(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Lead(mm)

-

Lead

-

Effective Stroke(mm)

-

Motor Position

- BC Motor Direct Connection

- BL Motor On Left Side

- BM Motor On Lower Side

- BR Motor On Right Side

-

Motor Brand & Power

-

Sensor Position

- C Motor Side

- D Motor Opposite Side

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 17 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Single Axis Robots E-MGT5, Guide Built in Type, Semi-Sealed Type(General Use)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- **RoHS Compliant is available for some part numbers.

Please contact with MISUMI for detail effective date.

The product does not come with a driver, which must be purchased separately - The product does not come with a coupling, which must be purchased separately

- The product comes with a sensor kit, which is unnecessary to select

Product Description

The output shaft of Economy series Aluminum Alloy Embedded Actuators E-MGT5 Series is 7mm in diameter. The product only includes the main unit, not the driver and coupling, which must be purchased separately. The product comes with a sensor kit, for which only mounting direction needs to be selected.

The aluminum alloy base is directly embedded in the steel track and then ground, the walking height and straightness accuracy are improved, up to ±0.02 or less.

Small size, easy to assemble

| Components | Body | Embedded Guide | Ball Screw | Ball Screw Nut | Slide Block | Cover |

Material Material | Aluminum Alloy | Bearing Steel | Bearing Steel | Alloy Steel | Aluminum Alloy | Stainless Steel |

Surface treatment Surface treatment | Clear Anodized | Heat Treatment | - | - | Clear Anodized | - |

Unit (mm)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| L | 270.5 | 320.5 | 370.5 | 420.5 | 470.5 | 520.5 | 570.5 | 620.5 | 670.5 | 720.5 | 770.5 | 820.5 | 870.5 | 920.5 | 970.5 | 1020.5 |

| A | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 |

| P | 25 | 75 | 125 | 175 | 225 | 275 | 325 | 375 | 425 | 475 | 525 | 575 | 625 | 675 | 725 | 775 |

| Mass (kg) | 1.65 | 1.79 | 1.92 | 2.11 | 2.39 | 2.5 | 2.52 | 2.75 | 2.86 | 2.95 | 3.15 | 3.28 | 3.44 | 3.58 | 3.71 | 4.09 |

Unit (mm)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| L | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| A | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 |

| P | 25 | 75 | 125 | 175 | 225 | 275 | 325 | 375 | 425 | 475 | 525 | 575 | 625 | 675 | 725 | 775 |

| Mass (kg) | 1.68 | 1.80 | 2.03 | 2.14 | 2.42 | 2.53 | 2.58 | 2.78 | 2.89 | 2.98 | 3.18 | 3.31 | 3.47 | 3.60 | 3.74 | 4.12 |

Unit (mm)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| L | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| A | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 |

| P | 25 | 75 | 125 | 175 | 225 | 275 | 325 | 375 | 425 | 475 | 525 | 575 | 625 | 675 | 725 | 775 |

| Mass (kg) | 1.68 | 1.80 | 2.03 | 2.14 | 2.42 | 2.53 | 2.58 | 2.78 | 2.89 | 2.98 | 3.18 | 3.31 | 3.47 | 3.60 | 3.74 | 4.12 |

Unit (mm)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| L | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| A | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 | 25 | 75 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 |

| P | 25 | 75 | 125 | 175 | 225 | 275 | 325 | 375 | 425 | 475 | 525 | 575 | 625 | 675 | 725 | 775 |

| Mass (kg) | 1.68 | 1.80 | 2.03 | 2.14 | 2.42 | 2.53 | 2.58 | 2.78 | 2.89 | 2.98 | 3.18 | 3.31 | 3.47 | 3.60 | 3.74 | 4.12 |

■Basic Information

| Drive Method | Ball Screw | |

| Ball Screw | Precision | C7 |

| O.D. (mm) | Φ12 | |

| Body width (mm) | 54 | |

| Drive power (W) | 100W | |

| Operating Environment | General | |

■ Model specification

| Part Number |  Lead (mm) Lead (mm) |  Stroke Stroke(50mm increments |  Motor Position |  Motor Brand |  Motor Output |  Sensor Position | Motor Opposite Side (mm) | Max. Payload kg) | Max. Speed (mm/sec) | Rated Thrust (N) | |

Type Type | Horizontal Use | Vertical Use | |||||||||

| E-MGT5 | 5 | 50~800 | BC (Motor Direct) BM (Bottom Down) BL (Left Folded) BR (Right Folded) | M (Mitsubishi) P (Panasonic) Y (Yaskawa) T (Delta Electronics) Z (Prepared by Customer) | 10 (100W) | C (Motor Side) D (Motor Opposite Side) | ±0.01 | 30 | 10 | 250 | 341 |

| 10 | 15 | 5 | 500 | 170 | |||||||

| 20 | 10 | 2.5 | 1000 | 85 | |||||||

A motor is not included to this product and it must be purchased separately.

A motor is not included to this product and it must be purchased separately. When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed.

When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed. Select a motor with brake for vertical use.

Select a motor with brake for vertical use. When Z is selected as the motor brand (prepared by customer), please provide the motor model and output when placing an order. (If necessary, provide the motor mounting dimensions)

When Z is selected as the motor brand (prepared by customer), please provide the motor model and output when placing an order. (If necessary, provide the motor mounting dimensions) As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.

As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.| Part Number | Lead (mm) | Motor Output (W) | Max. Movement Speed (mm/sec) | |||||||||||||||

| 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | |||

| E-MGT5 | 5 | 100 | 250 | 225 | 200 | 175 | 150 | |||||||||||

| 10 | 500 | 450 | 400 | 350 | 300 | |||||||||||||

| 20 | 1000 | 900 | 800 | 700 | 600 | |||||||||||||

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.

Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.■ Accessories

Accessories Accessories | Accessories Name | Part Number | Quantity | ||

| Sensor | C-MSX674N-2M (NPN) | 3 | |||

| Motor connection method | BC | Coupling (mm) | 7×8 Motor Side (100W) | 1 | |

| BL/BR/BM | Motor End Timing Pulley | S3M-24 Teeth-8 | 1 | ||

| Screw End Timing Pulley | S3M-24 Teeth-7 | ||||

| Timing Belt | S3M-174-10 | 1 | |||

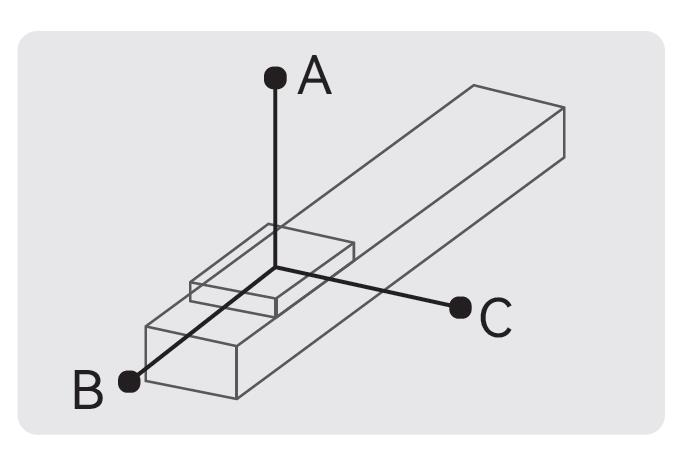

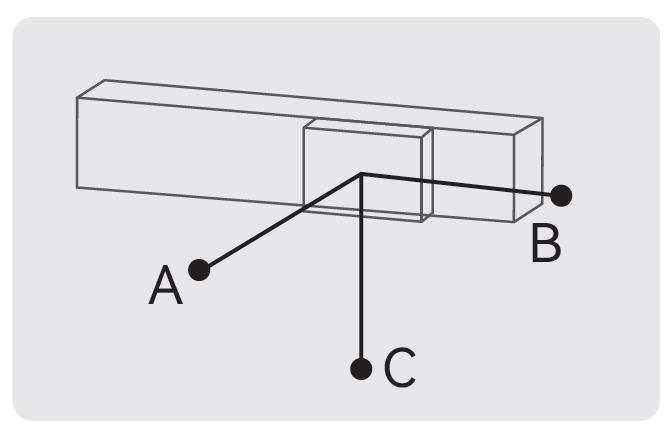

■ Allowable load center of gravity overhang (mm)

| Horizontal Mount | A | B | C | |

| Lead 5 | 10kg | 650 | 75 | 100 |

| 20kg | 440 | 32 | 45 | |

| 30kg | 270 | 19 | 25 | |

| Lead 10 | 10kg | 600 | 145 | 185 |

| 20kg | 370 | 70 | 85 | |

| 30kg | 250 | 42 | 52 | |

| Lead 20 | 5kg | 320 | 120 | 130 |

| 8kg | 220 | 70 | 80 | |

| 10kg | 175 | 55 | 60 | |

| Wall Mount | A | B | C | |

| Lead 5 | 10kg | 100 | 75 | 650 |

| 20kg | 45 | 32 | 420 | |

| 30kg | 25 | 19 | 260 | |

| Lead 10 | 5kg | 180 | 145 | 600 |

| 10kg | 85 | 68 | 370 | |

| 15kg | 52 | 42 | 250 | |

| Lead 20 | 5kg | 130 | 120 | 320 |

| 8kg | 75 | 70 | 220 | |

| 10kg | 60 | 55 | 170 | |

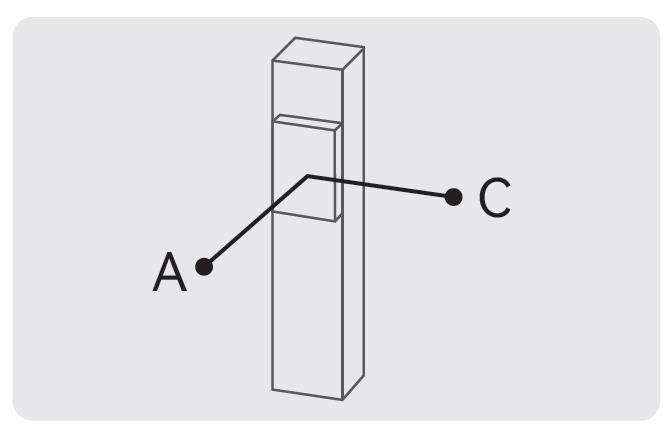

| Vertical Mount | A | C | |

| Lead 5 | 6kg | 145 | 145 |

| 8kg | 110 | 110 | |

| 10kg | 90 | 90 | |

| Lead 10 | 1kg | 800 | 800 |

| 3kg | 260 | 260 | |

| 5kg | 155 | 155 | |

| Lead 20 | 1kg | 600 | 600 |

| 2kg | 300 | 300 | |

| 2.5kg | 250 | 250 | |

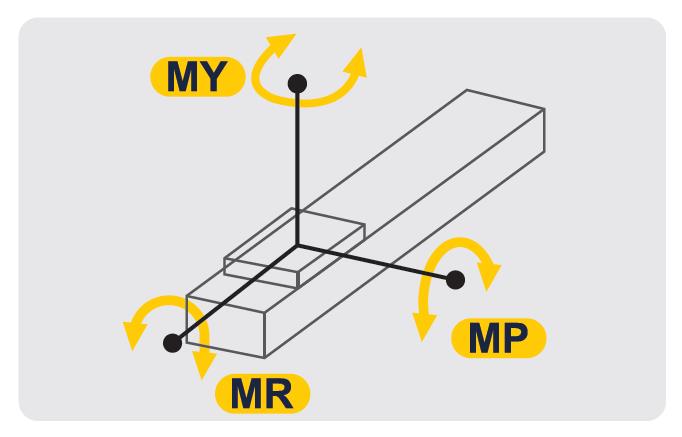

■ Static allowable moment N·m

| Horizontal Mount | |

| MY | 103 |

| MP | 103 |

| MR | 144 |

■ List of recommendable servo motor

Motor code is to identify drive components to be attached. This option does not provide a motor and must be purchased separately

Motor code is to identify drive components to be attached. This option does not provide a motor and must be purchased separately| Brand | Motor Code | With/Without Brake | Motor Output | Voltage | Servo Motor Model | Servo Amplifier Model |

| Mitsubishi | M | Without brake (Horizontal use) | 100W | 220V | HG-KR13J | MR-J4-10A |

| With brake (Vertical use) | HG-KR13BJ | |||||

| Panasonic | P | Without brake (Horizontal use) | 100W | 220V | MSMF012L1U2M | MADLN05SE |

| With brake (Vertical use) | MSMF012L1V2M | |||||

| Yaskawa | Y | Without brake (Horizontal use) | 100W | 220V | SGM7J-01AFC6S | SGD7S-R90A00A002 |

| With brake (Vertical use) | SGM7J-01AFC6E | |||||

| Delta Electronics | T | Without brake (Horizontal use) | 100W | 220V | ECMA-C20401FS | ASD-B2-0121-B |

| With brake (Vertical use) | ECMA-C20401GS |

2.Single Axis Robots, Small and lightweight

3.Single Axis Robots, High precision ±0.01mm

4.Single Axis Robots, High rigidity

5.Single Axis Robots, Low noise

6.Single Axis Robots, Complete accessories

■ Please avoid using in the following environments

1. Dust environment (especially metal powder)

2. Splash water, oil environment

3. Close to the fire source

4. Organic solvent, salty environment

5. Environment with direct sunlight and heat radiation

6. Environment with strong vibration and impact

7. Environment with corrosive gas and flammable gas

■ Operating environment

Use environment: normal temperature (no freezing, non-condensing)

| Application Industry | Semiconductor |

| Purpose | Moving assembly unit using a Economy series single-axis actuator |

| |

| Application Industry | LCD detection |

| Purpose | Focus adjustment mechanism according to the size of the subject |

| |

| Application Industry | Detection |

| Purpose | Multi-axis mechanism using Economy series single-axis actuators. It supports multi-point inspection and equipment that inspects multiple workpieces at the same time |

| |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| E-MGT5-L5-[50-800/50]-[BC,BL,BM,BR]-M10-[C,D] |

| E-MGT5-L5-[50-800/50]-[BC,BL,BM,BR]-P10-[C,D] |

| E-MGT5-L5-[50-800/50]-[BC,BL,BM,BR]-T10-[C,D] |

| E-MGT5-L5-[50-800/50]-[BC,BL,BM,BR]-Y10-[C,D] |

| E-MGT5-L10-[50-800/50]-[BC,BL,BM,BR]-M10-[C,D] |

| E-MGT5-L10-[50-800/50]-[BC,BL,BM,BR]-P10-[C,D] |

| E-MGT5-L10-[50-800/50]-[BC,BL,BM,BR]-T10-[C,D] |

| E-MGT5-L10-[50-800/50]-[BC,BL,BM,BR]-Y10-[C,D] |

| E-MGT5-L20-[50-800/50]-[BC,BL,BM,BR]-M10-[C,D] |

| E-MGT5-L20-[50-800/50]-[BC,BL,BM,BR]-P10-[C,D] |

| E-MGT5-L20-[50-800/50]-[BC,BL,BM,BR]-T10-[C,D] |

| E-MGT5-L20-[50-800/50]-[BC,BL,BM,BR]-Y10-[C,D] |

| E-MGT5-L20-[50-800/50]-[BC,BL,BM,BR]-Z-[C,D] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Lead (mm) | Lead | Effective Stroke (mm) | Motor Position | Motor Brand & Power | Sensor Position |

|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 17 Day(s) | 5 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M10 Mitsubishi 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 5 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P10 Panasonic 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 5 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T10 Delta 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 5 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y10 Yaskawa 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 10 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M10 Mitsubishi 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 10 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P10 Panasonic 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 10 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T10 Delta 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 10 | - | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y10 Yaskawa 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 20 | 20 | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M10 Mitsubishi 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 20 | 20 | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P10 Panasonic 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 20 | 20 | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T10 Delta 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 20 | 20 | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y10 Yaskawa 100W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 17 Day(s) | 20 | 20 | 50 ~ 800 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Z Prepared by Customer | C Motor Side / D Motor Opposite Side |

Loading...Tải…

Basic InformationThông tin cơ bản

| Type | Slider | Drive Method | Rolled Ball Screw | Main Body, Peripheral Components | Main Body |

|---|---|---|---|---|---|

| Positioning Repeatability(µm) | ±10 | Cable | Not Provided | Number of Tables | 1 pc. |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy