(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- CY3B

-

Stroke(mm)

- 1,000

- 1,005

- 1,006

- 1,025

- 1,050

- 1,070

- 1,100

- 1,145

- 1,190

- 1,200

- 1,240

- 1,300

- 1,370

- 1,374

- 1,394

- 1,465

- 1,500

- 1,538

- 1,570

- 1,580

- 1,700

- 1,710

- 1,800

- 1,870

- 1,900

- 1,962

- 2,000

- 2,500

- 3,000

- 3,600

- 4,000

- 5,000

- 20

- 25

- 27

- 28

- 30

- 35

- 36

- 37

- 38

- 40

- 43

- 44

- 45

- 48

- 49

- 50

- 52

- 54

- 55

- 57

- 60

- 61

- 62

- 63

- 65

- 66

- 67

- 68

- 70

- 72

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 83

- 85

- 88

- 89

- 90

- 92

- 94

- 95

- 96

- 99

- 100

- 102

- 103

- 105

- 107

- 110

- 112

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 128

- 129

- 130

- 132

- 133

- 134

- 135

- 138

- 140

- 142

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 163

- 165

- 166

- 167

- 168

- 170

- 171

- 172

- 174

- 175

- 176

- 177

- 178

- 180

- 182

- 183

- 185

- 186

- 187

- 188

- 190

- 191

- 195

- 196

- 197

- 198

- 199

- 200

- 201

- 202

- 203

- 204

- 205

- 206

- 207

- 208

- 209

- 210

- 212

- 214

- 215

- 216

- 217

- 218

- 220

- 222

- 223

- 224

- 225

- 226

- 227

- 228

- 229

- 230

- 232

- 233

- 234

- 235

- 236

- 237

- 238

- 240

- 242

- 243

- 244

- 245

- 246

- 247

- 249

- 250

- 251

- 252

- 254

- 255

- 256

- 257

- 258

- 259

- 260

- 261

- 262

- 263

- 264

- 265

- 266

- 267

- 268

- 270

- 271

- 272

- 273

- 274

- 275

- 278

- 279

- 280

- 282

- 284

- 285

- 286

- 287

- 288

- 290

- 294

- 295

- 297

- 300

- 302

- 304

- 305

- 306

- 308

- 310

- 311

- 312

- 313

- 315

- 317

- 319

- 320

- 321

- 322

- 323

- 324

- 325

- 326

- 327

- 328

- 329

- 330

- 331

- 332

- 333

- 335

- 336

- 337

- 338

- 339

- 340

- 342

- 343

- 345

- 347

- 349

- 350

- 351

- 352

- 353

- 354

- 355

- 356

- 357

- 360

- 361

- 363

- 364

- 365

- 367

- 369

- 370

- 372

- 374

- 375

- 376

- 377

- 378

- 379

- 380

- 382

- 383

- 384

- 385

- 386

- 387

- 388

- 389

- 390

- 394

- 395

- 397

- 400

- 402

- 403

- 405

- 406

- 407

- 408

- 409

- 410

- 413

- 415

- 416

- 418

- 420

- 421

- 422

- 424

- 425

- 427

- 430

- 434

- 435

- 438

- 440

- 441

- 442

- 443

- 444

- 445

- 446

- 450

- 452

- 453

- 454

- 455

- 456

- 459

- 460

- 461

- 465

- 466

- 467

- 468

- 469

- 470

- 471

- 474

- 475

- 476

- 477

- 478

- 480

- 482

- 483

- 484

- 485

- 487

- 490

- 492

- 494

- 495

- 500

- 501

- 503

- 504

- 505

- 506

- 508

- 510

- 512

- 514

- 515

- 516

- 517

- 520

- 521

- 522

- 525

- 527

- 528

- 529

- 530

- 531

- 533

- 534

- 535

- 537

- 540

- 543

- 545

- 546

- 547

- 549

- 550

- 555

- 556

- 557

- 558

- 559

- 560

- 561

- 564

- 565

- 566

- 567

- 568

- 569

- 570

- 573

- 574

- 575

- 576

- 579

- 580

- 582

- 584

- 585

- 586

- 588

- 590

- 593

- 595

- 596

- 597

- 599

- 600

- 605

- 608

- 609

- 610

- 611

- 612

- 613

- 614

- 615

- 616

- 617

- 618

- 620

- 625

- 626

- 628

- 629

- 630

- 632

- 635

- 637

- 638

- 640

- 641

- 644

- 645

- 647

- 649

- 650

- 651

- 652

- 655

- 656

- 660

- 663

- 665

- 668

- 670

- 671

- 675

- 680

- 681

- 684

- 685

- 686

- 688

- 690

- 692

- 694

- 695

- 700

- 704

- 705

- 707

- 710

- 711

- 713

- 715

- 720

- 725

- 726

- 729

- 730

- 732

- 735

- 738

- 739

- 740

- 741

- 745

- 748

- 750

- 751

- 752

- 755

- 759

- 760

- 762

- 763

- 764

- 765

- 766

- 770

- 775

- 778

- 780

- 781

- 785

- 790

- 795

- 800

- 803

- 805

- 808

- 810

- 815

- 816

- 818

- 820

- 822

- 825

- 826

- 828

- 829

- 830

- 834

- 835

- 836

- 837

- 838

- 839

- 840

- 844

- 845

- 850

- 854

- 855

- 860

- 865

- 868

- 870

- 872

- 875

- 876

- 879

- 880

- 883

- 885

- 886

- 890

- 895

- 897

- 900

- 905

- 908

- 910

- 912

- 913

- 914

- 915

- 917

- 920

- 921

- 922

- 925

- 927

- 930

- 935

- 940

- 945

- 950

- 952

- 953

- 955

- 960

- 965

- 967

- 968

- 970

- 973

- 975

- 980

- 982

- 985

- 990

- 991

- 992

- 993

- 995

- 996

- 1001

- 1008

- 1010

- 1015

- 1016

- 1020

- 1030

- 1031

- 1033

- 1035

- 1040

- 1044

- 1045

- 1049

- 1055

- 1058

- 1060

- 1062

- 1064

- 1067

- 1075

- 1080

- 1085

- 1086

- 1087

- 1090

- 1095

- 1098

- 1101

- 1105

- 1110

- 1111

- 1112

- 1114

- 1115

- 1118

- 1120

- 1125

- 1126

- 1129

- 1130

- 1132

- 1134

- 1135

- 1136

- 1139

- 1140

- 1141

- 1144

- 1149

- 1150

- 1153

- 1160

- 1165

- 1170

- 1171

- 1175

- 1176

- 1180

- 1185

- 1188

- 1195

- 1205

- 1210

- 1213

- 1214

- 1215

- 1219

- 1220

- 1225

- 1229

- 1230

- 1235

- 1236

- 1239

- 1242

- 1243

- 1244

- 1245

- 1246

- 1250

- 1251

- 1255

- 1259

- 1260

- 1264

- 1267

- 1269

- 1270

- 1275

- 1280

- 1283

- 1284

- 1285

- 1288

- 1289

- 1290

- 1293

- 1294

- 1295

- 1305

- 1310

- 1311

- 1315

- 1316

- 1318

- 1320

- 1324

- 1327

- 1328

- 1329

- 1330

- 1331

- 1332

- 1335

- 1338

- 1339

- 1340

- 1343

- 1344

- 1349

- 1350

- 1353

- 1356

- 1360

- 1364

- 1365

- 1375

- 1376

- 1377

- 1380

- 1388

- 1389

- 1390

- 1395

- 1400

- 1405

- 1409

- 1410

- 1412

- 1414

- 1415

- 1416

- 1420

- 1422

- 1423

- 1425

- 1428

- 1430

- 1432

- 1440

- 1444

- 1450

- 1455

- 1456

- 1460

- 1461

- 1470

- 1472

- 1474

- 1475

- 1480

- 1485

- 1487

- 1490

- 1494

- 1505

- 1510

- 1515

- 1520

- 1525

- 1526

- 1530

- 1535

- 1540

- 1542

- 1545

- 1547

- 1550

- 1552

- 1553

- 1554

- 1555

- 1560

- 1564

- 1565

- 1566

- 1575

- 1581

- 1582

- 1585

- 1586

- 1593

- 1595

- 1600

- 1601

- 1602

- 1605

- 1610

- 1612

- 1615

- 1620

- 1623

- 1625

- 1626

- 1627

- 1628

- 1630

- 1635

- 1640

- 1645

- 1646

- 1648

- 1650

- 1660

- 1670

- 1675

- 1680

- 1695

- 1698

- 1699

- 1701

- 1705

- 1720

- 1724

- 1725

- 1726

- 1730

- 1739

- 1740

- 1750

- 1755

- 1760

- 1763

- 1765

- 1770

- 1775

- 1778

- 1780

- 1790

- 1793

- 1797

- 1799

- 1805

- 1810

- 1820

- 1825

- 1830

- 1835

- 1840

- 1848

- 1849

- 1850

- 1860

- 1864

- 1875

- 1880

- 1885

- 1890

- 1891

- 1910

- 1915

- 1920

- 1921

- 1925

- 1926

- 1930

- 1935

- 1936

- 1940

- 1950

- 1958

- 1960

- 1965

- 1970

- 1973

- 1975

- 1988

- 2001

- 2005

- 2010

- 2015

- 2020

- 2025

- 2030

- 2032

- 2035

- 2036

- 2040

- 2044

- 2050

- 2060

- 2065

- 2068

- 2070

- 2080

- 2089

- 2090

- 2100

- 2110

- 2114

- 2115

- 2120

- 2125

- 2150

- 2155

- 2160

- 2163

- 2165

- 2170

- 2173

- 2175

- 2180

- 2183

- 2184

- 2185

- 2190

- 2195

- 2199

- 2200

- 2219

- 2220

- 2222

- 2225

- 2235

- 2240

- 2250

- 2254

- 2260

- 2270

- 2275

- 2293

- 2300

- 2305

- 2310

- 2320

- 2330

- 2337

- 2340

- 2344

- 2350

- 2355

- 2360

- 2370

- 2374

- 2375

- 2384

- 2400

- 2411

- 2414

- 2415

- 2417

- 2420

- 2430

- 2440

- 2446

- 2450

- 2460

- 2465

- 2470

- 2475

- 2477

- 2480

- 2485

- 2520

- 2527

- 2530

- 2540

- 2542

- 2550

- 2560

- 2570

- 2575

- 2589

- 2590

- 2595

- 2600

- 2610

- 2620

- 2630

- 2650

- 2655

- 2660

- 2667

- 2670

- 2700

- 2710

- 2720

- 2725

- 2730

- 2740

- 2750

- 2780

- 2800

- 2810

- 2811

- 2820

- 2848

- 2850

- 2860

- 2870

- 2885

- 2890

- 2900

- 2910

- 2950

- 2965

- 3020

- 3048

- 3070

- 3090

- 3100

- 3120

- 3200

- 3250

- 3300

- 3315

- 3400

- 3410

- 3450

- 3500

- 3515

- 3540

- 3620

- 3640

- 3650

- 3800

- 3850

- 4030

- 4100

- 4120

- 4200

- 4346

- 4400

- 4450

- 4500

- 4746

- 4800

-

Max. Load Mass (Horizontal Mounting)(kg)

-

Max. Load Mass(kg)

-

Table Size: Length L(mm)

-

Cylinder I.D.(Ø)

-

Environment

- General Purpose

- Heat Resistant

-

Table Size: Width W(mm)

-

Table Size: Height H(mm)

-

Port Screw Type

-

Custom-made Specifications

-

Made-to-order

- Heat-resistant cylinder (-10 to 150°C)

- CY1□6 compatible part specification

- Low speed cylinder (7 to 50 mm/s)

- Low-speed cylinder (15 to 50 mm/s)

- Air supply changed to axial direction

- Hard chrome plating on outer surface of cylinder tube

- Helical coil insert thread specification

- High-speed specification rodless cylinder

- Hydro specification rodless cylinder

- Long-stroke type

- Lubrication-free exterior specification

- Lubrication-free exterior specification (with dust seal)

- None

- Rodless cylinder with floating joint

- Tapping positions for mounting slider added

- With magnetic shielding plate

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 4 Day(s) or Less

- 31 Day(s) or Less

- 32 Day(s) or Less

- 35 Day(s) or Less

- 37 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series (CY3B6-65)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- Refer to the catalog for product specifications.

- Product pictures are representations. CAD data is not supported by some of the model numbers.

Product Description

The CY3B series is the basic type of the Magnetically Coupled Rodless Cylinder with improved bearing performance.

[Features]

· A good lubrication film is formed on the outer peripheral surface of the cylinder tube for improved durability.

· Reduced sliding resistance.

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series Details

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, product image

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series Specifications

| Tube inner diameter (mm) | 6 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|---|---|---|

| Usable fluids | Air | ||||||||

| Guaranteed pressure resistance | 1.05 MPa | ||||||||

| Maximum operating pressure | 0.7 MPa | ||||||||

| Minimum operating pressure | 0.16 | 0.16 | 0.16 | 0.16 | 0.15 | 0.14 | 0.12 | 0.12 | 0.12 |

| Ambient temperature and working fluid temperature | -10 to 60°C (however, no freezing) | ||||||||

| Operating piston speed | 50 to 500 mm/s | ||||||||

| Cushion | Rubber cushion | ||||||||

| Lubrication | Not required (lubrication-free) | ||||||||

| Allowable difference of stroke length (mm) | 0 to 250 st: (0 to +1.0), 251 to 1,000 st: (0 to +1.4), 1,001 st and above: (0 to +1.8) | ||||||||

| Mounting orientation | Horizontal, slanted, verticalNote) | ||||||||

| Mounting nuts (2 nuts) | Standard equipment (accessories) | ||||||||

| Magnetic retention force (N) | 19.6 | 53.9 | 137 | 231 | 363 | 588 | 922 | 1,471 | 2,256 |

Note: When mounting vertically, intermediate stopping using an air pressure circuit cannot be done.

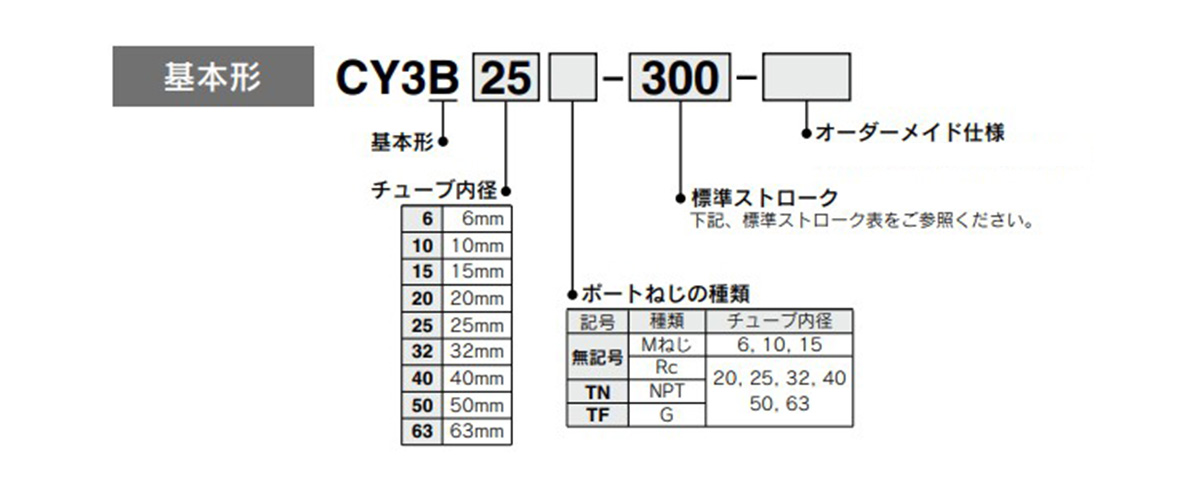

Model number indication method

Model number example

Standard stroke table

| Tube inner diameter (mm) | Standard stroke (mm) | Manufacturable Maximum stroke (mm) |

|---|---|---|

| 6 | 50, 100, 150 and 200 | 300 |

| 10 | 50, 100, 150, 200, 250 and 300 | 500 |

| 15 | 50, 100, 150, 200, 250, 300, 350 400, 450, 500 | 1,000 |

| 20 | 100, 150, 200, 250, 300, 350, 400, 450 500, 600, 700, 800 | 1,500 |

| 25 | 3,000 | |

| 32 | ||

| 40 | 100, 150, 200, 250, 300, 350, 400, 450 500, 600, 700, 800, 900, 1,000 | 3,000 |

| 50 | 5,000 | |

| 63 |

- *Long stroke type (XB11) when the stroke exceeds 2,000 st.

- *The longer the stroke, the larger the amount of deflection in the cylinder tube. Pay attention to the mounting bracket and clearance value.

- *Intermediate stroke can be adjusted in 1‑mm increments.

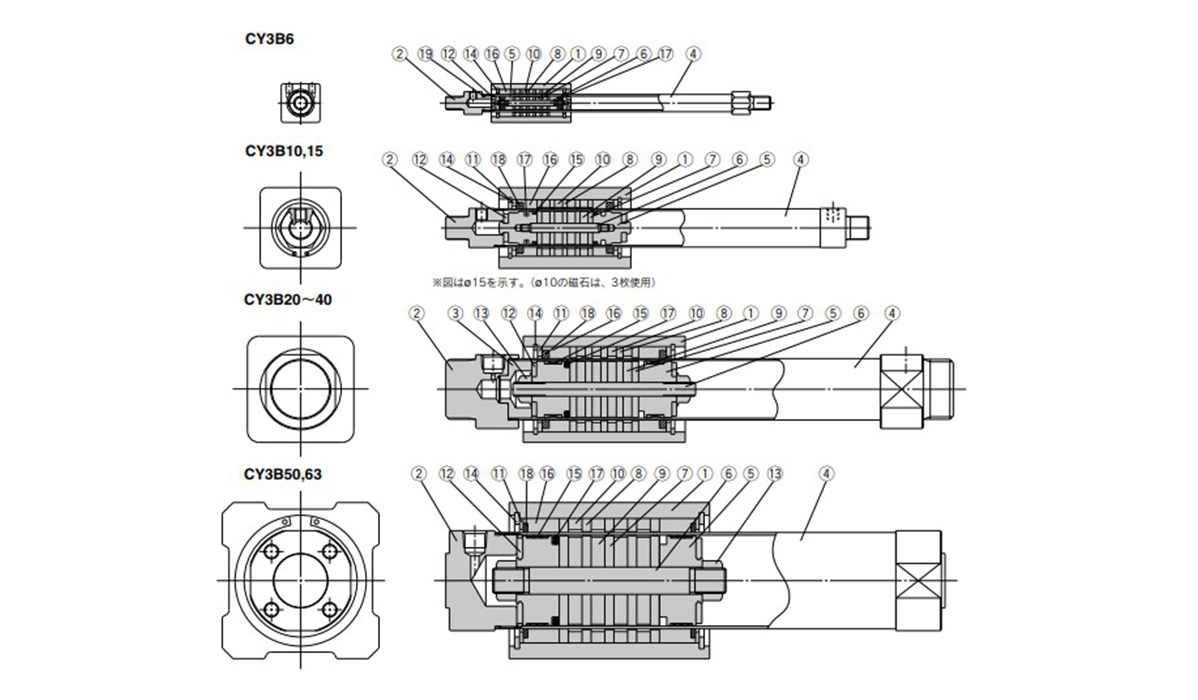

Structural Drawing

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, structural drawing

Components

| Number | Part name | Materials | Additional notes | ||

|---|---|---|---|---|---|

| 1 | Body | Aluminum alloy | Hard anodized aluminum | ||

| 2 | Head cover | ø6 (diameter 6 mm), ø10 (diameter 10 mm) | Brass | - | |

| ø15 (diameter 15 mm) to ø63 (diameter 63 mm) | Aluminum alloy | ||||

| 3 | End collar | Aluminum alloy | ø20 to 40 (diameter 20 to 40 mm) only | ||

| 4 | Cylinder tube | Stainless steel | - | ||

| 5 | Piston | ø6 (diameter 6 mm) | Brass | ø6 (diameter 6 mm) | Electroless Ni plating |

| ø10 to 63 (diameter 10 to 63 mm) | Aluminum alloy | ø10 to 63 (diameter 10 to 63 mm) | Chromate | ||

| 6 | Shaft | Stainless steel | - | ||

| 7 | Piston-side yoke | Rolled steel | Zinc chromate | ||

| 8 | External moving element side yoke | Rolled steel | Zinc chromate | ||

| 9 | Magnet A | - | - | ||

| 10 | Magnet B | - | - | ||

| 11 | Spacer | Aluminum alloy | No ø6 (diameter 6 mm) | ||

| 12 | Damper | Urethane rubber | - | ||

| 13 | Piston nut | Carbon steel | No ø6 to 15 (diameter 6 to 15 mm) | ||

| 14 | C-type retaining ring for hole | Carbon tool steel | Phosphate coated | ||

| 15 | Wear ring A | Special resin | - | ||

| 16 | Wear ring B | Special resin | - | ||

| 17 | Piston packing | NBR | - | ||

| 18 | Lub-retainer | Special resin | No ø6 (diameter 6 mm) | ||

| 19 | Cylinder tube gasket | NBR | ø6 (diameter 6 mm) and ø10 (diameter 10 mm) only | ||

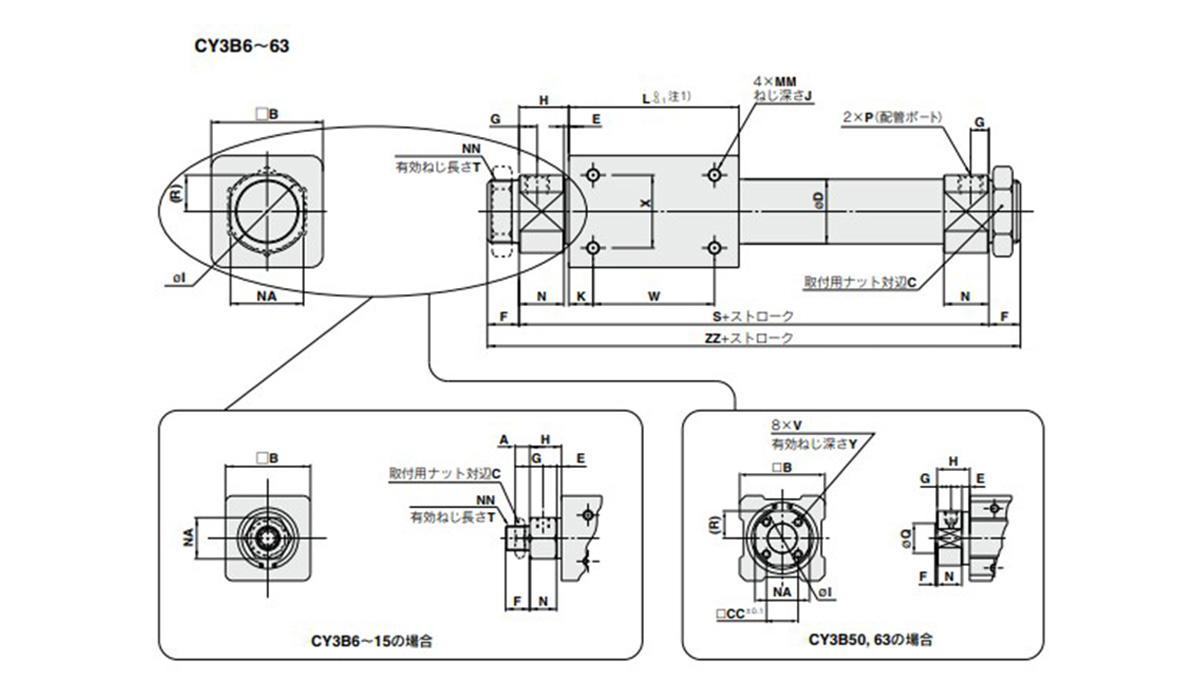

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, example dimensions

Basic type CY3B6 to CY3B63, dimensional drawing

Note 1: ø50 (diameter 50 mm) and ø63 (diameter 63 mm) are L (-0.2 to 0).

(Unit: mm)

| Model | A | B | C | CC | D | E | F | G | H | I | J | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CY3B6 | 4 | 17 | 8* | - | 7.6 | 4 | 8* | 5 | 13.5* | - | 4.5 | 5 | 35 |

| CY3B10 | 4 | 25 | 14 | - | 12 | 1.5 | 9 | 5 | 12.5 | - | 4.5 | 4 | 38 |

| CY3B15 | 4 | 35 | 14 | - | 16.6* | 2 | 10 | 5.5 | 13 | - | 6 | 11 | 57 |

| CY3B20 | 8 | 36 | 26 | - | 21.6* | 2* | 13 | 7.5* | 20 | 28 | 6 | 8 | 66 |

| CY3B25 | 8 | 46 | 32 | - | 26.4* | 2* | 13 | 7.5* | 20.5 | 34 | 8 | 10 | 70 |

| CY3B32 | 8 | 60 | 32 | - | 33.6* | 2* | 16 | 8* | 22 | 40 | 8 | 15 | 80 |

| CY3B40 | 10 | 70 | 41 | - | 41.6* | 3* | 16 | 11 | 29 | 50 | 10 | 16 | 92 |

| CY3B50 | - | 86 | - | 32 | 52.4* | 8 | 2 | 14 | 33 | 58* | 12 | 25 | 110 |

| CY3B63 | - | 100 | - | 38 | 65.4* | 8 | 2 | 14 | 33 | 72* | 12 | 26 | 122 |

| Model | MM | N | NA | NN | Q | R | S | T | V |

|---|---|---|---|---|---|---|---|---|---|

| CY3B6 | M3 × 0.5 | 9.5* | 10* | M6 × 1* | - | - | 62* | 6.5 | - |

| CY3B10 | M3 × 0.5 | 11 | 14 | M10 × 1 | - | - | 63 | 7.5 | - |

| CY3B15 | M4 × 0.7 | 11 | 17 | M10 × 1 | - | - | 83 | 8 | - |

| CY3B20 | M4 × 0.7 | 18* | 24 | M20 × 1.5 | - | 12* | 106 | 10 | - |

| CY3B25 | M5 × 0.8 | 18.5* | 30 | M26 × 1.5 | - | 15* | 111 | 10 | - |

| CY3B32 | M6 × 1 | 20* | 36 | M26 × 1.5 | - | 18* | 124 | 13 | - |

| CY3B40 | M6 × 1 | 26* | 46 | M32 × 2 | - | 23* | 150 | 13 | - |

| CY3B50 | M8 × 1.25 | 25 | 55 | - | 30 (-0.037 to -0.007) | 27.5* | 176 | - | M8 × 1.25 |

| CY3B63 | M8 × 1.25 | 25 | 69 | - | 32 (-0.043 to -0.007) | 34.5* | 188 | - | M10 × 1.5 |

(Unit: mm)

| Model | W | X | Y | ZZ | P (piping port) | ||

|---|---|---|---|---|---|---|---|

| No mark | TN* | TF* | |||||

| CY3B6 | 25 | 10 | - | 78* | M3 × 0.5* | - | - |

| CY3B10 | 30 | 16 | - | 81 | M5 × 0.8 | - | - |

| CY3B15 | 35 | 19 | - | 103 | M5 × 0.8 | - | - |

| CY3B20 | 50 | 25 | - | 132 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B25 | 50 | 30 | - | 137 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B32 | 50 | 40 | - | 156 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B40 | 60 | 40 | - | 182 | Rc 1/4 | NPT1/4 | G1/4 |

| CY3B50 | 60 | 60 | 16 | 180 | Rc 1/4 | NPT1/4 | G1/4 |

| CY3B63 | 70 | 70 | 16 | 192 | Rc 1/4 | NPT1/4 | G1/4 |

Note 2: Dimensions marked with "*" are different from the CY1B series.

Note 3: Mounting nuts can be screwed on only for the effective thread length of the head cover (T dimension). When mounting a cylinder, consider the thickness of flange, etc.

| Part Number |

|---|

| CY3B6-65 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Stroke (mm) | Max. Load Mass (Horizontal Mounting) (kg) | Max. Load Mass (kg) | Table Size: Length L (mm) | Cylinder I.D. (Ø) | Environment | Table Size: Width W (mm) | Table Size: Height H (mm) | Port Screw Type | Custom-made Specifications | Made-to-order |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

4,230,000 VND | 1 Piece(s) | 32 Day(s) | 65 | 0.05~0.8 | 0.2 | 35 | 6 | General Purpose | 17 | 17 | M screw | 0.16 to 0.7 | None |

Loading...Tải…

Basic InformationThông tin cơ bản

| Type | Rodless Cylinder | Table Material | Aluminum Alloy | Rodless Cylinder Joint Type | Magnetic |

|---|---|---|---|---|---|

| Table Surface Treatment | Hard Anodize | Guide Type | Prototype | Cushion | Rubber cushion |

Please check the type/dimensions/specifications of the part CY3B6-65 in the Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần CY3B6-65 trong chuỗi Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Products like this...

| Part Number |

|---|

| CY3B10-100-X210 |

| CY3B10-100-X324 |

| CY3B10-100-XB13 |

| CY3B6-65-X1468 |

| CY3B6-68 |

| CY3B6-70 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to ShipSố ngày giao hàng | Stroke (mm) | Max. Load Mass (Horizontal Mounting) (kg) | Max. Load Mass (kg) | Table Size: Length L (mm) | Cylinder I.D. (Ø) | Environment | Table Size: Width W (mm) | Table Size: Height H (mm) | Port Screw Type | Custom-made Specifications | Made-to-order |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 100 | 0.05~0.8 | 0.4 | 38 | 10 | General Purpose | 25 | 25 | M screw | 0.16 to 0.7 | Lubrication-free exterior specification | ||

- | 1 Piece(s) | Quote | 100 | 0.05~0.8 | 0.4 | 38 | 10 | General Purpose | 25 | 25 | M screw | 0.16 to 0.7 | Lubrication-free exterior specification (with dust seal) | ||

- | 1 Piece(s) | Quote | 100 | 0.05~0.8 | 0.4 | 38 | 10 | General Purpose | 25 | 25 | M screw | 0.16 to 0.7 | Low speed cylinder (7 to 50 mm/s) | ||

- | 1 Piece(s) | Quote | 65 | 0.05~0.8 | 0.2 | 35 | 6 | General Purpose | 17 | 17 | M screw | 0.16 to 0.7 | CY1□6 compatible part specification | ||

- | 1 Piece(s) | Quote | 68 | 0.05~0.8 | 0.2 | 35 | 6 | General Purpose | 17 | 17 | M screw | 0.16 to 0.7 | None | ||

- | 1 Piece(s) | Quote | 70 | 0.05~0.8 | 0.2 | 35 | 6 | General Purpose | 17 | 17 | M screw | 0.16 to 0.7 | None |

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy