(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- HYDG

- HYG

-

Cylinder (Tube) Inner Diameter(Ø)

-

Stroke(mm)

-

Operating Pressure(MPa)

-

Specifications

- With built-in magnet and switch rail

- Without magnet

-

Port thread type

- G

- M Screw

- NPT

- Rc

-

Auto Switches

-

Lead Wire

- 0.5

- 3

- 5

-

The number of the switches

-

Sealing materials

- External FKM

- NBR

-

Grease

- Food compatible grease

- Standard grease (for non-food)

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 31 Day(s) or Less

- 32 Day(s) or Less

- 37 Day(s) or Less

Specify AlterationsChỉ định thay đổi

HYG Series Hygienic Design Cylinder (HYDG20R-20-F6N)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- ■ SMC Product Line

Webpages for products currently without individual pages on this site will be released on an ad-hoc basis. - Refer to the manufacturer's catalog for specification and material details.

- Product images may be representative images. Refer to the manufacturer's catalog for shape details.

- CAD data is not supported for some model numbers.

Product Description

HYG Series Hygienic Design Cylinder with an easy-to-clean format.

[Features]

· Air cylinder with improved water resistance.

· To keep the product flat, grooves for auto switches and holes for cushion needles, etc. have been eliminated.

· Approximately 5 times increase in lifespan (compared to manufacturer's current models).

· Able to handle food grease (NSF-H1 certified).

· NBR or FKM can be selected as the external sealant material.

· Mounting part: ISO standard (VDMA) compliant (HYC).

HYG Series Hygienic Design Cylinder Details

HYG Series Hygienic Design Cylinder product image

HYG Series Hygienic Design Cylinder Specifications

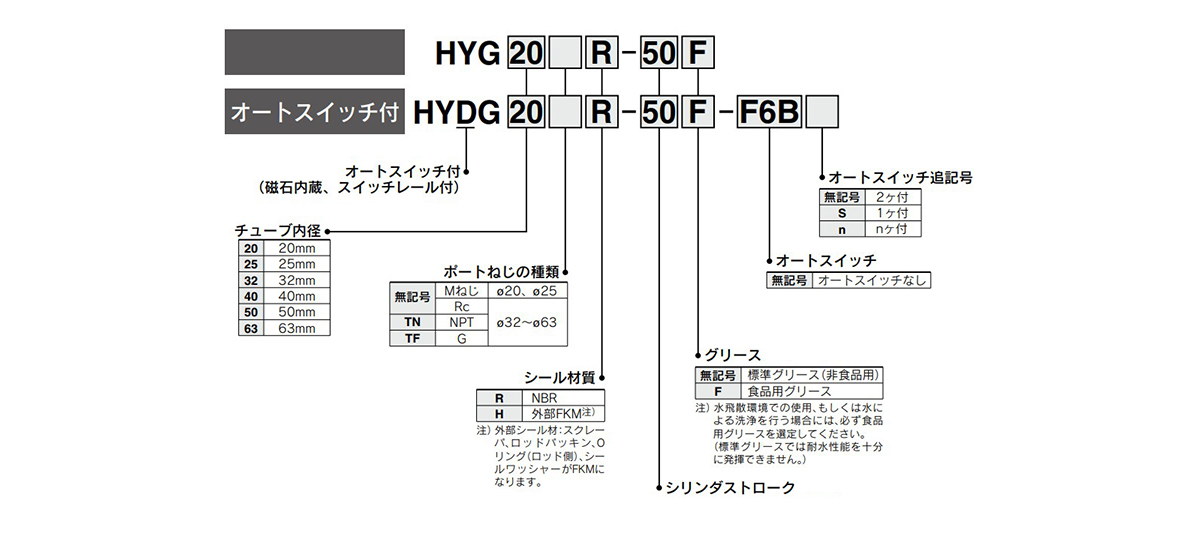

Model Number Notation

Model number examples

Specifications

| Tube Inner Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|

| Action | Double acting | |||||

| Fluid | Air | |||||

| Minimum operating pressure | 0.2 MPa | 0.15 MPa | ||||

| Maximum operating pressure | 1.0 MPa | |||||

| Proof Pressure | 1.5 MPa | |||||

| Ambient and Working Fluid Temperature | 0°C to 60°C | |||||

| Lubrication | Not required | |||||

| Piston Speed | 50 to 500 mm/s (with pressure at 1.0 MPa)* | |||||

| Cushioning | Rubber cushion | |||||

| Stroke length tolerance | (0 to +1.5) mm | |||||

*Use the product below the allowable kinetic energy.

Diagram

Diagram: HYG Series Hygienic Design Cylinder

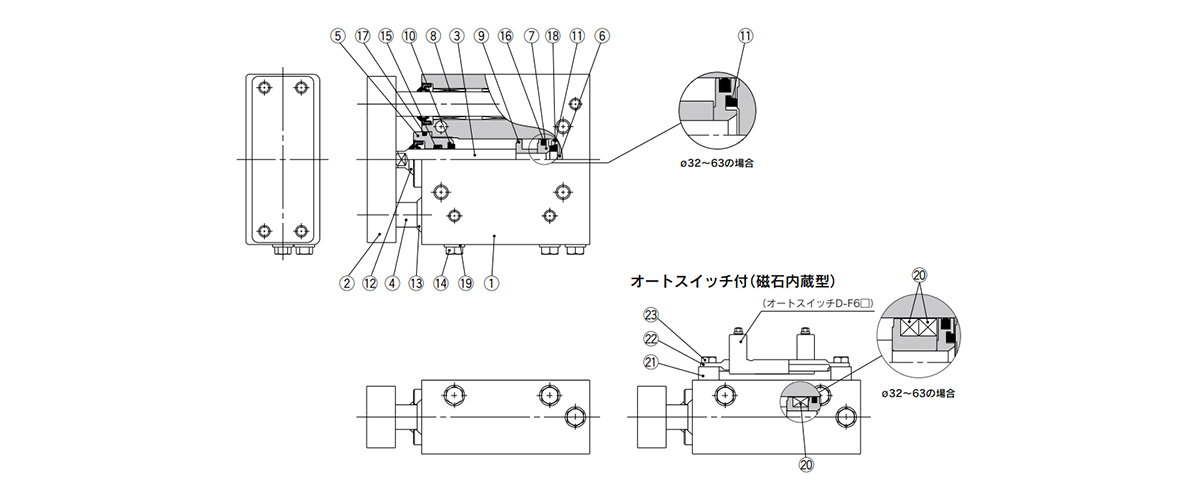

Components

| Number | Part Name | Material | Quantity | Notes |

|---|---|---|---|---|

| 1 | Body | Aluminum alloy | 1 | Anodic oxide film |

| 2 | Plate | Aluminum alloy | 1 | Anodic oxide film |

| 3 | Piston rod | Stainless steel | 1 | Hard chrome plating |

| 4 | Guide rod | Stainless steel | 2 | Special coating |

| 5 | Rod cover | Aluminum alloy | 1 | Anodic oxide film |

| 6 | Head cover | Aluminum alloy | 1 | Chromate |

| 7 | Piston | Aluminum alloy | 1 | - |

| 8 | Bushing | Stainless steel | 4 | Special coating |

| 9 | Magnetic holder | Aluminum alloy | 1 | Chromate |

| 10 | Bumper A | Resin | 1 | - |

| 11 | Damper B | Resin | 1 | - |

| 12 | Scraper (piston rod) | Stainless steel + NBR | 1 | (FKM can be selected) |

| 13 | Scraper (guide rod) | Stainless steel + NBR | 2 | (FKM can be selected) |

| 14 | Port plug | Stainless steel | 3 | - |

| 15 | Rod packing | NBR | 1 | (FKM can be selected) |

| 16 | Piston packing | NBR | 1 | - |

| 17 | O-ring (rod end) | NBR | 1 | (FKM can be selected) |

| 18 | O-ring (head end) | NBR | 1 | - |

| 19 | Seal washer | Stainless steel + NBR | 3 | (FKM can be selected) |

| 20 | Magnet | - | 1 | (Only built-in magnet) (Over ø32 [32‑mm diameter]: 2 magnets) |

| 21 | Switch rail base | Stainless steel | 2 | (Only built-in magnet) |

| 22 | Switch rail | Stainless steel | 1 | (Only built-in magnet) |

| 23 | Hexagon bolt | Stainless steel | 2 | (Only built-in magnet) |

Replacement Parts / Seal Kit

| Tube inner diameter | Part No. | Set contents |

|---|---|---|

| 20 | HYG20□-PS | Set of (15), (16), (17), (19) listed above |

| 25 | HYG25□-PS | |

| 32 | HYG32□-PS |

- *Place the seal material symbol in □.

| Symbol | Material |

|---|---|

| R | NBR |

| H | External FKM* |

- *External seal: rod seal, O-ring (rod side) and seal washer are made from FKM.

- *Seal kit includes (15), (16), (17) and (19). Order the seal kit based on the bore size.

- *Since the seal kit does not include a grease pack, order it separately.

Grease package (food compatible grease): GR-H-010 (10 g)

Grease package (standard grease): GR-S-010 (10 g) - *To replace or repair seals of cylinder bore size 40 mm or greater, please contact the manufacturer with your request.

Please contact the manufacturer when the cylinder has to be disassembled for the purpose of replacing seals, etc.

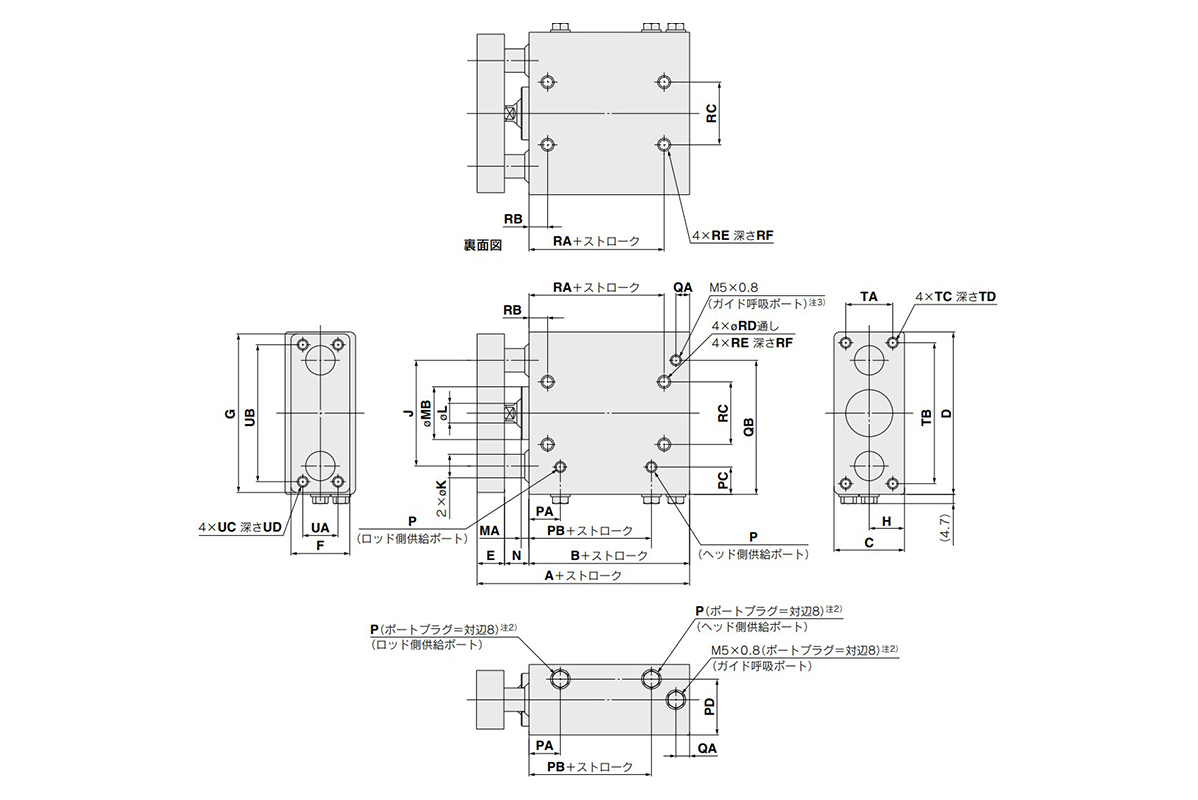

HYG Series Hygienic Design Cylinder Example Dimensions

Dimensional drawings: without auto switch HYG20, 25

(Units: mm)

| Tube inner diameter | Standard Stroke | A | B | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 30 st or less | 31 to 50 st | 51 to 100 st | 101 st or more | 30 st or less | 31 to 50 st | 51 to 100 st | 101 st or more | ||

| 20 | 20, 30, 50, 100, 150, 200 | 78.5 | 88.5 | 108.5 | 128.5 | 52 | 62 | 82 | 102 |

| 25 | 86 | 96 | 116 | 136 | 56.5 | 66.5 | 86.5 | 106.5 | |

(Units: mm)

| Tube inner diameter | C | D | E | F | G | H | J | K | L | MA | MB | N | P | PA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 36 | 83 | 14 | 30 | 81 | 18 | 54 | 12 | 10 | 4 | 27 | 12.5 | M5 × 0.8 | 16 |

| 25 | 42 | 93 | 16 | 38 | 91 | 21 | 64 | 16 | 12 | 4.5 | 32 | 13.5 | M5 × 0.8 | 18 |

(Units: mm)

| Tube inner diameter | PB | PC | PD | QA | QB | RA | RB | RC | RD | RE | RF | TA | TB | TC | TD | UA | UB | UC | UD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 32.5 | 14 | 28.5 | 7 | 68.5 | 39 | 9.5 | 32 | 5.4 | M6 × 1 | 12 | 24 | 72 | M5 × 0.8 | 13 | 18 | 70 | M5 × 0.8 | 10 |

| 25 | 34.5 | 15 | 34 | 8.5 | 78.5 | 41.5 | 9.5 | 38 | 5.4 | M6 × 1 | 12 | 29 | 80 | M6 × 1 | 14.5 | 26 | 78 | M6 × 1 | 12 |

- *The figure above shows the condition when shipped (top piping). Change the port plug position for side piping.

- *For more information on piping, refer to the specific product precautions.

| Part Number |

|---|

| HYDG20R-20-F6N |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Pressure (MPa) | Specifications | Port thread type | Auto Switches | Lead Wire | The number of the switches | Sealing materials | Grease |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 20 | 20 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | F6N | 0.5 | 2 | NBR | Standard grease (for non-food) |

Loading...Tải…

Basic InformationThông tin cơ bản

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Guided |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Cushion | Rubber cushion |

Please check the type/dimensions/specifications of the part HYDG20R-20-F6N in the HYG Series Hygienic Design Cylinder series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần HYDG20R-20-F6N trong chuỗi HYG Series Hygienic Design Cylinder.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Products like this...

| Part Number |

|---|

| HYDG20H-100 |

| HYDG20H-100-F6B |

| HYDG20H-100-F6BL |

| HYDG20R-20-F6NZ |

| HYDG20R-200 |

| HYDG20R-200-F6B |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to ShipSố ngày giao hàng | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Pressure (MPa) | Specifications | Port thread type | Auto Switches | Lead Wire | The number of the switches | Sealing materials | Grease |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 20 | 100 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | Without switch | - | - | External FKM | Standard grease (for non-food) | ||

- | 1 Piece(s) | Quote | 20 | 100 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | F6B | 0.5 | 2 | External FKM | Standard grease (for non-food) | ||

- | 1 Piece(s) | Quote | 20 | 100 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | F6B | 3 | 2 | External FKM | Standard grease (for non-food) | ||

- | 1 Piece(s) | Quote | 20 | 20 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | F6N | 5 | 2 | NBR | Standard grease (for non-food) | ||

- | 1 Piece(s) | Quote | 20 | 200 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | Without switch | - | - | NBR | Standard grease (for non-food) | ||

- | 1 Piece(s) | Quote | 20 | 200 | 0.2 to 1.0 | With built-in magnet and switch rail | M Screw | F6B | 0.5 | 2 | NBR | Standard grease (for non-food) |

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy