(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 24/11/2024 to 6:00 (ICT) 25/11/2024. We apologize for the inconvenience.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Cylinder (Tube) Inner Diameter(Ø)

-

Environment, Applications

- Standard

- Heat Resistant

-

Cushion

-

Specifications

- Built-in magnet

- Without magnet

-

Port thread type

- G

- NPT

- Rc

-

Auto Switches

- P3DW

- P3DWA

- P4DW

- F5BA

- F5NT

- F5P

- F5PW

- G5BA

- G5NB

- G5NT

- G5P

- G5PW

- P5DW

- Y7BA

- Y7BW

- Y7BWV

- Y7NW

- Y7P

- Y7PW

- F9G

- F9H

- M9B

- M9BA

- M9BAV

- M9BV

- M9BW

- M9BWV

- M9N

- M9NA

- M9NV

- M9NW

- M9NWV

- M9P

- M9PA

- M9PAV

- M9PV

- M9PW

- M9PWV

- B30

- B30J

- B31

- B31J

- A33

- A33C

- A34

- A34C

- B35

- B35J

- G39

- G39C

- K39

- K39C

- A44

- A44C

- J51

- A53

- B53

- A54

- B54

- A56

- A59W

- B59W

- F59

- F59F

- F59W

- G59

- G59F

- G59W

- J59

- J59W

- K59

- K59W

- Y59A

- Y59B

- A64

- B64

- A67

- Y69A

- Y69B

- P70

- Z73

- P74

- P74-376

- Z76

- Z80

- A90

- A90V

- A93

- A93V

- A96

- A96V

- Without switch

-

Lead Wire

- 0.5

- 0.5 (SC type)

- 0.5 (SE type)

- 0.5 (M8 3-pin plug connector)

- 0.5 (M8 4-pin plug connector)

- 0.5 (M12 4-pin A-cord [normal-key] plug connector)

- 1

- 1 (M8 3-pin plug connector)

- 1 (M8 4-pin plug connector)

- 1 (M12 4-pin A-cord [normal-key] plug connector)

- 3

- 3 (M12 4-pin A-cord [normal-key] plug connector)

- 5

-

The number of the switches

-

Swinging Receiving Metal

- Shipped together

- Without bracket

-

Rod Tip Metal Fitting

- Single knuckle joint

- U-Shaped Knuckle Joint

- Without bracket

-

Type of Mount Support

- Axial foot type

- Basic type

- Center trunnion type

- Head-end flange

- Rod-end flange type

- Single clevis

- U-Shaped Clevis Type

-

Bellows

-

Tube Material

- Aluminum tube

- Iron tube

-

Custom-made Specifications

- Heat-resistant cylinder (-10 to 110°C)

- Reed type heat-resistant cylinder with auto switch (-10 to 120°C)

- Heat-resistant cylinder (-10 to 150°C)

- Spatter-resistant specification coil scraper, grease for welding, piston rod: S45C

- Spatter resistant coil scraper, lube-retainer, grease for welding, piston rod: S45C

- Spatter-resistant specification coil scraper, lube-retainer, grease for welding, piston rod: SUS304

- Compact type with SS400 flange

- Change to the trunnion bracket mounting position (A type)

- Change to trunnion bracket mounting position (B type)

- Double clevis pin and double knuckle pin material: stainless steel

- Double knuckle joint with spring pin

- Fluororubber seal

- Fluororubber seal / Built-in hard plastic magnet

- Grease for food processing equipment

- Material: stainless steel

- Material: stainless steel (piston rod: with hard chrome plating)

- Mount rod-side trunnion on front of rod cover

- None

- Tandem type cylinder

- Tie-rod, cushion valve, tie-rod nut, etc.: made of stainless steel

- With coil scraper

- With powerful scraper

-

Connector type

- None

-

type

- CA2

- CDA2

-

Stroke(mm)

- 1

- 1,000

- 1,002

- 1,005

- 1,006

- 1,010

- 1,015

- 1,020

- 1,025

- 1,030

- 1,035

- 1,040

- 1,042

- 1,045

- 1,050

- 1,055

- 1,060

- 1,061

- 1,065

- 1,070

- 1,075

- 1,079

- 1,080

- 1,085

- 1,090

- 1,095

- 1,100

- 1,102

- 1,105

- 1,110

- 1,113

- 1,115

- 1,120

- 1,125

- 1,130

- 1,135

- 1,140

- 1,145

- 1,148

- 1,150

- 1,155

- 1,159

- 1,160

- 1,170

- 1,175

- 1,180

- 1,185

- 1,190

- 1,195

- 1,199

- 1,200

- 1,205

- 1,210

- 1,215

- 1,218

- 1,220

- 1,225

- 1,227

- 1,230

- 1,235

- 1,240

- 1,245

- 1,250

- 1,252

- 1,255

- 1,258

- 1,260

- 1,270

- 1,275

- 1,280

- 1,285

- 1,290

- 1,300

- 1,310

- 1,315

- 1,320

- 1,325

- 1,330

- 1,335

- 1,340

- 1,350

- 1,355

- 1,360

- 1,365

- 1,370

- 1,375

- 1,380

- 1,385

- 1,390

- 1,400

- 1,410

- 1,415

- 1,420

- 1,425

- 1,430

- 1,437

- 1,440

- 1,442

- 1,445

- 1,450

- 1,455

- 1,460

- 1,470

- 1,475

- 1,480

- 1,485

- 1,490

- 1,500

- 1,501

- 1,502

- 1,503

- 1,505

- 1,510

- 1,515

- 1,520

- 1,525

- 1,530

- 1,535

- 1,540

- 1,545

- 1,550

- 1,555

- 1,560

- 1,570

- 1,575

- 1,580

- 1,585

- 1,590

- 1,600

- 1,606

- 1,610

- 1,620

- 1,625

- 1,630

- 1,640

- 1,645

- 1,650

- 1,660

- 1,670

- 1,680

- 1,690

- 1,700

- 1,710

- 1,720

- 1,730

- 1,735

- 1,740

- 1,750

- 1,760

- 1,765

- 1,770

- 1,775

- 1,800

- 1,850

- 1,900

- 1,935

- 1,950

- 2,000

- 2,100

- 2,150

- 2,200

- 2,220

- 2,300

- 2,400

- 2,500

- 2,600

- 2,610

- 2,620

- 2,640

- 2,650

- 2,700

- 3

- 5

- 7

- 8

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 62

- 63

- 64

- 65

- 66

- 68

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 109

- 110

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 155

- 156

- 157

- 158

- 159

- 160

- 162

- 163

- 165

- 166

- 168

- 169

- 170

- 172

- 173

- 174

- 175

- 176

- 178

- 179

- 180

- 181

- 182

- 183

- 184

- 185

- 187

- 188

- 190

- 191

- 192

- 193

- 194

- 195

- 197

- 198

- 200

- 201

- 203

- 204

- 205

- 206

- 207

- 208

- 210

- 212

- 213

- 214

- 215

- 216

- 217

- 218

- 219

- 220

- 222

- 223

- 224

- 225

- 228

- 229

- 230

- 232

- 234

- 235

- 236

- 237

- 238

- 239

- 240

- 242

- 243

- 244

- 245

- 247

- 248

- 250

- 252

- 253

- 254

- 255

- 256

- 258

- 260

- 265

- 267

- 268

- 269

- 270

- 271

- 272

- 273

- 274

- 275

- 278

- 280

- 283

- 285

- 288

- 289

- 290

- 291

- 292

- 293

- 295

- 297

- 299

- 300

- 301

- 304

- 305

- 308

- 310

- 311

- 313

- 315

- 318

- 320

- 322

- 323

- 325

- 326

- 327

- 328

- 329

- 330

- 332

- 334

- 335

- 336

- 340

- 343

- 345

- 347

- 349

- 350

- 351

- 352

- 355

- 357

- 358

- 360

- 361

- 363

- 364

- 365

- 366

- 368

- 369

- 370

- 371

- 375

- 376

- 377

- 380

- 381

- 384

- 385

- 387

- 390

- 395

- 396

- 397

- 398

- 400

- 402

- 405

- 406

- 408

- 410

- 412

- 415

- 417

- 418

- 420

- 424

- 425

- 426

- 429

- 430

- 432

- 435

- 440

- 445

- 450

- 451

- 452

- 453

- 454

- 455

- 456

- 457

- 458

- 460

- 464

- 465

- 466

- 467

- 470

- 472

- 475

- 480

- 484

- 485

- 487

- 490

- 491

- 492

- 495

- 496

- 500

- 501

- 502

- 503

- 504

- 505

- 506

- 508

- 510

- 514

- 515

- 516

- 520

- 522

- 525

- 530

- 532

- 533

- 535

- 539

- 540

- 544

- 545

- 547

- 550

- 553

- 554

- 555

- 559

- 560

- 564

- 565

- 566

- 570

- 571

- 574

- 575

- 580

- 582

- 585

- 588

- 590

- 592

- 593

- 595

- 599

- 600

- 602

- 605

- 607

- 610

- 612

- 615

- 620

- 624

- 625

- 630

- 632

- 634

- 635

- 638

- 640

- 642

- 645

- 646

- 650

- 654

- 655

- 656

- 660

- 663

- 665

- 668

- 670

- 675

- 678

- 680

- 685

- 688

- 690

- 695

- 700

- 705

- 707

- 708

- 710

- 715

- 716

- 720

- 725

- 730

- 735

- 736

- 740

- 742

- 744

- 745

- 750

- 752

- 754

- 755

- 756

- 757

- 758

- 760

- 762

- 765

- 770

- 775

- 780

- 785

- 787

- 788

- 790

- 795

- 800

- 801

- 805

- 806

- 808

- 810

- 815

- 819

- 820

- 821

- 825

- 830

- 835

- 840

- 845

- 850

- 853

- 854

- 855

- 860

- 865

- 870

- 875

- 880

- 885

- 890

- 892

- 895

- 900

- 903

- 905

- 908

- 910

- 915

- 920

- 925

- 930

- 931

- 932

- 935

- 940

- 942

- 943

- 944

- 945

- 950

- 955

- 956

- 960

- 962

- 965

- 970

- 975

- 976

- 980

- 985

- 990

- 995

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 4 Day(s) or Less

- 31 Day(s) or Less

- 32 Day(s) or Less

- 35 Day(s) or Less

- 37 Day(s) or Less

- 42 Day(s) or Less

- 62 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- See catalog for specification details.

- Product pictures are representations. CAD data is not supported for some model numbers.

Product Description

An air cylinder with easy air cushion control.

[Features]

· Weight reduced by up to 15%.

· Various switches such as compact auto switches and strong magnetic field resistant switches can be mounted.

· Part numbers are set for products with rod-end brackets and pivot brackets. (No need to order separately.)

*See catalog for specification details.

Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series Specifications

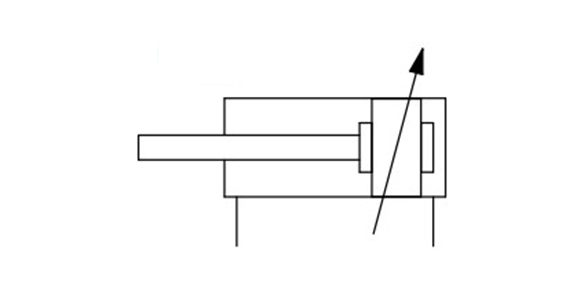

Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series external appearance

Symbol Double acting Air cushion

Specifications

| Tube Internal Diameter (mm) | 40 | 50 | 63 | 80 | 100 | ||

|---|---|---|---|---|---|---|---|

| Applicable fluids | Air | ||||||

| Operating method | Double acting | ||||||

| Proof pressure | 1.5 MPa | ||||||

| Maximum operating pressure | 1.0 MPa | ||||||

| Ambient temperature and working fluid temperature | Without auto switch: -10°C to 70°C*1 With auto switch: -10°C to 60°C*1 | ||||||

| Minimum operating pressure | 0.05 MPa | ||||||

| Operating piston speed | 50 to 500 mm/s | ||||||

| Cushioning | Air cushion or rubber bumper | ||||||

| Stroke length tolerance | Up to 250st: (0 to +1.0) 251 to 1,000st: (0 to +1.4) 1,001 to 1,500st: (0 to +1.8) 1,501 to 1,800st: (0 to +2.2) | ||||||

| Lubrication | Not required (non-lube) | ||||||

| Mounting style | Basic type, foot type, rod-end flange type, head-end flange type single clevis type, double clevis type, center trunnion type | ||||||

| Allowable kinetic energy (J)*2 | Air cushion | When activated | 2.8 | 4.6 | 7.8 | 16 | 29 |

| When not activated | 0.33 | 0.56 | 0.91 | 1.5 | 2.68 | ||

| Rubber cushion | 1.8 | 3.6 | 6.0 | 12.0 | 12.0 | ||

- *1No freezing.

- *2Activate the air cushion when operating the cylinder. If this is not done, the piston rod assembly or the tie-rods will be damaged if the allowable kinetic energy exceeds the values shown in the above table.

Standard Strokes

| Bore size | Standard strokeNote 1) | Max. manufacturable stroke | |

|---|---|---|---|

| Stroke range (1) | Stroke range (2) | ||

| 40 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500 | Up to 1,800 | Up to 2,700 |

| 50, 63 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600 | ||

| 80, 100 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700 | ||

Note 1) Intermediate strokes not listed above are produced to order.

Note 2) Applicable strokes should be confirmed according to the usage. For details, please refer to "Air Cylinder Model Selection" in the manufacturer's catalog. In addition, products that exceed stroke range 1 may not be able to fulfill the specifications due to deflection, etc.

Note 3) Please consult with the manufacturer for manufacturability and the part numbers when exceeding the stroke range 2.

Note 4) The stroke range with rod boot is 20 to 1,800 mm. Please consult with the manufacturer support center when exceeding 1,800 mm strokes.

Mounting Brackets / Part No.

(Unit: mm)

| Tube Internal Diameter (mm) | 40 | 50 | 63 | 80 | 100 |

|---|---|---|---|---|---|

| Axial foot*1 | CA2-L04 | CA2-L05 | CA2-L06 | CA2-L08 | CA2-L10 |

| Flange | CA2-F04 | CA2-F05 | CA2-F06 | CA2-F08 | CA2-F10 |

| Single clevis | CA2-C04 | CA2-C05 | CA2-C06 | CA2-C08 | CA2-C10 |

| Double clevis*2 | CA2-D04 | CA2-D05 | CA2-D06 | CA2-D08 | CA2-D10 |

- *1When axial foot brackets are used, order two pieces per cylinder.

- *2A clevis pin, flat washers and split pins are shipped together with the clevis types.

Allowable Kinetic Energy

Allowable Kinetic Energy graph

Example) Find the upper limit of rod-end load when an air cylinder of ø63 is operated at 500 mm/s.

From a point indicating 500 mm/s on the horizontal axis, extend a line upward and find a point where it intersects with a line for the 63‑mm bore size. Extend a line from the intersection to the left and find a load mass of 60 kg.

Dimensional Outline Drawing (Dimensions Other Than Those Shown Below Are the Same As the Standard Type)

CA2 Series dimensional outline drawing

(Unit: mm)

| Tube I.D. | øe | f |

|---|---|---|

| 40 | 26 | 13.5 |

| 50 | 30 | 12.5 |

| 63 | 30 | 12.5 |

| 80 | 36 | 16.5 |

| 100 | 42 | 16 |

- *The mounting dimensions of the mounting bracket are the same as the standard type.

- *See the manufacturer's catalog for details.

Structural drawing

CA2 Series Structural Drawing

Component Parts

| Number | Description | Material | Note |

|---|---|---|---|

| 1 | Rod Cover | Die-cast aluminum | Trivalent chromated |

| 2 | Head cover | Die-cast aluminum | Trivalent chromated |

| 3 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 4 | Piston rod | Carbon steel | Hard chrome plating |

| 5 | Piston | Aluminum Alloy | - |

| 6 | Cushion ring | Aluminum Alloy | Anodized |

| 7 | Cushion ring B | Aluminum Alloy | Anodized |

| 8 | Bushing | Resin/Copper alloy (Multiple layers) | - |

| 9 | Cushion valve | Steel wire | Trivalent zinc chromated |

| 10 | Tie-rod | Carbon steel | Trivalent zinc chromated |

| 11 | Retaining Ring | Steel for spring | Phosphate coated |

| 12 | Spring washer | Steel wire | Trivalent zinc chromated |

| 13 | Tie-rod nut | Rolled steel | Trivalent zinc chromated |

| 14 | Wear ring | Resin | - |

| 15 | Cushion seal | Urethane | - |

| 16 | Rod Gasket | NBR | - |

| 17 | Piston Gasket | NBR | - |

| 18 | Cushion valve seal | NBR | - |

| 19 | Cylinder tube gasket | NBR | - |

| 20 | Rod-end nut | Rolled steel | Trivalent zinc chromated |

Replacement Parts / Seal Kit

| Bore size (mm) | Order number | Content |

|---|---|---|

| 40 | CA2-40Z-PS | Set of nos. (15), (16), (17), (19) |

| 50 | CA2-50Z-PS | |

| 63 | CA2-63Z-PS | |

| 80 | CA2-80Z-PS | |

| 100 | CA2-100Z-PS |

- *Seal kit includes 15, 16, 17 and 19. Order the seal kit based on each bore size.

- *Do not disassemble the trunnion type. Refer to the manufacturer's catalog.

- *Seal kit includes a grease pack (ø40, ø50: 10 g, ø63, ø80: 20 g, ø100: 30 g). Order with the following part number when only the grease pack is needed. Grease pack part number: GR-S-010 (10 g), GR-S-020 (20 g)

- *Product pictures are representations. CAD data is not supported for some model numbers.

- *See the manufacturer's catalog for other specifications, standard type, included fitting dimensions, etc.

| Part Number |

|---|

| CA2T80-1365Z |

| CA2T100-1365Z |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Environment, Applications | Cushion | Specifications | Port thread type | Auto Switches | Lead Wire | The number of the switches | Swinging Receiving Metal | Rod Tip Metal Fitting | Type of Mount Support | Bellows | Tube Material | Custom-made Specifications | Connector type |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 80 | 1,365 | Standard | Air cushion | Without magnet | Rc | - | - | - | Without bracket | Without bracket | Center trunnion type | None | Aluminum tube | None | - | ||

- | 1 Piece(s) | Quote | 100 | 1,365 | Standard | Air cushion | Without magnet | Rc | - | - | - | Without bracket | Without bracket | Center trunnion type | None | Aluminum tube | None | - |

Loading...Tải…

Basic InformationThông tin cơ bản

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Standard |

|---|---|---|---|---|---|

| Additional Function | Standard | Operating Pressure(MPa) | 0.05 to 1.0 |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy