(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- NPJH

- NPJH-N

- NPJL

- NPJL-N

- NPJS

- NPJS-N

- NPJX

- PJH

- PJH-N

- PJL

- PJL-N

- PJS

- PJS-N

- PJX

- PJX-N

-

Pin Material

- Steel

- Plastic

- Steel

-

Outer Dia. M(mm)

-

Stroke (S)(mm)

-

Thread Locking Treatment

- Not Provided

- Provided

-

Main Body Surface Treatment

- Black Oxide

- Electroless Nickel Plating

-

Pin Surface Treatment

- Not Provided

- Black Oxide

- Trivalent Chromate

-

Tip Heat Treatment

- Not Provided

- Carburized

-

Initial Load (Range)(N)

- 0.01~50

- 50.01~100

-

Min. Load(N)

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- Same day

- 4 Day(s) or Less

- 6 Day(s) or Less

- 8 Day(s) or Less

Specify AlterationsChỉ định thay đổi

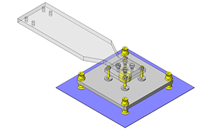

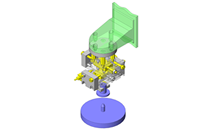

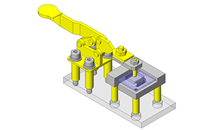

Spring Plungers - Steel (PJL-N16-10)

- Volume Discount

- All

- Sale Items

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

Products with loosening prevention have been treated with loosening prevention treatment (epoxy resin adhesive) in advance. Workability is improved with no need for thread locking agents! Achieved reduced screw locking agent application work and stable quality of loosening prevention. [Features that prevent loosening] - When screwed in, the microcapsules are destroyed and hardening begins. ・Excellent chemical resistance and heat resistance.

| Load Category | Type | Body | Pin | Spring | Operating Temperature | ||||||

| Standard | Thread-lock Untreated | [ M ]Material | [ H ]Hardness | [ S ] Surface Treatment | [ M ]Material | [ H ]Hardness | [ S ] Surface Treatment | [ M ]Material | |||

| Steel Nose | Ultra Light Load | PJS | PJS~N | S45C | 29~35HRC | Blackening | S45C | 57~63HRC (Carburized) | Trivalent Chromate | SWP-B | -30~80°C |

| Light Load | PJL | PJL-N | |||||||||

| Heavy Load | PJH | PJH-N | Blackening | ||||||||

| Extra Heavy Load | PJX | PJX~N | Nickel Plating | ||||||||

| Plastic Tip | Ultra Light Load | NPJS | NPJS~N | Blackening | Polyacetal | ~ | ~ | ||||

| Light Load | NPJL | NPJL~N | |||||||||

| Heavy Load | NPJH | NPJH~N | |||||||||

| Extra Heavy Load | NPJX | ~ | Nickel Plating | ||||||||

Specifications

| Part Number |

| NPJH3-1.5 PJS-N10-5 |

| Part Number | d | ℓ | L | B | Ultra Light Load | Light Load | Heavy Load | Extra Heavy Load | Unit Price | ||||||||||||||||

| Type | M (Coarse) | S | Ultra Light / Light / Heavy Load | Extra Heavy Load | min. | N Load | max. | min. | N Load | max. | min. | N Load | max. | min. | N Load | max. | Ultra Light / Light / Heavy Load | Extra Heavy Load | |||||||

| (Steel Tip) PJS (* only) PJL PJH PJX (* only) (Plastic Tip) NPJS (* only) NPJL (* only) NPJH (* only) NPJX (* only) | 3 | **1.5 | 1.1 | 10(15) | 10 | 15 | 0.9 | 0.05 | 0.32 | 0.44 | 1.6 | 0.9 | 4.2 | 2.5 | 5.1 | ||||||||||

| **3 | 1.1 | 15(20) | 15 | 20 | 0.9 | 0.09 | 0.32 | 0.29 | 1 | 1.1 | 4.9 | 2.5 | 6.8 | ||||||||||||

| 4 | **2 | 1.6 | 15(24) | 15 | 24 | 1.3 | 0.23 | 0.65 | 0.9 | 4.1 | 1.9 | 8.7 | 6.3 | 15.3 | |||||||||||

| **4 | 1.6 | 24 | 24 | 24 | 1.3 | 0.24 | 0.65 | 0.7 | 2.2 | 0.29 | 8.3 | 4.8 | 15 | ||||||||||||

| 5 | **3 | 2.0 | 20(27) | 20 | 27 | 1.5 | 0.74 | 2.95 | 1.5 | 9.8 | 2 | 22.5 | 11 | 30.4 | |||||||||||

| **5 | 2.0 | 27(39) | 27 | 39 | 1.5 | 0.72 | 2.95 | 1.6 | 10.4 | 2.5 | 23.4 | 11.6 | 31.5 | ||||||||||||

| 6 | **3 | 2.5 | 25(30) | 25 | 30 | 2 | 0.85 | 3.2 | 3.4 | 10.4 | 12.5 | 33.8 | 17.2 | 46.6 | |||||||||||

| **5 | 2.5 | 30(36) | 30 | 36 | 2 | 0.85 | 3.2 | 1.9 | 9.7 | 6.2 | 32.6 | 16.8 | 47.4 | ||||||||||||

| 10 | 2.5 | 30 | 39 | - | 2 | - | - | 1.5 | 10.9 | 5 | 32.7 | - | - | - | |||||||||||

| 8 | **3 | 3.1 | 25(27) | 25 | 27 | 2.5 | 0.9 | 3.3 | 3.5 | 9.4 | 11.7 | 31.2 | 28.1 | 56.9 | |||||||||||

| **5 | 3.1 | 27(30) | 27 | 35 | 2.5 | 0.9 | 3.3 | 2.9 | 9.6 | 8.3 | 31.9 | 10.5 | 39.9 | ||||||||||||

| 10 | 3.1 | 30 | 43 | - | 2.5 | - | - | 3.1 | 11.2 | 8.4 | 36.4 | - | - | - | |||||||||||

| 10 | **5 | 3.8 | 30 | 30 | 35 | 3 | 1.9 | 4.7 | 2.6 | 14.1 | 11.4 | 51 | 17 | 73.7 | |||||||||||

| **10 | 3.8 | 30 | 43 | 53 | 3 | 1.7 | 4.7 | 2.9 | 14.6 | 9.5 | 60.8 | 13.7 | 75.5 | ||||||||||||

| 15 | 3.8 | 30 | 58 | - | 3 | - | - | 3.4 | 17 | 7.2 | 57.3 | - | - | - | |||||||||||

| 12 | **5 | 5.5 | 30(35) | 30 | 43 | 4 | 1.5 | 4.7 | 3.5 | 17.1 | 5.6 | 41 | 35.3 | 107.9 | |||||||||||

| **10 | 5.5 | 35 | 43 | 58 | 4 | 1.3 | 5.9 | 2.5 | 21.1 | 5.2 | 55.9 | 12.7 | 107.9 | ||||||||||||

| **15 | 5.5 | 35 | 51 | 78 | 4 | 1.6 | 5.9 | 2.3 | 19.4 | 5.1 | 53.6 | 16.7 | 140.2 | ||||||||||||

| 20 | 5.5 | 35 | 78 | - | 4 | - | - | 4.1 | 22.5 | 8.7 | 56.1 | - | - | - | |||||||||||

| 16 | **10 | 8 | 35 | 60 | 60 | 5 | 1.7 | 12.8 | 12.1 | 38 | 26.5 | 78 | 29.6 | 157.9 | |||||||||||

| **15 | 8 | 35 | 60 | 70 | 5 | 1.7 | 12.8 | 9.7 | 39.7 | 14.2 | 79.4 | 10 | 142.2 | ||||||||||||

| **20 | 8 | 35 | 85 | 90 | 5 | 1.7 | 12.8 | 8.6 | 40.1 | 16.8 | 80.4 | 4.3 | 146.1 | ||||||||||||

| * 30 | 8 | 35 | 125 | 125 | 5 | - | - | 17 | 38 | 19.8 | 81.2 | 5.2 | 140.7 | ||||||||||||

| 40 | 8 | 35 | 125 | - | 5 | 5.5 | 41.2 | 7.6 | 84.3 | - | - | - | |||||||||||||

| 50 | 8 | 35 | 155 | 5 | 4.4 | 48.3 | 7.5 | 78.8 | |||||||||||||||||

| 60 | 8 | 35 | 159 | 5 | 4.1 | 49.6 | 6.4 | 78.1 | |||||||||||||||||

| 70 | 8 | 35 | 185 | 5 | 3.1 | 55.7 | 4.3 | 95 | |||||||||||||||||

| 80 | 8 | 35 | 185 | 5 | 2.5 | 51.3 | 3.2 | 103.5 | |||||||||||||||||

| 20 | * 15 | 10 | 45 | 60 | 80 | 6 | 14.4 | 79.4 | 22.5 | 147.1 | 14.5 | 274.6 | |||||||||||||

| 20 | 10 | 45 | 72 | - | 6 | 13.9 | 83.4 | 23 | 157.9 | - | - | - | |||||||||||||

| 30 | 10 | 45 | 96 | 6 | 13.6 | 88.3 | 18.6 | 154 | |||||||||||||||||

| 40 | 10 | 45 | 120 | 6 | 13.4 | 109.8 | 26.8 | 195.1 | |||||||||||||||||

| 24 | 7 | 10 | 45 | 60 | - | 10 | - | - | 27.8 | 65.9 | 40.7 | 127.9 | - | ||||||||||||

| * 15 | 10 | 45 | 60 | 84 | 10 | 25.5 | 106.9 | 46.9 | 226.5 | 55.1 | 375.2 | ||||||||||||||

| 20 | 10 | 45 | 75 | - | 10 | 15.3 | 101 | 43.1 | 224.6 | - | - | - | |||||||||||||

| 30 | 10 | 45 | 100 | 10 | 19.1 | 100 | 47.8 | 231.4 | |||||||||||||||||

| 40 | 10 | 45 | 124 | 10 | 17.1 | 98.1 | 44.1 | 225.5 | |||||||||||||||||

| 30 | 15 | 14 | 45 | 66 | 14 | 9.3 | 104.4 | 32.4 | 259.9 | ||||||||||||||||

| 20 | 14 | 45 | 78 | 14 | 55.2 | 156.9 | 72.6 | 356.5 | |||||||||||||||||

| [ ! ]ℓ dimensions with ( ) are applicable to the Extra Heavy Load Type. | 30 | 14 | 45 | 100 | 14 | 28.4 | 128.3 | 41.6 | 290.3 | ||||||||||||||||

| 40 | 14 | 45 | 123 | 14 | 14.7 | 109.2 | 44.4 | 303 | |||||||||||||||||

■No Thread Locking Compound

| Part Number | d | ℓ | L | B | Ultra Light Load | Light Load | Heavy Load | Extra Heavy Load | Unit Price | ||||||||||||||||

| Type | M (Coarse) | S | Ultra Light / Light / Heavy Load | Extra Heavy Load | min. | N Load | max. | min. | N Load | max. | min. | N Load | max. | min. | N Load | max. | Ultra Light / Light / Heavy Load | Extra Heavy Load | |||||||

| (Steel Tip) PJS-N PJL-N PJH-N PJX-N (Plastic Tip) NPJS-N NPJL-N NPJH-N | 5 | 3 | 2.0 | 20(27) | 20 | 27 | 1.5 | 0.74 | 2.95 | 1.5 | 9.8 | 2 | 22.5 | 11 | 30.4 | ||||||||||

5 | 2.0 | 27(39) | 27 | 39 | 1.5 | 0.72 | 2.95 | 1.6 | 10.4 | 2.5 | 23.4 | 11.6 | 31.5 | ||||||||||||

6 | 3 | 2.5 | 25(30) | 25 | 30 | 2 | 0.85 | 3.2 | 3.4 | 10.4 | 12.5 | 33.8 | 17.2 | 46.6 | |||||||||||

5 | 2.5 | 30(36) | 30 | 36 | 2 | 0.85 | 3.2 | 1.9 | 9.7 | 6.2 | 32.6 | 16.8 | 47.4 | ||||||||||||

8 | 3 | 3.1 | 25(27) | 25 | 27 | 2.5 | 0.9 | 3.3 | 3.5 | 9.4 | 11.7 | 31.2 | 28.1 | 56.9 | |||||||||||

5 | 3.1 | 27(30) | 27 | 35 | 2.5 | 0.9 | 3.3 | 2.9 | 9.6 | 8.3 | 31.9 | 10.5 | 39.9 | ||||||||||||

| 10 | 5 | 3.8 | 30 | 30 | 35 | 3 | 1.9 | 4.7 | 2.6 | 14.1 | 11.4 | 51 | 17 | 73.7 | |||||||||||

10 | 3.8 | 30 | 43 | 53 | 3 | 1.7 | 4.7 | 2.9 | 14.6 | 9.5 | 60.8 | 13.7 | 75.5 | ||||||||||||

12 | 5 | 5.5 | 30(35) | 30 | 43 | 4 | 1.5 | 4.7 | 3.5 | 17.1 | 5.6 | 41 | 35.3 | 107.9 | |||||||||||

10 | 5.5 | 35 | 43 | 58 | 4 | 1.3 | 5.9 | 2.5 | 21.1 | 5.2 | 55.9 | 12.7 | 107.9 | ||||||||||||

15 | 5.5 | 35 | 51 | 78 | 4 | 1.6 | 5.9 | 2.3 | 19.4 | 5.1 | 53.6 | 16.7 | 140.2 | ||||||||||||

16 | 10 | 8 | 35 | 60 | 60 | 5 | 1.7 | 12.8 | 12.1 | 38 | 26.5 | 78 | 29.6 | 157.9 | |||||||||||

| [ ! ]ℓ dimensions with ( ) are applicable to the Extra Heavy Load Type. | 15 | 8 | 35 | 60 | 70 | 5 | 1.7 | 12.8 | 9.7 | 39.7 | 14.2 | 79.4 | 10 | 142.2 | |||||||||||

20 | 8 | 35 | 85 | 90 | 5 | 1.7 | 12.8 | 8.6 | 40.1 | 16.8 | 80.4 | 4.3 | 146.1 | ||||||||||||

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| PJL-N16-10 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | RoHS | Pin Material | Outer Dia. M (mm) | Stroke (S) (mm) | Thread Locking Treatment | Main Body Surface Treatment | Pin Surface Treatment | Tip Heat Treatment | Initial Load (Range) (N) | Min. Load (N) | Max. Load (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

214,153 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Steel] S45C | 16 | 10 | Not Provided | Black Oxide | Trivalent Chromate | Carburized | 0.01~50 | 5.9 | 39.2 |

Loading...Tải…

Basic InformationThông tin cơ bản

| Body Material | S45C | Mounting Method | Screw-In | Screw Type of Pin Plunger | Spherical Type |

|---|---|---|---|---|---|

| Wrench Hole Shape | Hex |

Please check the type/dimensions/specifications of the part PJL-N16-10 in the Spring Plungers - Steel series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần PJL-N16-10 trong chuỗi Spring Plungers - Steel.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Products like this...

| Part Number |

|---|

| NPJH-N12-15 |

| NPJH-N12-5 |

| NPJH-N16-10 |

| PJL-N16-15 |

| PJL-N16-20 |

| PJL-N5-3 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to ShipSố ngày giao hàng | RoHS | Pin Material | Outer Dia. M (mm) | Stroke (S) (mm) | Thread Locking Treatment | Main Body Surface Treatment | Pin Surface Treatment | Tip Heat Treatment | Initial Load (Range) (N) | Min. Load (N) | Max. Load (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

190,798 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Plastic] Polyacetal | 12 | 15 | Not Provided | Black Oxide | Not Provided | Not Provided | 0.01~50 | 4.9 | 49 | |

127,198 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Plastic] Polyacetal | 12 | 5 | Not Provided | Black Oxide | Not Provided | Not Provided | 0.01~50 | 18.6 | 49 | |

214,153 VND | 1 Piece(s) | Available | 6 Day(s) or more | 10 | [Plastic] Polyacetal | 16 | 10 | Not Provided | Black Oxide | Not Provided | Not Provided | 0.01~50 | 12.7 | 78.5 | |

214,153 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Steel] S45C | 16 | 15 | Not Provided | Black Oxide | Trivalent Chromate | Carburized | 0.01~50 | 3.9 | 39.2 | |

267,742 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Steel] S45C | 16 | 20 | Not Provided | Black Oxide | Trivalent Chromate | Carburized | 0.01~50 | 4.9 | 39.2 | |

110,308 VND | 1 Piece(s) | Available | 4 Day(s) or more | 10 | [Steel] S45C | 5 | 3 | Not Provided | Black Oxide | Trivalent Chromate | Carburized | 0.01~50 | 2 | 9.8 |

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy