(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- C-AHTFW□□-H8M

- C-AHTF□□-H8M

-

Belt Width Used(mm)

-

Number of Teeth(T)

-

Shaft Bore Dia. d(mm)

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- Same day

- 19 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Idlers HTD 8M (Part Number)

- Until 31/12/2024

- Volume Discount

- All

- Sale Items

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

- CAD Data unavailable

(i)

Caution

thận trọng

- **RoHS Compliant is available for some part numbers.

Please contact with MISUMI for detail effective date.

Product Description

RoHS Compliant Product

Economy HTD 8M Idler Pulley

- Cost-effective aluminum alloy

- Fits multiple belt widths.

- Variety of teeth counts available

- Central or side bearings

- Clear anodized for longevity

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of Timing Pulley Overview

Usually, flat-belt pulleys and flat belts are widely used in mechanisms design for transmitting rotational power generated by motors. Driving and transmission are realized through the friction fit between flat-belt pulleys and flat belts.

Product of Timing Pulley Features

・MISUMI Economy series idlers tooth profiles conform to JIS and ISO standards, matching with the standard belt tooth profile for smoother rotation.

| 5M Tooth Profile | MISUMI Economy series (Good engagement) | Products circulating on the market * |

| Engagement of Timing Pulley and Timing Belt |  |  |

| Clearance | Small | Large |

| Positioning Accuracy | Height | Low |

■Rotation Stability of MISUMI Economy series Idlers

| ・MISUMI economy series idler uses MISUMI Economy series bearing with stabler quality and lower noise |  |

| Diameter of Pulley Tooth Top Circle d0 | 5.96≤d0≤203.20 |

| Runout Tolerance (Circumferential Runout) | ≤0.13 |

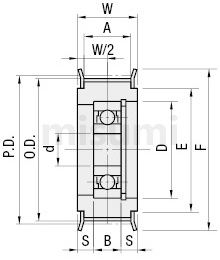

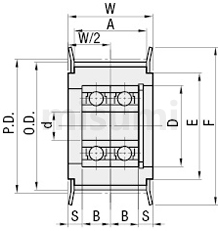

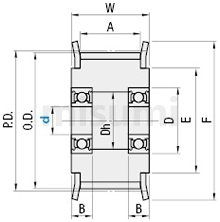

Dimensional of Timing Pulley Drawing

| ●Central Bearing | ●Both Sides Bearing | |

| <Single Bearing> | <Double Bearing> | |

|  |  |

Bearing is pressed fit.

Bearing is pressed fit. Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting)

Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting) MISUMI makes no commitment to the bearing brand

MISUMI makes no commitment to the bearing brandTapped Hole Size Table

(Shaft Bore Specs.: P·N)

| dH7 Shaft Hole ID | 2-M (Coarse Thread) | Single Model of Fixing Screw | Box Model of Fixing Screw |

| 8 to 12 | M4 | MSSU4-3 | BOX-MSSU4-3 |

| 13 to 17 | M5 | MSSU5-4 | BOX-MSSU5-4 |

| 18 to 20 | M6 | MSSU6-5 | BOX-MSSU6-5 |

Timing Pulley are not provided with fixing screws. You may purchase them separately referring to the recommended fixing screw models.

Timing Pulley are not provided with fixing screws. You may purchase them separately referring to the recommended fixing screw models.Specifications of Timing Pulley Overview

Material Material |  Surface Treatment Surface Treatment | |

| Timing Pulley | Flange | |

| Aluminum Alloy | Aluminum Alloy | Clear Anodized |

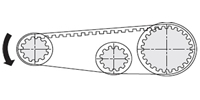

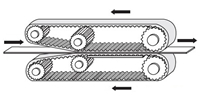

Usage of Timing Pulley Method

| Usage Method Example of Timing Pulley Drawing | Instructions for Use of Timing Belt Idlers and Timing Belt |

| ①Timing Pulley Driving The driven wheel is driven by the driving wheel for transmission |

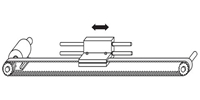

| ②Timing Pulley Linear driving Reciprocating motion is carried out through the self-end timing toothed belt. |

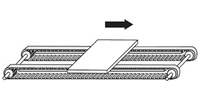

| Usage Method Example of Timing Pulley Drawing | Instructions for Use of Timing Belt Idlers and Timing Belt |

| ③Timing Pulley Conveyance Plates are conveyed by two timing toothed belts |

| ④Timing Pulley Traction transmission Workpieces are clamped and transmitted by the belt |

HTD 8M timing belt idlers, suitable for MISUMI HTD 8M timing belts.

HTD 8M timing belt idlers, suitable for MISUMI HTD 8M timing belts.Example of Timing Pulley Use

Belt tension device (manual)

■Mechanism function

1. Move the roller on the adjustment side, and tighten and fix it when the conveyor belt opens.

2. For multiple driving applications, the engagement rate can be improved by setting the roller in the middle position.

■ Role of the timing belt idler

1. The belt is tensioned by fixing the belt assembly distance with the timing belt idler

and with the assistance of the urethane roller.

For more information, please click Example for Belt Tension Device.

Related of Timing Pulley Industries

| Semiconductor | Automotive | Smart phone | ||

|  |  | ||

| Medical | Electronic & Electrical Appliances | Robotics | ||

|  |  |

Timing Pulley Precautions

Bearing is pressed fit.

Bearing is pressed fit. Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting)

Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting) MISUMI makes no commitment to the bearing brand

MISUMI makes no commitment to the bearing brandRelated of Timing Pulley Documents

①Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (drive).

②Data on the selection of timing pulleys and timing toothed belts, tensioning force, etc. (transmission & conveyance).

③Main causes and countermeasures for the damage, breakage, abnormal noise of timing toothed belts.

④Reference data on the replacement time of timing toothed belts.

⑤Data on dimensional tolerance of timing pulleys and timing idlers.

Related of Timing Pulley Products

| Idlers HTD 3M | Idlers HTD 5M | Timing Belts HTD 8M | ||

|  |  | ||

| Typical Timing Pulley model C-HTPA14H3M060-K-P5 | Typical Timing Pulley model: C-HTPA14H5M090-A-N8 | Typical Timing Pulley model: C-HTBN1000H8M-200 | ||

| Advantages: short delivery time, multiple types | Advantages: Short delivery time, multiple types | Advantages: short delivery time, multiple types |

| Part Number |

|---|

| C-AHTF30H8M300 |

| C-AHTFW30-H8M300-20 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Belt Width Used (mm) | Number of Teeth (T) | Shaft Bore Dia. d (mm) |

|---|---|---|---|---|---|---|---|

427,309 VND 363,213 VND | 2 Piece(s) | Available | 19 Day(s) | 30 | 30 | 20 | |

427,309 VND 363,213 VND | 2 Piece(s) | Available | 19 Day(s) | 30 | 30 | 20 |

Loading...Tải…

| ●Central Bearing | ●Both Sides Bearing | |

| <Single Bearing> | <Double Bearing> | |

|  |  |

Bearing is pressed fit.

Bearing is pressed fit.  Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting)

Bearing Accuracy: JIS/ISO Class 0 (Before press-fitting) MISUMI makes no commitment to the bearing brand

MISUMI makes no commitment to the bearing brandTapped Hole Size Table

(Shaft Bore Specs.: P·N)

| dH7 Shaft Hole ID | 2-M (Coarse Thread) | Single Model of Fixing Screw | Box Model of Fixing Screw |

| 8 to 12 | M4 | MSSU4-3 | BOX-MSSU4-3 |

| 13 to 17 | M5 | MSSU5-4 | BOX-MSSU5-4 |

| 18 to 20 | M6 | MSSU6-5 | BOX-MSSU6-5 |

Timing pulleys are not provided with fixing screws. You may purchase them separately referring to the recommended fixing screw models.

Timing pulleys are not provided with fixing screws. You may purchase them separately referring to the recommended fixing screw models. Material Material |  Surface Treatment Surface Treatment | |

| Pulley | Flange | |

| Aluminum Alloy | Aluminum Alloy | Clear Anodized |

■ Dimension Specification Table

| Part Number | Shaft Diameter d | P.D. | O.D. | F | E | A | W | S | Bearing size | |||

| Number of Teeth | Applicable Belt | No. | D | B | ||||||||

| 20 | H8M150 | 12 | 50.93 | 49.56 | 58 | 40 | 17 | 22 | 6 | 6201ZZ×1 | 32 | 10 |

| H8M250 | 15 | 28 | 33 | 5.5 | 6202ZZ×2 | 35 | 11 | |||||

| 22 | H8M150 | 12 | 56.02 | 54.65 | 61 | 45 | 17 | 22 | 6 | 6201ZZ×1 | 32 | 10 |

| 24 | H8M150 | 12 | 61.12 | 59.74 | 67 | 50 | 17 | 22 | 6 | 6201ZZ×1 | 32 | 10 |

| H8M250 | 28 | 33 | 6.5 | 6201ZZ×2 | ||||||||

| H8M300 | 15 | 33 | 38 | 8 | 6202ZZ×2 | 35 | 11 | |||||

| H8M400 | 44 | 49 | 13.5 | |||||||||

| 25 | H8M150 | 15 | 63.66 | 62.29 | 70 | 56 | 17 | 22 | 5.5 | 6202ZZ×1 | 35 | 11 |

| 26 | H8M150 | 15 | 66.21 | 64.84 | 74 | 58 | 17 | 22 | 5.5 | 6202ZZ×1 | 35 | 11 |

| 28 | H8M150 | 15 | 71.3 | 69.93 | 80 | 60 | 17 | 22 | 5.5 | 6202ZZ×1 | 35 | 11 |

| 30 | H8M150 | 15 | 76.39 | 75.02 | 87 | 67 | 17 | 22 | 5.5 | 6202ZZ×1 | 35 | 11 |

| H8M250 | 28 | 33 | 5.5 | 6202ZZ×2 | ||||||||

| H8M300 | 20 | 33 | 38 | 5 | 6204ZZ×2 | 47 | 14 | |||||

| H8M400 | 44 | 49 | 10.5 | |||||||||

| 32 | H8M150 | 20 | 81.49 | 80.12 | 87 | 67 | 17 | 22 | 4 | 6204ZZ×1 | 47 | 14 |

| 34 | H8M150 | 20 | 86.58 | 85.21 | 95 | 75 | 17 | 22 | 4 | 6204ZZ×1 | 47 | 14 |

| 40 | H8M150 | 25 | 101.86 | 100.49 | 111 | 90 | 17 | 22 | 3.5 | 6205ZZ×1 | 52 | 15 |

| Part Number | Shaft Diameter d | P.D. | O.D. | F | E | A | W | Dh | Bearing size | |||

| Number of Teeth | Applicable Belt | No. | D | B | ||||||||

| 22 | H8M250 | 12 | 56.02 | 54.65 | 61 | 45 | 28 | 33 | 27 | 6201ZZ×2 | 32 | 10 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 24 | H8M250 | 12 | 61.12 | 59.74 | 67 | 50 | 28 | 33 | 27 | 6201ZZ×2 | 32 | 10 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 25 | H8M250 | 12 | 63.66 | 62.29 | 70 | 56 | 28 | 33 | 27 | 6201ZZ×2 | 32 | 10 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 26 | H8M150 | 12 | 66.21 | 64.84 | 74 | 58 | 17 | 22 | 25 | 6001ZZ×2 | 28 | 8 |

| H8M250 | 28 | 33 | ||||||||||

| H8M300 | 33 | 38 | 27 | 6201ZZ×2 | 32 | 10 | ||||||

| H8M400 | 44 | 49 | ||||||||||

| 28 | H8M250 | 15 | 71.3 | 69.93 | 80 | 60 | 28 | 33 | 30 | 6202ZZ×2 | 35 | 11 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 30 | H8M150 | 15 | 76.39 | 75.02 | 87 | 67 | 17 | 22 | 29 | 6002ZZ×2 | 32 | 9 |

| H8M250 | 28 | 33 | ||||||||||

| H8M300 | 33 | 38 | 30 | 6202ZZ×2 | 35 | 11 | ||||||

| H8M400 | 44 | 49 | ||||||||||

| 30 | H8M250 | 20 | 76.39 | 75.02 | 87 | 67 | 28 | 33 | 37 | 6004ZZ×2 | 42 | 12 |

| H8M300 | 33 | 38 | 41 | 6204ZZ×2 | 47 | 14 | ||||||

| H8M400 | 44 | 49 | ||||||||||

| 32 | H8M250 | 20 | 81.49 | 80.12 | 87 | 67 | 28 | 33 | 41 | 6204ZZ×2 | 47 | 14 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 34 | H8M250 | 20 | 86.58 | 85.21 | 95 | 75 | 28 | 33 | 41 | 6204ZZ×2 | 47 | 14 |

| H8M300 | 33 | 38 | ||||||||||

| H8M400 | 44 | 49 | ||||||||||

| 40 | H8M250 | 25 | 101.86 | 100.49 | 111 | 90 | 28 | 33 | 43 | 6005ZZ×2 | 47 | 12 |

| H8M300 | 33 | 38 | 47 | 6205ZZ×2 | 52 | 15 | ||||||

| H8M400 | 44 | 49 | ||||||||||

Basic InformationThông tin cơ bản

| Type | Idlers with Teeth | Belt Type | 8M | Material | Ultra Super Duralmin Type Aluminum Alloy |

|---|---|---|---|---|---|

| Surface Treatment | Clear Anodize | Timing Pulley / Idler | Idlers |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy