(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- MISUMI Việt Nam đồng hành cùng Kỹ sư tương lai trong cuộc thi SMAE Award 2024. Xem chi tiết.

MISUMI Vietnam accompanies Future Engineers in the SMAE Award 2024 competition. See more.

Series Name

轴孔经(加工完毕)d1

轴孔经(加工完毕)d2

外径D

全长L

Application

Features

Allowable Misalignment

Body Material

Product Category

Buffer Material

Shaft Tightening Method

Shaft Hole Shape

type

Days to Ship

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Series Name

- Jaw

- Jaw

-

轴孔经(加工完毕)d1(Ø)

-

轴孔经(加工完毕)d2(Ø)

-

外径D(Ø)

-

全长L(mm)

-

Application

- Standard

- For Servo Motors

- Stepping Motor

-

Features

-

Allowable Misalignment

-

Angular Misalignment

Angular Misalignment -

Eccentricity

Eccentricity -

Axial Misalignment

Axial Misalignment

-

-

Body Material

- Aluminum Alloy

-

Product Category

- Coupling Main Body

-

Buffer Material

- Polyurethane

-

Shaft Tightening Method

- Fastening Bolt

-

Shaft Hole Shape

- Standard

-

type

- E-LMPJC

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 8 Day(s) or Less

- 14 Day(s) or Less

- 17 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Jaw Couplings Clamping Type

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

- CAD Data unavailable

(i)

Caution

thận trọng

- There is an update in specs L, F, M of some products in March 2024, please refer the below link for the detailed changes.

"Notification"

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

Product Overview

・Jaw coupling is composed of 2 metal jaw disks in the coupling part and 1 elastomer resin adjustment ring.

・The resin adjustment ring can alleviate the inertial load impact during start and stop.

・Easy to disassemble and assemble.

・Recommended for stepper motors and general-purpose motors.

・The resin adjustment ring can alleviate the inertial load impact during start and stop.

・Easy to disassemble and assemble.

・Recommended for stepper motors and general-purpose motors.

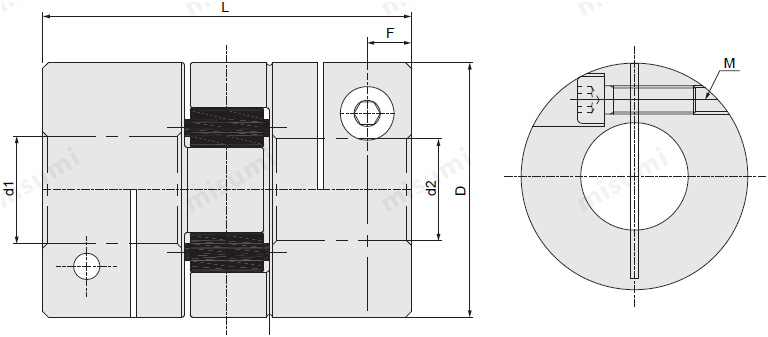

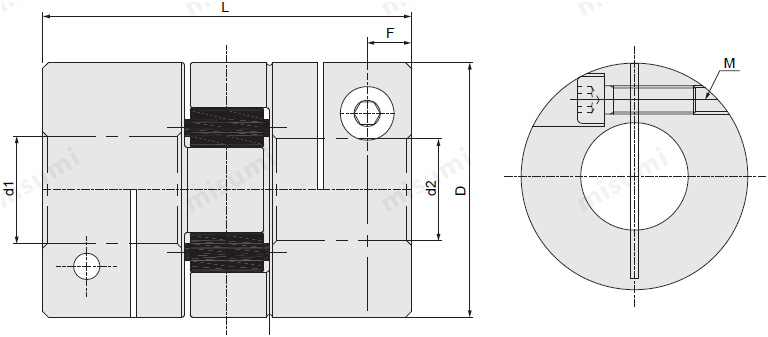

Dimensional Drawing

E-LMPJC

・Material table

| Parts |  Material Material |  Surface Treatment Surface Treatment |  Accessory Accessory |

| Hub | Aluminum Alloy | Clear Anodized | Clamp Screw |

| Spacer | Polyurethane | - |

Specification Table

Please follow the selection steps ~

~ to select the part no.

to select the part no.

■Characteristic Values

The allowable torque varies with temperature.

The allowable torque varies with temperature.

Press the adjustment ring into the body to assemble.

Press the adjustment ring into the body to assemble.

Press Spacer to the body when install.

Press Spacer to the body when install.

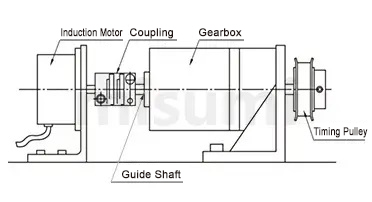

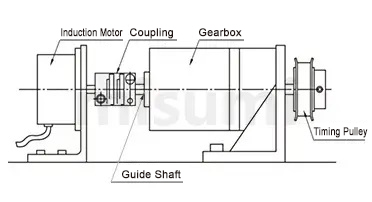

Use example of coupling 1: motor × gear box

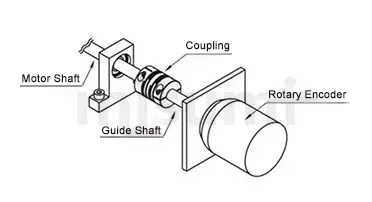

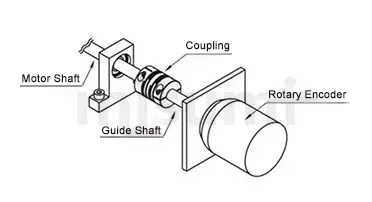

Use example of coupling 3: motor × encoder

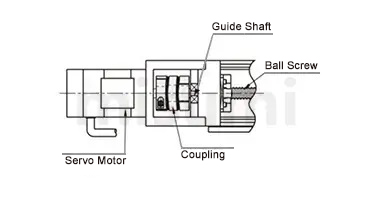

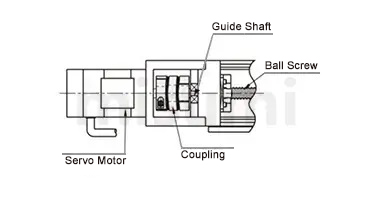

Use example of coupling 2: motor × ball screw

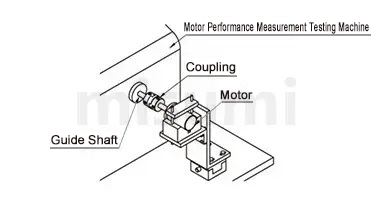

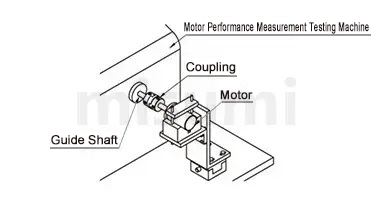

Use example of coupling 4: motor × measuring tester

~

~ to select the part no.

to select the part no.Part No.( Type· Type· DL) DL) | - |  d1 d1 | - |  d2 d2 |

| E-LMPJC20L25 E-LMPJC20L30 E-LMPJC30L35 | - - - | 5 7 7 | - - - | 6 8 9 |

Unit:mm

| Part No. |  d1、 d1、 d2 Shaft Hole dia (d1≤d2) d2 Shaft Hole dia (d1≤d2) | LF | LP | F | |||||||||||||||||||||||||||||||||

Type Type |  D D | L | |||||||||||||||||||||||||||||||||||

| E-LMPJC | 20 | L25 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 16.6 | 8.6 | 4.0 | |||||||||||||||||||||||

| 20 | L30 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 19.1 | 8.6 | 5.3 | ||||||||||||||||||||||||

| 25 | L30 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 20.5 | 11.6 | 5.6 | ||||||||||||||||||||

| 25 | L34 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 22.5 | 11.6 | 5.6 | ||||||||||||||||||||

| 30 | L35 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 22.5 | 10.9 | 5.75 | ||||||||||||||||||

| 30 | L40 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 25 | 10.9 | 7 | ||||||||||||||||||

| 35 | L50 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 30 | 11.5 | 10 | ||||||||||||||||||

| 40 | L40 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | |||||||||||||||||||||

| 40 | L50 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 31.1 | 13.7 | 10 | |||||||||||||||||

| 40 | L55 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 33.6 | 13.7 | 10 | |||||||||||||||||

| 40 | L66 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 39.1 | 13.7 | 12.75 | |||||||||||||||||

| 55 | L78 | 12 | 12.7 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 46.2 | 16.1 | 15.5 | ||||||||||||||||||

| 65 | L90 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 52.9 | 16.7 | 18.1 | ||||||||||||||||||

| 80 | L114 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 67 | 22.5 | 15.5 | ||||||||||||||||||||

| 95 | L126 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 74.5 | 24.0 | 20.0 | |||||||||||||||||||

| 105 | L140 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 60 | 83.2 | 26.4 | 20.0 | ||||||||||||||||||

| 120 | L160 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 93.7 | 27.4 | 25.0 | |||||||||||||||||

■Characteristic Values

| Part No. | Rated Torque (N·m) | Angular Misalignment ( ° ) | Lateral Misalignment (mm) | Static Torsional Spring Constant (N·m/rad) | Max. Rotational Speed (r/min) | Moment of Inertia (kg·m2) | Allowable Axial Misalignment (mm) | Clamp Screw | Mass g | |||

| Type | D | L | M | Tightening Torque (N.m) | ||||||||

| E-LMPJC | ||||||||||||

| 20 | L25 | 2.8 | 1 | 0.02 | 55 | 17000 | 1.0x10-6 | ±0.6 | M3 | 1.5 | 15 | |

| 20 | L30 | 1 | 0.02 | 55 | 17000 | 1.1x10-6 | ±0.6 | M4 | 3.5 | 19 | ||

| 25 | L30 | 6 | 1 | 0.02 | 65 | 16000 | 5.2x10-6 | ±0.6 | M4 | 3.5 | 33 | |

| 25 | L34 | 1 | 0.02 | 65 | 16000 | 5.2x10-6 | ±0.6 | M4 | 3.5 | 42 | ||

| 30 | L35 | 6.5 | 1 | 0.02 | 72 | 12000 | 6.2x10-6 | ±0.6 | M4 | 3.5 | 50 | |

| 30 | L40 | 1 | 0.02 | 72 | 12000 | 6.2x10-6 | ±0.6 | M4 | 8 | 60 | ||

| 35 | L50 | 15 | 1 | 0.02 | 200 | 10000 | 8.1x10-6 | ±0.6 | M5 | 8 | 45 | |

| 40 | L40 | 32 | 1 | 0.02 | 450 | 10000 | 3.8x10-5 | ±0.8 | 115 | |||

| 40 | L50 | 1 | 0.02 | 450 | 10000 | 3.8x10-5 | ±0.8 | 115 | ||||

| 40 | L55 | 1 | 0.02 | 500 | 10000 | 3.8x10-5 | ±0.8 | 127 | ||||

| 40 | L66 | 1 | 0.02 | 550 | 10000 | 3.9x10-5 | ±0.8 | 154 | ||||

| 55 | L78 | 46 | 1 | 0.02 | 1500 | 8000 | 1.6x10-3 | ±0.8 | M6 | 13 | 341 | |

| 65 | L90 | 109 | 1 | 0.02 | 2800 | 6000 | 3.8x10-3 | ±0.8 | M8 | 28 | 583 | |

| 80 | L114 | 135 | 1 | 0.02 | 3500 | 4600 | 1.8x10-3 | ±1.0 | M8 | 28 | 1000 | |

| 95 | L126 | 250 | 1 | 0.02 | 5000 | 3800 | 1.8x10-3 | ±1.0 | M10 | 40 | 1500 | |

| 105 | L140 | 420 | 1 | 0.02 | 5400 | 3400 | 3.1x10-3 | ±1.0 | M12 | 75 | 2000 | |

| 120 | L160 | 520 | 1 | 0.02 | 6500 | 3000 | 4.3x10-3 | ±1.0 | M12 | 75 | 2500 | |

The allowable torque varies with temperature.

The allowable torque varies with temperature. Press the adjustment ring into the body to assemble.

Press the adjustment ring into the body to assemble. Press Spacer to the body when install.

Press Spacer to the body when install.

| Shaft Bore Dia. d1·d2 | b(Keyway Width) | t Keyway Depth | Keyway Nominal Dim. b X h | |

| LK | RK | |||

| 8~10 | 3 | 3 | 1.4 | 3x3 |

| 11~12 | 4 | 4 | 1.8 | 4x4 |

| 13~17 | 5 | 5 | 2.3 | 5x5 |

| 18~22 | 6 | 6 | 2.8 | 6x6 |

| 23~30 | 8 | 8 | 3.3 | 8x7 |

| 31~38 | 10 | 10 | 3.3 | 10x8 |

| 39~44 | 12 | 12 | 3.3 | 12x8 |

| 45~50 | 14 | 14 | 3.8 | 14x9 |

| 51~58 | 16 | 16 | 4.3 | 16x10 |

| 59~65 | 18 | 18 | 4.4 | 18x11 |

| 66~75 | 20 | 20 | 4.9 | 20x12 |

| 76~85 | 22 | 22 | 5.4 | 22x14 |

| 86~95 | 25 | 25 | 5.4 | 25x14 |

Product Features

The characteristics of Jaw Coupling are as follows:

It has a simple structure, no lubrication required / easy to repair and inspect / maintenance-free. It can operated continuously for a long time.

Polyurethane elastic parts are wear-resistant and oil-resistant, have large load capacity, long service life, and are safe and reliable.

This product is suitable for medium and high-speed applications.

It has a simple structure, no lubrication required / easy to repair and inspect / maintenance-free. It can operated continuously for a long time.

Polyurethane elastic parts are wear-resistant and oil-resistant, have large load capacity, long service life, and are safe and reliable.

This product is suitable for medium and high-speed applications.

Usage Method

■Mounting method

STEP1 Insert the coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and coupling bore.

Then, when inserting the coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the coupling with high accuracy.

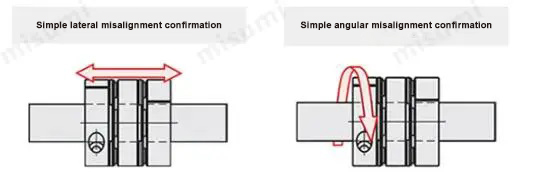

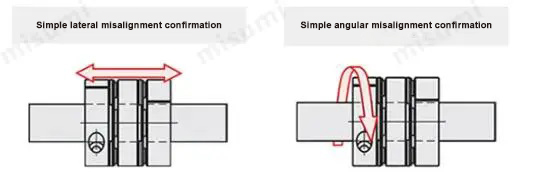

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the coupling slide axially and confirm its smooth movement.

Then, rotate the coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type coupling, so carry out positioning securely. STEP4 Installation

STEP4 Installation

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

STEP1 Insert the coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and coupling bore.

Then, when inserting the coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the coupling with high accuracy.

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the coupling slide axially and confirm its smooth movement.

Then, rotate the coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type coupling, so carry out positioning securely.

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

Example of Use

Use example of coupling 1: motor × gear box

Use example of coupling 3: motor × encoder

Use example of coupling 2: motor × ball screw

Use example of coupling 4: motor × measuring tester

Precautions

■ Calibration and adjustment

1. The coupling allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced. Be sure to make calibration and adjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviations occur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

1. The coupling allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced. Be sure to make calibration and adjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviations occur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

| Part Number |

|---|

| E-LMPJC14L22-[3,4]-[3,4] |

| E-LMPJC20L25-[4,5,6,6.35,7,8,9,9.525,10]-[4,5,6,6.35,7,8,9,9.525,10] |

| E-LMPJC20L30-[4,5,6,6.35,7,8,9,9.525,10]-[4,5,6,6.35,7,8,9,9.525,10] |

| E-LMPJC25L30-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14] |

| E-LMPJC25L34-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14] |

| E-LMPJC30L35-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16] |

| E-LMPJC30L40-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16] |

| E-LMPJC35L50-[8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20]-[8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20] |

| E-LMPJC40L40-[8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22]-[8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22] |

| E-LMPJC40L50-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22]-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22] |

| E-LMPJC40L55-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22]-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22] |

| E-LMPJC40L66-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22]-[7,8,9,9.525,10,11,12,12.7,13,14,15,16,17,18,19,20,22] |

| E-LMPJC55L78-[12,12.7,13,14,15,16,17,18,19,20,22,24,25,28,30]-[12,12.7,13,14,15,16,17,18,19,20,22,24,25,28,30] |

| E-LMPJC65L90-[14,15,16,17,18,19,20,22,24,25,28,30,32,35,38]-[14,15,16,17,18,19,20,22,24,25,28,30,32,35,38] |

| E-LMPJC80L114-[19,20,22,24,25,28,30,32,35,38,40,42,45]-[19,20,22,24,25,28,30,32,35,38,40,42,45] |

| E-LMPJC95L126-[20,22,24,25,28,30,32,35,38,40,42,45,50,55]-[20,22,24,25,28,30,32,35,38,40,42,45,50,55] |

| E-LMPJC105L140-[20,22,24,25,28,30,32,35,38,40,42,45,50,55,60]-[20,22,24,25,28,30,32,35,38,40,42,45,50,55,60] |

| E-LMPJC120L160-[25,28,30,32,35,38,40,42,45,50,55,60,65,70,75,80]-[25,28,30,32,35,38,40,42,45,50,55,60,65,70,75,80] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Series Name | 轴孔经(加工完毕)d1 (Ø) | 轴孔经(加工完毕)d2 (Ø) | 外径D (Ø) | 全长L (mm) | Application | Features | Allowable Misalignment | Body Material | Product Category | Buffer Material | Operating Temperature (°C) | Shaft Tightening Method | Shaft Hole Shape |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 14 Day(s) | - | 4 | 4 | - | - | - | - | - | - | - | - | - | - | - | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 4 ~ 10 | 4 ~ 10 | 20 | 25 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 4 ~ 10 | 4 ~ 10 | 20 | 30 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 5 ~ 14 | 5 ~ 14 | 25 | 30 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 5 ~ 14 | 5 ~ 14 | 25 | 34 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 5 ~ 16 | 5 ~ 16 | 30 | 35 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 5 ~ 16 | 5 ~ 16 | 30 | 40 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 8 ~ 20 | 8 ~ 20 | 35 | 50 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 8 ~ 22 | 8 ~ 22 | 40 | 40 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 7 ~ 22 | 7 ~ 22 | 40 | 50 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 7 ~ 22 | 7 ~ 22 | 40 | 55 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 8 Day(s) | [Jaw] Jaw | 7 ~ 22 | 7 ~ 22 | 40 | 66 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 12 ~ 30 | 12 ~ 30 | 55 | 78 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 14 ~ 38 | 14 ~ 38 | 65 | 90 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 19 ~ 45 | 19 ~ 45 | 80 | 114 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 20 ~ 55 | 20 ~ 55 | 95 | 126 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 14 Day(s) | [Jaw] Jaw | 20 ~ 60 | 20 ~ 60 | 105 | 140 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard | ||

- | 1 Piece(s) | 17 Day(s) | [Jaw] Jaw | 25 ~ 80 | 25 ~ 80 | 120 | 160 | Standard / For Servo Motors / Stepping Motor | High Torque Type / Low Moment of Inertia / Vibration Insulation | Angular Misalignment / Eccentricity / Axial Misalignment | Aluminum Alloy | Coupling Main Body | Polyurethane | -20~60 | Fastening Bolt | Standard |

Loading...Tải…

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Frequently asked question (FAQ)FAQ

- Question:Question: What are the characteristics of claw couplings?

- Answer:Answer: Claw couplings can absorb vibration, compensate radial and angular deviation, and are maintenance free, oil resistant and electrically insulated.

- Question:Question: What are the applications of claw couplings?

- Answer:Answer: Applicable motor types for claw couplings: recommended for stepping motors and universal motors.

- Question:Question: How to select according to the purpose, environment, working conditions?

- Answer:Answer: Please refer to the link page for specific instructions. https://www.misumi.com.cn/special/coupling/select/situation/

- Question:Question: What is a coupling?

- Answer:Answer: A coupling is a part that connects two different rotating bodies (motor shaft, ball screw, etc.) and aims at transmitting torque. The load of assembly adjustment is reduced by absorbing the axis deviation (lateral misalignment, angular misalignment and axial amplitude) between rotating bodies. And in case of accidental overload, the coupling is destroyed and the rotating bodies are disconnected to protect the expensive power part and the whole device.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy