Technical information

【Questions】

I would like to know the correct usage of the end mill for chamfering and V-groove machining

I often use chamfering and V-grooving end mills for machining parts, but I am troubled by frequent chipping of the blade tip. Please tell me the tips for using the tool.

【Answers】

The followings are important points for chamfering and V-groove machining.

1. Chamfering

・It is necessary to process under the condition settings that consider the maximum depth of cut.

・If the amount of cutting is large, stepwise cutting is recommended.

2. V-groove machining

・V-groove machining is mainly considered when using a normal square end mill and when using a dedicated tool.

(1) When using a normal square end mill

It is a method of cutting the V-groove by tilting the tool or workpiece. If high accuracy is not required for the shape of the bottom of the V-groove, machining with a radius or end mill with corner chamfer is also an option.

(2) When using an end mill for V-groove machining

・When using only the tip of the tool, consider the peripheral speed and set a higher rotational speed.

・If the cutting amount is large, stepwise cutting is recommended.

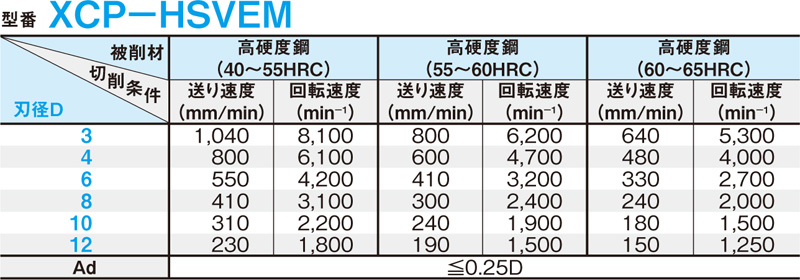

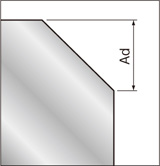

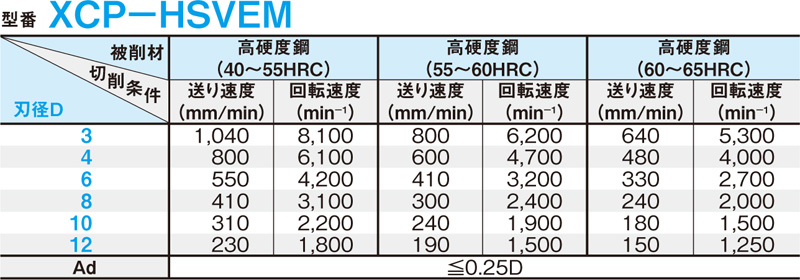

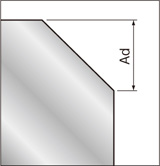

Recommended Cutting Conditions

●When chamfering holes, use 50% feed under the following chamfering conditions. (Only chamfering)

●Use a machine and chuck that are rigid and highly accurate.

●Select the cutting oil suitable for the work material.

●If the machining machine you are using does not increase the rotational speed, reduce the feed speed and rotational speed by the same ratio.

●Limit the run-out of the blade tip when installing the end mill to within 0.01 mm.

| Part Number | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Tool Diameter (D)

(mm) | Shank Diameter (d) | Tip Core Thickness | Overall Length L |

|---|

|

1,572,500 VND

|

1 Piece(s)

| Available |

4 Day(s) or more

| 8 | 8 | ≦0.5 | 60 |

Loading...Tải…

Specifications/Overview

●

●Ideal for chamfering high hardness steel up to 65 HRC. (V-groove machining is not possible because there is no cutting edge at the tip)

●High-efficiency machining is possible by adopting a 6-flute shape.

●With a coating that achieves high oxidation-resistance temperature and high hardness, it is ideal for high speed machining and dry machining of heat-treated steel and high-hardness steel.

●The finish of the surface roughness of the workpiece after machining is very good.

Basic InformationThông tin cơ bản

Please check the type/dimensions/specifications of the part XCP-HSVEM8 in the XCP Series Carbide Chamfer End Mill for High Hardness Steel Machining / 6-Flute / Short Type series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần XCP-HSVEM8 trong chuỗi XCP Series Carbide Chamfer End Mill for High Hardness Steel Machining / 6-Flute / Short Type.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy