(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- C-UL

- C-UTT

-

Free Length L(mm)

-

Inner Dia. D-2d (or D)(Ø)

-

Outer Dia. D (or D1)(Ø)

-

Height with the max. load applied ([Free Length] – [Allowable Deflection])(mm)

-

Spring Constant(N/mm)

-

Allowable Load (Configurable Range)(N)

- ~1.50

- 1.51~4.50

- 4.51~8.50

- 8.51~16.00

- 16.01~30.00

- 30.01~50.00

-

Max. Load(N)

-

Wire Dia.(Ø)

-

End Surface Status

- With Grinding

- Without Grinding

-

Total Coils

-

Solid Length(mm)

-

Allowable Displacement(mm)

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- Same day

- 8 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Round Wire Coil Springs, Defection O.D. Referenced, Stainless Steel, Light Load (C-UL3-30)

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

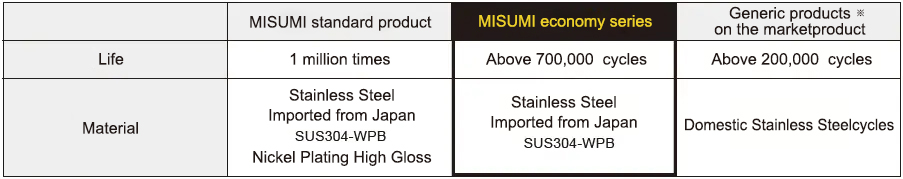

This is an economy item, The price is cheaper than the MISUMI standard product.

Economy Round Wire Coil Springs

- Achieve exacting specifications with our outer diameter prioritized Round Wire Coil Springs.

- Enjoy high-quality stainless steel springs at a fraction of the cost with our Economy Series.

- Ideal for applications requiring less stress with durability.

- Choose from a wide range of diameters and lengths to match your needs.

- Designed to operate efficiently up to a percentage of maximum displacement.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

♢Stainless Round Wire Springs are also magnetic. Please be careful.

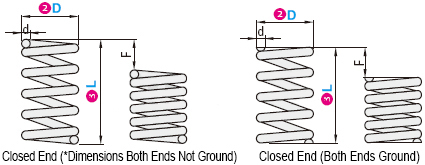

Dimensional Drawings

Specification Table

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only.

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only.| Type | D-L | d | Reference Length | F max. | N {kgf} max. | Fa% | ||

| C-UL | 2- | 5* | 0.2 | 1.65 | 2 | 0.98 | {0.1} | 40 |

| 10* | 0.26 | 5.07 | 4 | 1.96 | {0.2} | |||

| 15* | 6 | 2.94 | {0.3} | |||||

| 3- | 5* | 0.3 | 2 | 2 | 2.0 | {0.2} | ||

| 10* | 0.35 | 3.7 | 4 | 3.9 | {0.4} | |||

| 15* | 0.4 | 6.6 | 6 | 5.9 | {0.6} | |||

| 20* | 8 | 7.8 | {0.8} | |||||

| 25* | 0.45 | 11.7 | 10 | 9.8 | {1} | |||

| 30* | 12 | 11.8 | {1.2} | |||||

| 4- | 5* | 0.35 | 2.1 | 2 | 2.0 | {0.2} | ||

| 10* | 0.45 | 5.3 | 4 | 3.9 | {0.4} | |||

| 15* | 6 | 5.9 | {0.6} | |||||

| 20* | 0.5 | 8 | 8 | 7.8 | {0.8} | |||

| 25* | 10 | 9.8 | {1 } | |||||

| 30* | 0.55 | 12.7 | 12 | 11.8 | {1.2} | |||

| 40 | 0.6 | 19.8 | 16 | 15.7 | {1.6} | |||

| 5- | 5* | 0.4 | 2.2 | 2 | 2.0 | {0.2} | ||

| 10* | 0.5 | 4.75 | 4 | 3.9 | {0.4} | |||

| 15* | 6 | 5.9 | {0.6} | |||||

| 20* | 0.55 | 6.88 | 8 | 7.8 | {0.8} | |||

| 25* | 10 | 9.8 | {1} | |||||

| 30 | 0.65 | 14.95 | 12 | 11.8 | {1.2} | |||

| 40 | 16 | 15.7 | {1.6} | |||||

| 6- | 5* | 0.45 | 2.3 | 2 | 2.0 | {0.2} | ||

| 10* | 0.55 | 4.4 | 4 | 3.9 | {0.4} | |||

| 15* | 6 | 5.9 | {0.6} | |||||

| 20 | 0.65 | 8.5 | 8 | 7.8 | {0.8} | |||

| 25 | 10 | 9.8 | {1 } | |||||

| 30 | 0.7 | 12.6 | 12 | 11.8 | {1.2} | |||

| 35 | 14 | 13.7 | {1.4} | |||||

| 8- | 10 | 0.65 | 4.6 | 4 | 3.9 | {0.4} | ||

| 15 | 0.75 | 8.3 | 6 | 5.9 | {0.6} | |||

| 20 | 8 | 7.8 | {0.8} | |||||

| 25 | 10 | 9.8 | {1 } | |||||

| 30 | 0.8 | 10.4 | 12 | 11.8 | {1.2} | |||

| 35 | 14 | 13.7 | {1.4} | |||||

| 40 | 16 | 15.7 | {1.6} | |||||

| 45 | 0.85 | 14.5 | 18 | 17.7 | {1.8} | |||

| 10- | 10 | 0.75 | 4.7 | 4 | 3.9 | {0.4} | ||

| 15 | 0.8 | 6.2 | 6 | 5.9 | {0.6} | |||

| 20 | 8 | 7.8 | {0.8} | |||||

| 25 | 0.9 | 9.5 | 10 | 9.8 | {1 } | |||

| 30 | 12 | 11.8 | {1.2} | |||||

| 35 | 14 | 13.7 | {1.4} | |||||

| 50 | 1.0 | 15.5 | 20 | 19.6 | {2.0} | |||

| 60 | 1.1 | 23.7 | 24 | 23.5 | {2.4} | |||

| 12- | 15 | 0.9 | 6.75 | 6 | 5.9 | {0.6} | ||

| 20 | 1.0 | 10 | 8 | 7.8 | {0..8} | |||

| 25 | 1.0 | 10 | 10 | 9.8 | {1.0} | |||

| 40 | 1.2 | 21.6 | 16 | 15.7 | {1.6} | |||

| 13- | 20 | 1.0 | 8.25 | 8 | 7.8 | {0.8} | ||

| 30 | 1.1 | 12.1 | 12 | 11.8 | {1.2} | |||

| 40 | 1.1 | 12.1 | 16 | 15.7 | {1.6} | |||

| 16- | 15 | 1.1 | 7.7 | 6 | 5.9 | {0.6} | ||

| 25 | 1.2 | 10.8 | 10 | 9.8 | {1.0} | |||

| 20- | 30 | 1.7 | 12.8 | 12 | 35.3 | {3.6} | ||

■C-UTT: Fmax. (allowable displacement) = L×Fa%

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only.

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only.| Type | D-L | d | Reference Length | F max. | N {kgf} max. | Fa% | ||

| C-UTT | 3- | 5* | 0.35 | 2.8 | 2 | 2.9 | {0.3} | 40 |

| 10* | 0.4 | 4.8 | 4 | 5.9 | {0.6} | |||

| 15* | 0.45 | 8.3 | 6 | 8.8 | {0.9} | |||

| 20* | 30 | |||||||

| 4- | 5* | 0.4 | 2.6 | 2 | 2.9 | {0.3} | 40 | |

| 10* | 0.45 | 3.9 | 4 | 5.9 | {0.6} | |||

| 15* | 0.5 | 6 | 6 | 8.8 | {0.9} | |||

| 20* | 0.55 | 9.4 | 8 | 11.8 | {1.2} | |||

| 30 | 0.6 | 14.4 | 10 | 14.7 | {1.5} | 33 | ||

| 5- | 5* | 0.45 | 2.6 | 2 | 2.9 | {0.3} | 40 | |

| 10* | 0.5 | 3.6 | 4 | 5.9 | {0.6} | |||

| 15 | 0.6 | 7.5 | 6 | 8.8 | {0.9} | |||

| 20 | 8 | 11.8 | {1.2} | |||||

| 25 | 0.65 | 10.7 | 10 | 14.7 | {1.5} | |||

| 30 | 0.7 | 15.4 | 12 | 17.7 | {1.8} | |||

| 6- | 5* | 0.5 | 2.4 | 2 | 3.9 | {0.4} | ||

| 10 | 0.6 | 4.2 | 4 | 7.8 | {0.8} | |||

| 15 | 0.7 | 7.4 | 6 | 11.8 | {1.2} | |||

| 20 | 8 | 15.7 | {1.6} | |||||

| 25 | 0.8 | 13.6 | 10 | 19.6 | {2.0} | |||

| 30 | 12 | 23.5 | {2.4} | |||||

| 35 | 0.85 | 17.5 | 14 | 27.5 | {2.8} | |||

| 40 | 0.9 | 23.4 | 16 | 31.4 | {3.2} | |||

| 45 | 0.9 | 23.4 | 18 | 35.3 | {3.6} | |||

| 8- | 10 | 0.75 | 5.3 | 4 | 7.8 | {0.8} | 40 | |

| 15 | 6 | 11.8 | {1.2} | |||||

| 20 | 0.9 | 10.4 | 8 | 15.7 | {1.6} | |||

| 25 | 10 | 19.6 | {2.0} | |||||

| 30 | 1.0 | 17 | 12 | 23.5 | {2.4} | |||

| 35 | 14 | 27.5 | {2.8} | |||||

| 40 | 16 | 31.4 | {3.2} | |||||

| 45 | 1.1 | 25.3 | 18 | 35.3 | {3.6} | |||

| 70 | 1.2 | 39.6 | 28 | 54.9 | {5.6} | |||

| 10- | 10 | 0.85 | 5.1 | 4 | 7.8 | {0.8} | ||

| 15 | 6 | 11.8 | {1.2} | |||||

| 20 | 1.0 | 9.5 | 8 | 15.7 | {1.6} | |||

| 25 | 10 | 19.6 | {2.0} | |||||

| 30 | 1.1 | 14.3 | 12 | 23.5 | {2.4} | |||

| 35 | 14 | 27.5 | {2.8} | |||||

| 40 | 1.2 | 20.4 | 16 | 31.4 | {3.2} | |||

| 45 | 1.2 | 20.4 | 18 | 35.3 | {3.6} | |||

| 60 | 1.3 | 29.9 | 24 | 47.1 | {4.8} | |||

| 13- | 15 | 1.0 | 5.75 | 6 | 11.8 | {1.2} | ||

| 20 | 1.2 | 10.5 | 8 | 15.7 | {1.6} | |||

| 25 | 10 | 19.6 | {2.0} | |||||

| 30 | 1.3 | 15 | 12 | 23.5 | {2.4} | |||

| 35 | 14 | 27.5 | {2.8} | |||||

| 40 | 1.4 | 20.3 | 16 | 31.4 | {3.2} | |||

| 45 | 1.4 | 20.3 | 18 | 35.3 | {3.6} | |||

| 50 | 1.5 | 27.8 | 20 | 39.2 | {4.0} | |||

| 16- | 15 | 1.2 | 7.2 | 6 | 11.8 | {1.2} | ||

| 20 | 1.3 | 9.1 | 8 | 15.7 | {1.6 | |||

| 25 | 1.3 | 9.1 | 10 | 19.6 | {2.0} | |||

| 30 | 1.4 | 12.3 | 12 | 23.5 | {2.4} | |||

| 35 | 1.5 | 16.5 | 14 | 27.5 | {2.8} | |||

| 40 | 1.6 | 21.6 | 16 | 31.4 | {3.2} | |||

| 20- | 30 | 1.8 | 12.6 | 12 | 47.1 | {4.8} | ||

| 50 | 2.2 | 27.5 | 20 | 78.5 | {8.0} | |||

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only.

The outer diameter standard type gives priority to guaranteeing the outer diameter, while the inner diameter is for reference only. Both ends of C-UL models with * are not ground.

Both ends of C-UL models with * are not ground. Be sure to use within the allowable displacement Fmax.(mm)

Be sure to use within the allowable displacement Fmax.(mm) Calculation method of laps (reference value):

Calculation method of laps (reference value):Total number of laps = solid length ÷ wire diameter (d)-1

Effective laps=total number of laps-2

The number of laps is a reference value. There will be some deviations among batches. The solid length is a reference value. There will be slight differences among batches. Moreover, if it is used under the limit condition of the solid length, it may cause the spring to be deformed or be damaged after using only a limited number of times.

The number of laps is a reference value. There will be some deviations among batches. The solid length is a reference value. There will be slight differences among batches. Moreover, if it is used under the limit condition of the solid length, it may cause the spring to be deformed or be damaged after using only a limited number of times. The solid length is a reference value. There will be slight differences among batches.

The solid length is a reference value. There will be slight differences among batches.■Spring Constant The spring constant

D12 is for C-UY・C-UR・C-UF・C-UBB only. D14 is for C-UBB only.

D12 is for C-UY・C-UR・C-UF・C-UBB only. D14 is for C-UBB only.| Type | C-UV | C-UY | C-UR | C-UF | C-UL | C-UTT | C-UM | C-UH | C-UBB | |||||||||||||||||||

| D | ||||||||||||||||||||||||||||

| 2 | 0.05{0.005} | 0.2{0.02} | 0.3{0.03} | 0.5{0.05} | ||||||||||||||||||||||||

| 3 | N/mm 0.05 {kgf/mm}{0.005} | N/mm 0.098 {kgf/mm}{0.01} | N/mm 0.29 {kgf/mm} {0.03} | N/mm 0.49 {kgf/mm} {0.05} | N/mm 0.98 {kgf/mm} {0.1} | 1.5{0.15} | ||||||||||||||||||||||

| 4 | 2.0 {0.2} | 2.9{0.3} | 4.9{0.5} | |||||||||||||||||||||||||

| 5 | N/mm 2.0 {kgf/mm} {0.2} | |||||||||||||||||||||||||||

| 6 | N/mm 2.9 {kgf/mm} {0.3} | N/mm 5.9 {kgf/mm} {0.6} | N/mm 9.8 {kgf/mm} {1.0} | |||||||||||||||||||||||||

| 8 | ||||||||||||||||||||||||||||

| 10 | N/mm 0.2 {kgf/mm} {0.02} | |||||||||||||||||||||||||||

| 12 | ||||||||||||||||||||||||||||

| 13 | N/mm 9.8 {kgf/mm} {1.0} | N/mm 19.6 {kgf/mm} {2.0} | ||||||||||||||||||||||||||

| 14 | ||||||||||||||||||||||||||||

| 16 | ||||||||||||||||||||||||||||

| 20 | 0.3{0.03} | 0.5{0.05} | 0.98{0.1} | 2.9{0.3} | 3.9{0.4} | 4.9{0.5} | 14.7{1.5} | 29.4{3.0} | ||||||||||||||||||||

| Fmax. | F=L×70% | F=L×75% | F=L×60% | F=L×45% | F=L×40% | F=L×40% | F=L×35% | F=L×30% | F=L×25% | |||||||||||||||||||

Product Feature

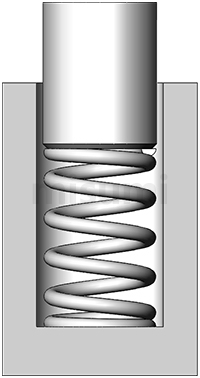

Select an appropriate Round Wire Springs type according to the actual installation situation, and refer to the published content for the specific inner and outer diameter tolerance values.

* The solid length is a reference value. If it is used under the limit condition of the solid length, the spring may be deformed, or damaged after using only a limited number of times. Therefore, use within the allowable displacementFmax.(mm).

To increase the usage count, it is recommended to use the spring up to 70% of the allowable displacement Fmax..

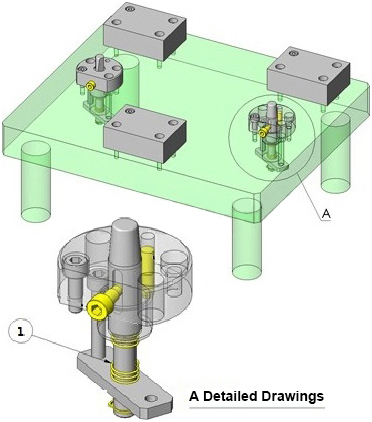

Example of Use of Round Wire Springs

A Round Wire Springs is mechanism for positioning the workpiece based on the hole reference.

Loosening during positioning can be reduced by using a tapered pin to eliminate the deviation caused by the tolerance of each workpiece hole.

Select the compression spring to move from the beginning of the positioning contact with the workpiece.

Precautions

Operating temperature of Round Wire Springs

SWP-A……Normal temperature (0~40℃)

Stainless steel……-10~100℃

Spring oil tempered steel wire……Normal temperature (0~40℃)

*If the spring is used under conditions exceeding the above temperature, the load value may decrease due to usage conditions.

*When used in an environment with high and low temperature differences and humidity such as outdoors, it is recommended to choose stainless steel products.

* Heat-resistant springs can also be used. For details, refer to the Plastic Mold Components Catalog.

Stainless steel springs are also magnetic. Please be careful.

Related Products

|  |  |

| (Economy series) Round Wire Springs - Outer Diameter Standard Stainless Steel, Ultra Light Load, Spring Constant 0.05 to 0.98 N/mm | (Economy series) Round Wire Springs - Inner Diameter Standard Stainless Steel, Light Load, Spring Constant 0.29 to 0.49 N/mm | (Economy series) Round Wire Springs - Outer Diameter Standard Stainless Steel, Heavy Load, Spring Constant 2.0 to 14.7 N/mm |

| Reason for Recommendation: MISUMI Basic Round Wire Springs, Outer Diameter Standard Type, Ultra Light Load Type | Reason for Recommendation: MISUMI Basic Round Wire Springs, Inner Diameter Standard Type, Light Load Type | Reason for Recommendation: MISUMI Basic Round Wire Springs, Outer Diameter Standard Type, Heavy Load Type |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| C-UL3-30 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Free Length L (mm) | Inner Dia. D-2d (or D) (Ø) | Outer Dia. D (or D1) (Ø) | Height with the max. load applied ([Free Length] – [Allowable Deflection]) (mm) | Spring Constant (N/mm) | Allowable Load (Configurable Range) (N) | Max. Load (N) | Wire Dia. (Ø) | End Surface Status | Total Coils | Solid Length (mm) | Allowable Displacement (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

3,814 VND | 1 Piece(s) | Available | Same day | 30 | 2.1 | 3 | 18 | 0.98 | 8.51~16.00 | 11.8 | 0.45 | Without Grinding | 25 | 11.7 | 12 |

Loading...Tải…

Basic InformationThông tin cơ bản

| Material | SUS304-WPB |

|---|

Please check the type/dimensions/specifications of the part C-UL3-30 in the Round Wire Coil Springs, Defection O.D. Referenced, Stainless Steel, Light Load series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần C-UL3-30 trong chuỗi Round Wire Coil Springs, Defection O.D. Referenced, Stainless Steel, Light Load.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Frequently asked question (FAQ)FAQ

- Question:Question: How long is the life of a basic round wire coil spring?

-

Answer:Answer:

Unfortunately, there are no specific test values as reference regarding the life of a round wire coil spring because there is individual difference to a certain extent and the installation conditions are complicated.

The usage count varies with the operating temperature, environment, and amount of deformation. To increase the usage count, it is recommended to use the spring up to 70% of the allowable displacement Fmax.. - Question:Question: What are the JIS standards for general spring-related materials?

-

Answer:Answer:

Piano wires: JIS G 3522

Iron wires: JIS G 3532

Hard drawn steel wires: JIS G 3521

Stainless steel wires for springs: JIS G 4313 - Question:Question: What influence will the usage without a spring rail have on the spring?

-

Answer:Answer:

The usage without a spring rail will cause buckling of the spring, bending of its body and other problems, leading to breakage due to high stress locally generated on the inner side of the bending part. To ensure the service life of the spring, install the spring using the shaft, outer diameter guide rail, etc.

※Basically, it is ideal to use the spring on the intermediate shaft of the inner diameter side guide rail, passing it through from the upper surface to the lower surface. - Question:Question: What influence will the usage count of more than 300,000 times beyond the maximum displacement (when used close to the solid length) have on the spring?

- Answer:Answer: The usage count of more than 300,000 times beyond the maximum displacement (when used close to the solid length) will cause high stress breakage above the calculated value on the section. In addition, near the solid length, the effective coil part will gradually get close and the spring constant will increase. Therefore, be sure to use within the allowable displacement Fmax.(mm).

- Question:Question: What is the difference between a piano steel wire spring and a hard drawn steel wire spring?

-

Answer:Answer:

There is little difference in appearance between the two materials. In short, the piano wire is an advanced material, and the hard drawn steel wire is a general material.

The piano wire is often used as a spring for precision machinery while the hard drawn steel wire is mostly used as a peripheral spring for groceries or blinds.

They are both high-carbon steels with almost the same chemical composition. The production of piano wires is time-consuming and they are expensive because there is additional standardized management and inspection of impurities, the depth of surface scars, and the depth of decarburized layer.

Although the subtle difference is invisible to the naked eye, it has a great influence on the quality of the spring.

Products like this...

| Part Number |

|---|

| C-UL10-25 |

| C-UL10-30 |

| C-UL10-35 |

| C-UL3-5 |

| C-UL4-10 |

| C-UL4-15 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to ShipSố ngày giao hàng | Free Length L (mm) | Inner Dia. D-2d (or D) (Ø) | Outer Dia. D (or D1) (Ø) | Height with the max. load applied ([Free Length] – [Allowable Deflection]) (mm) | Spring Constant (N/mm) | Allowable Load (Configurable Range) (N) | Max. Load (N) | Wire Dia. (Ø) | End Surface Status | Total Coils | Solid Length (mm) | Allowable Displacement (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

5,565 VND | 1 Piece(s) | Available | Same day | 25 | 8.2 | 10 | 15 | 0.98 | 8.51~16.00 | 9.8 | 0.9 | With Grinding | 9.6 | 9.5 | 10 | |

5,565 VND | 1 Piece(s) | Available | Same day | 30 | 8.2 | 10 | 18 | 0.98 | 8.51~16.00 | 11.8 | 0.9 | With Grinding | 9.6 | 9.5 | 12 | |

6,171 VND | 1 Piece(s) | Available | Same day | 35 | 8.2 | 10 | 21 | 0.98 | 8.51~16.00 | 13.7 | 0.9 | With Grinding | 9.6 | 9.5 | 14 | |

3,208 VND | 1 Piece(s) | Available | Same day | 5 | 2.4 | 3 | 3 | 0.98 | 1.51~4.50 | 2 | 0.3 | Without Grinding | 5.7 | 2 | 2 | |

3,208 VND | 1 Piece(s) | Available | Same day | 10 | 3.1 | 4 | 6 | 0.98 | 1.51~4.50 | 3.9 | 0.45 | Without Grinding | 10.8 | 5.3 | 4 | |

3,208 VND | 1 Piece(s) | Available | Same day | 15 | 3.1 | 4 | 9 | 0.98 | 4.51~8.50 | 5.9 | 0.45 | Without Grinding | 10.8 | 5.3 | 6 |

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy