(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Thể lệ và Giải thưởng cuộc thi "Thiết kế máy Tự động hóa 2025" do MISUMI Việt Nam tổ chức. Xem chi tiết.

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Stroke(mm)

-

Lead

-

Motor Position

- BC Direct Connection

- RC Parallel Connection

-

Motor Code/ Output

- M50W

- P50W

- M100W

- P100W

- Customized Motor

-

Mounting Direction

- FA Front Flange

- GD With Guiding Mechanism

- HA Horizontal

- NA Body Mounting

-

Number of Sensor(pcs)

-

type

- E-ECTL40

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 15 Day(s) or Less

Specify AlterationsChỉ định thay đổi

Electric Cylinder, Standard Type E-ECTL40

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

-

- Order Qty.Số lượng đặt hàng :

-

-

- PriceĐơn giá :

- ---

-

- Total PriceTổng合計합계 :

- ---

-

- Days to shipThời gian xuất hàng出荷日출하일 :

- ---

Product Overview

An Electric Cylinder is a device that converts the rotational motion of an electric motor into linear motion through a ball screw, driving the extension and retraction of the cylinder rod.

Compared with traditional hydraulic and pneumatic cylinder, it has the characteristis of energy saving, space-saving design, low noise, pollution fee and low maintenance cost, achieving the goal of overall cost reduction.

The structure of a MISUMI Electric Cylinder is composed of an aluminum alloy body, ball screw, and push rod. The motor bracket's mounting hole size and position are processed according to the customer's specified motor brand. A customized motor bracket and sensor switches are optional.

Compared with traditional hydraulic and pneumatic cylinder, it has the characteristis of energy saving, space-saving design, low noise, pollution fee and low maintenance cost, achieving the goal of overall cost reduction.

The structure of a MISUMI Electric Cylinder is composed of an aluminum alloy body, ball screw, and push rod. The motor bracket's mounting hole size and position are processed according to the customer's specified motor brand. A customized motor bracket and sensor switches are optional.

Dimensional Drawing

| BC(Direct connection) | RC(Parallel connection) |

| |||||||||||||||||||||

|  |

| E-ECTL40 Stroke S | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| L | Direct connection | 286 | 336 | 386 | 436 | 486 | 536 | 586 | 636 | 686 | 736 |

| Parallel connection | 263 | 313 | 363 | 413 | 463 | 513 | 563 | 613 | 663 | 713 | |

| Body mass (kg) | Direct connection | 1.39 | 1.62 | 1.86 | 2.09 | 2.33 | 2.56 | 2.79 | 3.03 | 3.26 | 3.49 |

| Parallel connection | 1.59 | 1.82 | 2.06 | 2.29 | 2.52 | 2.76 | 2.99 | 3.22 | 3.46 | 3.69 | |

When choose GD (Guide mechanism), the total length L is L-13

When choose GD (Guide mechanism), the total length L is L-13Specification Table

Please follow the selection steps ~

~ select the model and parameters to order.

select the model and parameters to order.

※1 The maximum speed is a reference value based on the servo motor's maximum speed of 3000 rpm. If the stroke exceeds 300, the speed should be reduced accordingly to avoid resonance.

This product does not include a motor; the customer needs to purchase the motor separately.

This product does not include a motor; the customer needs to purchase the motor separately.

When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided.

The motor acceleration and deceleration time should be set to at least 0.2 seconds.

The motor acceleration and deceleration time should be set to at least 0.2 seconds.

■Recommended servo motor list

■Components

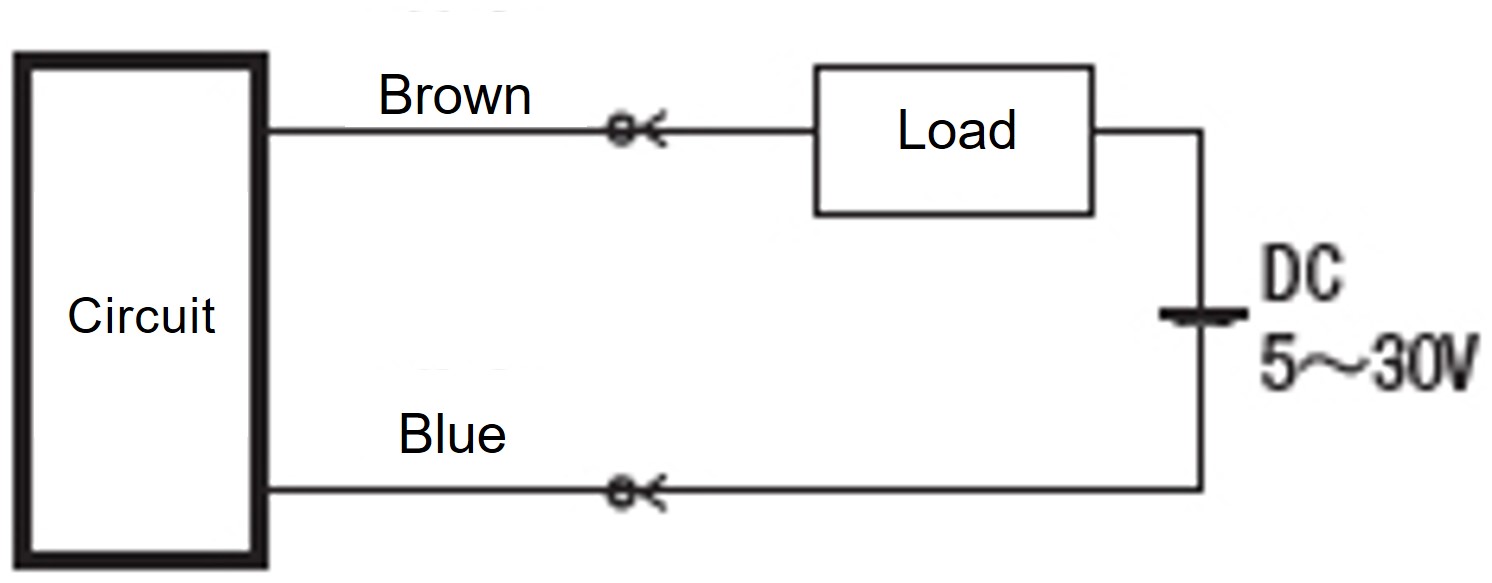

■E-ECTL Sensor specification

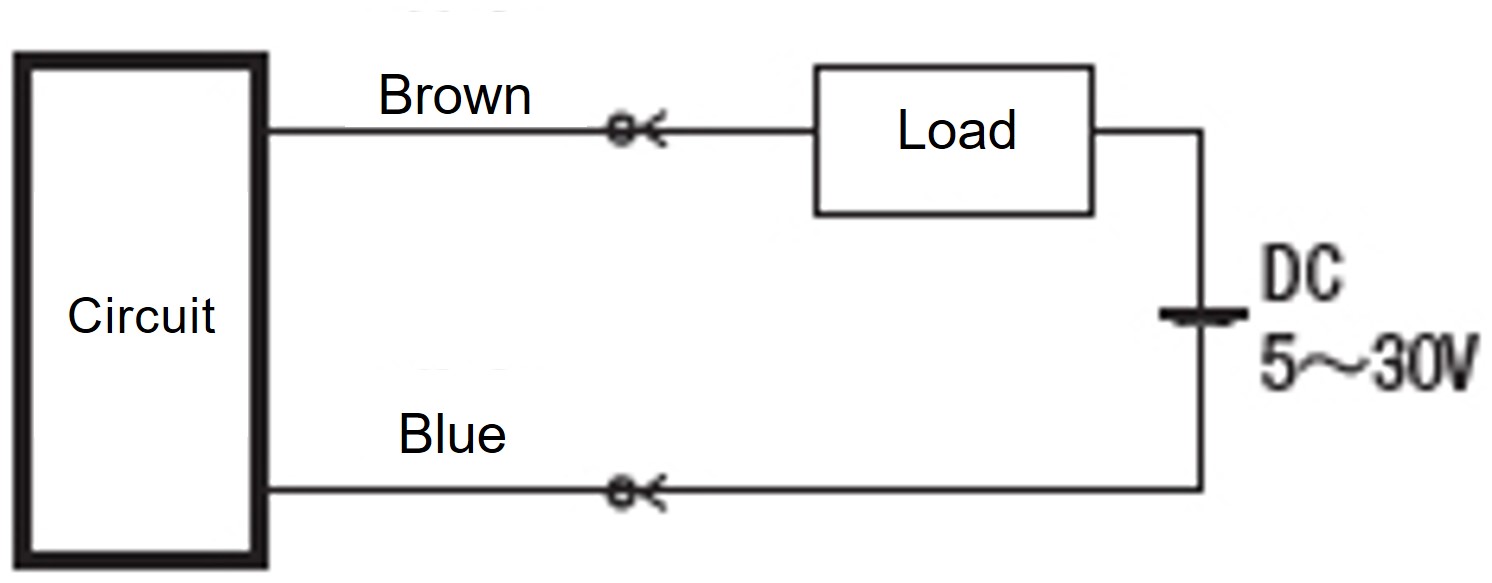

■Sensor wiring diagram

■Sensor parameters

~

~ select the model and parameters to order.

select the model and parameters to order. | Model( Type) Type) | - |  Lead Lead | - |  Stroke S Stroke S | - |  Motor Direction Motor Direction | - |  Motor type Motor type | - |  Mounting method Mounting method | - |  Number of Sensor Number of Sensor | |

| E-ECTL40 | - | 05 | - | S100 | - | BC | - | P100W | - | NA | - | C0 |

| Model |  Stroke S Stroke S |  Motor Direction Motor Direction |  Motor type Motor type |  Mounting Method Mounting Method |  Number of Sensor Number of Sensor | Rated Thrust (N) | Max Speed (mm/s)※1 | Max. Payload(kg) | Positioning Repeatability(mm) | Body Width | Ball Screw | |||

Type Type |  Lead Lead(mm) | 50mm incremental | Brand | Power W | Horizontal Use | Vertical Use | ||||||||

| E-ECTL40 | 05 | 50~500 | BC (Direct connection) RC (Parallel connection) | P (Panasonic) M (Mitsubishi) Z (Customized) | 50W | NA (Body Mounting) FA (Front Flange) HA (Horizontal) GD (With Guiding Mechanism) | C0(Not provided) C1(1 pcs) C2(2 pcs) C3(3 pcs) | 170 | 250 | 15 | 5 | ±0.01 | □45 | Φ12 (C7) |

| 100W | 340 | 30 | 10 | |||||||||||

| 10 | 50W | 85 | 500 | 10 | 2.5 | |||||||||

| 100W | 170 | 15 | 5 | |||||||||||

This product does not include a motor; the customer needs to purchase the motor separately.

This product does not include a motor; the customer needs to purchase the motor separately.When the motor code is specified as Z, the motor shaft diameter and installation dimensions must be provided.

The motor acceleration and deceleration time should be set to at least 0.2 seconds.

The motor acceleration and deceleration time should be set to at least 0.2 seconds.■Motor code and corresponding brand

| Code | Brand | |

| P | Panasonic | |

| M | Mitsubishi / Yaskawa / Delta / Siemens Inovance / Xinjie / Leadshine / Omron / HCFA | |

| Z | Customized | |

■Motor mounting hole dimension

■Recommended servo motor list

| Brand | Motor code | With / Without Brake | Power | Voltage | Servo Motor Model | Driver Model |

| Panasonic | P | Without Brake (Horizontal Use) | 50W | 220V | MSMF5AZL1U2M | MADLN05SE |

| With Brake (Vertical Use) | MSMF5AZL1V2M | |||||

| Without Brake (Horizontal Use) | 100W | MSMF012L1U2M | MADLN05SE | |||

| With Brake (Vertical Use) | MSMF012L1V2M | |||||

| Without Brake (Horizontal Use) | 200W | MHMF022L1U2M | MADLN15SE | |||

| With Brake (Vertical Use) | MHMF022L1V2M | |||||

| Without Brake (Horizontal Use) | 400W | MHMF042L1U2M | MBDLN25SE | |||

| With Brake (Vertical Use) | MHMF042L1V2M | |||||

| Without Brake (Horizontal Use) | 750W | MHMF082L1U2M | MCDLN35SE | |||

| With Brake (Vertical Use) | MHMF082L1V2M | |||||

| Without Brake (Horizontal Use) | 1000W | MDMF102L1G6M | MDDLN45SE | |||

| With Brake (Vertical Use) | MDMF102L1H6M | |||||

| Without Brake (Horizontal Use) | 1500W | MDMF152L1G6 | MDDLN55SE | |||

| With Brake (Vertical Use) | MDMF152L1H6 | |||||

| Without Brake (Horizontal Use) | 2000W | MDMF202L1G6 | MEDLN83SE | |||

| With Brake (Vertical Use) | MDMF202L1H6 | |||||

| Mitsubishi | M | Without Brake (Horizontal Use) | 50W | 220V | HG-MR053 | MR-J4-10B |

| With Brake (Vertical Use) | HG-MR053B | |||||

| Without Brake (Horizontal Use) | 100W | HG-KN13J-S100 | MR-JE-10A | |||

| With Brake (Vertical Use) | HG-KN13BJ-S100 | |||||

| Without Brake (Horizontal Use) | 200W | HG-KN23J-S100 | MR-JE-20A | |||

| With Brake (Vertical Use) | HG-KN23BJ-S100 | |||||

| Without Brake (Horizontal Use) | 400W | HG-KN43J-S100 | MR-JE-40A | |||

| With Brake (Vertical Use) | HG-KN43BJ-S100 | |||||

| Without Brake (Horizontal Use) | 750W | HG-KN73J-S100 | MR-JE-70A | |||

| With Brake (Vertical Use) | HG-KN73BJ-S100 | |||||

| Without Brake (Horizontal Use) | 1000W | HG-SN102J-S100 | MR-JE-100A | |||

| With Brake (Vertical Use) | HG-SN102BJ-S100 | |||||

| Without Brake (Horizontal Use) | 1500W | HG-SN152J-S100 | MR-JE-200A | |||

| With Brake (Vertical Use) | HG-SN152BJ-S100 | |||||

| Yaskawa | M | Without Brake (Horizontal Use) | 50W | 220V | SGM7J-01AFC6S | SGD7S-R90A00A002 |

| With Brake (Vertical Use) | SGM7J-01AFC6E | |||||

| Without Brake (Horizontal Use) | 100W | SGM7J-01AFC6S | SGD7S-R90A00A002 | |||

| With Brake (Vertical Use) | SGM7J-01AFC6E | |||||

| Without Brake (Horizontal Use) | 200W | SGM7J-02AFC6S | SGD7S-1R6A00A002 | |||

| With Brake (Vertical Use) | SGM7J-02AFC6E | |||||

| Without Brake (Horizontal Use) | 400W | SGM7J-04AFC6S | SGD7S-2R8A00A002 | |||

| With Brake (Vertical Use) | SGM7J-04AFC6E | |||||

| Without Brake (Horizontal Use) | 750W | SGM7J-08AFC6S | SGD7S-5R5A00B202 | |||

| With Brake (Vertical Use) | SGM7J-08AFC6E | |||||

| Delta | M | Without Brake (Horizontal Use) | 100W | 220V | ECM-B3L-C20401RS1 | ASD-B3-0121-L |

| With Brake (Vertical Use) | ECM-B3L-C20401SS1 | |||||

| Without Brake (Horizontal Use) | 200W | ECM-B3M-C20602RS1 | ASD-B3-0221-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20602SS1 | |||||

| Without Brake (Horizontal Use) | 400W | ECM-B3M-C20604RS1 | ASD-B3-0421-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20604SS1 | |||||

| Without Brake (Horizontal Use) | 750W | ECM-B3M-C20807RS1 | ASD-B3-0721-L | |||

| With Brake (Vertical Use) | ECM-B3M-C20807SS1 | |||||

| P | Without Brake (Horizontal Use) | 1000W | ECM-B3M-E21310RS1 | ASD-B3-0121-L | ||

| With Brake (Vertical Use) | ECM-B3M-E21310SS1 | |||||

| Without Brake (Horizontal Use) | 1500W | ECM-B3M-E21315RS1 | ASD-B3-1521-L | |||

| With Brake (Vertical Use) | ECM-B3M-E21315SS1 | |||||

| Without Brake (Horizontal Use) | 2000W | ECM-B3M-E21320RS1 | ASD-B3-2023-L | |||

| With Brake (Vertical Use) | ECM-B3M-E21320SS1 |

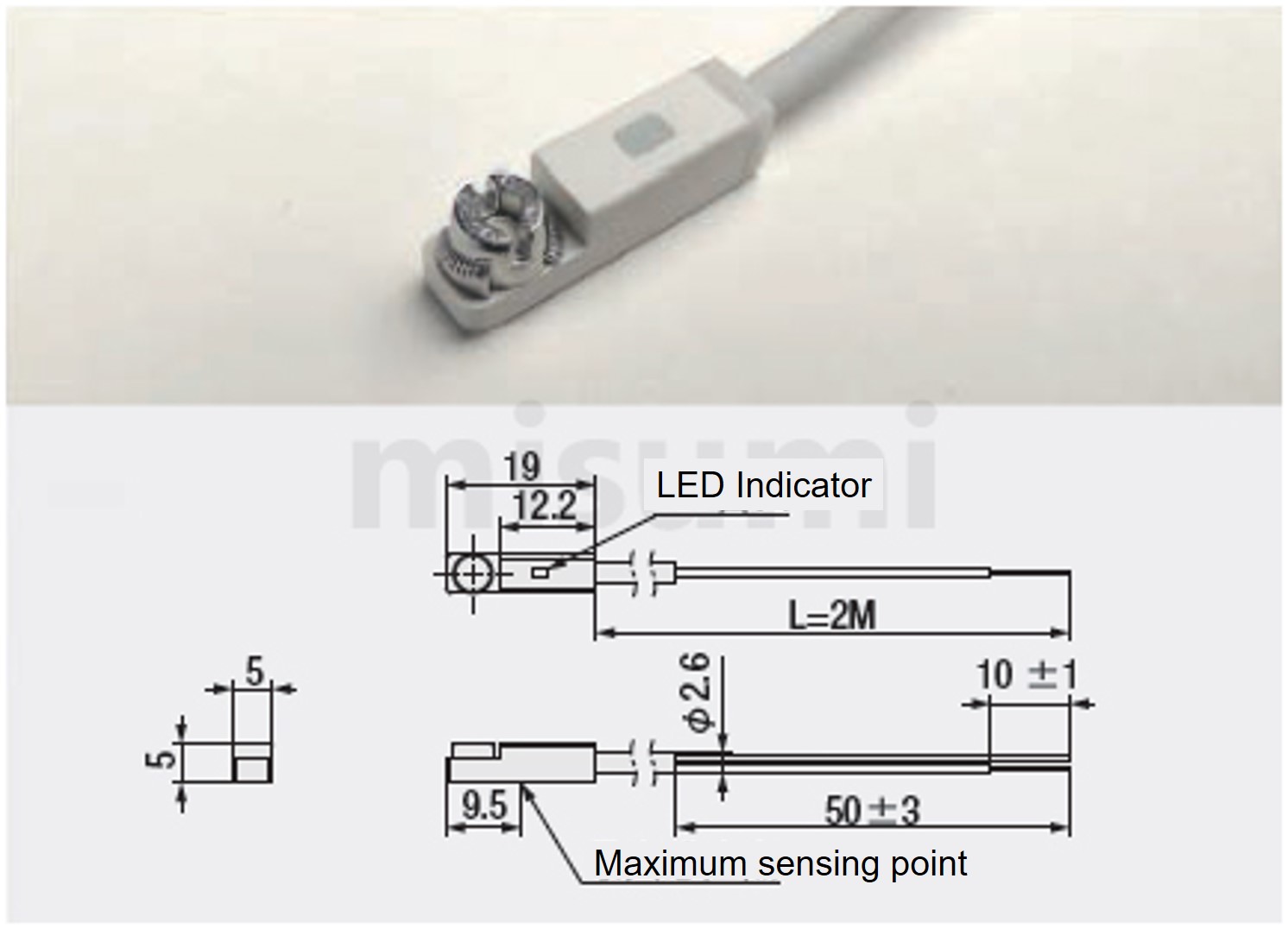

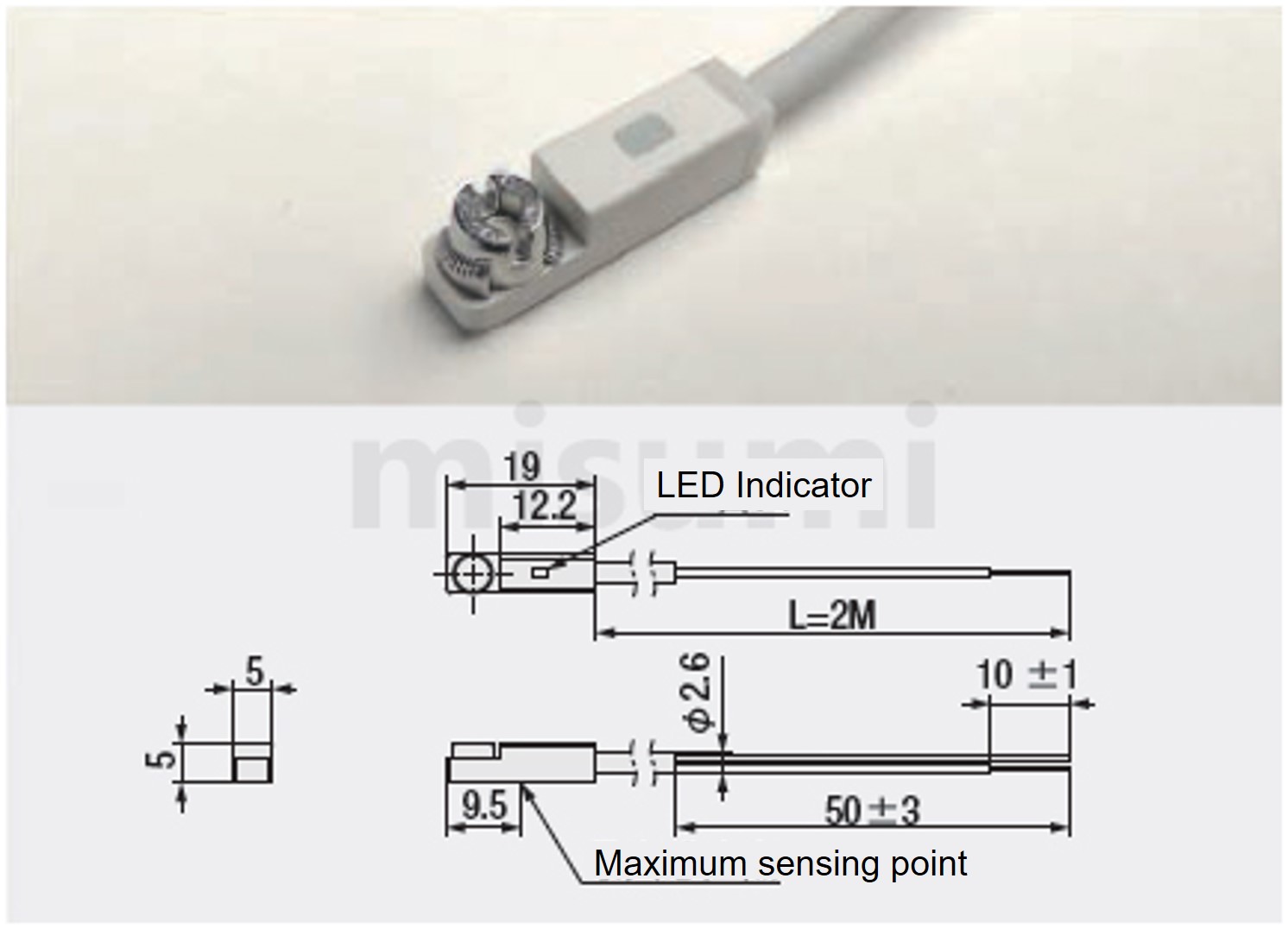

■Components

| Component name | Type | 50W・100W | |||

| Direct connection | Coupling | Clamping tye with Keyway | Outside diameter | Ball screw side | Motor side |

| Φ20 | Φ8 | Φ8 | |||

| Parallel connection | Ball screw pulley | Nickel plated steel | 2GT-40Teeth×Φ8 | ||

| Motor pulley | 2GT-40Teeth×Φ8 | ||||

| Timing belt | Glass fiber core rubber | 196-2GT-12 | |||

| Sensor(Optional) | DMST-020-2M (DC 2-wire, Normal open) | ||||

■E-ECTL Sensor specification

■Sensor wiring diagram

■Sensor parameters

| Mode | Output Type | Install Method | Detection Method | Working Voltage | Current Consumption | Output Current | Repeatability | Switching Frequency | Indicator Light | Working Environment Temperature | Cable Length | Protection Rating |

| DMST DMSE | DC 2-wire, Normal open | Screw clamp to cylinder groove | Magnet ring | 5~30V DC | ≦0.05mA | ≦100mA | <0.2㎜ | ≦2000Hz | Red light | -20~+70℃ | 2m | IP67 |

Product Features

■Structure

■Advantages

・Positioning Repeatability ±0.01

・Commonly used for vertical installations and axial thrust applications.

・Suitable for pressing, riveting, clamping, and pushing/pulling mechanisms.

・Can replace pneumatic cylinders for similar functions.

■Advantages

・Positioning Repeatability ±0.01

・Commonly used for vertical installations and axial thrust applications.

・Suitable for pressing, riveting, clamping, and pushing/pulling mechanisms.

・Can replace pneumatic cylinders for similar functions.

| Main body installation | Front flange installation |

|  |

| Horizontal installation | Installation with guide |

|  |

Precautions

■Precautions for use

①Operating environment: Room temperature (-20℃ to 40℃). Avoid corrosive, flammable, electromagnetic, or moist environments.

②Ensure the installation surface is vibration and pressure-resistant, with flatness within ±0.05mm/500mm.

③Use a motor with a brake when the electric cylinder is mounted vertically.

④Protect the cylinder from vibration and impact. Prevent the push rod from rotating and the cylinder from deforming.

①Operating environment: Room temperature (-20℃ to 40℃). Avoid corrosive, flammable, electromagnetic, or moist environments.

②Ensure the installation surface is vibration and pressure-resistant, with flatness within ±0.05mm/500mm.

③Use a motor with a brake when the electric cylinder is mounted vertically.

④Protect the cylinder from vibration and impact. Prevent the push rod from rotating and the cylinder from deforming.

Usage Methods

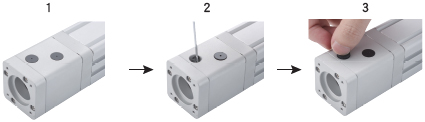

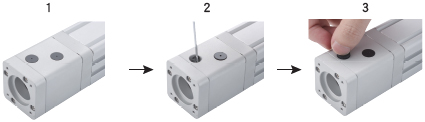

■Motor Installation and Timing Belt Adjustment Method

Standard type direct connection E-ECTL

1) Open the plastic hole cover and manually turn the coupling bolt to align with the hole.

2) Use a hex wrench to loosen the coupling bolt, then tighten it after installing the motor.

3) Finally, reinsert the plastic hole cover to complete the motor installation.

Standard type parrallel connection_E-ECTL

1) Remove the motor cover and install the motor. Note that the motor mounting screws don't need to be tightened yet to allow position adjustment.

2) Install the timing pulley on the motor shaft, ensuring it is parallel with the timing pulley on the ball screw.

3) Tighten the timing pulley screw and install the timing belt.

4) Adjust the timing belt tension using the adjusting screw on the body.

5) Use a tension tester to measure the belt tension to ensure it matches the reference value (see the table below).

6) Finally, tighten the motor mounting screws and re-install the motor cover to complete the installation.

Electric cylinder belt tension value (reference)

Standard type direct connection E-ECTL

1) Open the plastic hole cover and manually turn the coupling bolt to align with the hole.

2) Use a hex wrench to loosen the coupling bolt, then tighten it after installing the motor.

3) Finally, reinsert the plastic hole cover to complete the motor installation.

Standard type parrallel connection_E-ECTL

1) Remove the motor cover and install the motor. Note that the motor mounting screws don't need to be tightened yet to allow position adjustment.

2) Install the timing pulley on the motor shaft, ensuring it is parallel with the timing pulley on the ball screw.

3) Tighten the timing pulley screw and install the timing belt.

4) Adjust the timing belt tension using the adjusting screw on the body.

5) Use a tension tester to measure the belt tension to ensure it matches the reference value (see the table below).

6) Finally, tighten the motor mounting screws and re-install the motor cover to complete the installation.

Electric cylinder belt tension value (reference)

| Motor Power (W) | Electric Cylinder Model | Timing belt type | Belt width (mm) | Belt center distance (mm) | Belt thickness (mm) | Tension value N (reference) |

| 100W | E-ECTL40/E-ECRL5 | 2GT | 12 | 55 | 1.3 | 12~17 |

| 200W | E-ECTL50/E-ECRL8 | 3GT | 15 | 81 | 2.5 | 32~42 |

| 400W | E-ECTL60/E-ECRL8 | |||||

| E-ECTLT60 | 5GT | 75 | 4 | 60~75 | ||

| 750W | E-ECTL75/E-ECRL10 | 107 | ||||

| E-ECTLT75 | 8YU | 25 | 104 | 5.2 | 125~155 | |

| 1000W | E-ECTL90/E-ECTLT90 | 8M | 30 | 128 | 6.1 | 409~450 |

| 1500W | ||||||

| 2000W | E-ECTL90 | |||||

| E-ECTLT110 | 50 | 160 | 573~630 |

Example of Use

■Standard Electric Cylinder usage examples

Application: Transfer mechanism

・Utilize the telescopic function of the vertically mounted electric cylinder to pick and place workpieces on conveyors at different heights.

・Adopt the transplanting mechanism of the electric cylinder, ensuring stable and fast lifting to avoid damage to workpieces during pick-and-place operations.

Application: Transfer mechanism

・Utilize the telescopic function of the vertically mounted electric cylinder to pick and place workpieces on conveyors at different heights.

・Adopt the transplanting mechanism of the electric cylinder, ensuring stable and fast lifting to avoid damage to workpieces during pick-and-place operations.

Related documents

■Regular Lubrication Method

・The Electric Cylinder requires regular lubrication. Initially, add grease after 300 hours of operation. Subsequently, lubricate every 2000 hours.

・Use general lithium-based grease No. 3 (GB7324-1994). Mobil lithium grease EP3 is recommended.

・Use a grease gun for lubrication. Do not use liquid lubricants.

Standard type

1)Remove the silencer and apply grease to the ball screw.

2)Manually extend the push rod several times to ensure the entire screw is lubricated.

※Note: Standard E-ECTL75 and above, along with high-thrust models, include grease nipples for bearing lubrication.

・The Electric Cylinder requires regular lubrication. Initially, add grease after 300 hours of operation. Subsequently, lubricate every 2000 hours.

・Use general lithium-based grease No. 3 (GB7324-1994). Mobil lithium grease EP3 is recommended.

・Use a grease gun for lubrication. Do not use liquid lubricants.

Standard type

1)Remove the silencer and apply grease to the ball screw.

2)Manually extend the push rod several times to ensure the entire screw is lubricated.

※Note: Standard E-ECTL75 and above, along with high-thrust models, include grease nipples for bearing lubrication.

Related Products

| Single Axis Robots, Guide Built in Type | Single Axis Actuators KS series | Electric Cylinder, Radial type | ||

|  |  | ||

| Representative Part number: E-MGT5-L10-100-BC-P10-C | Representative Part number: C-KS4001-B1-100-F1-W2 | Representative Part number: E-ECRL5-05-S100-BC-P100W |

Application Industry

| Electronic | Smartphone | Lithium battery | ||

|  |  | ||

| Automotive | Robotics | Medical | ||

|  |  |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

Loading...Tải…

| Part Number |

|---|

| E-ECTL40-05-S[50-500/50]-[BC,RC]-[M50W,M100W,P50W,P100W,Z]-[FA,GD,HA,NA]-C[0,1,2,3] |

| E-ECTL40-10-S[50-500/50]-[BC,RC]-[M50W,M100W,P50W,P100W,Z]-[FA,GD,HA,NA]-C[0,1,2,3] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Stroke (mm) | Lead | Motor Position | Motor Code/ Output | Mounting Direction | Number of Sensor (pcs) |

|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 15 Day(s) | 50 ~ 500 | 05 | BC Direct Connection / RC Parallel Connection | M50W / P50W / M100W / P100W / Customized Motor | FA Front Flange / GD With Guiding Mechanism / HA Horizontal / NA Body Mounting | 0 ~ 3 | ||

- | 1 Piece(s) | 15 Day(s) | 50 ~ 500 | 10 | BC Direct Connection / RC Parallel Connection | M50W / P50W / M100W / P100W / Customized Motor | FA Front Flange / GD With Guiding Mechanism / HA Horizontal / NA Body Mounting | 0 ~ 3 |

| Part Number |

|---|

Loading...Tải…

Basic InformationThông tin cơ bản

| Type | Rod | Drive Method | Rolled Ball Screw | Main Body, Peripheral Components | Main Body |

|---|---|---|---|---|---|

| Positioning Repeatability(µm) | ±10 |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Material

Material Surface treatment

Surface treatment

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy