(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- MISUMI Việt Nam đẩy mạnh hợp tác với cơ sở đào tạo nhằm nâng cao chất lượng nguồn nhân lực kỹ sư tương lai. Xem chi tiết.

MISUMI Vietnam cooperates with Training Institutions to enhance the quality of future engineering workforce. See more.

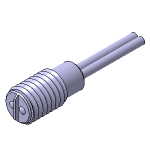

OMRON Fiber Units(Head Shape:Screw)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

![Fiber Optic Unit [E32]](//vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_b$)

OMRON

Fiber unit to fulfill various needs

Detection Distance(mm) Type Detection Type Light Axis Arrangement Type Head Shape Detection Light Type Detection Object Amplifier Installation Type Detection Light Color Head Material Detection distance 【classification】(mm) Operating Environment Protection Structure Fiber Type (Selectable only when Amplifier is not installed) Fiber clothing material Fiber minimum bend R(mm) 10~250 ~ 20000 Fiber Unit Transparent / Reflection - Screw - Colored Surface / Transparent Body / Small Area Separated Type - - - Standard / Heat Resistant / Oil Resistant / Chemical Resistant / Vacuum - - - 1 ~ 35 From: 574,000 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

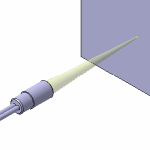

![Fiber Sensor Value Pack [E3X-V]](//vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419694.jpg?$product_view_b$)

Fiber Sensor Value Pack [E3X-V]

OMRON

For small workpiece is detection, fiber sensor value pack

Detection Distance(mm) Type Detection Type Light Axis Arrangement Type Head Shape Detection Light Type Detection Object Amplifier Installation Type Detection Light Color Head Material Detection distance 【classification】(mm) Operating Environment Protection Structure Fiber Type (Selectable only when Amplifier is not installed) Fiber clothing material Fiber minimum bend R(mm) - Fiber Unit Transparent / Reflection Emitting and Receiving Sections Integrated, Single / Emitting and Receiving Sections Separated Screw Standard Colored Surface / Small Area Separated Type Red - ~200 / ~1000 Standard / Cold Resistant IP50 Flexible Vinyl Chloride 1 From: 2,106,742 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Detection Distance(mm) |

| Type |

| Detection Type |

| Light Axis Arrangement Type |

| Head Shape |

| Detection Light Type |

| Detection Object |

| Amplifier Installation Type |

| Detection Light Color |

| Head Material |

| Detection distance 【classification】(mm) |

| Operating Environment |

| Protection Structure |

| Fiber Type (Selectable only when Amplifier is not installed) |

| Fiber clothing material |

| Fiber minimum bend R(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | OMRON | OMRON |

| Product SeriesDòng sản phẩm | ||

| CADCAD |

| |

| From | 574,000 VND Special Price On Sale Till 31/03/2025 | 2,106,742 VND- |

| Days to ShipSố ngày giao hàng | Same day or more | 4 Day(s) or more |

| Detection Distance(mm) | 10~250 ~ 20000 | - |

| Type | Fiber Unit | Fiber Unit |

| Detection Type | Transparent / Reflection | Transparent / Reflection |

| Light Axis Arrangement Type | - | Emitting and Receiving Sections Integrated, Single / Emitting and Receiving Sections Separated |

| Head Shape | Screw | Screw |

| Detection Light Type | - | Standard |

| Detection Object | Colored Surface / Transparent Body / Small Area | Colored Surface / Small Area |

| Amplifier Installation Type | Separated Type | Separated Type |

| Detection Light Color | - | Red |

| Head Material | - | - |

| Detection distance 【classification】(mm) | - | ~200 / ~1000 |

| Operating Environment | Standard / Heat Resistant / Oil Resistant / Chemical Resistant / Vacuum | Standard / Cold Resistant |

| Protection Structure | - | IP50 |

| Fiber Type (Selectable only when Amplifier is not installed) | - | Flexible |

| Fiber clothing material | - | Vinyl Chloride |

| Fiber minimum bend R(mm) | 1 ~ 35 | 1 |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Detection Distance(mm)

- 0~15

- 2~6

- 5

- 5.4~9

- 6

- 8

- 8~20

- 10

- 10~20

- 10~250

- 12

- 12~30

- 15~38

- 16

- 17

- 20

- 27

- 30

- 40~1400

- 50

- 53

- 60

- 90

- 100

- 110

- 120

- 130

- 140

- 150

- 150~1500

- 180

- 190

- 200

- 250

- 280

- 300

- 350

- 360

- 400

- 450

- 550

- 600

- 680

- 800

- 900

- 950

- 1000

- 1100

- 1200

- 1350

- 1500

- 1550

- 1700

- 1780

- 1800

- 2200

- 2600

- 2700

- 2800

- 3500

- 3800

- 4000

- 20000

The detecting distance can vary with your amplifier, operating environment and the detected object.

-

Type

- Photoelectric Sensor

- Fiber Unit

- Fiber Sensor (Amplifier)

-

Detection Type

- Transparent

- Reflection

- Recurrent Reflection

-

Light Axis Arrangement Type

- Emitting and Receiving Sections Integrated, Single

- Emitting and Receiving Sections Integrated, Reflection Plate Used

- Emitting and Receiving Sections Separated

-

Head Shape

-

Cylindrical

-

Square

-

Screw

-

Hex

-

Pipe Fitting

-

Low Profile

-

Cylindrical

-

Detection Light Type

-

Standard

-

Small Spots

-

Wide

-

Standard

-

Detection Object

- Colored Surface

- Transparent Body

- Mirror Surface Body

- Small Area

- Thin Line Shape

- Liquid Surface (Pipe Mounting)

- Liquid Surface (Contacting)

- Wafer Mapping

- Label

-

Amplifier Installation Type

- Separated Type

-

Detection Light Color

-

Head Material

-

Detection distance 【classification】(mm)

- ~10

- ~20

- ~30

- ~50

- ~100

- ~200

- ~300

- ~400

- ~500

- ~1000

- ~2000

- ~3000

- ~4000

* ~20 represents over 10, and 20 or less.

-

Operating Environment

-

Protection Structure

-

Fiber Type (Selectable only when Amplifier is not installed)

-

Fiber clothing material

-

Fiber minimum bend R(mm)

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to Fiber UnitsDanh mục liên quan đến Fiber Units

FAQ Fiber Units for Sensors

- Question: What are the main types of fiber optic cables and their applications?

- Answer: Fiber Optic Cable Types and Applications: 5 Examples

1. Multimode Fiber (MMF): Applications for example, connecting servers within a data center for high-speed data transfer.

2. Single-mode Fiber (SMF): Applications for example, submarine cables, high-speed internet.

3. Dispersion-Shifted Fiber (DSF): Applications for example, high-bandwidth long-distance ,

Connecting undersea data centers for efficient data transmission.

4. Polarization-Maintaining Fiber (PMF): Applications for example,Optical sensors, coherent transmission systems.

5. Plastic Optical Fiber (POF): Applications for example, indoor applications, decorative lighting, connecting LED lights within a building for decorative purposes. - Question: How do fiber optic sensors work, and in what industries are they most commonly used?

- Answer: Fiber optic sensors work by utilizing the properties of light. When light travels through the fiber optic cable, any changes in the surrounding environment, like temperature, pressure, cause changes in the light's properties. These changes are then measured and converted into electrical signals, providing valuable information about the environment.

Example in each Industries:

1.Oil and Gas: Monitoring pipelines for leaks and corrosion, measuring pressure and temperature.

2.Aerospace: Sensing strain, vibration, and temperature in aircraft components.

3.Medical: Monitoring vital signs during surgery, measuring blood pressure and flow.

4.Civil Engineering: Monitoring structural integrity of bridges, buildings, and dams.

5.Telecommunications: Monitoring network performance and optimizing signal transmission. - Question: What are the differences between optical fiber and optic cables in terms of performance and usage?

- Answer: Although the terms "optical fiber" and "optic cable" sound different, they both refer to the same technology: a cable that transmits data using light through thin strands of glass or plastic. The core of this technology is the individual strand, known as "optical fiber," while the "optic cable" encompasses the entire assembly, including protective coatings and strengthening materials.

These cables are used across various applications, including providing high-speed internet access, powering the modern telecommunications infrastructure, connecting servers and storage devices within data centers, and even delivering cable TV signals. - Question: Can you explain the benefits and limitations of using fibre optic technology in data transmission?

- Answer: Benefits:

• High speed and bandwidth: Offers significantly higher data transmission rates compared to copper cables, enabling faster data transfer and supporting bandwidth-intensive applications.

• Low signal attenuation: Signals travel much farther with minimal degradation, allowing for long-distance data transmission without the need for repeaters.

• Immunity to electromagnetic interference: Unaffected by electrical noise and interference, ensuring reliable data transmission in critical environments.

• Lightweight and flexible: Cables are lighter and easier to handle than copper cables, making them ideal for complex installations.

Limitations:

• Cost: Fibre optic cables and equipment are generally more expensive than copper alternatives.

• Installation complexity: Requires specialized skills and tools for proper installation and maintenance.

• Fragility: Fibre optic cables are more fragile than copper cables and susceptible to damage from physical impacts. - Question: What factors should one consider when choosing the right fiber cables for a specific application?

- Answer: 1. Application: Distance, bandwidth needs, environmental conditions.

2. Cable type: Multimode or Single-mode based on distance and bandwidth.

3. Cable features: Core diameter, jacket type, and connector compatibility.

4. Cost and budget: Balancing performance, price, and future needs.

5. Regulations: Compliance with relevant standards like TIA/EIA or ISO/IEC.

6. Futureproofing: Choosing cables supporting future expansion and upgrades. - Question: How does one accurately measure and calculate the required length of fiber wire for an installation?

- Answer: 1. Plan the route: Carefully map the cable path, noting bends, obstacles, and elevation changes.

2. Measure straight sections: Use a measuring wheel or laser distance meter for accurate measurements.

3. Calculate bend allowance: Estimate additional length for bends based on bend radius and angle.

4. Utilize specialized tools: Consider Visual Optical Length Testers (VOLTs) for faster and more precise measurements.

5. Add buffer: Allow extra length for splicing, repairs, and future adjustments.

![Fiber Optic Unit [E32]](http://vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_b$)

![Fiber Sensor Value Pack [E3X-V]](http://vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419694.jpg?$product_view_b$)

![Fiber Optic Unit [E32]](http://vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419683.jpg?$product_view_c$)

![Fiber Sensor Value Pack [E3X-V]](http://vn.misumi-ec.com/linked/material/mech/OMR1/PHOTO/OMR1_221000419694.jpg?$product_view_c$)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy