(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Ball Rollers

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

Recommended

You can add up to 6 items per a category to the compare list.

MiSUMi Economy

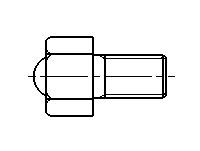

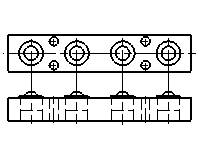

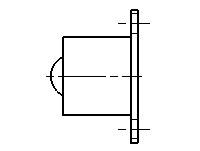

MiSUMi EconomyBall Rollers Milled, Threaded Stud

MiSUMi EconomyMISUMI

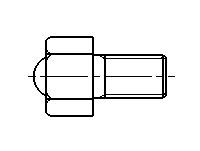

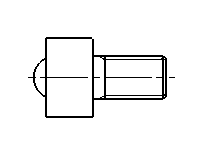

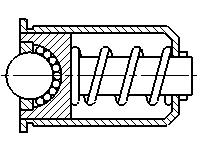

- Ball Rollers Milled, Threaded Stud, C-BCBE series from MISUMI. - This is an economy item; The price is cheaper than the MISUMI standard product. - This product bears the load through the small steel ball bearing surface arranged on the circumference. Therefore, the number of small steel balls bearing the load is more, and more contacting small steel balls can be used to distribute the load. - Load capacity of Ball transfer can be selected up to 1176 N.

- Volume Discount

Load Capacity(N) Shape Type Outer Dia. D(Ø) Load Capacity Range(N) Body Material Ball Material 1176 (120) Round Threaded Stud Standard 42 500.1~5000 Steel Steel From: 291,236 VND Days to Ship: Số ngày giao hàng: Same day  Same day

Same day

-

Economy series

You can add up to 6 items per a category to the compare list.

MiSUMi Economy

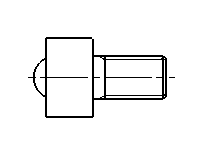

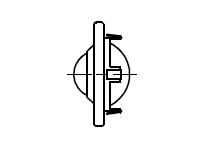

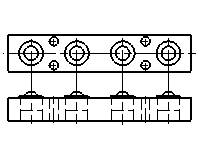

MiSUMi EconomyBall Rollers Milled, Flange Mounting Type

MiSUMi EconomyMISUMI

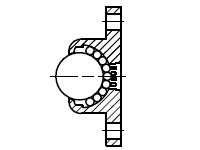

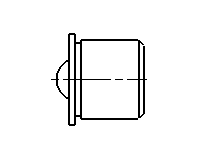

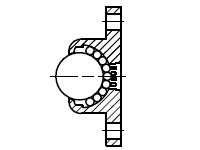

- Ball Rollers Milled, Flange Mounting type, C-BCF series from MISUMI. - This is a cost-effective option with a lower price compared to the MISUMI standard product. - This product supports the load through a circular arrangement of small steel ball bearings on its surface. This design allows for a higher number of load-bearing steel balls, enabling better load distribution. - The C-BCF ball transfer can be used in vertical, horizontal, and inclined applications. - The load capacity of the ball transfer can be selected up to 1176 N.

- Volume Discount

Load Capacity(N) Shape Type Outer Dia. D(Ø) Load Capacity Range(N) Body Material Ball Material 1176 (120) Flange Standard 66 500.1~5000 Steel Steel From: 458,245 VND Days to Ship: Số ngày giao hàng: Same day  Same day

Same day

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| SpecificationsĐặc điểm kĩ thuật |

| Load Capacity(N) |

| Shape |

| Type |

| Outer Dia. D(Ø) |

| Load Capacity Range(N) |

| Body Material |

| Ball Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | MISUMI |

| Product SeriesDòng sản phẩm | ||

| CADCAD |

|

|

| From | 291,236 VND | 458,245 VND |

| Days to ShipSố ngày giao hàng | Same day | Same day |

| SpecificationsĐặc điểm kĩ thuật | ||

| Load Capacity(N) | 1176 (120) | 1176 (120) |

| Shape | Round Threaded Stud | Flange |

| Type | Standard | Standard |

| Outer Dia. D(Ø) | 42 | 66 |

| Load Capacity Range(N) | 500.1~5000 | 500.1~5000 |

| Body Material | Steel | Steel |

| Ball Material | Steel | Steel |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Load Capacity(N)

- 1

- 2

- 4

- 4.9

- 5

- 6

- 7

- 8

- 8.8

- 9.8

- 10

- 11

- 12

- 14

- 14.7

- 19.6

- 19.62

- 21

- 23

- 24

- 27

- 29.4

- 30

- 33

- 34

- 41

- 44 (4.5)

- 49

- 49.05

- 49.6 (5)

- 50

- 55

- 62

- 68

- 68.6

- 69

- 78

- 78.4

- 78.48

- 78.5

- 82

- 98

- 98.1

- 107

- 117.6 (12)

- 147

- 157

- 176

- 196

- 196.1

- 196.2

- 216

- 245

- 274 (28)

- 274.4 (28)

- 284

- 294

- 294.2

- 294.3

- 330 (34)

- 343

- 392

- 412

- 470.4 (48)

- 490

- 490.5

- 510

- 588

- 588.6

- 686

- 730

- 770

- 784

- 784.5

- 784.8

- 882

- 980

- 1020

- 1038

- 1056

- 1080

- 1176

- 1176 (120)

- 1180

- 1210

- 1296

- 1372

- 1470

- 1471.5

- 1510

- 1512

- 1530

- 1550

- 1568

- 1570

- 1728

- 1764

- 1910

- 1944

- 1960

- 1962

- 2040

- 2160

- 2200

- 2292

- 2320

- 2376

- 2401

- 2420

- 2450

- 2548

- 2550

- 2592

- 2640

- 2646

- 2674

- 2744

- 2800

- 2940

- 2943

- 3020

- 3024

- 3056

- 3060

- 3090

- 3240

- 3380

- 3430

- 3438

- 3528

- 3570

- 3630

- 3672

- 3680

- 3820

- 3870

- 3920

- 4056

- 4080

- 4104

- 4116

- 4202

- 4320

- 4410

- 4500

- 4530

- 4536

- 4584

- 4640

- 4732

- 4830

- 4900

- 4905

- 4966

- 5100

- 5150

- 5348

- 5390

- 5400

- 5408

- 5420

- 5610

- 5730

- 5880

- 6040

- 6084

- 6120

- 6620

- 6750

- 6760

- 6860

- 7130

- 7350

- 7436

- 7550

- 7640

- 8090

- 8112

- 8150

- 8660

- 8788

- 8820

- 9060

- 9120

- 9170

- 9464

- 9560

- 9680

- 9800

- 10140

- 10300

- 10600

- 11000

- 11760

- 11800

- 12100

- 12500

- 13200

- 13600

- 14000

- 14700

- 14872

- 15100

- 16600

- 18100

- 19600

- 21100

- 22600

- 24100

- 25700

- 27200

- 28700

- No

-

Shape

-

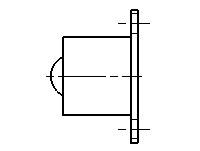

Hex Head Stud

-

Round Threaded Stud

-

Cylindrical

-

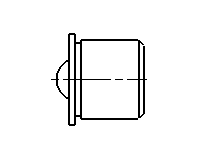

Flange

-

Set Screw

-

Unit

-

One-Touch

-

Table

- Others

-

Hex Head Stud

-

Type

-

Standard

-

Spring-Loaded

-

Garbage Discharge

-

Pneumatically Driven

- Others

-

Standard

-

Outer Dia. D(Ø)

- 8

- 9

- 10

- 11

- 12

- 12.2

- 13

- 15

- 15.8

- 16

- 16.5

- 17

- 18

- 18.5

- 19

- 19.2

- 19.5

- 20

- 20.5

- 21

- 22

- 23

- 24

- 25

- 25.7

- 25.8

- 26

- 27

- 27.5

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 34.4

- 34.5

- 35

- 36

- 38

- 39

- 39.5

- 41

- 41.3

- 42

- 44

- 45

- 46

- 47

- 48

- 50

- 50.2

- 51

- 51.5

- 52

- 53

- 55

- 55.5

- 55.8

- 56

- 57

- 58

- 59.3

- 60

- 65

- 65.2

- 66

- 67

- 69

- 70

- 71

- 71.8

- 72

- 75

- 76

- 77

- 78

- 80

- 85

- 88

- 95

- 96

- 96.8

- 100

- 107

- 110

- 120

- 130

- 140

- 151.2

- 155

- 180

- 187

- 200

- 300

- 304

- 400

- 401

- 456

- No

-

Load Capacity Range(N)

- 1.0~10.0

- 10.1~20.0

- 20.1~50.0

- 50.1~100.0

- 100.1~500.0

- 500.1~5000

- 5000.1~10000

- 10000.1~20000

- 20000.1 or more

-

Body Material

- Steel

- Stainless Steel

- Plastic

- Aluminum

-

Ball Material

- Steel

- Stainless Steel

- Plastic

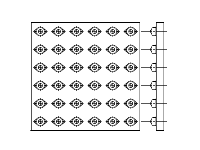

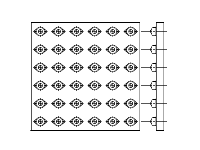

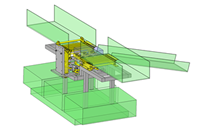

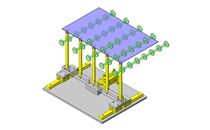

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to Ball RollersDanh mục liên quan đến Ball Rollers

-

- Belt Conveyors, Plastic Chain Conveyors

- Roller Conveyors

- Wheel Conveyors, Roller Carriers

- Screws

- Accessories for Conveyor

- Flat Belts, Pulleys

- Conveyer Timing Belts

- Plastic Modular Belts

- Conveyer Chains, Sprockets

- Plastic Chains

- Rollers

- Industrial Brushes

- Bearings with Resin

- Ball Rollers

- Elevators

- Frames for Conveyors

-

FAQ Ball Rollers

- Question: What is a ball roller and how does it work?

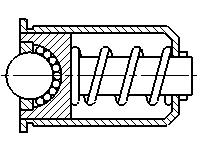

- Answer: A ball roller , also known as a ball transfer unit, is a device used in material handling applications to facilitate the movement of objects. It consists of multiple small ball bearings held within a housing. The balls are designed to rotate freely, allowing objects to be smoothly transferred or rotated in any direction.

- Question: What are the advantages of using ball rollers in material handling applications?

- Answer: Ball roller offer several advantages in material handling applications. They provide a low-friction surface, enabling easy and smooth movement of objects. Ball transfers allow for multidirectional movement, making them suitable for applications that require quick and efficient changes in direction. They are also durable, capable of handling heavy loads, and can be easily integrated into conveyor systems or workstations.

- Question: How do you select the right type of ball roller for your specific application?

- Answer: When selecting a ball roller , consider factors such as the weight and size of the objects being transferred, the operating environment, and the desired movement flexibility. It is important to choose a ball transfer with a load capacity that meets your application requirements. Consulting with a supplier or engineer can help determine the appropriate type and specifications for your specific needs.

- Question: What are the different materials used to make ball rollers and how do they affect performance?

- Answer: Ball roller can be made from various materials, including steel, stainless steel, and plastic. Steel ball transfers offer high load capacity and durability, making them suitable for heavy-duty applications. Stainless steel transfers are corrosion-resistant and ideal for environments with moisture or harsh chemicals. Plastic transfers are lightweight and non-corrosive, suitable for lighter loads and quieter operation. The choice of material depends on factors such as load capacity, operating conditions, and specific application requirements.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy