(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Belt Width Used

Number of Teeth

Pulley Shape

Material

Shaft Bore Dia. d

Number of Teeth

type

CAD

Days to Ship

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Belt Width Used(mm)

-

Number of Teeth(T)

-

Pulley Shape

- Shape E

- Shape F

-

Material

- Aluminum

- Aluminum

-

Shaft Bore Dia. d(mm)

-

Number of Teeth

-

type

- E-HHAA□□S5M

- E-HHTA□□S5M

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 9 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Timing Pulleys Keyless/High Torque/S5M/With Standard Keyless Bushing (Part Number)

- Until 31/12/2024

- Volume Discount

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Filter By :

- All

- Sale Items

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Overview

Usually, timing pulleys and timing belts are widely used to design mechanisms for transmitting rotational power generated by motors.

Driving and transmission are realized through the engagement between the teeth of timing pulleys and timing belts.

Driving and transmission are realized through the engagement between the teeth of timing pulleys and timing belts.

Dimensional Drawing

There may be no surface treatment in the shaft bore.

There may be no surface treatment in the shaft bore. Values in ( ) for dimension Y apply to Shaft Bore Dia. 12 or more.

Values in ( ) for dimension Y apply to Shaft Bore Dia. 12 or more. The flange is riveted.

The flange is riveted.Specifications Overview

| Part Number |  Material Material |  Surface Treatment Surface Treatment | ||||||

| Belt Width 10mm | Belt Width 15mm | Belt Width 25mm | Pulley | Flange | Kyless Bushing | Pulley | Flange | Kyless Bushing |

| A: 11 W: 16 | A: 17 W: 22 Y: 14 | A: 27 W: 32 Y: 14(22・23.5) | ||||||

| E-HHAA□□S5M100 | E-HHAA□□S5M150 | E-HHAA□□S5M250 | Aluminum Alloy 2024 | Aluminum Alloy 5056 | A2014 | Clear Anodized | ||

| E-HHTA□□S5M100 | E-HHTA□□S5M150 | E-HHTA□□S5M250 | Aluminum Alloy 7A09 | Aluminum Alloy 5056 | Equivalent to S45C | Clear Anodized | - | |

Film hardness of hard clear anodize is 300HV~.

Film hardness of hard clear anodize is 300HV~. If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating on other pages.

If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating on other pages.Specification Table

| Part Number |  Pulley PulleyShape |  dH7 range (select Shaft Bore Dia. according to Table 1) dH7 range (select Shaft Bore Dia. according to Table 1) | P.D. | O.D. | F | E | ||||||||

| E-HHAA | E-HHTA | |||||||||||||

Type Type |  Number of Teeth Number of Teeth |  Type & Nominal Width Type & Nominal Width | S5M100 | S5M150 | S5M100 | S5M150 | S5M250 | |||||||

| Shape E | Shape F | Shape E | Shape E | Shape F | Shape E | Shape F | ||||||||

| E-HHAA E-HHTA | 20 | S5M100 *A:11 *W:16 S5M150 *A:17 *W:22 *Y:14 S5M250 *A:27 *W:32 *Y:14 (d12~22:Y=22) (d24~:Y=23.5) | E F | 6 | - | - | - | - | - | - | 31.83 | 30.87 | 36 | 24 |

| 22 | 8 | - | - | - | - | - | - | 35.01 | 34.05 | 40 | 27 | |||

| 24 | 8・10 | - | 8 | 8 | 8 | 8 | 8 | 38.2 | 37.24 | 45 | 30 | |||

| 25 | 8・10 | - | 8 | 8 | 8 | 8 | 8 | 39.79 | 38.83 | |||||

| 26 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 41.38 | 40.42 | 48 | 35 | |||

| 28 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 8・10 | 44.56 | 43.6 | |||||

| 30 | 10・12 | 10・12 | 10 | 10 | 10 | 10 | 10 | 47.75 | 46.79 | 52 | 36 | |||

| 32 | 10~15 | 10~15 | 10~14 | 10~14 | 10 | 10~14 | 10~14 | 50.93 | 49.97 | 55 | 40 | |||

| 34 | 10~16 | 10~16 | 10~14 | 10~16 | 10 | 10~16 | 10~16 | 54.11 | 53.15 | 61 | 45 | |||

| 36 | 10~16 | 10~16 | 10~14 | 10~16 | 10 | 10~16 | 10~16 | 57.3 | 56.34 | |||||

| 40 | 10~16 | 10~16 | 10~14 | 10~19 | 10 | 10~19 | 10~19 | 63.66 | 62.7 | 67 | 50 | |||

| 44 | - | - | 12~14 | 12~22 | - | 12~22 | 12~22 | 70.03 | 69.07 | 74 | 58 | |||

| 48 | 12~14 | 12~22 | 12~24 | 12~24 | 76.39 | 75.43 | 83 | 63 | ||||||

| 50 | 12~14 | 12~22 | 12~28 | 12~28 | 79.58 | 78.62 | 87 | 67 | ||||||

| 60 | 12~14 | 12~22 | 12~30 | 12~30 | 95.49 | 94.53 | 99 | 80 | ||||||

| 72 | 12~14 | 12~22 | 12~35 | 12~30 | 114.59 | 113.63 | 119 | 100 | ||||||

Select Shaft Bore Dia. according to Table 1.

Select Shaft Bore Dia. according to Table 1. Refer to Table 1 for the performance of aluminum alloy keyless bushing and

Refer to Table 1 for the performance of aluminum alloy keyless bushing and  Details of Keyless Bushing for that of S45C equivalent keyless bushing.

Details of Keyless Bushing for that of S45C equivalent keyless bushing.■Table 1: Shaft Bore Dia. Selection

| dH7 | E-HHAA | E-HHTA | D1 | (L) | ||||

| Allowable max. torque (N・m) | D2 | B | G | n | Allowable max. torque (N・m) | |||

| 6 | 4 | 17 | 4 | 20 | 0.5 | - | - | - |

| 8 | 6 | 19 | 5 | 22 | 0.5 | 19.6 | 23.5 | 6 |

| 10 | 8 | 21 | 5 | 24 | 0.5 | 27.5 | 25.5 | |

| 12 | 12 | 24 | 6 | 27 | 1 | 44.1 | 28.5 | 6.5 |

| 14 | 18 | 26 | 6 | 29 | 1 | 63.7 | 30.5 | |

| 15 | 25 | 28 | 7 | 31 | 1.2 | 80.4 | 31.5 | |

| 16 | 26 | 29 | 7 | 32 | 1.2 | 83.3 | 33 | |

| 17 | - | - | - | - | - | 92.2 | 33.5 | |

| 18 | 95.1 | 34.5 | ||||||

| 19 | 98.1 | 35.5 | ||||||

| 20 | 216 | 42 | 8 | |||||

| 22 | 255 | 44 | ||||||

| 24 | 363 | 46 | ||||||

| 25 | 392 | 47 | ||||||

| 28 | 441 | 50 | 8.5 | |||||

| 30 | 500 | 52 | ||||||

| 32 | 530 | 54 | ||||||

| 35 | 883 | 62 | 10 | |||||

Product Features

Features of MISUMI Keyless Timing Pulleys

Feature 1: Keyless timing pulleys require no keyway machining, and round shaft and round hole can be used directly.

Urgent design changes can be made due to the reduction of cutting and machining time.

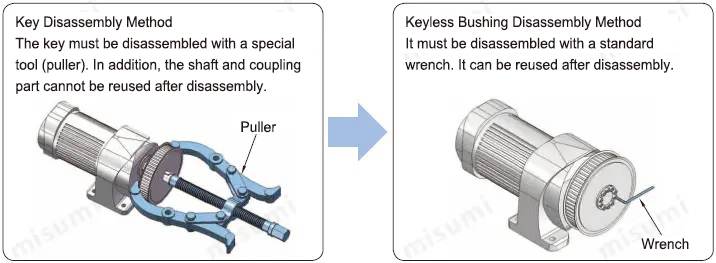

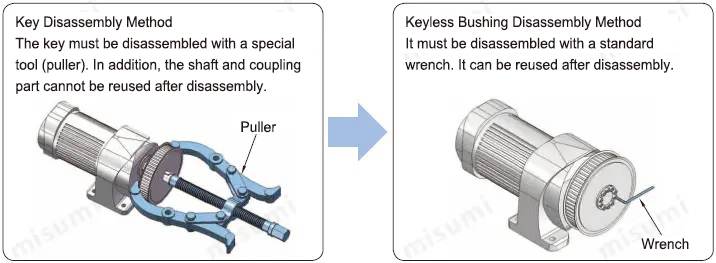

Feature 2: Keyless timing pulleys are connected with bolts only, allowing for easy installation and removal.

Equipment maintenance can be easily carried out without using a special tool. Parts are reusable, effectively reducing the cost.

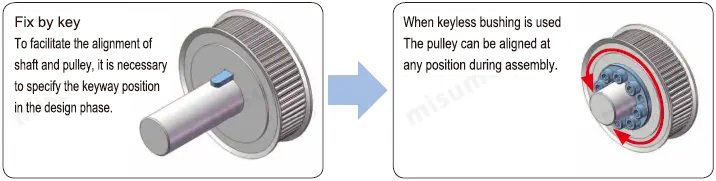

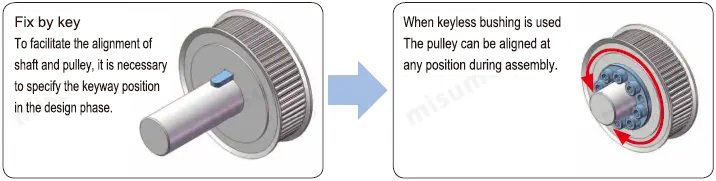

Feature 3: Keyless timing pulleys enable free alignment at any position during assembly.

Alignment control is possible during assembly, thus eliminating the need to align the key and tooth in the design phase.

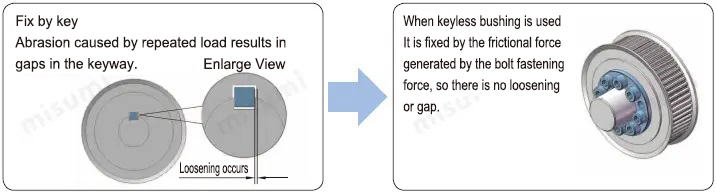

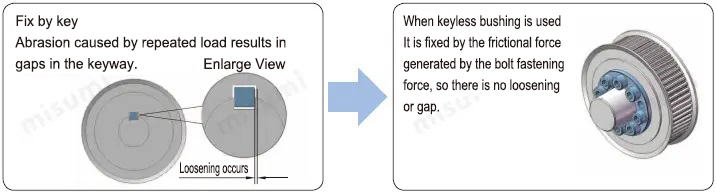

Feature 4: Keyless timing pulleys have no loosening. When a key is used, the keyway becomes loose, but there is no gap in the keyless bushing. It is therefore suitable for places where there are repeated forward and reverse rotations.

Long-term high coaxiality connection can be achieved. Suitable for servo motors and other places where there are repeated forward and reverse rotations.

Feature 5: A notch is provided in the shoulder of the inner pulley to allow the inner bushing to be crimped against the bore of the coupling part by tightening the lock bolt.

This enables positive control of the runout of the coupling end face and outer diameter, thus delivering a good centering effect.

When the lock bolt is tightened, there is no axial movement of the pulley bore, and the product has no backlash.

Feature 1: Keyless timing pulleys require no keyway machining, and round shaft and round hole can be used directly.

Urgent design changes can be made due to the reduction of cutting and machining time.

Feature 2: Keyless timing pulleys are connected with bolts only, allowing for easy installation and removal.

Equipment maintenance can be easily carried out without using a special tool. Parts are reusable, effectively reducing the cost.

Feature 3: Keyless timing pulleys enable free alignment at any position during assembly.

Alignment control is possible during assembly, thus eliminating the need to align the key and tooth in the design phase.

Feature 4: Keyless timing pulleys have no loosening. When a key is used, the keyway becomes loose, but there is no gap in the keyless bushing. It is therefore suitable for places where there are repeated forward and reverse rotations.

Long-term high coaxiality connection can be achieved. Suitable for servo motors and other places where there are repeated forward and reverse rotations.

Feature 5: A notch is provided in the shoulder of the inner pulley to allow the inner bushing to be crimped against the bore of the coupling part by tightening the lock bolt.

This enables positive control of the runout of the coupling end face and outer diameter, thus delivering a good centering effect.

When the lock bolt is tightened, there is no axial movement of the pulley bore, and the product has no backlash.

Usage Method

■Mounting method for keyless timing pulleys

①Wipe off the stains on the shaft surface and apply a layer of lubricant or grease. (Do not use any lubricant or grease that contains molybdenum abrasion inhibiting agent.)

②Also wipe the contact surface between the timing pulley and the bushing, and apply lubricant or grease. In addition, the fastening bolt thread surface and bearing surface must be applied lubricant or grease.

③Insert the timing pulley and bushing into the shaft after temporary assembly. (Do not tighten the bushing directly with the bolt without putting it through the shaft.)

④After positioning is completed, tighten the bolts gently (about 1/4 of the specified tightening torque) and diagonally in sequence with a torque wrench.

⑤Tighten with increased tightening torque (about 1/2 of the specified tightening torque).

⑥Tighten again to the specified tightening torque.

⑦Tighten the fastening bolt circumferentially in sequence.

■Disassembly method for keyless timing pulleys

①Work with the unit at a complete stop.

②Loose the fastening bolt circumferentially in sequence

③Insert the bolt into the threaded hole for disassembly and evenly screw it in.

④When reinstalling, repeat the steps in “Installation”.

①Wipe off the stains on the shaft surface and apply a layer of lubricant or grease. (Do not use any lubricant or grease that contains molybdenum abrasion inhibiting agent.)

②Also wipe the contact surface between the timing pulley and the bushing, and apply lubricant or grease. In addition, the fastening bolt thread surface and bearing surface must be applied lubricant or grease.

③Insert the timing pulley and bushing into the shaft after temporary assembly. (Do not tighten the bushing directly with the bolt without putting it through the shaft.)

④After positioning is completed, tighten the bolts gently (about 1/4 of the specified tightening torque) and diagonally in sequence with a torque wrench.

⑤Tighten with increased tightening torque (about 1/2 of the specified tightening torque).

⑥Tighten again to the specified tightening torque.

⑦Tighten the fastening bolt circumferentially in sequence.

■Disassembly method for keyless timing pulleys

①Work with the unit at a complete stop.

②Loose the fastening bolt circumferentially in sequence

③Insert the bolt into the threaded hole for disassembly and evenly screw it in.

④When reinstalling, repeat the steps in “Installation”.

Precautions

① If there are requirements for rust prevention, give priority to products with surface treatment of electroless nickel plating on other pages.

Please refer to surface treatment and rust prevention methods

surface treatment and rust prevention methods

② When installing a keyless bushing, be sure to apply lubricant or grease to the shaft surface, the contact surface between the pulley and the bushing, and the fastening bolt.

Otherwise it will not be securely tightened and may cause the shaft to idle.

③Tighten the bolt after inserting the bushing into the shaft. (If the bolts is tightened before inserting the bushing, it will cause deformation of the bushing.)

④Use a torque spanner to tighten the bolts.

⑤Do not use bolts other than those supplied.

Please refer to

surface treatment and rust prevention methods

surface treatment and rust prevention methods② When installing a keyless bushing, be sure to apply lubricant or grease to the shaft surface, the contact surface between the pulley and the bushing, and the fastening bolt.

Otherwise it will not be securely tightened and may cause the shaft to idle.

③Tighten the bolt after inserting the bushing into the shaft. (If the bolts is tightened before inserting the bushing, it will cause deformation of the bushing.)

④Use a torque spanner to tighten the bolts.

⑤Do not use bolts other than those supplied.

Example of Use

■Mechanism name

Dustproof Lifting Machine

■Mechanism function

Lifting machine for heavy workpieces

Use in dusty places

■Function of Keyless Timing Pulleys

Rotates ball screws by means of a keyless toothed timing belt, lifting and lowering the positioning stage

For details, please click Dustproof Lifting Machine

Dustproof Lifting Machine

■Mechanism function

Lifting machine for heavy workpieces

Use in dusty places

■Function of Keyless Timing Pulleys

Rotates ball screws by means of a keyless toothed timing belt, lifting and lowering the positioning stage

For details, please click Dustproof Lifting Machine

Application Industries

| Smart Phones | Medical | Electronic & Electrical | ||

|  |  | ||

| Automotive | Robotics | Lithium battery | ||

|  |  |

Related Products

| Flat-belt idlers, Width (T), 6 to 32 mm | Flat Belts For General Use | High Torque Timing Pulleys S2M Type | ||

|  |  | ||

| Representative model: HBG15-6 | Representative model: HBLT350-4.23 | Representative model: HTPA48S2M040-B-N10 | ||

| Advantages: short delivery time, multiple types | Advantage: custom size | Advantages: short delivery time, multiple types |

Related Documents

Technical Data of Toothed Timing Belts and Timing Pulleys

①Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (drive).

②Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (transmission & conveyance).

③Main causes and countermeasures for the damage, breakage, abnormal noise of toothed timing belts.

④Reference data on the replacement time of toothed timing belts.

⑤Data on dimensional tolerance of timing pulleys.

①Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (drive).

②Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (transmission & conveyance).

③Main causes and countermeasures for the damage, breakage, abnormal noise of toothed timing belts.

④Reference data on the replacement time of toothed timing belts.

⑤Data on dimensional tolerance of timing pulleys.

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

Loading...Tải…

Basic InformationThông tin cơ bản

| Type | Keyless Bushings | Belt Type | S5M |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy