(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

MISUMI Locating Pins(Surface Treatment:Hard Chrome Plating Page3)

|

Basic Shape

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

91 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

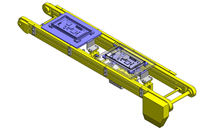

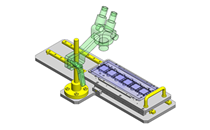

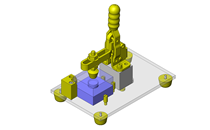

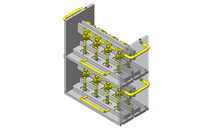

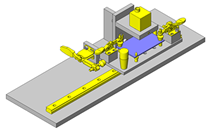

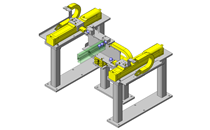

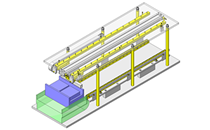

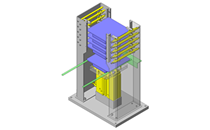

Locating Pins - Shouldered (Tapered - Shoulder Thickness Configurable-Tapped)

MISUMI

- Locating Pins - Shouldered (Tapered - Shoulder Thickness Configurable-Tapped) from MISUMI. - Insertion guide tip shape can be selected 2 types, round, and diamond. - SUS440C or 13Cr stainless has an identification groove on D part. - A machining step remains on the shoulder top for Diamond Shape. - SUS304 may not be polished and may have no centering hole. - The material of pin can be selected 3 types, steel SKS3 Equivalent, stainless steel SUS304, SUS440C or 13Cr stainless.

Basic Shape Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Shouldered Round / Diamond Tapered Not Provided Tapped Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 3 ~ 20 0/-0.01 5 ~ 20 g6 Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Basic Shape |

| Insertion Guide Tip Shape |

| Insertion Guide Tip Type |

| Insertion Guide Specifications |

| Mounting Side Shape |

| Surface Treatment |

| Heat Treatment |

| Material |

| Insertion Guide Outer Dia. D1(mm) |

| Insertion Guide Tolerance |

| Mounting Side Outer Dia. d(mm) |

| Mounting Side Tolerance |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI |

| Product SeriesDòng sản phẩm | Locating Pins - Shouldered (Tapered - Shoulder Thickness Configurable-Tapped) |

| CADCAD |

|

| From | - |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more |

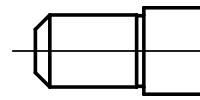

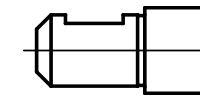

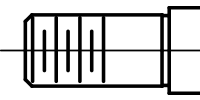

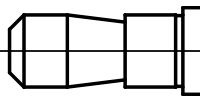

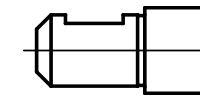

| Basic Shape | Shouldered |

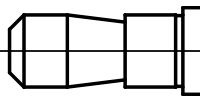

| Insertion Guide Tip Shape | Round / Diamond |

| Insertion Guide Tip Type | Tapered |

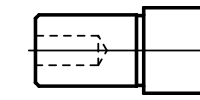

| Insertion Guide Specifications | Not Provided |

| Mounting Side Shape | Tapped |

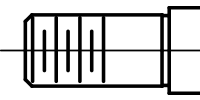

| Surface Treatment | Hard Chrome Plating |

| Heat Treatment | Not Provided / Directly Quenching |

| Material | Steel / Stainless Steel |

| Insertion Guide Outer Dia. D1(mm) | 3 ~ 20 |

| Insertion Guide Tolerance | 0/-0.01 |

| Mounting Side Outer Dia. d(mm) | 5 ~ 20 |

| Mounting Side Tolerance | g6 |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

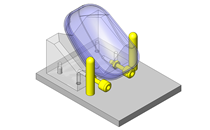

Insertion Guide Tip Shape

-

Round

Round -

Diamond

Diamond -

Square Head

Square Head -

Triangle

Triangle

-

-

Insertion Guide Tip Type

-

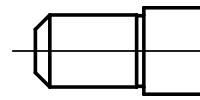

Tapered

Tapered -

Round Tapered

Round Tapered -

Taper R

Taper R -

R

R -

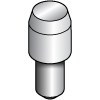

Spherical

Spherical -

Flat

Flat -

Ball End

Ball End -

Bullet Nose

Bullet Nose

-

-

Insertion Guide Specifications

-

Not Provided

Not Provided -

With Screw Mount Hole

With Screw Mount Hole -

With Hex Socket

With Hex Socket -

With Flathead Slot

With Flathead Slot -

Tapped

Tapped

-

-

Mounting Side Shape

-

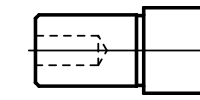

Straight (Press-Fit)

Straight (Press-Fit) -

Tapped

Tapped -

Threaded

Threaded -

Circumference Groove

Circumference Groove -

Notch

Notch -

Set Screw Flat

Set Screw Flat

-

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

- Hard Chrome Plating

- Buffed

- Hard Chrome Plating + Buffed

- Anodize

- Polishing

- Isonite Treatment

-

Heat Treatment

- Not Provided

- Carburized

- Directly Quenching

- Surface Ionitrided

-

Material

- Steel

- Stainless Steel

- Resin

- Aluminum

-

Insertion Guide Outer Dia. D1(mm)

[3-30/0.1mm Unit(s)][1-35/0.01mm Unit(s)]

-

Insertion Guide Tolerance

-

Mounting Side Outer Dia. d(mm)

- 1

- 2

- 3

- 4

- 5

- 6

- 6S

- 6T

- 7

- 8

- 8S

- 8T

- 10

- 10S

- 10T

- 12

- 12S

- 12T

- 13

- 13T

- 13.9

- 14

- 15

- 15.9

- 16

- 16S

- 16T

- 18

- 19

- 19.9

- 20

- 20T

- 22

- 24

- 25

- 30

- 32

- 38

- 39

- 40

- 50

- 56

-

Mounting Side Tolerance

Related Categories to Locating PinsDanh mục liên quan đến Locating Pins

FAQ Locating Pins

- Question: What are locating pins?

- Answer: Locating pins are essential components used in factory automation to achieve precise alignment and positioning of workpieces during assembly and machining processes. These pins are inserted into precision holes or bushings to establish accurate alignment and prevent movement or misalignment of parts.

- Question: What are the main benefits of using locating pins?

- Answer: The use of locating pins offers several benefits in factory automation. They ensure accurate and repeatable positioning, improving the overall quality and consistency of assembled products. Locating pins also enhance productivity by reducing assembly time and minimizing errors. They provide stability and prevent movement or shifting of components, resulting in better alignment and fit. Additionally, locating pins help to maintain proper tolerances and ensure efficient machining processes.

- Question: What are the different types of locating pins?

- Answer: There are various types of locating pins, including dowel locating pins and conical locating pins. Dowel locating pins have a cylindrical shape and are commonly used for precise alignment in fixtures. Conical locating pins feature a tapered design, allowing for self-centering and enhanced stability.

- Question: What materials are locating pins made from?

- Answer: Locating pins are typically made from durable and corrosion-resistant materials such as hardened steel, stainless steel, or tungsten carbide. The choice of material depends on the specific application requirements, including load capacity, environmental conditions, and desired longevity.

- Question: How do I install and use locating pins effectively?

- Answer: To install locating pins, align the pin with the pre-drilled hole or bushing and gently insert it until it is securely in place. Ensure that the pin fits snugly and does not protrude excessively. When using locating pins, it is essential to follow the design specifications and guidelines provided by the manufacturer. Proper maintenance, including periodic cleaning and lubrication, can also help ensure optimal performance and longevity of locating pins.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy