(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Carbide Square End Mills(Torsion Angle (θ):Weak torsion (15 to 25˚))

[What is a carbide square end mill?]

A type of milling cutter. It is a tool that can perform complicated shaping such as linear or non-linear side surfaces inside grooves and holes, by using a carbide base material, with a cutting edge on the outside or the end surface, and moving the rotated tool in multiple directions. Major Japanese cutting manufacturer products are now expanding their areas of activity in the world manufacturing industry.

Search by specifying the lower class categoryTìm kiếm bằng cách chỉ định danh mục lớp thấp hơn

Square End Mills (Carbide)

Square End Mills (Carbide) Multi-Function Square End Mills (Carbide)

Multi-Function Square End Mills (Carbide) High Helical End Mills (Carbide)

High Helical End Mills (Carbide) Roughing End Mills (Carbide)

Roughing End Mills (Carbide) Long Neck Square End Mills (Carbide)

Long Neck Square End Mills (Carbide)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

33 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

- On Sale Till 31/03/2025

XAC series carbide roughing end mill, fine pitch / regular model

MISUMI

Strongly supports the cost reduction of roughing with the limited special price for standard sizes

- Volume Discount

- TiAlN

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 16 ~ 38 - 6 ~ 20 3 ~ 4 57 ~ 104 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN C plane Roughing From: 1,478,634 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

ULTRA FX Micro Grain Carbide End Mills TiAlN Corted 2 Flutes for Counterboring_FX-ZDS

OSG

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ An end mill dedicated to counter boring. It can be used not only for drilling counterbore holes for hex bolts, but also as a pre-machining tool for drilling on slopes.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 8 ~ 38 - 6 ~ 20 2 50 ~ 125 general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] Weak torsion (15 to 25˚) Countersinking TiAlN With Lead Square From: 1,544,642 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / short model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- 4 Flutes

- S (Short)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 10 ~ 38 17 ~ 66 6 ~ 20 4 57 ~ 104 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ The flute length is the same as the cutting diameter and features a 25° helix angle.・ Since the helix angle is weak, the tilt of the workpiece is suppressed to a minimum.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.5 ~ 12 0.5 ~ 12 - 4 ~ 12 2 40 ~ 70 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Aluminum[◎] / Copper[◎] / Resin[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts Non-Coated With Lead Square From: 821,618 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide end mill for key grooves, 2-flute / short model

MISUMI

[Features]·Demonstrates high performance in processing general steel, SUS304, and heat-treated steel (up to 50 HRC)·2-flute end mill for keyway machining·The end cutting edge shape is almost flat, so the workpiece can be finished flat.·Short flute length type that is resistant to chattering (1.5 times longer than cutting diameter)·Since the cutting edge has been processed into a sharp corner, it is also possible to machining corner edges·Optimal for machining in low to medium rotation range due to the general-purpose 30° helix angle·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties

- Volume Discount

- TS

- General Steel

- 2 Flutes

- S (Short)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 2 ~ 14 3 ~ 21 - 6 ~ 16 2 45 ~ 75 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) Sharp Edge Square From: 839,032 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / regular model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 15 ~ 45 20 ~ 92 6 ~ 20 3 ~ 4 60 ~ 130 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / long model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- 4 Flutes

- L (Long)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 25 ~ 65 30 ~ 112 6 ~ 20 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TSC series carbide roughing end mill, fine pitch / long regular model

MISUMI

[Features]·Roughing end mill capable of coarse and middle to coarse machining with fine pitch nick·Long shank type ideal for deep cavity milling·It has coating with high oxidation resistance and high hardness, and achieves a long service lifespan. Effective in high-speed machining and dry machining as coating properties·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- Volume Discount

- TS

- General Steel

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 20 15 ~ 45 20 ~ 95 6 ~ 20 3 ~ 4 100 ~ 150 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts For High Hardness (Silicon Group) Micro R Roughing Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CrN Coated Carbide Square End Mill for Copper Electrode Machining, 2-Flute / Regular Model

MISUMI

The CrN coating with excellent lubricity exhibits power in copper electrode processing

- Volume Discount

- CrN

- Copper

- 2 Flutes

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.5 ~ 12 1.5 ~ 36 - 4 ~ 12 2 50 ~ 90 Aluminum[○] / Copper[◎] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts CrN Sharp Edge Square From: 507,835 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Square End Mill for Copper Electrode Machining, 2-Flute / Regular Model

MISUMI

A non-coated type that has achieved both the cost reduction and processing performance

- Volume Discount

- Non-Coated

- Copper

- 2 Flutes

- R (Regular)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.5 ~ 20 1.5 ~ 60 - 4 ~ 20 2 50 ~ 130 Aluminum[○] / Copper[◎] / Graphite[○] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts Non-Coated Sharp Edge Square From: 650,173 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Long Neck for Copper Work, 2-Flute CURIB

NACHI(FUJIKOSHI)

Ideal for fine processing of copper electrodes. Also suitable for aluminum. Available in various sizes and can be used for all kinds of machining.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.3 ~ 6 0.4 ~ 9 1 ~ 60 4 ~ 6 2 45 ~ 120 Aluminum[◎] / Copper[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts CrN Sharp Edge Long-Neck Square From: 858,484 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![CRN-ES2000, for Copper Electrode Cutting, 2-Flute Square [Alteration Supported Product]](//vn.misumi-ec.com/linked/material/fs/UNO1/PHOTO/223000439643.jpg?$product_view_b$)

CRN-ES2000, for Copper Electrode Cutting, 2-Flute Square [Alteration Supported Product]

UNION TOOL

[Features]· CrN coating, which is effective in copper cutting, achieves a longer operating life· The blade design dedicated for copper achieves excellent cutting quality

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.2 ~ 12 0.6 ~ 40 - 4 ~ 12 2 40 ~ 100 Aluminum[○] / Copper[◎] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts CrN Sharp Edge Square From: 475,077 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CRN-ES4000 For Copper Electrode Processing, 4-Flute, Square

UNION TOOL

[Features]· CrN coating, which is effective in copper cutting, achieves a longer operating life· The blade design dedicated for copper achieves excellent cutting quality· O.D. Tolerance: 0/-0.02 (D ≤ 6), 0/-0.03 (D ≥ 8)

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 12 9 ~ 36 - 6 ~ 12 4 50 ~ 100 Aluminum[○] / Copper[◎] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts CrN Sharp Edge Square From: 671,010 VND Days to Ship: Số ngày giao hàng: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SSF120 CBN Super Surface End Mill

NS TOOL

[Features]・ Ideal for reference surface preparation machining during fine machining・ A stable machined surface is achieved by adopting a unique shape and corner radius.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.2 ~ 2 0.1 ~ 1 0.5 ~ 5 4 1 50 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / High Hardness Steel-HRC65[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts Non-Coated Micro R Square From: 4,009,931 VND Days to Ship: Số ngày giao hàng: 12 Day(s)  12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

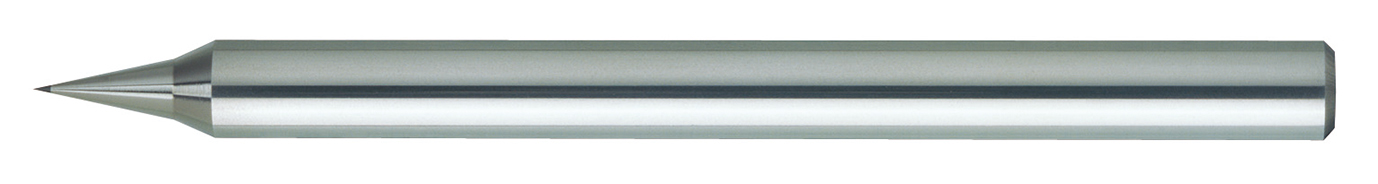

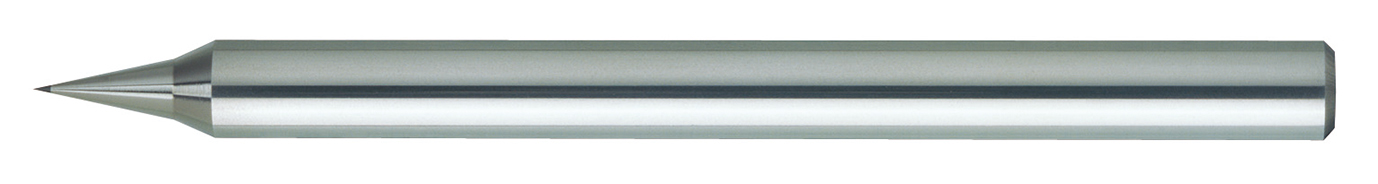

NS TOOL

Sharp edge achieved by matching NS machining technology with carefully selected CBN material

- CAD :

- 2D

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.03 ~ 0.1 0.03 ~ 0.1 - 4 1 50 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / High Hardness Steel-HRC65[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts Non-Coated Sharp Edge Square From: 6,177,388 VND Days to Ship: Số ngày giao hàng: 12 Day(s)  12 Day(s)

12 Day(s)

-

You can add up to 6 items per a category to the compare list.

DX For Copper Electrode / Aluminum / Plastic, 2-Blade End Mill

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ Two-flute end mill for copper electrodes, aluminum and plastics.Achieves one of the best vertical precision. A higher-grade finishing surface precision can be obtained.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.5 ~ 6 1 ~ 12 - 4 ~ 6 2 45 ~ 60 Aluminum[◎] / Copper[◎] / Resin[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts Non-Coated Sharp Edge Square From: 805,960 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MX225 MUGEN-COATING 2-Flute LEAD 25 End Mill

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ The flute length is the same as the cutting diameter and features a 25° helix angle.・ Designed with increased rigidity to minimize chattering and tilting during groove machining.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.3 ~ 12 0.3 ~ 12 - 4 ~ 12 2 45 ~ 80 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN With Lead Square From: 343,078 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MX425 MUGEN-COATING 4-Flute LEAD 25 End Mill

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ The flute length is the same as the cutting diameter and features a 25° helix angle.・ Designed with increased rigidity to minimize chattering and tilt of the machining surface.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 1 ~ 12 1 ~ 12 - 4 ~ 12 4 45 ~ 80 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN With Lead Square From: 613,961 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MUGEN-COATING PREMIUM 2-Flute LEAD 25 End Mill MXH225

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ Supports heat-resistant alloys such as stainless steel and titanium by adopting MUGEN Coating Premium.・ The flute length is the same as the cutting diameter and features a 25° helix angle.・ Designed with increased rigidity to minimize chattering and tilting during groove machining.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.1 ~ 6 0.1 ~ 6 - 4 ~ 6 2 45 ~ 50 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove For High Hardness (Silicon Group) With Lead Square From: 433,373 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MUGEN-COATING PREMIUM 2-Flute Sharp Edge LEAD 25 End Mill MXH225P

NS TOOL

[Notice] Alterations can now be specified. Please select from "Standard/Alterations Category" of narrowing conditions.[Features]・ By using MUGEN Coating Premium, a sharp corner available with heat-resistant alloys such as stainless steel and titanium.・ The flute length is the same as the cutting diameter and features a 25° helix angle.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 0.1 ~ 6 0.1 ~ 6 - 4 ~ 6 2 45 ~ 50 general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] Weak torsion (15 to 25˚) Plane / Side / Groove For High Hardness (Silicon Group) Sharp Edge Square From: 433,373 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TAC4, 4-flute, A-cut End Mill MA

ASAHI TOOLS

Ideal for improving efficiency in side milling.·Machining applications (machining shape): side milling / slotting·Materials: Carbide·Work material: general steel / heat-treated steel / stainless steel / cast iron / aluminum / copper / resin・ Coating: Uncoated

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 15 ~ 50 25 ~ 60 - 16 ~ 42 4 80 ~ 160 general steel[○] / Quenched and tempered steel[○] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] Weak torsion (15 to 25˚) Side / Groove Non-Coated C plane Square From: 3,885,596 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ASAHI TOOLS

JIS usage classification symbol. Uses a tip material equivalent to M30 for roughing. Improves rough machining performance for nonferrous metals, cast iron, steel, etc.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 20 ~ 40 40 ~ 80 - 20 ~ 42 4 130 ~ 180 general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Weak torsion (15 to 25˚) Side / Groove Non-Coated C plane Roughing From: 11,993,296 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ASAHI TOOLS

JIS usage classification symbol. Uses a tip material equivalent to M30 for roughing. Improves rough machining performance for nonferrous metals, cast iron, steel, etc.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 20 ~ 40 60 ~ 120 - 20 ~ 42 4 150 ~ 220 general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] Weak torsion (15 to 25˚) Side / Groove Non-Coated C plane Roughing From: 14,491,345 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SPSRC4A SP Series Roughing End Mill 4-Flute OK Coat

OKAZAKI SEIKO

Its unique roughing shape and the effect of OK coating enable heavy cutting and high speed machining.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 25 12 ~ 45 - 4 ~ 25 4 50 ~ 120 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] Weak torsion (15 to 25˚) Plane / Side / Groove TiAlN C plane Roughing From: 1,396,658 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 10 ~ 60 10 ~ 200 - 12 ~ 42 2 100 ~ 310 Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] Weak torsion (15 to 25˚) - Non-Coated C plane Square From: 5,359,355 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DIJET

Ultrafine particle carbide alloy with excellent wear resistance ensures long tool life.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 4 ~ 25 8 ~ 50 - 6 ~ 25 3 ~ 4 55 ~ 130 general steel[◎] / Quenched and tempered steel[◎] / Cast Iron[◎] Weak torsion (15 to 25˚) Side / Groove TiAlN - Roughing From: 4,788,828 VND Days to Ship: Số ngày giao hàng: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Roughing End Mill Regular 4-Flute for High Hardness Steel 3682

GUHRING

Capable of rough machining of hardened materials up to hardness of 56 HRC.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 6 ~ 20 - - 6 ~ 20 4 57 ~ 104 - Weak torsion (15 to 25˚) - - - Roughing From: 3,463,130 VND Days to Ship: Số ngày giao hàng: 24 Day(s) or more  24 Day(s) or more

24 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

High Chip Flow Performance Wave Shaped Blade for Ruffing 3RDSM, 4RDSM, 5RDSM (Medium)

KYOCERA

·Roughing corrugated cutting edge·For coarse machining, the repertoire includes 3, 4, and 5 flutes.The sine curve cutting edge reduces cutting force.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 5 ~ 8 13 ~ 16 - 6 ~ 8 3 57 ~ 63 general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] Weak torsion (15 to 25˚) Plane / Side / Groove TiAlN - Roughing From: 1,842,672 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Solid Fiber Cutter With/Without Coating CSFRP

EIKOSHA

[Features]· Ideal for machining carbon fiber and glass fiber.· Without base blade.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 10 ~ 45 - 4 ~ 20 6 ~ 16 50 ~ 110 - Weak torsion (15 to 25˚) Plane / Side / Countersinking Non-Coated - Roughing From: 1,533,321 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Carbide Solid Fiber Cutter with End Cutting Edge With/Without Coating CSFRPE

EIKOSHA

[Features]· Ideal for machining carbon fiber and glass fiber.· With base blade.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 20 10 ~ 45 - 4 ~ 20 Outer Diameter 6/Bottom Blade 3 ~ Outer Diameter 16/Bottom Blade 8 50 ~ 110 - Weak torsion (15 to 25˚) Plane / Side / Groove / Countersinking Non-Coated Sharp Edge Roughing From: 1,601,848 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

YG 1

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 3 ~ 25 8 ~ 50 - 6 ~ 25 3 ~ 5 50 ~ 100 general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] Weak torsion (15 to 25˚) Plane / Side / Groove / Inclined Cuts TiAlN - Long-Neck Square From: 986,171 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroMill Plura Carbide Square End Mill 2P

SANDVIK

High quality carbide end mill tools for a highly productive, efficient and reliable milling solution

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type 2 ~ 20 - - 2.9 ~ 20 2 38 ~ 150 Aluminum[○] / Copper[○] Weak torsion (15 to 25˚) Plane / Side - - Square From: 1,847,650 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

DXL 2-Flute Long End Mill For Copper Electrode/Aluminum/Plastic

NS TOOL

[Features]· 2-flute long end mill for copper electrode, aluminum and plastic.

Blade diameter (D)(φ) Blade length (ℓ)(mm) Underneck length (ℓ1)(mm) Shank diameter (d)(mm) Number of flutes(sheet) Overall Length (L)(mm) work material Torsion Angle (θ) Machining Application Coating Blade tip shape Type - - - - - - Aluminum[◎] / Copper[◎] / Resin[◎] Weak torsion (15 to 25˚) Plane / Side Non-Coated Sharp Edge Square From: 3,004,982 VND Days to Ship: Số ngày giao hàng: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| SpecificationsĐặc điểm kĩ thuật |

| Blade diameter (D)(φ) |

| Blade length (ℓ)(mm) |

| Underneck length (ℓ1)(mm) |

| Shank diameter (d)(mm) |

| Number of flutes(sheet) |

| Overall Length (L)(mm) |

| work material |

| Torsion Angle (θ) |

| Machining Application |

| Coating |

| Blade tip shape |

| Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | OSG | MISUMI | NS TOOL | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | NACHI(FUJIKOSHI) | UNION TOOL | UNION TOOL | NS TOOL | NS TOOL | NS TOOL | NS TOOL | NS TOOL | NS TOOL | NS TOOL | ASAHI TOOLS | ASAHI TOOLS | ASAHI TOOLS | OKAZAKI SEIKO | DIJET | DIJET | GUHRING | KYOCERA | EIKOSHA | EIKOSHA | YG 1 | SANDVIK | NS TOOL |

| Product SeriesDòng sản phẩm | XAC series carbide roughing end mill, fine pitch / regular model | ULTRA FX Micro Grain Carbide End Mills TiAlN Corted 2 Flutes for Counterboring_FX-ZDS | TSC series carbide roughing end mill, fine pitch / short model | TSC series carbide end mill for key grooves, 2-flute / short model | TSC series carbide roughing end mill, fine pitch / regular model | TSC series carbide roughing end mill, fine pitch / long model | TSC series carbide roughing end mill, fine pitch / long regular model | CrN Coated Carbide Square End Mill for Copper Electrode Machining, 2-Flute / Regular Model | Carbide Square End Mill for Copper Electrode Machining, 2-Flute / Regular Model | CRN-ES2000, for Copper Electrode Cutting, 2-Flute Square [Alteration Supported Product] | DX For Copper Electrode / Aluminum / Plastic, 2-Blade End Mill | MUGEN-COATING PREMIUM 2-Flute Sharp Edge LEAD 25 End Mill MXH225P | Roughing End Mill Regular 4-Flute for High Hardness Steel 3682 | High Chip Flow Performance Wave Shaped Blade for Ruffing 3RDSM, 4RDSM, 5RDSM (Medium) | Carbide Solid Fiber Cutter with End Cutting Edge With/Without Coating CSFRPE | DXL 2-Flute Long End Mill For Copper Electrode/Aluminum/Plastic | |||||||||||||||||

| CADCAD |

| ||||||||||||||||||||||||||||||||

| From | 1,478,634 VND Special Price On Sale Till 31/03/2025 | 1,544,642 VND | 821,618 VND | 839,032 VND | 507,835 VND | 650,173 VND | 858,484 VND | 475,077 VND | 671,010 VND | 4,009,931 VND | 6,177,388 VND | 805,960 VND | 343,078 VND | 613,961 VND | 433,373 VND | 433,373 VND | 3,885,596 VND | 11,993,296 VND | 14,491,345 VND | 1,396,658 VND | 5,359,355 VND | 4,788,828 VND | 3,463,130 VND | 1,842,672 VND | 1,533,321 VND | 1,601,848 VND | 986,171 VND | 1,847,650 VND | 3,004,982 VND | ||||

| Days to ShipSố ngày giao hàng | Same day or more | 6 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 12 Day(s) | 12 Day(s) | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 24 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more |

| SpecificationsĐặc điểm kĩ thuật |

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

| Blade diameter (D)(φ) | 6 ~ 20 | 3 ~ 20 | 5 ~ 20 | 0.5 ~ 12 | 2 ~ 14 | 3 ~ 20 | 6 ~ 20 | 5 ~ 20 | 0.5 ~ 12 | 0.5 ~ 20 | 0.3 ~ 6 | 0.2 ~ 12 | 3 ~ 12 | 0.2 ~ 2 | 0.03 ~ 0.1 | 0.5 ~ 6 | 0.3 ~ 12 | 1 ~ 12 | 0.1 ~ 6 | 0.1 ~ 6 | 15 ~ 50 | 20 ~ 40 | 20 ~ 40 | 5 ~ 25 | 10 ~ 60 | 4 ~ 25 | 6 ~ 20 | 5 ~ 8 | 3 ~ 20 | 3 ~ 20 | 3 ~ 25 | 2 ~ 20 | - |

| Blade length (ℓ)(mm) | 16 ~ 38 | 8 ~ 38 | 10 ~ 38 | 0.5 ~ 12 | 3 ~ 21 | 15 ~ 45 | 25 ~ 65 | 15 ~ 45 | 1.5 ~ 36 | 1.5 ~ 60 | 0.4 ~ 9 | 0.6 ~ 40 | 9 ~ 36 | 0.1 ~ 1 | 0.03 ~ 0.1 | 1 ~ 12 | 0.3 ~ 12 | 1 ~ 12 | 0.1 ~ 6 | 0.1 ~ 6 | 25 ~ 60 | 40 ~ 80 | 60 ~ 120 | 12 ~ 45 | 10 ~ 200 | 8 ~ 50 | - | 13 ~ 16 | 10 ~ 45 | 10 ~ 45 | 8 ~ 50 | - | - |

| Underneck length (ℓ1)(mm) | - | - | 17 ~ 66 | - | - | 20 ~ 92 | 30 ~ 112 | 20 ~ 95 | - | - | 1 ~ 60 | - | - | 0.5 ~ 5 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Shank diameter (d)(mm) | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 4 ~ 12 | 6 ~ 16 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 4 ~ 12 | 4 ~ 20 | 4 ~ 6 | 4 ~ 12 | 6 ~ 12 | 4 | 4 | 4 ~ 6 | 4 ~ 12 | 4 ~ 12 | 4 ~ 6 | 4 ~ 6 | 16 ~ 42 | 20 ~ 42 | 20 ~ 42 | 4 ~ 25 | 12 ~ 42 | 6 ~ 25 | 6 ~ 20 | 6 ~ 8 | 4 ~ 20 | 4 ~ 20 | 6 ~ 25 | 2.9 ~ 20 | - |

| Number of flutes(sheet) | 3 ~ 4 | 2 | 4 | 2 | 2 | 3 ~ 4 | 4 | 3 ~ 4 | 2 | 2 | 2 | 2 | 4 | 1 | 1 | 2 | 2 | 4 | 2 | 2 | 4 | 4 | 4 | 4 | 2 | 3 ~ 4 | 4 | 3 | 6 ~ 16 | Outer Diameter 6/Bottom Blade 3 ~ Outer Diameter 16/Bottom Blade 8 | 3 ~ 5 | 2 | - |

| Overall Length (L)(mm) | 57 ~ 104 | 50 ~ 125 | 57 ~ 104 | 40 ~ 70 | 45 ~ 75 | 60 ~ 130 | 100 ~ 150 | 100 ~ 150 | 50 ~ 90 | 50 ~ 130 | 45 ~ 120 | 40 ~ 100 | 50 ~ 100 | 50 | 50 | 45 ~ 60 | 45 ~ 80 | 45 ~ 80 | 45 ~ 50 | 45 ~ 50 | 80 ~ 160 | 130 ~ 180 | 150 ~ 220 | 50 ~ 120 | 100 ~ 310 | 55 ~ 130 | 57 ~ 104 | 57 ~ 63 | 50 ~ 110 | 50 ~ 110 | 50 ~ 100 | 38 ~ 150 | - |

| work material | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Aluminum[◎] / Copper[◎] / Resin[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | Aluminum[○] / Copper[◎] / Resin[○] | Aluminum[○] / Copper[◎] / Graphite[○] / Resin[○] | Aluminum[◎] / Copper[◎] | Aluminum[○] / Copper[◎] / Resin[○] | Aluminum[○] / Copper[◎] / Resin[○] | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / High Hardness Steel-HRC65[◎] | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / High Hardness Steel-HRC60[◎] / High Hardness Steel-HRC65[◎] | Aluminum[◎] / Copper[◎] / Resin[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[◎] / Titanium[○] / Copper[◎] / Resin[◎] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] | general steel[◎] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[◎] / Stainless Steel[◎] / Aluminum[○] / Titanium[◎] / Copper[○] / Resin[○] | general steel[○] / Quenched and tempered steel[○] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] / Resin[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[◎] / Cast Iron[◎] / Aluminum[○] / Titanium[○] | Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / Cast Iron[◎] | - | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] | - | - | general steel[○] / Quenched and tempered steel[◎] / High Hardness Steel-HRC55[○] / Stainless Steel[○] / Cast Iron[○] | Aluminum[○] / Copper[○] | Aluminum[◎] / Copper[◎] / Resin[◎] |

| Torsion Angle (θ) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) | Weak torsion (15 to 25˚) |

| Machining Application | Plane / Side / Groove / Inclined Cuts | Countersinking | Plane / Side / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove / Inclined Cuts | Plane / Side / Groove | Plane / Side / Groove | Side / Groove | Side / Groove | Side / Groove | Plane / Side / Groove | - | Side / Groove | - | Plane / Side / Groove | Plane / Side / Countersinking | Plane / Side / Groove / Countersinking | Plane / Side / Groove / Inclined Cuts | Plane / Side | Plane / Side |

| Coating | TiAlN | TiAlN | For High Hardness (Silicon Group) | Non-Coated | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | CrN | Non-Coated | CrN | CrN | CrN | Non-Coated | Non-Coated | Non-Coated | TiAlN | TiAlN | For High Hardness (Silicon Group) | For High Hardness (Silicon Group) | Non-Coated | Non-Coated | Non-Coated | TiAlN | Non-Coated | TiAlN | - | TiAlN | Non-Coated | Non-Coated | TiAlN | - | Non-Coated |

| Blade tip shape | C plane | With Lead | Micro R | With Lead | Sharp Edge | Micro R | Micro R | Micro R | Sharp Edge | Sharp Edge | Sharp Edge | Sharp Edge | Sharp Edge | Micro R | Sharp Edge | Sharp Edge | With Lead | With Lead | With Lead | Sharp Edge | C plane | C plane | C plane | C plane | C plane | - | - | - | - | Sharp Edge | - | - | Sharp Edge |

| Type | Roughing | Square | Roughing | Square | Square | Roughing | Roughing | Roughing | Square | Square | Long-Neck Square | Square | Square | Square | Square | Square | Square | Square | Square | Square | Square | Roughing | Roughing | Roughing | Square | Roughing | Roughing | Roughing | Roughing | Roughing | Long-Neck Square | Square | Square |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Blade diameter (D)(φ)

-

0.01~0.99

- 0.01

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.31

- 0.32

- 0.33

- 0.34

- 0.35

- 0.36

- 0.37

- 0.38

- 0.39

- 0.4

- 0.41

- 0.42

- 0.43

- 0.44

- 0.45

- 0.46

- 0.47

- 0.48

- 0.49

- 0.5

- 0.51

- 0.52

- 0.53

- 0.54

- 0.55

- 0.56

- 0.57

- 0.58

- 0.59

- 0.6

- 0.61

- 0.62

- 0.63

- 0.64

- 0.65

- 0.66

- 0.67

- 0.68

- 0.69

- 0.7

- 0.71

- 0.72

- 0.73

- 0.74

- 0.75

- 0.76

- 0.77

- 0.78

- 0.79

- 0.8

- 0.81

- 0.82

- 0.83

- 0.84

- 0.85

- 0.86

- 0.87

- 0.88

- 0.89

- 0.9

- 0.91

- 0.92

- 0.93

- 0.94

- 0.95

- 0.96

- 0.97

- 0.98

- 0.99

-

1~1.99

- 1

- 1.01

- 1.02

- 1.03

- 1.04

- 1.05

- 1.06

- 1.07

- 1.08

- 1.09

- 1.1

- 1.11

- 1.12

- 1.13

- 1.14

- 1.15

- 1.16

- 1.17

- 1.18

- 1.19

- 1.2

- 1.21

- 1.22

- 1.23

- 1.24

- 1.25

- 1.26

- 1.27

- 1.28

- 1.29

- 1.3

- 1.31

- 1.32

- 1.33

- 1.34

- 1.35

- 1.36

- 1.37

- 1.38

- 1.39

- 1.4

- 1.41

- 1.42

- 1.43

- 1.44

- 1.45

- 1.46

- 1.47

- 1.48

- 1.49

- 1.5

- 1.51

- 1.52

- 1.53

- 1.54

- 1.55

- 1.56

- 1.57

- 1.58

- 1.59

- 1.6

- 1.61

- 1.62

- 1.63

- 1.64

- 1.65

- 1.66

- 1.67

- 1.68

- 1.69

- 1.7

- 1.71

- 1.72

- 1.73

- 1.74

- 1.75

- 1.76

- 1.77

- 1.78

- 1.79

- 1.8

- 1.81

- 1.82

- 1.83

- 1.84

- 1.85

- 1.86

- 1.87

- 1.88

- 1.89

- 1.9

- 1.91

- 1.92

- 1.93

- 1.94

- 1.95

- 1.96

- 1.97

- 1.98

- 1.99

-

2~2.99

- 2

- 2.01

- 2.02

- 2.03

- 2.04

- 2.05

- 2.06

- 2.07

- 2.08

- 2.09

- 2.1

- 2.11

- 2.12

- 2.13

- 2.14

- 2.15

- 2.16

- 2.17

- 2.18

- 2.19

- 2.2

- 2.21

- 2.22

- 2.23

- 2.24

- 2.25

- 2.26

- 2.27

- 2.28

- 2.29

- 2.3

- 2.31

- 2.32

- 2.33

- 2.34

- 2.35

- 2.36

- 2.37

- 2.38

- 2.39

- 2.4

- 2.41

- 2.42

- 2.43

- 2.44

- 2.45

- 2.46

- 2.47

- 2.48

- 2.49

- 2.5

- 2.51

- 2.52

- 2.53

- 2.54

- 2.55

- 2.56

- 2.57

- 2.58

- 2.59

- 2.6

- 2.61

- 2.62

- 2.63

- 2.64

- 2.65

- 2.66

- 2.67

- 2.68

- 2.69

- 2.7

- 2.71

- 2.72

- 2.73

- 2.74

- 2.75

- 2.76

- 2.77

- 2.78

- 2.79

- 2.8

- 2.81

- 2.82

- 2.83

- 2.84

- 2.85

- 2.86

- 2.87

- 2.88

- 2.89

- 2.9

- 2.91

- 2.92

- 2.93

- 2.94

- 2.95

- 2.96

- 2.97

- 2.98

- 2.99

-

3~3.99

- 3

- 3.01

- 3.02

- 3.03

- 3.04

- 3.05

- 3.06

- 3.07

- 3.08

- 3.09

- 3.1

- 3.11

- 3.12

- 3.13

- 3.14

- 3.15

- 3.16

- 3.17

- 3.175

- 3.18

- 3.19

- 3.2

- 3.21

- 3.22

- 3.23

- 3.24

- 3.25

- 3.26

- 3.27

- 3.28

- 3.29

- 3.3

- 3.31

- 3.32

- 3.33

- 3.34

- 3.35

- 3.36

- 3.37

- 3.38

- 3.39

- 3.4

- 3.41

- 3.42

- 3.43

- 3.44

- 3.45

- 3.46

- 3.47

- 3.48

- 3.49

- 3.5

- 3.51

- 3.52

- 3.53

- 3.54

- 3.55

- 3.56

- 3.57

- 3.58

- 3.59

- 3.6

- 3.61

- 3.62

- 3.63

- 3.64

- 3.65

- 3.66

- 3.67

- 3.68

- 3.69

- 3.7

- 3.71

- 3.72

- 3.73

- 3.74

- 3.75

- 3.76

- 3.77

- 3.78

- 3.79

- 3.8

- 3.81

- 3.82

- 3.83

- 3.84

- 3.85

- 3.86

- 3.87

- 3.88

- 3.89

- 3.9

- 3.91

- 3.92

- 3.93

- 3.94

- 3.95

- 3.96

- 3.97

- 3.98

- 3.99

-

4~4.99

- 4

- 4.01

- 4.02

- 4.03

- 4.04

- 4.05

- 4.06

- 4.07

- 4.08

- 4.09

- 4.1

- 4.11

- 4.12

- 4.13

- 4.14

- 4.15

- 4.16

- 4.17

- 4.18

- 4.19

- 4.2

- 4.21

- 4.22

- 4.23

- 4.24

- 4.25

- 4.26

- 4.27

- 4.28

- 4.29

- 4.3

- 4.31

- 4.32

- 4.33

- 4.34

- 4.35

- 4.36

- 4.37

- 4.38

- 4.39

- 4.4

- 4.41

- 4.42

- 4.43

- 4.44

- 4.45

- 4.46

- 4.47

- 4.48

- 4.49

- 4.5

- 4.51

- 4.52

- 4.53

- 4.54

- 4.55

- 4.56

- 4.57

- 4.58

- 4.59

- 4.6

- 4.61

- 4.62

- 4.63

- 4.64

- 4.65

- 4.66

- 4.67

- 4.68

- 4.69

- 4.7

- 4.71

- 4.72

- 4.73

- 4.74

- 4.75

- 4.76

- 4.77

- 4.78

- 4.79

- 4.8

- 4.81

- 4.82

- 4.83

- 4.84

- 4.85

- 4.86

- 4.87

- 4.88

- 4.89

- 4.9

- 4.91

- 4.92

- 4.93

- 4.94

- 4.95

- 4.96

- 4.97

- 4.98

- 4.99

-

5~5.99

- 5

- 5.01

- 5.02

- 5.03

- 5.04

- 5.05

- 5.06

- 5.07

- 5.08

- 5.09

- 5.1

- 5.11

- 5.12

- 5.13

- 5.14

- 5.15

- 5.16

- 5.17

- 5.18

- 5.19

- 5.2

- 5.21

- 5.22

- 5.23

- 5.24

- 5.25

- 5.26

- 5.27

- 5.28

- 5.29

- 5.3

- 5.31

- 5.32

- 5.33

- 5.34

- 5.35

- 5.36

- 5.37

- 5.38

- 5.39

- 5.4

- 5.41

- 5.42

- 5.43

- 5.44

- 5.45

- 5.46

- 5.47

- 5.48

- 5.49

- 5.5

- 5.51

- 5.52

- 5.53

- 5.54

- 5.55

- 5.56

- 5.57

- 5.58

- 5.59

- 5.6

- 5.61

- 5.62

- 5.63

- 5.64

- 5.65

- 5.66

- 5.67

- 5.68

- 5.69

- 5.7

- 5.71

- 5.72

- 5.73

- 5.74

- 5.75

- 5.76

- 5.77

- 5.78

- 5.79

- 5.8

- 5.81

- 5.82

- 5.83

- 5.84

- 5.85

- 5.86

- 5.87

- 5.88

- 5.89

- 5.9

- 5.91

- 5.92

- 5.93

- 5.94

- 5.95

- 5.96

- 5.97

- 5.98

- 5.99

-

6~6.9

- 6

- 6H

- 6.01

- 6.05

- 6.1

- 6.2

- 6.25

- 6.3

- 6.35

- 6.4

- 6.5

- 6.57

- 6.6

- 6.7

- 6.75

- 6.8

- 6.9

-

7~7.99

- 7

- 7.01

- 7.02

- 7.03

- 7.04

- 7.05

- 7.06

- 7.07

- 7.08

- 7.09

- 7.1

- 7.11

- 7.12

- 7.13

- 7.14

- 7.15

- 7.16

- 7.17

- 7.18

- 7.19

- 7.2

- 7.21

- 7.22

- 7.23

- 7.24

- 7.25

- 7.26

- 7.27

- 7.28

- 7.29

- 7.3

- 7.31

- 7.32

- 7.33

- 7.34

- 7.35

- 7.36

- 7.37

- 7.38

- 7.39

- 7.4

- 7.41

- 7.42

- 7.43

- 7.44

- 7.45

- 7.46

- 7.47

- 7.48

- 7.49

- 7.5

- 7.51

- 7.52

- 7.53

- 7.54

- 7.55

- 7.56

- 7.57

- 7.58

- 7.59

- 7.6

- 7.61

- 7.62

- 7.63

- 7.64

- 7.65

- 7.66

- 7.67

- 7.68

- 7.69

- 7.7

- 7.71

- 7.72

- 7.73

- 7.74

- 7.75

- 7.76

- 7.77

- 7.78

- 7.79

- 7.8

- 7.81

- 7.82

- 7.83

- 7.84

- 7.85

- 7.86

- 7.87

- 7.88

- 7.89

- 7.9

- 7.91

- 7.92

- 7.93

- 7.94

- 7.95

- 7.96

- 7.97

- 7.98

- 7.99

-

8~8.9

- 8

- 8H

- 8.01

- 8.02

- 8.1

- 8.15

- 8.2

- 8.21

- 8.25

- 8.3

- 8.4

- 8.5

- 8.6

- 8.7

- 8.75

- 8.8

- 8.9

-

9~9.99

- 9

- 9.01

- 9.02

- 9.03

- 9.04

- 9.05

- 9.06

- 9.07

- 9.08

- 9.09

- 9.1

- 9.11

- 9.12

- 9.13

- 9.14

- 9.15

- 9.16

- 9.17

- 9.18

- 9.19

- 9.2

- 9.21

- 9.22

- 9.23

- 9.24

- 9.25

- 9.26

- 9.27

- 9.28

- 9.29

- 9.3

- 9.31

- 9.32

- 9.33

- 9.34

- 9.35

- 9.36

- 9.37

- 9.38

- 9.39

- 9.4

- 9.41

- 9.42

- 9.43

- 9.44

- 9.45

- 9.46

- 9.47

- 9.48

- 9.49

- 9.5

- 9.51

- 9.52

- 9.53

- 9.54

- 9.55

- 9.56

- 9.57

- 9.58

- 9.59

- 9.6

- 9.61

- 9.62

- 9.63

- 9.64

- 9.65

- 9.66

- 9.67

- 9.68

- 9.69

- 9.7

- 9.71

- 9.72

- 9.73

- 9.74

- 9.75

- 9.76

- 9.77

- 9.78

- 9.79

- 9.8

- 9.81

- 9.82

- 9.83

- 9.84

- 9.85

- 9.86

- 9.87

- 9.88

- 9.89

- 9.9

- 9.91

- 9.92

- 9.93

- 9.94

- 9.95

- 9.96

- 9.97

- 9.98

- 9.99

-

10~10.9

- 10

- 10H

- 10.1

- 10.15

- 10.2

- 10.3

- 10.4

- 10.5

- 10.6

- 10.7

- 10.8

- 10.9

-

11~11.99

- 11

- 11.01

- 11.02

- 11.03

- 11.04

- 11.05

- 11.06

- 11.07

- 11.08

- 11.09

- 11.1

- 11.11

- 11.12

- 11.13

- 11.14

- 11.15

- 11.16

- 11.17

- 11.18

- 11.19

- 11.2

- 11.21

- 11.22

- 11.23

- 11.24

- 11.25

- 11.26

- 11.27

- 11.28

- 11.29

- 11.3

- 11.31

- 11.32

- 11.33

- 11.34

- 11.35

- 11.36

- 11.37

- 11.38

- 11.39

- 11.4

- 11.41

- 11.42

- 11.43

- 11.44

- 11.45

- 11.46

- 11.47

- 11.48

- 11.49

- 11.5

- 11.51

- 11.52

- 11.53

- 11.54

- 11.55

- 11.56

- 11.57

- 11.58

- 11.59

- 11.6

- 11.61

- 11.62

- 11.63

- 11.64

- 11.65

- 11.66

- 11.67

- 11.68

- 11.69

- 11.7

- 11.71

- 11.72

- 11.73

- 11.74

- 11.75

- 11.76

- 11.77

- 11.78

- 11.79

- 11.8

- 11.81

- 11.82

- 11.83

- 11.84

- 11.85

- 11.86

- 11.87

- 11.88

- 11.89

- 11.9

- 11.91

- 11.92

- 11.93

- 11.94

- 11.95

- 11.96

- 11.97

- 11.98

- 11.99

-

12~12.9

- 12

- 12H

- 12.1

- 12.2

- 12.3

- 12.4

- 12.5

- 12.6

- 12.7

- 12.8

- 12.9

-

13~13.9

- 13

- 13.1

- 13.2

- 13.3

- 13.4

- 13.5

- 13.6

- 13.7

- 13.8

- 13.9

-

14~14.9

- 14

- 14.1

- 14.2

- 14.3

- 14.4

- 14.5

- 14.6

- 14.7

- 14.8

- 14.9

-

15~15.99

- 15

- 15.1

- 15.2

- 15.3

- 15.4

- 15.5

- 15.51

- 15.52

- 15.53

- 15.54

- 15.55

- 15.56

- 15.57

- 15.58

- 15.59

- 15.6

- 15.61

- 15.62

- 15.63

- 15.64

- 15.65

- 15.66

- 15.67

- 15.68

- 15.69

- 15.7

- 15.71

- 15.72

- 15.73

- 15.74

- 15.75

- 15.76

- 15.77

- 15.78

- 15.79

- 15.8

- 15.81

- 15.82

- 15.83

- 15.84

- 15.85

- 15.86

- 15.87

- 15.88

- 15.89

- 15.9

- 15.91

- 15.92

- 15.93

- 15.94

- 15.95

- 15.96

- 15.97

- 15.98

- 15.99

-

16~16.9

- 16

- 16.1

- 16.2

- 16.3

- 16.4

- 16.5

- 16.6

- 16.7

- 16.8

- 16.9

-

17~17.9

- 17

- 17.1

- 17.2

- 17.3

- 17.4

- 17.5

- 17.6

- 17.7

- 17.8

- 17.9

-

18~18.9

- 18

- 18.1

- 18.2

- 18.3

- 18.4

- 18.5

- 18.6

- 18.7

- 18.8

- 18.9

-

19~19.99

- 19

- 19..5

- 19.1

- 19.2

- 19.3

- 19.4

- 19.5

- 19.51

- 19.52

- 19.53

- 19.54

- 19.55

- 19.56

- 19.57

- 19.58

- 19.59

- 19.6

- 19.61

- 19.62

- 19.63

- 19.64

- 19.65

- 19.66

- 19.67

- 19.68

- 19.69

- 19.7

- 19.71

- 19.72

- 19.73

- 19.74

- 19.75

- 19.76

- 19.77

- 19.78

- 19.79

- 19.8

- 19.81

- 19.82

- 19.83

- 19.84

- 19.85

- 19.86

- 19.87

- 19.88

- 19.89

- 19.9

- 19.91

- 19.92

- 19.93

- 19.94

- 19.95

- 19.96

- 19.97

- 19.98

- 19.99

-

20~20.5

- 20

- 20.5

-

21~21.5

- 21

- 21.5

-

22~22.5

- 22

- 22.5

-

23~23.5

- 23

- 23.5

-

24~24.5

- 24

- 24.5

-

25~25.5

- 25

- 25.5

-

26~26.5

- 26

- 26.5

-

27~27.5

- 27

- 27.5

-

28~28.5

- 28

- 28.5

-

29~29.5

- 29

- 29.5

-

30

-

31

-

32

-

33

-

34

-

35

-

36

-

37

-

38

-

39

-

40

-

41

-

42

-

43

-

44

-

45

-

46

-

47

-

48

-

49

-

50

-

51

-

52

-

53

-

54

-

55

-

56

-

57

-

58

-

59

-

60

-

-

Blade length (ℓ)(mm)

-

0.01~0.9

- 0.01

- 0.02

- 0.03

- 0.04

- 0.045

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.12

- 0.135

- 0.15

- 0.16

- 0.2

- 0.23

- 0.24

- 0.25

- 0.3

- 0.32

- 0.4

- 0.45

- 0.5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- 0.8

- 0.9

-

1~1.9

- 1

- 1.05

- 1.1

- 1.2

- 1.25

- 1.3

- 1.35

- 1.4

- 1.5

- 1.6

- 1.7

- 1.75

- 1.8

- 1.9

-

2~2.9

- 2

- 2.1

- 2.2

- 2.25

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

-

3~3.9

- 3

- 3.1

- 3.2

- 3.3

- 3.4

- 3.5

- 3.6

- 3.7

- 3.75

- 3.8

- 3.9

-

4~4.9

- 4

- 4.1

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.7

- 4.8

- 4.9

-

5~5.9

- 5

- 5.1

- 5.2

- 5.25

- 5.3

- 5.4

- 5.5

- 5.6

- 5.7

- 5.8

- 5.9

-

6~6.9

- 6

- 6.1

- 6.2

- 6.25

- 6.3

- 6.4

- 6.5

- 6.6

- 6.7

- 6.75

- 6.8

- 6.9

-

7~7.9

- 7

- 7.1

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 7.9

-

8~8.9

- 8

- 8.1

- 8.2

- 8.25

- 8.3

- 8.4

- 8.5

- 8.6

- 8.7

- 8.8

- 8.9

-

9~9.9

- 9

- 9.1

- 9.2

- 9.3

- 9.4

- 9.5

- 9.6

- 9.7

- 9.8

- 9.9

-

10~10.9

- 10

- 10.1

- 10.2

- 10.3

- 10.4

- 10.5

- 10.6

- 10.7

- 10.8

- 10.9

-

11~11.9

- 11

- 11.1

- 11.2

- 11.3

- 11.4

- 11.5

- 11.6

- 11.7

- 11.8

- 11.9

-

12

-

12~12.9

- 12.2

- 12.3

- 12.4

- 12.5

- 12.6

- 12.8

- 12.9

-

13~13.8

- 13

- 13.1

- 13.2

- 13.3

- 13.4

- 13.5

- 13.6

- 13.8

-

14~14.8

- 14

- 14.1

- 14.2

- 14.3

- 14.4

- 14.5

- 14.6

- 14.7

- 14.8

-

15~15.9

- 15

- 15.2

- 15.3

- 15.4

- 15.5

- 15.6

- 15.8

- 15.9

-

16~16.8

- 16

- 16.2

- 16.4

- 16.5

- 16.6

- 16.8

-

17~17.8

- 17

- 17.1

- 17.2

- 17.3

- 17.4

- 17.5

- 17.6

- 17.7

- 17.8

-

18~18.8

- 18

- 18.2

- 18.3

- 18.4

- 18.5

- 18.6

- 18.8

-

19~19.8

- 19

- 19.2

- 19.4

- 19.5

- 19.6

- 19.8

-

20~20.8

- 20

- 20.1

- 20.2

- 20.4

- 20.5

- 20.6

- 20.7

- 20.8

-

21~21.9

- 21

- 21.2

- 21.3

- 21.4

- 21.5

- 21.6

- 21.8

- 21.9

-

22~22.8

- 22

- 22.2

- 22.4

- 22.5

- 22.6

- 22.8

-

23~23.8

- 23

- 23.1

- 23.2

- 23.4

- 23.5

- 23.6

- 23.8

-

24~24.9

- 24

- 24.2

- 24.3

- 24.4

- 24.5

- 24.6

- 24.8

- 24.9

-

25~25.8

- 25

- 25.2

- 25.4

- 25.5

- 25.6

- 25.8

-

26~26.8

- 26

- 26.2

- 26.4

- 26.5

- 26.6

- 26.7

- 26.8

-

27~27.9

- 27

- 27.2

- 27.3

- 27.4

- 27.5

- 27.6

- 27.8

- 27.9

-

28~28.8

- 28

- 28.2

- 28.4

- 28.5

- 28.8

-

29~29.80

- 29

- 29.1

- 29.2

- 29.5

- 29.6

- 29.7

- 29.80

-

30~30.9

- 30

- 30.3

- 30.4

- 30.5

- 30.6

- 30.8

- 30.9

-

31~31.8

- 31

- 31.2

- 31.5

- 31.6

- 31.8

-

32~32.8

- 32

- 32.1

- 32.4

- 32.5

- 32.7

- 32.8

-

33~33.9

- 33

- 33.2

- 33.3

- 33.6

- 33.9

-

34~34.8

- 34

- 34.2

- 34.4

- 34.5

- 34.8

-

35~35.80

- 35

- 35.1

- 35.2

- 35.4

- 35.5

- 35.6

- 35.7

- 35.80

-

36~36.8

- 36

- 36.4

- 36.5

- 36.8

-

37~37.6

- 37

- 37.2

- 37.5

- 37.6

-

38~38.8

- 38

- 38.4

- 38.5

- 38.8

-

39~39.6

- 39

- 39.2

- 39.5

- 39.6

-

40~40.8

- 40

- 40.4

- 40.5

- 40.8

-

41~41.6

- 41

- 41.2

- 41.5

- 41.6

-

42~42.8

- 42

- 42.4

- 42.5

- 42.8

-

43~43.6

- 43

- 43.2

- 43.5

- 43.6

-

44~44.8

- 44

- 44.4

- 44.5

- 44.8

-

45~45.5

- 45

- 45.2

- 45.5

-

46~46.8

- 46

- 46.4

- 46.5

- 46.8

-

47~47.80

- 47

- 47.2

- 47.5

- 47.6

- 47.80

-

48~48.5

- 48

- 48.5

-

49~49.5

- 49

- 49.5

-

50~50.5

- 50

- 50.5

-

51~51.5

- 51

- 51.5

-

52

-

53~53.5

- 53

- 53.5

-

54~54.5

- 54

- 54.5

-

55~55.5

- 55

- 55.5

-

56

-

57~57.5

- 57

- 57.5

-

58~58.5

- 58

- 58.5

-

59~59.5

- 59

- 59.5

-

60~60.50

- 60

- 60.50

-

62

-

63

-

64

-

65

-

66

-

67

-

70~70.50

- 70

- 70.50

-

72

-

75

-

76

-

78

-

80

-

82

-

83

-

85

-

90

-

95

-

100

-

103

-

105

-

110

-

115

-

120

-

125

-

130

-

150

-

180

-

200

-

-

Underneck length (ℓ1)(mm)

-

Shank diameter (d)(mm)

-

Number of flutes(sheet)

-

Overall Length (L)(mm)

-

work material

- general steel

- Quenched and tempered steel

- High Hardness Steel-HRC55

- High Hardness Steel-HRC60

- High Hardness Steel-HRC65

- Stainless Steel

- Cast Iron

- Aluminum

- Titanium

- Copper

- Graphite

- Resin

-

Torsion Angle (θ)

-

Machining Application

-

Coating

- For High Hardness (Silicon Group)

- TiAlN

- For General Steels (AlCrN, etc.)

- TiCN

- TiN

- DLC

- CrN

- Dia Coat

- Non-Coated

- DG

- AlTiN

- BLUE

- TiSiN

- HS

- FX

- X코팅

- TACrN

- TiALN

- DIA

- A+

-

Blade tip shape

-

Type

- Square

- Roughing

- Long-Neck Square

- High Helical

![CRN-ES2000, for Copper Electrode Cutting, 2-Flute Square [Alteration Supported Product]](http://vn.misumi-ec.com/linked/material/fs/UNO1/PHOTO/223000439643.jpg?$product_view_b$)

![CRN-ES2000, for Copper Electrode Cutting, 2-Flute Square [Alteration Supported Product]](http://vn.misumi-ec.com/linked/material/fs/UNO1/PHOTO/223000439643.jpg?$product_view_c$)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy