(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 8:00 to 21:00 (ICT) 29/9/2024. We apologize for the inconvenience.

- [Thông Báo] Xác Nhận Dữ Liệu Người Dùng Web, Phục Vụ Dự Án Hỗ Trợ Chat Qua Zalo OA. Xem chi tiết.

[Announcement] User Data Confirmation for the Chat Support Project via Zalo OA. See more.

MISUMI Spring Plungers(Tip Heat Treatment:Hardening)

Brand |

|

|---|---|

Filter By |

|

| CAD |

|

| Days to Ship |

|

2 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

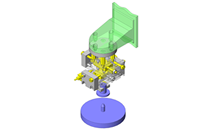

Spring Plungers / Wrenches / Block Plungers - Stainless Steel

MISUMI

- Spring Plungers - Stainless Steel- Screw Type of Pin Plunger: Spherical Type.- Body Material: Equivalent Stainless Steel SUS304- Nose Material: Stainless Steel SUS404C and Plastic Polyacetal.- Nose Hardness (For Stainless Steel type): 55HRC~- Spring Material: Stainless Steel SUS631.- The operating Temperature: -30~260° C (Stainless Steel nose type)- The operating Temperature: -30~80° C (Plastic nose type)- Mounting Thread size: 3, 4, 5, 6, 8, 10, 12 and 16 mm.- Mounting Method: Screw-In type.- Wrench Hole Shape: Hex.

- Volume Discount

Outer Dia. M(mm) Stroke S(mm) Tip Material Body Material Mounting Method Initial Load (Range)(N) Lock Tip Heat Treatment Screw Type of Pin Plunger Wrench Hole Shape Main Body Surface Treatment Tip Surface Treatment 3 ~ 16 1.5 ~ 20 Stainless Steel Stainless Steel Screw-In 0.01~50 Not Provided Hardening Spherical Hex Not Provided / Electroless Nickel Plating Not Provided From: 166,280 VND Special Price Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

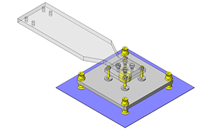

Short Spring Plungers - Stainless Steel

MISUMI

- Short Spring Plungers - Stainless Steel- Screw Type of Pin Plunger: Short Spring Plunger Spherical type.- Body Material: Stainless Steel SUS304 Equivalent.- Pin Material: Stainless Steel SUS440C and Plastic Polyacetal.- Pin Hardness (For Stainless Steel type): 55HRC~- Spring Material: Stainless Steel SUS631J1.- The operating Temperature: -30~260° C (Stainless Steel tip type)- The operating Temperature: -30~80° C (Plastic tip type)- Mounting Thread size: 3, 4, 5, 6, 8, 10, 12 and 16 mm.- Mounting Method: Screw-In type.- Wrench Hole Shape: Hex.

- Volume Discount

Outer Dia. M(mm) Stroke S(mm) Tip Material Body Material Mounting Method Initial Load (Range)(N) Lock Tip Heat Treatment Screw Type of Pin Plunger Wrench Hole Shape Main Body Surface Treatment Tip Surface Treatment 3 ~ 16 1 ~ 4.5 Stainless Steel Stainless Steel Screw-In 0.01~50 Not Provided Hardening Short Stroke Hex Not Provided / Electroless Nickel Plating Not Provided From: 162,360 VND Days to Ship: Số ngày giao hàng: Same day or more  Same day or more

Same day or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| CADCAD |

| From |

| Days to ShipSố ngày giao hàng |

| Outer Dia. M(mm) |

| Stroke S(mm) |

| Tip Material |

| Body Material |

| Mounting Method |

| Initial Load (Range)(N) |

| Lock |

| Tip Heat Treatment |

| Screw Type of Pin Plunger |

| Wrench Hole Shape |

| Main Body Surface Treatment |

| Tip Surface Treatment |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | MISUMI | MISUMI |

| Product SeriesDòng sản phẩm | Spring Plungers / Wrenches / Block Plungers - Stainless Steel | |

| CADCAD |

|

|

| From | 166,280 VND Special Price On Sale Till 31/03/2025 | 162,360 VND- |

| Days to ShipSố ngày giao hàng | Same day or more | Same day or more |

| Outer Dia. M(mm) | 3 ~ 16 | 3 ~ 16 |

| Stroke S(mm) | 1.5 ~ 20 | 1 ~ 4.5 |

| Tip Material | Stainless Steel | Stainless Steel |

| Body Material | Stainless Steel | Stainless Steel |

| Mounting Method | Screw-In | Screw-In |

| Initial Load (Range)(N) | 0.01~50 | 0.01~50 |

| Lock | Not Provided | Not Provided |

| Tip Heat Treatment | Hardening | Hardening |

| Screw Type of Pin Plunger | Spherical | Short Stroke |

| Wrench Hole Shape | Hex | Hex |

| Main Body Surface Treatment | Not Provided / Electroless Nickel Plating | Not Provided / Electroless Nickel Plating |

| Tip Surface Treatment | Not Provided | Not Provided |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Outer Dia. M(mm)

-

Stroke S(mm)

-

Tip Material

- Steel

- Stainless Steel

- Plastic

- Others

- S45C

-

Body Material

- Steel

- Stainless Steel

- Aluminum

- S45C

-

Mounting Method

- Screw-In

- Press Fit

- Screw Clamp

-

Initial Load (Range)(N)

-

Lock

- Not Provided

- Provided

-

Tip Heat Treatment

-

Screw Type of Pin Plunger

-

Wrench Hole Shape

-

Main Body Surface Treatment

-

Tip Surface Treatment

Related Categories to Spring PlungersDanh mục liên quan đến Spring Plungers

FAQ Spring Plungers

- Question: How do spring plungers contribute to the efficiency of injection molding processes?

- Answer: Spring plungers boost injection molding efficiency by securely holding mold components, ensuring precise alignment for consistent results. During setup, they allow quick and effortless adjustment, reducing downtime. Their spring-loaded design maintains component position while enabling easy repositioning, simplifying the process. By streamlining setup and operation, spring plungers enhance productivity in injection molding, benefiting manufacturers by saving time and improving overall efficiency.

- Question: What is the importance of ball plungers in automation?

- Answer: Ball plungers are important in automation because they help things get in the right spot and stay there. Even though they're small, they're super good at making sure parts are in the exact place they need to be. They're used in tools and fixtures to keep stuff secure and move it exactly where it needs to go on the assembly line. Ball plungers are great because they make sure everything runs smoothly and works well, making factories more efficient and products better.

- Question: How is stainless steel utilized in plunger design?

- Answer: Stainless steel is often picked for plungers because it's good at resisting rust and staying strong, even when it's used a lot. It's durable and reliable, which means it lasts a long time without getting damaged, even in tough conditions or when exposed to chemicals that could corrode other materials. That's why it's commonly used in plungers for things like machines in factories, cars, and precision tools, where performance and low maintenance are essential.

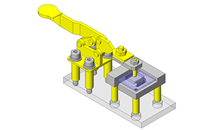

- Question: What role do locating, positioning, jigs & fixtures play in plunger technology?

- Answer: Locating, positioning, jigs, and fixtures are super important in plunger technology. Locating mechanisms make sure plungers and workpieces are in the right spot for machining or assembly, reducing mistakes. Positioning devices control how plungers move, so they go exactly where they're supposed to. Jigs and fixtures hold everything in place securely during machining or assembly, which helps prevent errors and makes things work faster and better. Overall, these parts work together to make plunger technology work smoothly and produce high-quality results.

- Question: What are the characteristics of spring plungers with flat tip?

- Answer: Spring plungers with flat tips are versatile tools designed for precise positioning and secure holding of components. Their flat tip ensures even pressure distribution, minimizing the risk of damage to surfaces. These plungers provide strong retention force, securely holding components in place. Some models allow for adjusting the spring tension to customize the holding force. Made from durable materials like steel or stainless steel, they offer longevity and resistance to wear. They are easy to install and replace, making setup and maintenance hassle-free.

- Question: What are the key considerations when selecting materials for plungers?

- Answer: When selecting materials for plungers, consider their strength, durability, and corrosion resistance. Ensure they can withstand operational forces without wearing out quickly. Check if they're resistant to rust and can handle the temperatures they'll encounter. Also, factor in the cost and ease of manufacturing. By evaluating these factors, you can choose materials that meet the needs of your application, providing long-lasting performance without breaking the bank. Ultimately, selecting the right materials ensures reliable and efficient operation of plungers in various industrial settings.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy