: Same day  Same day

Same day

-

Economy series

You can add up to 6 items per a category to the compare list.

MiSUMi Economy

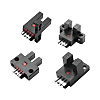

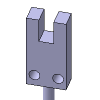

MiSUMi EconomyPhoto Microsensors, Connector Type

MiSUMi EconomyMISUMI

Photo Microsensors, Connector TypePhotomicrosensors are an economy item, The price is cheaper than the MISUMI standard product. They offer a wide variety of shape to choose from.[Feature]● Shape : Standard, L type, T type and Y type● Detection Distance (mm.): 5● Sensing modess : NPN Output (Normally Open) and PNP Output (Normally Open)● Connection method : Connector type[Application]Photomicrosensors are a versatile type of sensor that can be used to measure speed, count objects, and more.

- Volume Discount

Shape Slit Width(mm) Max. Head Size Width W(mm) Max. Head Size Height H(mm) Max. Head Size Length L(mm) Type T 5 13.7 26 22.2 From: 75,363 VND Days to Ship: Số ngày giao hàng: Same day  Same day

Same day

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Shape |

| Slit Width(mm) |

| Max. Head Size Width W(mm) |

| Max. Head Size Height H(mm) |

| Max. Head Size Length L(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | MISUMI |

| Product SeriesDòng sản phẩm | ||

| CADCAD |

|

|

| From | 87,783 VND- | 75,363 VND- |

| Days to ShipSố ngày giao hàng | Same day | Same day |

| Shape | Type T | Type T |

| Slit Width(mm) | 5 | 5 |

| Max. Head Size Width W(mm) | 26 | 13.7 |

| Max. Head Size Height H(mm) | 14 | 26 |

| Max. Head Size Length L(mm) | 26.2 | 22.2 |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Shape

-

Type K

-

Type T

-

Type Y

-

Type L

-

Type F

-

Type R

-

Type U

-

Portrait

-

Landscape

-

Optical Fiber

-

Solid Installation

-

Pipe Fitting

-

Type K

-

Slit Width(mm)

-

Max. Head Size Width W(mm)

-

Max. Head Size Height H(mm)

-

Max. Head Size Length L(mm)

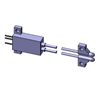

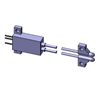

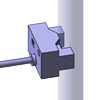

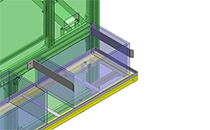

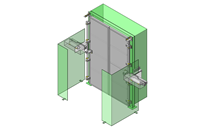

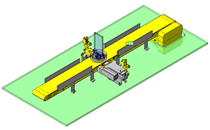

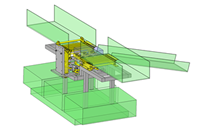

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to PhotomicrosensorsDanh mục liên quan đến Photomicrosensors

FAQ Photomicrosensors

- Question: How do I choose the right Photomicrosensor for my machine, considering specifications like Shape, Slit Width, and Maximum Head Size Dimensions (W x H x L)?

- Answer: Here's a step-by-step guide to choose the right Photomicrosensor for your machine.

1.Understand the Application Requirements: For example, the type of objects or materials being detected, the distance between the sensor and the object, and any environmental conditions that may affect the sensor's performance.

2. Sensor Shape :Photo microsensors come in various shapes, such as rectangular, U-shape, R-shape, and more . Choose a shape that fits the physical constraints of your machine and the installation area.

3. Slit Width : The slit width determines the size of the opening through which the sensor detects objects. Select a slit width that is appropriate for the size of the object you need to detect.

4. Dimensions (W x H x L) :Consider the available space in your machine for sensor installation. Measure the space where the sensor will be mounted and ensure that the chosen sensor's maximum head size dimensions fit within these constraints

5. Detection Range : Evaluate the detection range of the sensor. It should be compatible with the distance at which objects need to be detected in your machine.

6.Operating voltage: Photomicrosensors operate at different voltages. Choose a sensor that is compatible with the power supply on your machine.

7. Output Type: Determine what type of output signal your machine's control system can accept and interface with. Photomicrosensors typically offer outputs such as NPN of PNP.

8. Operating Environment: Some sensors are designed for harsh environments and can withstand factors like dust, humidity, and temperature fluctuations. Ensure the selected sensor is suitable for your machine's operating conditions. - Question: How can I ensure the Photomicrosensors are compatible with my machine, and are there specific applications or industries where these sensors are particularly advantageous?

- Answer: 1. Understand Your Machine's Requirements: Begin by thoroughly understanding your machine's specific needs, including the detection distance, object characteristics, and environmental conditions.

2. Technical Specifications: Match the Photomicrosensor’s technical specifications to your machine's requirements. Check the sensor's shape, slit width, size, and output type (e.g., NPN, PNP) to ensure they align with your machine's design and space constraints.

3. Detection Range: Ensure the sensor's detection range covers the required distance for object detection within your machine.

Advantageous Applications and Industries:

4. Environmental Conditions: Verify that the sensor can operate reliably in the environmental conditions within your machine. Consider factors like temperature, humidity and dust.

Photomicrosensors find applications and provide advantages in several industries:

1. Packaging: They are crucial for detecting package presence, product counting, and label positioning in packaging machinery.

2. Pharmaceuticals: Ensuring precise filling, sorting, and quality control in pharmaceutical manufacturing.

3. Textiles: Used for thread break detection and fabric positioning in textile machinery.

4. Food and Beverage: Valuable in monitoring fill levels, cap presence, and label detection in food and beverage processing and packaging. - Question: How can I optimize the utilization of Photomicrosensors in various applications, and are there guidelines available for maximizing their efficiency and lifespan?

- Answer: Optimizing Utilization:

1. Choose the Right Sensor Type: Select the appropriate Photomicrosensor type based on your application's requirements, such as detection range, object characteristics, and environmental conditions.

2. Position Sensors Thoughtfully: Ensure precise and stable sensor positioning for accurate object detection.

3. Regular Maintenance: Establish a maintenance schedule for cleaning and inspecting sensors. Dust or dirt on the emitter or receiver can affect performance.

4. Calibration: Periodically calibrate the sensors to maintain accuracy, especially in critical applications where precise detection is crucial.

5. Comprehensive Testing: Conduct thorough testing to verify that the sensors are performing as expected. Test under various operating conditions to account for potential variations.

Maximizing Efficiency and Lifespan:

1. Proper Voltage and Power Supply: Ensure the sensors receive the correct voltage and power supply as specified by the manufacturer. Using the recommended power source prevents damage and extends sensor lifespan.

2. Light Source Maintenance: If the Photomicrosensor employs a separate light source (e.g., LED), replace it according to the manufacturer's guidelines to maintain consistent performance.

3. Cable Connections: Periodically inspect cable connections to ensure they are secure. Loose connections can result in intermittent operation or sensor failure.

4. Prevent Overexposure: Protect the sensor from direct exposure to intense light sources or reflections that could damage the receiver. This is especially critical in applications with high levels of ambient light.

5. Grounding and EMI/RFI Protection: Proper grounding helps prevent electrical interference. Use shielded cables to guard against electromagnetic interference (EMI) and radio-frequency interference (RFI).

6. Adhere to Manufacturer Guidelines: Follow the manufacturer's recommendations for installation, maintenance, and troubleshooting. They often provide specific guidelines to maximize sensor lifespan.

7. Scheduled Replacement: Recognize that sensors may degrade over time due to continuous use. Consider implementing a schedule for periodic sensor replacement to prevent unexpected failures. - Question: What should I do if I encounter compatibility issues with the Photomicrosensors and my machine?

- Answer: If you encounter compatibility issues with Photomicrosensors and your machine, follow these steps:

1. Review Specifications: Double-check the technical specifications of both the sensors and your machine to identify any discrepancies or incompatibilities.

2. Troubleshooting: Systematically troubleshoot the issue by testing individual components, such as cables, power supplies, and sensors, to isolate the source of the problem.

3. Adjust Sensor Positioning: Ensure the sensors are positioned correctly and that there are no obstructions or reflections interfering with their operation.

4. Environmental Factors: Examine the operating environment for potential issues like excessive ambient light, dust, or temperature extremes. Make necessary adjustments or install protective measures.

5. Check Power Supply: Verify that the sensor is receiving the correct voltage and power supply as per its specifications.

6. Cable Connections: Inspect cable connections for secure and proper wiring. Loose or damaged connections can lead to compatibility problems.

7. Interference: Check for electromagnetic interference (EMI) or radio-frequency interference (RFI) that might affect the sensors.

8. Consult the Manufacturer: Reach out to the sensor manufacturer's technical support for assistance. They can provide specific guidance and solutions for compatibility issues.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy