Rotary Shaft

| Product name | Rotary Shafts - Both Ends Tapped with Key Grooves |

| Part number | PSFHKRW15-76-M5-N5-KA0-A25-KB56-B20 |

| Features | Tolerance Options: g6 (ground), h7 (ground) and h9 polished |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Economical

Back to page top

Available sizes

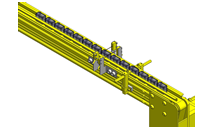

■Rotary Shaft (Both Ends Tapped, with Keyway Type)

| O.D. tolerance | Material | Surface Treatment |

|

| h9 (Cold-drawn) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | - |

| h7 (Ground) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | - |

| g6 (Ground) | 1045 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

| 304 Stainless Steel | - |

■Sizes

| O.D. Tolerance | O.D. | Length

(Configure in 1mm increments) |

| h9 | φ6 | 20.0~300.0 |

| φ8 | 20.0~400.0 |

| φ10 | 20.0~500.0 |

| φ12 | 30.0~600.0 |

| φ15 | 30.0~700.0 |

| φ20 | 40.0~800.0 |

| φ25 | 50.0~800.0 |

| φ30 | 60.0~800.0 |

| φ35 | 70.0~800.0 |

| h7 | φ6 | 20.0~300.0 |

| φ8 | 20.0~400.0 |

| φ10 | 20.0~500.0 |

| φ12 | 30.0~600.0 |

| φ15 | 30.0~700.0 |

| φ20 | 40.0~800.0 |

| φ25 | 50.0~800.0 |

| φ30 | 60.0~800.0 |

| φ35 | 70.0~800.0 |

| φ40 | 80.0~800.0 |

| φ50 | 100.0~800.0 |

| g6 | φ6 | 20.0~300.0 |

| φ8 | 20.0~400.0 |

| φ10 | 20.0~500.0 |

| φ12 | 30.0~600.0 |

| φ13 | 30.0~600.0 |

| φ15 | 30.0~700.0 |

| φ16 | 30.0~800.0 |

| φ17 | 40.0~800.0 |

| φ18 | 40.0~800.0 |

| φ20 | 40.0~800.0 |

| φ22 | 40.0~800.0 |

| φ25 | 50.0~800.0 |

| φ30 | 60.0~800.0 |

| φ35 | 70.0~800.0 |

| φ40 | 80.0~800.0 |

| φ50 | 100.0~800.0 |

■Detailed Keyway Dimensions of Rotary Shaft

| Shaft Dia. | b | t | r |

| Reference Dim. | Tolerance | Reference Dim. | Tolerance |

|

| 6 | 2 | -0.004

-0.029 | 1.2 | +0.1

0 | 0.08~

0.16 |

| 8・10 | 3 | 1.8 |

| 12 | 4 | 0

-0.03 | 2.5 |

| 13~17 | 5 | 3.0 | 0.16~

0.25 |

| 18~22 | 6 | 3.5 |

| 25・30 | 8 | 0

-0.036 | 4.0 | +0.2

0 |

| 35 | 10 | 5.0 | 0.25~

0.4 |

| 40 | 12 | 0

-0.043 | 5.0 |

| 50 | 14 | 5.5 |

Back to page top

Accuracy Info

■O.D. Tolerance Table

| O.D. | O.D. Tolerance |

| h9 | h7 | g6 |

| φ6 | 0

-0.030 | 0

-0.012 | -0.004

-0.012 |

| φ8 | 0

-0.036 | 0

-0.015 | -0.005

-0.014 |

| φ10 |

| φ12 | 0

-0.043 | 0

-0.018 | -0.006

-0.017 |

| φ13 | - | - |

| φ15 | 0

-0.043 | 0

-0.018 |

| φ16 | - | - |

| φ17 | - | - |

| φ18 | - | - |

| φ20 | 0

-0.052 | 0

-0.021 | -0.007

-0.020 |

| φ22 | - | - |

| φ25 | 0

-0.052 | 0

-0.021 |

| φ30 |

| φ35 | 0

-0.062 | 0

-0.025 | -0.009

-0.025 |

| φ40 | - |

| φ50 | - |

Back to page top

Timing Pulleys

| Product name | High Torque Timing Pulleys - 5GT |

| Part number | GPA50GT5120-A-N15 |

| Features | Circular Tooth Profile Pulleys with minimal backlash, suitable for positioning. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Effective for transmitting the driving force without slippage or speed changes

Back to page top

Available sizes

■Timing Pulleys (5GT Type)

| Material | Surface Treatment | Accessory

Set Screw |

| Pulley | Flange |

2017 Aluminum Alloy

(Duralumin) | 5052 Aluminum Alloy | Clear Anodize | 304 Stainless Steel |

|

| 1045 Carbon Steel | Low Carbon Steel | ― | Chromium-molybdenum steel

(Black Oxide) |

| Black Oxide |

■Sizes and Dimensions

| Number of teeth | Nominal

Width | Pulley

Shape | Shaft Bore

Specs. | Shaft Bore Specs.(Configure in 1mm increments) |

| Straight Bore | Straight Bore + Tap | New JIS Keywayed Bore + Tap | Stepped Holes - Stepped Holes

(Counterbore Holes on the Hub Side) | Both Ends Stepped Bore |

|

| Hole Dia. | Hole Dia. | Counterbore Hole Dia. | Counterbore

Depth | Hole Dia. | Counterbore Hole Dia. | Counterbore

Depth |

| No Hub | With Hub | No Hub | With Hub | No Hub | With Hub | No Hub | With Hub | No Hub | With Hub | With Hub, without Hub | No Hub | No Hub | No Hub |

| 14 | 9

12

15 | No Hub

With Hub | Straight Bore

Straight Bore

+Tap

New JIS

Keywayed Bore

+ Tap

Stepped Hole

Stepped Hole

(Counterbore Holes

on the Hub Side)

Both Ends

Stepped Bore | 6-10 | 6-8 | 6-8 | - | - | - | 6 | - | 8 | - | (When no hub)

2.0 ≤

Counterbore depth

≤ Ridge width - 2.0

(When with hub)

2.0 ≤

Counterbore depth

≤ Full length - 2.0 | 6 | 8 | 3-14

Total of

counterbore depth

≤ Width - 3

|

| 15 | 6-10 | 6-10 | 6-8 | 6-8 | 6 | 8-10 | 8 | 6-8 | 8-10 |

| 16 | 6-12 | 6-12 | 6-10 | 6 | 8 | 6-10 | 6-8 | 8-12 | 8-10 | 6-10 | 8-12 |

| 18 | 6-14 | 6-14 | 6-13 | 6-9 | 8-10 | 6-10 | 6-10 | 8-12 | 8-12 | 6-12 | 8-14 |

| 20 | 6-16 | 8-15 | 8-14 | 8-10 | 8-12 | 8 | 8-14 | 8-13 | 10-16 | 10-15 | 8-14 | 10-16 |

| 22 | 8-19 | 8-19 | 8-17 | 8-12 | 8-12 | 8 | 8-17 | 8-14 | 10-19 | 10-16 | 8-17 | 10-19 |

| 24 | 8-22 | 8-22 | 8-18 | 8-16 | 8-14 | 8-10 | 8-20 | 8-16 | 10-23 | 10-18 | 8-20 | 10-22 |

| 25 | 8-22 | 8-22 | 8-20 | 8-16 | 8-16 | 8-12 | 8-20 | 8-18 | 10-23 | 10-20 | 8-20 | 10-22 |

| 26 | 10-27 | 10-24 | 10-21 | 10-16 | 10-17 | 10-13 | 10-25 | 10-20 | 12-27 | 12-22 | 10-25 | 12-27 |

| 28 | 10-27 | 10-27 | 10-24 | 10-20 | 10-19 | 10-15 | 10-25 | 10-25 | 12-27 | 12-27 | 10-25 | 12-27 |

| 30 | 10-28 | 10-28 | 10-26 | 10-22 | 10-20 | 10-16 | 10-26 | 10-26 | 12-28 | 12-28 | 10-26 | 12-28 |

| 32 | 10-32 | 10-30 | 10-30 | 10-22 | 10-23 | 10-17 | 10-30 | 10-26 | 12-32 | 12-28 | 10-30 | 12-32 |

| 34 | 12-37 | 12-32 | 12-32 | 12-24 | 12-26 | 12-18 | 12-35 | 12-28 | 14-37 | 14-30 | 12-35 | 14-37 |

| 36 | 12-37 | 12-34 | 12-34 | 12-26 | 12-30 | 12-20 | 12-35 | 12-30 | 14-37 | 14-32 | 12-35 | 14-37 |

| 40 | 12-42 | 12-36 | 12-36 | 12-26 | 12-30 | 12-22 | 12-40 | 12-32 | 14-42 | 14-34 | 12-40 | 14-42 |

| 44 | 12-50 | 12-38 | 12-42 | 12-26 | 12-30 | 12-23 | 12-48 | 12-34 | 14-50 | 14-36 | 12-48 | 14-50 |

| 48 | 12-55 | 12-42 | 12-45 | 12-30 | 12-30 | 12-26 | 12-53 | 12-38 | 14-55 | 14-38 | 12-53 | 14-55 |

| 50 | 12-59 | 12-42 | 12-45 | 12-30 | 12-30 | 12-27 | 12-57 | 12-38 | 14-59 | 14-40 | 12-57 | 14-59 |

| 60 | 12-72 | 12-44 | 12-45 | 12-30 | 12-30 | 12-30 | 12-70 | 12-40 | 14-72 | 14-42 | 12-70 | 14-72 |

Back to page top

Selection steps

■Timing pulley selection steps

* Select the timing belt together with the timing pulley.

The automated selection tool is available

http://fawos.misumi.jp/FA_WEB/pulley_us/

- Determine Operating Conditions

- Designed power, rotational speed, rotation ratio, interim shaft distance, motion pattern, etc.

↓

- Belt selection

- Belt type/Belt width

↓

- Verify Specifications

-

- Confirmation of calculated shaft distance, etc.

- Confirmation of belt tension and load

Back to page top

Accuracy Info

■Shaft Bore Dia. of Timing Pulley

| Shaft Bore Dia. | Tolerance

(H7) |

|

| 6-10 | +0.015

0 |

| 10-18 | +0.018

0 |

| 18-30 | +0.021

0 |

| 30-50 | +0.025

0 |

| 50-80 | +0.030

0 |

Back to page top

Motors with Electromagnetic Brake

| Product name | Small gearhead motor with electromagnetic brake |

| Part number | PACMB90-W40-V100 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Effective for the equipment requiring strong brake force or heavy load

Back to page top

Available sizes

■Motors with Electromagnetic Brake

| Type | Outer Dimensions | Output (W) | Voltage (V) | Shaft Length | Gear Head Length | Motor Length |

Single-phase

3-Phase | 60 | 6 | 100 | 32 | 26 | 75 |

| 200 |

| 70 | 15 | 100 | 30 | 80 |

| 200 |

| 80 | 25 | 100 | 30 | 85 |

| 200 |

| 90 | 40 | 100 | 37 | 105 |

| 200 |

| 60 | 100 | 38 | 50 | 120 |

| 200 |

| 90 | 100 | 130 |

| 200 |

The 3-phase motor can be used in 220 V.

Back to page top

Selection steps

■Small geared motor selection steps

- Determination of the Driving Facility

- Specify the driving facility and overall dimensions, then check required conditions for the driving facility, such as the mass and travel speed of the material to be transferred.

↓

- Calculation of rotational speed and load

- Calculate the load torque, loading moment of inertia and rotational speed at the motor driving shaft.

↓

- Confirmation of Required Specifications

- Confirm the required specifications, position accuracies, position holding, speed ranges, operating environment, and environmental resistance, etc. at the drive section and equipment.

↓

- Motor Model Selection

- Select the models most suitable for the required specifications.

↓

- Interim Selection of Motor and Gearhead

- Select motor and gearhead candidates based on calculated rotational speeds, load torque and inertia values as well as the selected motor models.

↓

- Confirmation of the Selected Motor

- Finalize the selection by confirming that all the specifications of the motor and the gearhead adequately meet the requirements.

Back to page top

Performance info.

■Small Size Geared Motor (Speed, Load)

| Type | Outer Dimensions | Output (W) | Voltage (V) | 50Hz | 60Hz |

| Rated | Starting Torque

(N·m) | Rated | Starting Torque

(N·m) |

Rotational Speed

(r/min) | Torque

(N·m) | Rotational Speed

(r/min) | Torque

(N·m) |

| Single-phase | 60 | 6 | 100 | 1300 | 0.044 | 0.056 | 1600 | 0.035 | 0.056 |

| 200 | 1300 | 0.044 | 0.056 | 1600 | 0.035 | 0.056 |

| 70 | 15 | 100 | 1300 | 0.11 | 0.10 | 1600 | 0.088 | 0.10 |

| 200 | 1300 | 0.11 | 0.10 | 1600 | 0.088 | 0.10 |

| 80 | 25 | 100 | 1300 | 0.19 | 0.20 | 1600 | 0.16 | 0.20 |

| 200 | 1300 | 0.19 | 0.20 | 1600 | 0.16 | 0.20 |

| 90 | 40 | 100 | 1300 | 0.29 | 0.32 | 1625 | 0.24 | 0.32 |

| 200 | 1300 | 0.29 | 0.32 | 1625 | 0.24 | 0.32 |

| 60 | 100 | 1275 | 0.45 | 0.57 | 1600 | 0.36 | 0.57 |

| 200 | 1275 | 0.45 | 0.57 | 1600 | 0.36 | 0.57 |

| 90 | 100 | 1225 | 0.7 | 0.68 | 1525 | 0.56 | 0.70 |

| 200 | 1225 | 0.7 | 0.68 | 1525 | 0.56 | 0.70 |

| Type | Outer Dimensions | Output (W) | Voltage (V) | 50Hz | 60Hz |

| Rated | Starting Torque

(N·m) | Rated | Starting Torque

(N·m) |

Rotational Speed

(r/min) | Torque

(N·m) | Rotational Speed

(r/min) | Torque

(N·m) |

| 3-Phase | 80 | 25 | 200 | 1350 | 0.18 | 0.54 | 1625 | 0.15 | 0.4 |

| 1375 | 0.18 | 0.66 | 1650 | 0.15 | 0.5 |

| 90 | 40 | 1350 | 0.28 | 0.72 | 1625 | 0.24 | 0.51 |

| 1375 | 0.27 | 0.88 | 1675 | 0.23 | 0.63 |

| 60 | 1350 | 0.42 | 1.0 | 1625 | 0.35 | 0.69 |

| 1375 | 0.41 | 1.2 | 1650 | 0.34 | 0.87 |

| 90 | 1350 | 0.63 | 1.6 | 1625 | 0.53 | 1.1 |

| 1400 | 0.62 | 2.0 | 1650 | 0.52 | 1.4 |

Back to page top

Technical Calculations

■Technical Calculations for Electromagnetic Brake Motors

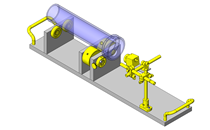

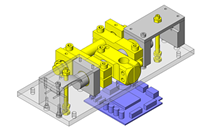

Outline of Small Size Geared Motor

Back to page top

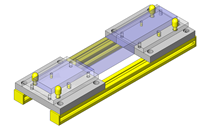

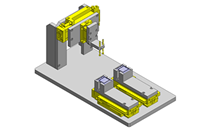

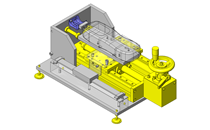

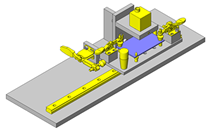

IDEA NOTE Fixed feed rate using AC motor

A fixed feed rate is achieved using an AC motor and positioning grooves for the workpieces.

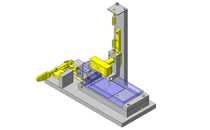

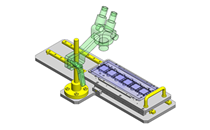

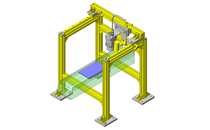

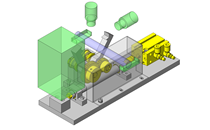

IDEA NOTE A single actuator creates lifting and carrying motions.

A parallel link structure is made by linking two eccentric shafts.

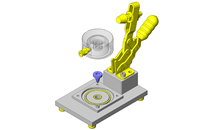

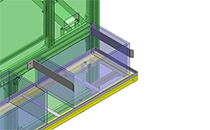

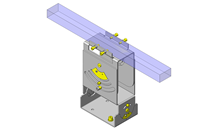

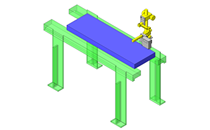

IDEA NOTE Dual single bearings

Two single bearing holders are mounted on either side of the thin plate, to serve as a double bearing.