(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Thể lệ và Giải thưởng cuộc thi "Thiết kế máy Tự động hóa 2025" do MISUMI Việt Nam tổ chức. Xem chi tiết.

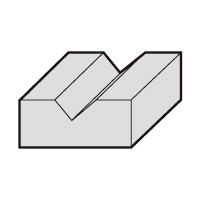

Chamfering / Centering Tools(Application:Chamfering/Horizontal Page5)

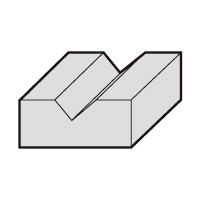

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentatio

Chamfering/countersinking tools are tools used for grinding center holes, positioning holes, grinding holes, or deburring and rounding the edges after side-surface machining. They are attached to machine tools such as drill press, lathe, machining center, etc. Center drills are used to position the initial indentation on the work material to avoid misalignment of the drill bit tip. Their materials include alloy carbide, powdered high-speed steel, cobalt high-speed steel and high-speed steel. Countersinking and chamfering cutters are capable of chamfering after drilling holes. Chamfering cutters with a hole on the tip allow for smooth cutting discharge on soft work materials such as copper and aluminum. Center drills have a 90° tip angle and they can be used for positioning and chamfering at the same time.

Search by specifying the lower class categoryTìm kiếm bằng cách chỉ định danh mục lớp thấp hơn

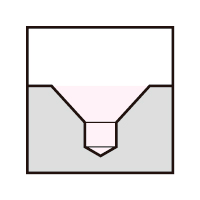

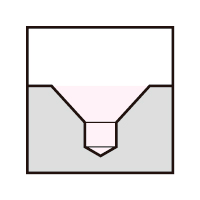

Centering/Countersink

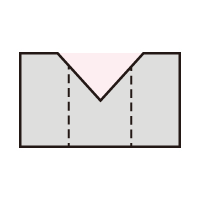

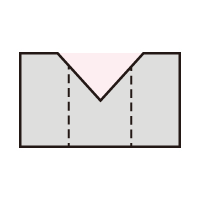

Centering/Countersink Chamfer, V-Grooves

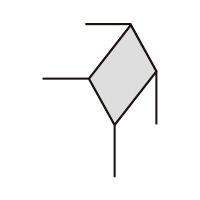

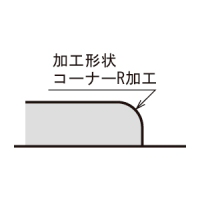

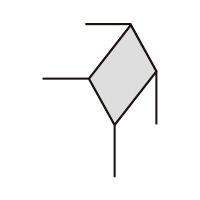

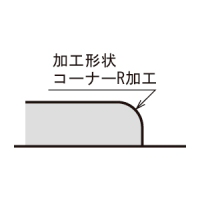

Chamfer, V-Grooves Inner R

Inner R Replaceable Blade Type Chamfering Tools/Tips/Blades

Replaceable Blade Type Chamfering Tools/Tips/Blades

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

184 itemsMặt hàng

- Sort By

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | THE CUT | TRUSCO NAKAYAMA | TRUSCO NAKAYAMA | YAMAWA MFG |

| Product SeriesDòng sản phẩm | ||||

| CADCAD | ||||

| From | 6,037,011 VND | 909,406 VND | 1,074,348 VND | 494,750 VND |

| Days to ShipSố ngày giao hàng | 8 Day(s) or more | 9 Day(s) | 6 Day(s) or more | 9 Day(s) or more |

| Tool Material Type | - | Cobalt HSS | Cobalt HSS | High-speed steel |

| Tool Diameter (D)(mm) | - | - | - | 0.5 ~ 5 |

| Tip angle (θ) | - | 90 | 60 | 90 |

| Application | Chamfering/Horizontal | Chamfering/Horizontal | Chamfering/Horizontal | Chamfering/Horizontal |

| work material | general steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Titanium[○] / Copper[○] | - | - | general steel[○] / Quenched and tempered steel[○] / Stainless Steel[○] / Aluminum[○] |

| Single blade, two blades | - | - | - | Single blade |

| Peripheral Blade Y/N | - | - | - | Available |

| Coating Y/N | - | NA | NA | Available |

| Coating Type | - | - | - | - |

| R Size (R)(mm) | - | - | - | - |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Tool Material Type

- High-speed steel

- Cobalt HSS

- Powder high-speed steel

- Carbide

- Vanadium High Speed Steel

- High-vanadium High Speed Steel

- SKH55

-

Tool Diameter (D)(mm)

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.35

- 0.4

- 0.45

- 0.45~2.1

- 0.45~2.7

- 0.5

- 0.55

- 0.6

- 0.65

- 0.65~2.1

- 0.65~2.7

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1–6

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2–10

- 2~13

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3~14

- 3 to 15

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.3

- 3.4

- 3.5

- 3.6

- 3.8

- 4

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.8

- 5

- 5/16

- 5/32

- 5/64

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.8

- 6

- 6.2

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 6.4

- 6.5

- 6.6

- 6.8

- 7

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 8

- 8.2

- 8.3

- 8.4

- 8.5

- 8.8

- 9

- 9.1

- 9.4

- 9.5

- 9.52

- 10

- 10.1

- 10.2

- 10.3

- 10.4

- 10.5

- 10.8

- 11

- 11.1

- 11.2

- 11.4

- 11.5

- 11.88

- 12

- 12.1

- 12.3

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 14.8

- 15

- 15.1

- 15.2

- 15.4

- 15.5

- 15.6

- 15.87

- 16

- 16.15

- 16.3

- 16.5

- 16.5,20.5,25.0,37.0

- 17

- 17.1

- 17.5

- 17.7

- 18

- 18.2

- 18.5

- 18.6

- 19

- 19.05

- 19.5

- 20

- 20.5

- 21

- 21.77

- 22

- 22.3

- 22.5

- 23

- 23.4

- 23.5

- 24

- 24.5

- 25

- 25.0(+0.3)

- Max: 25, Min: 4.2

- 25.20

- 25.3

- 25.5

- 26

- 26.5

- 26.6

- 27

- 27.5

- 28

- 28.5

- 29

- 29.9

- 30

- Max: 30, Min: 4

- 30.20

- 30.5

- 31

- Max: 31, Min: 10

- 31.5

- 31.7

- 31.9

- 32

- 32.6

- 32.7

- 33.1

- 33.3

- 34

- 34.1

- 34.8

- 34.9

- 35

- 35.4

- 35.5

- 35.9

- 36

- 36.9

- 37

- 37.1

- 37.9

- 38

- 39

- 39.83

- 40

- Max: 41, Min: 20

- 42

- 43

- 45

- 45.6

- 46

- 47

- 48

- 49

- 49.85~134.6

- 50

- 50.7

- 51

- 52

- 52.8

- 53

- 53.6

- 53.91

- 54

- 54.3

- 55

- 56

- 56.8

- 57.0

- 57.9

- 58

- 58.2

- 60

- 61.4

- 62

- 62.2

- 63

- 64

- 64.6

- 65

- 66

- 67.4

- 67.94

- 69.2

- 69.8

- 70

- 71.8

- 72

- 73.3

- 74

- 75

- 76

- 80

- 90

- 95

- 100

-

Tip angle (θ)

- 0–90

- 5~85

- 5~85°

- 15

- 20

- 25

- 30

- 35

- 40

- 45

- 45°

- 50

- 55

- 60

- 60°

- 60˚

- 60 × 120

- 65

- 70

- 75

- 80

- 90

- 90°

- Center Hole Angle: 90°

- Cutter Tip Angle: 100°

- 118

- 120

- 120°

- 120˚

- 125°

- 130

- 135

- 145+90

- 150

[60-160/1]

-

Application

-

Centering (Positioning)

-

Hole Chamfer

-

Chamfering/Horizontal

-

V Groove

-

Round Chamfer

-

Engraved

-

Drilling

-

Other

-

Centering (Positioning)

-

work material

- general steel

- Quenched and tempered steel

- high hardness steel

- Stainless Steel

- Cast Iron

- Aluminum

- Titanium

- Copper

- Graphite

- Resin

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

- 0.1

- 0.15

- 0.2

- 0.25

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- R0.5

- 0.5/1/1.5/2

- 0.5 to 4

- 0.5~5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- R0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1RM

- 1RY

- R1

- 1/2/3/4

- 1–3

- 1–5

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- 2RM

- 2RY

- R2

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.9

- 3

- 3RM

- 3RY

- R3

- 3.25

- 3.5

- R3.5

- 3.75

- 4

- 4RM

- 4RY

- R4

- 4.25

- 4.5

- R4.5

- 4.75

- 5

- 5RM

- R5

- 5–10

- 5.25

- 5.5

- 5.75

- 6

- R6

- 6.25

- 6.5

- 6.75

- 7

- R7

- 7.25

- 7.5

- 7.75

- 8

- R8

- 8.25

- 8.5

- 8.75

- 9

- R9

- 9.5

- 10

- R10

- 10.5

- 11

- 11.5

- 12

- R12

- 12.5

- R12.5

- 13

- 13.5

- 14

- 14.5

- 15

- R15

- 15.5

- 16

- R16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- XRM

- XRY

Related Categories to Chamfering / Centering ToolsDanh mục liên quan đến Chamfering / Centering Tools

-

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy