(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

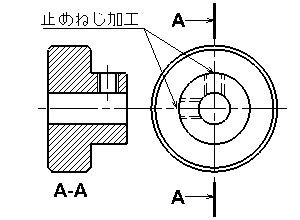

KYOWA Knob Screws(Tapped, Round Hole Machining:Blind Bore)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

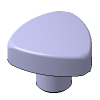

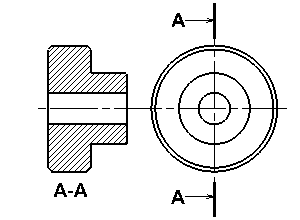

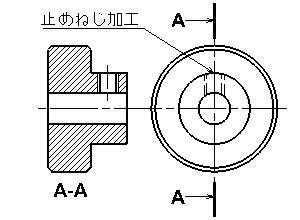

Plastic Parts, Tightening Handle Nut KRM-G Type

KYOWA

Tighten firmly. Tightening handle nut. Main body Polygon (cruciform), Type of mounting part Female thread (M), Female thread, Round hole processing, Blind hole, Main body material Polyamide, Mounting part material Brass, Mounting part surface treatment None

Mounting Section Dia. d (mm) or Nominal Dia. Mounting Section Type Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment M5 ~ M12 Tapped 9 ~ 16 Polygonal Shape Polyamide - Brass - - Not Provided Cross Shape - Not Provided Blind Bore None None From: 73,238 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Mounting Section Dia. d (mm) or Nominal Dia. |

| Mounting Section Type |

| Mounting Section, Length L(mm) |

| Main Body, Type |

| Main Body Material |

| Round Shape, Type |

| Mounting Section, Material |

| Threaded End Machining |

| Set Screw Flat Machining |

| Side Machined |

| Polygonal Shape, Type |

| T Shape, Type |

| Additional Function |

| Tapped, Round Hole Machining |

| Main Body, Surface Treatment |

| Mounting Section, Surface Treatment |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | KYOWA |

| Product SeriesDòng sản phẩm | |

| From | 73,238 VND- |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more |

| Mounting Section Dia. d (mm) or Nominal Dia. | M5 ~ M12 |

| Mounting Section Type | Tapped |

| Mounting Section, Length L(mm) | 9 ~ 16 |

| Main Body, Type | Polygonal Shape |

| Main Body Material | Polyamide |

| Round Shape, Type | - |

| Mounting Section, Material | Brass |

| Threaded End Machining | - |

| Set Screw Flat Machining | - |

| Side Machined | Not Provided |

| Polygonal Shape, Type | Cross Shape |

| T Shape, Type | - |

| Additional Function | Not Provided |

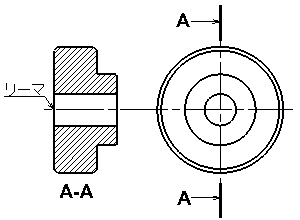

| Tapped, Round Hole Machining | Blind Bore |

| Main Body, Surface Treatment | None |

| Mounting Section, Surface Treatment | None |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Mounting Section Dia. d (mm) or Nominal Dia.

-

Mounting Section Type

- Threaded

- Threaded (Stepped)

- Tapped

- Tapped (Stepped)

- Round Bore

- Press Fit

- Others

-

Mounting Section, Length L(mm)

- 1.5

- 2

- 3

- 4

- 5

- 6

- 6.5

- 6.6

- 7

- 7.2

- 7.5

- 8

- 8.4

- 8.5

- 8.8

- 9

- 9.1

- 9.5

- 9.6

- 10

- 10.5

- 10.7

- 11

- 11.5

- 11.8

- 11.9

- 12

- 12.5

- 13

- 13.4

- 13.5

- 13.8

- 14

- 14.5

- 14.6

- 15

- 15.5

- 16

- 16.5

- 17

- 18

- 18.4

- 18.8

- 19

- 19.6

- 20

- 21

- 21.5

- 22

- 22.5

- 23

- 23.4

- 23.8

- 24

- 24.5

- 24.6

- 25

- 26

- 26.5

- 27

- 28

- 28.4

- 28.5

- 28.8

- 29

- 29.5

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 36.5

- 37

- 37.5

- 38

- 39

- 39.5

- 40

- 41

- 42

- 43.5

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 53.5

- 54

- 54.5

- 55

- 56

- 57

- 58

- 60

- 62

- 63

- 64

- 65

- 66

- 67

- 69

- 70

- 71

- 75

- 79

- 80

- 81

- 82

- 85

- 90

- 94

- 95

- 100

- 104

- 105

- 108

- 110

- 118

- 120

- 125

- 127

- 140

- 170

-

Main Body, Type

-

Round Shape

-

Polygonal Shape

-

T Shape

-

Wing Shape

-

Special Shape

-

Related Components

- Cylindrical

-

Round Shape

-

Main Body Material

- Stainless Steel

- Steel

- Aluminum

- Nylon

- Phenol

- ABS

- Polyacetal

- Brass

- Polyamide

- Polypropylene

- Melamine Plastic

- EPDM

- Others

- Vinyl

- Plastic_

-

Round Shape, Type

-

Cylindrical Shape

-

Clamp Shape

-

Mushroom Shape

-

Rose Shape

-

Volume Knob Shape

-

Balls

-

Cylindrical Shape

-

Mounting Section, Material

-

Threaded End Machining

- None

- Spherical

- With Pad

- Cone Point

-

Set Screw Flat Machining

-

Side Machined

-

Polygonal Shape, Type

-

T Shape, Type

-

Additional Function

-

Tapped, Round Hole Machining

-

Main Body, Surface Treatment

-

Mounting Section, Surface Treatment

Related Categories to Knob ScrewsDanh mục liên quan đến Knob Screws

FAQ Knob Screws

- Question: How do I properly install the knob screw?

- Answer: Here are some example to install a Knob Screws tapped type

1. Prepare the Surface: Clean and clear the area where the knob screw will be installed.

2. Choose the Right Screw: Select a screw with the appropriate size and thread that matches the knob.

3. Mark the Location: Use a pencil to mark where the knob screw will go, ensuring proper alignment.

4. Create Pilot Holes (if needed): Use a drill to create small guide holes in the marked spots, if the material is hard.

5. Insert the Screw: Place the screw through the knob and into the pilot hole or surface.

6. Tighten the Screw: Use a screwdriver to turn the screw clockwise, securely fastening the knob in place.

7. Test the Knob: Check the knob's movement and stability to ensure proper installation.

8. Adjust if Necessary: If the knob feels loose, you may need to tighten the screw further. - Question: Type of knobs screw?

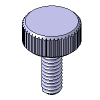

- Answer: There are various types of knob screws designed for specific applications. Here are a few common types:

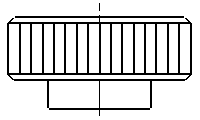

1. Round Knurled Thumb Screws: These have textured heads for better grip, often used in applications where a secure grip is essential.

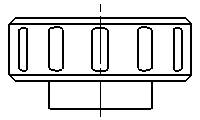

2. Lobed Knobs: Have a lobed design for a comfortable grip, commonly found on industrial and mechanical equipment.

3. Ball Knobs: These have a spherical shape and are commonly used on levers or control mechanisms.

4. T-Knobs: Shaped like the letter "T," these knobs are simple to turn and are used in applications where frequent adjustments are needed.

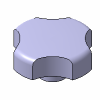

5. Star Knobs: Featuring a star-shaped head for easy turning, often used in applications requiring frequent adjustments.

6. Mushroom Knobs: Shaped like a mushroom. It is used for cabinets, drawers, and doors, these knobs provide a comfortable grip for opening and closing

- Question: How to choose the knob screw?

- Answer: Here are some example how to choose the knob screw

1. Usage: Identify its purpose, such as indoor/outdoor and specific applications like machines, jig fixtures, doors, cabinets, etc.

2. Material: Match durability to the environment (stainless steel, aluminum, brass and plastic (eg., ABS, Nylon and so on).

3. Thread Type and Thread Size : Ensure screw matches knob (Threaded, Tapped) or Press fit. and the thread size is appropriate to install

4. Size: Select a knob head size that is appropriate for your intended use.

5. Head Type: Choose based on knob design (eg.,round, T Shape, Wing Shape, Polygon shape etc.).

6. Easy to install : Ensure easy installation and tightening.

7. Follow Guidelines: Check knob manufacturer's recommendations. - Question: What is the usage for knob screw?

- Answer: The primary usage of a knob screw is to enable manual control, adjustment, or fastening in a wide range of applications. Here are additional examples of how knob screws are used:

1. Camera Tripods: Knob screws are used to secure the legs and adjust the height of camera tripods, aiding photographers in achieving stable shots.

2. HVAC Systems: Knob screws are used to control airflow direction and intensity in ventilation systems, enhancing indoor air quality and comfort.

3. Scientific Research Instruments: In laboratories, knob screws are employed to fine-tune the position of laser optics, ensuring precise experimental setups.

4. Automated Manufacturing: Knob screws play a role in industrial automation by adjusting the position of sensors. - Question: What is the difference of knob screw and door knob?

- Answer: Knob Screw:

A knob screw is a type of fastener used to secure or adjust objects together. It consists of a threaded and a head. The head is designed for easy gripping and turning by hand. Knob screws are commonly used in applications where frequent adjustments or temporary fastening is required. They are often found in devices like clamps, jigs, and fixtures. The main purpose of a knob screw is to provide a manual way of securing two components together without the need for additional tools.

Door Knob:

A door knob, on the other hand, is a handle or knob attached to a door that allows people to open and close the door. It is usually mounted on a spindle that connects the knob on the outside of the door to a mechanism on the inside, allowing the door to be latched or unlatched. Door knobs come in various designs and materials, and they serve both functional and aesthetic purposes. They are an integral part of doors in buildings and structures

In summary,

A knob screw is a threaded fastener used for securing or adjusting objects together, often by hand.

A door knob is a handle attached to a door, allowing people to open and close the door, serving a functional and aesthetic purpose.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy