(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

type

- CDQSKWB□

- CDQSKWF□

- CDQSKWLC□

- CDQSKWL□

- CQSKWB□

- CQSKWF□

- CQSKWLC□

- CQSKWL□

-

Cylinder (Tube) Inner Diameter(Ø)

-

Stroke(mm)

-

Body Options

-

Auto Switches

-

Lead Wire

- 0.5

- 1

- 3

- 5

- None

-

The number of the switches

-

Type of Mount Support

- Compact foot type

- Flange type

- Foot

- Through-Hole / Both Ends Tapped Common (Standard)

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 32 Day(s) or Less

Specify AlterationsChỉ định thay đổi

CQSKW Series Non-Rotating Rod Type, Double Acting, Double Rod (CDQSKWB12-15D-M9BWV)

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

thận trọng

- ■ SMC Product Line

Webpages for products currently without individual pages on this site will be released on an ad-hoc basis. - Refer to the manufacturer's catalog for specification and material details.

- Product images may be representative images. Refer to the manufacturer's catalog for shape details.

Product Description

Compact cylinder that is ideal for machine designs with small space requirements.

[Features]

· The compact auto switch (M9) will not protrude from the switch mounting groove.

· Even when auto switches are used, they do not take up extra space.

· The cross-section of the cylinder tube is the same configuration with or without an auto switch.

· Square body shape that gives you flexibility for designing machines.

· Auto switch mounting direction allows for flexible design requirements.

· 2-way basic cylinder mounting.

· Non-rotating rod with high non-rotating accuracy.

CQSKW Series Non-Rotating Rod Type: Double Acting, Double Rod Specifications

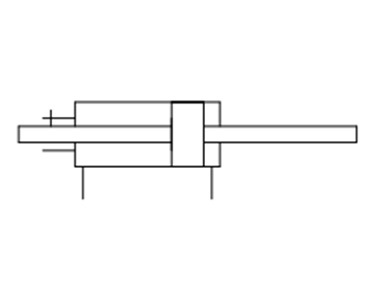

CQSKW Series symbol (without cushion)

| Tube Inner Diameter (mm) | 12 | 16 | 20 | 25 |

|---|---|---|---|---|

| Action | Double acting, double rod | |||

| Fluid | Air | |||

| Lubrication | Not required (non-lubricated) | |||

| Proof Pressure | 1.5 MPa | |||

| Maximum operating pressure | 1.0 MPa | |||

| Minimum operating pressure | 0.07 MPa | 0.05 MPa | ||

| Ambient and fluid temperature | Without auto switch: -10°C to +70 ℃ (no freezing) | |||

| With auto switch: -10°C to +60℃ (no freezing) | ||||

| Cushioning | None | |||

| Rod-end thread | Female thread | |||

| Stroke Length Tolerance | 0 to +1.0 mm | |||

| Piston Speed | 50 to 500 mm/s | |||

| Allowable kinetic energy J | 0.022 | 0.038 | 0.055 | 0.09 |

| Rod non-rotating accuracy | ±1 ° | ±0.7 ° | ||

Theoretical Output Table

(Unit: N)

| Tube inner diameter (mm) | Rod width across flats (mm) | Piston Area (mm2) | Operating Pressure (MPa) | ||

|---|---|---|---|---|---|

| 0.3 | 0.5 | 0.7 | |||

| 12 | 5.2 | 90 | 27 | 45 | 63 |

| 16 | 6.2 | 168 | 50 | 84 | 117 |

| 20 | 8.2 | 256 | 77 | 128 | 179 |

| 25 | 10.2 | 401 | 120 | 200 | 281 |

Diagram

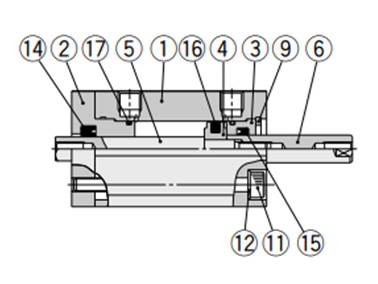

Diagram: standard, ø12 (12‑mm bore size)

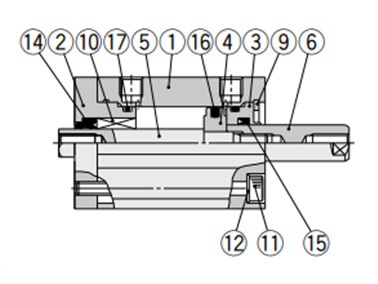

Diagram: standard, ø16 (16‑mm bore size) / ø20 (20‑mm bore size) / ø25 (25‑mm bore size)

Diagram: rod end male thread

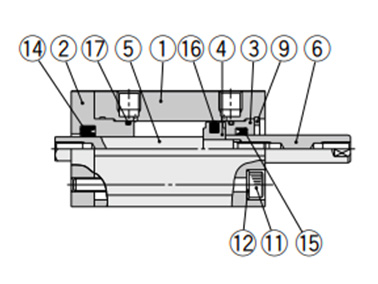

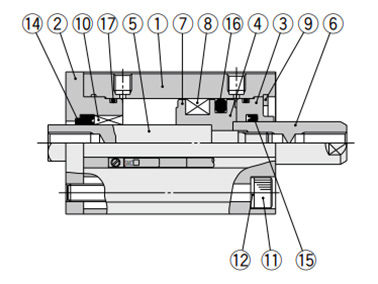

Diagram: with auto switch and built-in magnet, ø12 (12-mm bore size)

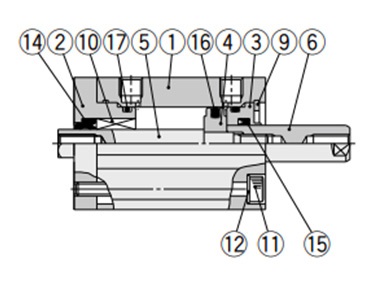

Diagram: with auto switch and built-in magnet, ø16 (16-mm bore size)

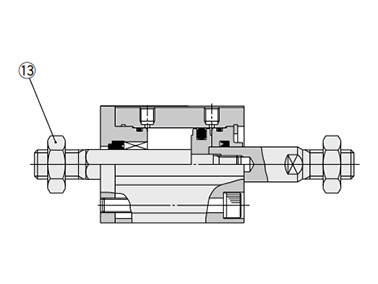

Diagram: with auto switch and built-in magnet, ø20 (20‑mm bore size) / ø25 (25‑mm bore size)

| Number | Part Name | Material | Notes |

|---|---|---|---|

| 1 | Cylinder Tube | Aluminum alloy | Hard anodized aluminum |

| 2 | Rod cover | Aluminum alloy | Anodized aluminum |

| 3 | Collar | Aluminum alloy | Anodized aluminum |

| 4 | Piston | Aluminum alloy | - |

| 5 | Piston rod A | Stainless steel | - |

| 6 | Piston rod B | Stainless steel | - |

| 7 | Spacer for Switch Type | Aluminum alloy | Chromate |

| 8 | Magnet | - | - |

| 9 | Retaining Ring | Carbon tool steel | Phosphate coated |

| 10 | Non-Rotating Guide | Oil-impregnated sintered alloy | ø16 (16‑mm bore size), ø20 (20‑mm bore size), ø25 (25‑mm bore size) |

| 11 | Hex Socket Head Cap Screw | Alloy steel | Nickel plated |

| 12 | Flat Washer | Rolled steel | Nickel plated |

| 13 | Rod end nut | Carbon steel | Zinc chromate |

| 14 | Rod seal for non-rotating | NBR | - |

| 15 | Rod packing | NBR | - |

| 16 | Piston packing | NBR | - |

| 17 | Tube gasket | NBR | - |

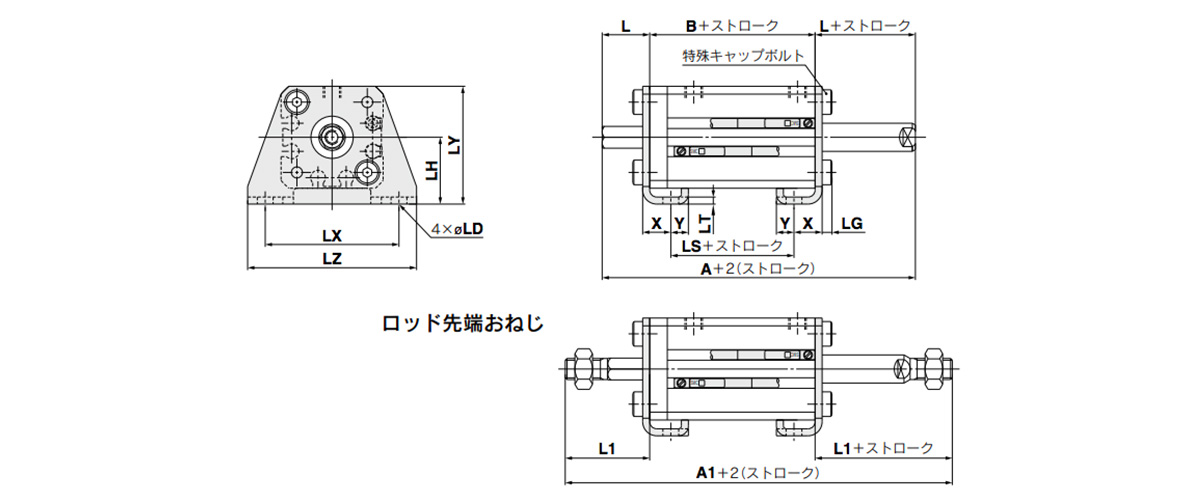

Drawing: ø12 to 25 (12‑mm to 25‑mm Bore Size)

Dimensional drawings: foot type; CQSKWL, CDQSKWL

(Units: mm)

| Tube inner diameter (mm) | Stroke range (mm) | Without auto switch | With auto switch | L | L1 | LD | LG | LH | LT | LX | LY | LZ | X | Y | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | A1 | B | LS | A | A1 | B | LS | |||||||||||||

| 12 | 5 to 30 | 54 | 75 | 27 | 15 | 59 | 80 | 32 | 20 | 13.5 | 24 | 4.5 | 2.8 | 17 | 2 | 34 | 29.5 | 44 | 8 | 4.5 |

| 16 | 5 to 30 | 54 | 78 | 27 | 15 | 59 | 83 | 32 | 20 | 13.5 | 25.5 | 4.5 | 2.8 | 19 | 2 | 38 | 33.5 | 48 | 8 | 5 |

| 20 | 5 to 50 | 60 | 88 | 31 | 19 | 70 | 98 | 41 | 29 | 14.5 | 28.5 | 6.6 | 4 | 24 | 3.2 | 48 | 42 | 62 | 9.2 | 5.8 |

| 25 | 5 to 50 | 64 | 99 | 34 | 19 | 74 | 109 | 44 | 29 | 15 | 32.5 | 6.6 | 4 | 26 | 3.2 | 52 | 46 | 66 | 10.7 | 5.8 |

- Foot bracket material: carbon steel

- Surface treatment: nickel plated

Precautions

Usage Precautions

Warning

*Do not apply reverse torque to the piston rods sticking out from both sides of this cylinder at the same time. Torque makes connection threads inside loosen, which may cause an accident or malfunction.

In addition, install or remove the load with the 2 flats of the piston rod fixed on the load mounting side. At this time, be careful not to apply torque to the non-rotating guide. Do not fix the other side of the 2 flats of the piston rod and then apply reverse torque.

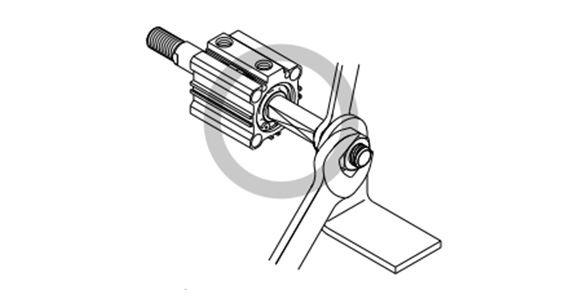

Example of correct usage of cylinder

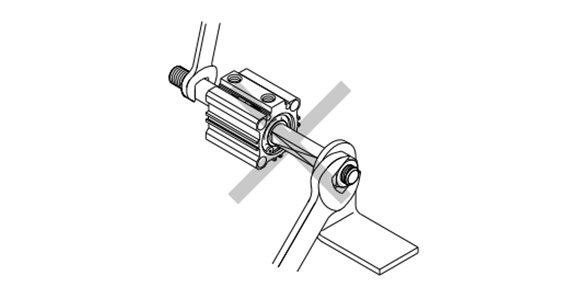

Example of incorrect use of cylinder

Caution

- *1Avoid applying rotational torque to the piston rod. The non-rotating guide may become deformed, compromising the accuracy. See below for the rotational torque allowance.

- *2The load on the piston rod must always be in an axial direction.

- ø12 (12‑mm bore size): 0.04 N·m or less

- ø16 (16‑mm bore size): 0.04 N·m or less

- ø20 (20‑mm bore size): 0.2 N·m or less

- ø25 (25‑mm bore size): 0.25 N·m or less

Installation and Removal of Retaining Rings

Caution

- *1For installation and removal, use an appropriate pair of pliers (tool for installing a type C-type retaining ring).

- *2Even when using an appropriate pair of pliers (tool for installing a type C retaining ring), proceed with caution as there is a danger of the retaining ring flying off the end of the pliers (tool) and causing bodily injury or damage to nearby equipment. After installation, make sure that the retaining ring is securely seated into the retaining ring groove before supplying air.

*See the manufacturer's catalog for product information other than that detailed above.

| Part Number |

|---|

| CDQSKWB12-15D-M9BWV |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Temperature (°C) | Operating Pressure (MPa) | Body Options | Auto Switches | Lead Wire | The number of the switches | Type of Mount Support |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 12 | 15 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9BWV | 0.5 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) |

Loading...Tải…

Basic InformationThông tin cơ bản

| Cylinder Operation Method | Double Acting | Rod Operation Method | Double rod | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | With rod detent function | Environment, Applications | Standard | End Locking | No |

| Valves | No |

Please check the type/dimensions/specifications of the part CDQSKWB12-15D-M9BWV in the CQSKW Series Non-Rotating Rod Type, Double Acting, Double Rod series.Vui lòng kiểm tra kiểu/kích thước/thông số kỹ thuật của phần CDQSKWB12-15D-M9BWV trong chuỗi CQSKW Series Non-Rotating Rod Type, Double Acting, Double Rod.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Products like this...

| Part Number |

|---|

| CDQSKWB12-10D-M9BV |

| CDQSKWB12-10D-M9BVL |

| CDQSKWB12-10D-M9BWV |

| CDQSKWB12-15D-M9NV |

| CDQSKWB12-15D-M9PWL |

| CDQSKWB12-15DM |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to ShipSố ngày giao hàng | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Temperature (°C) | Operating Pressure (MPa) | Body Options | Auto Switches | Lead Wire | The number of the switches | Type of Mount Support |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | 12 | 10 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9BV | 0.5 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) | ||

- | 1 Piece(s) | Quote | 12 | 10 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9BV | 3 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) | ||

- | 1 Piece(s) | Quote | 12 | 10 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9BWV | 0.5 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) | ||

- | 1 Piece(s) | Quote | 12 | 15 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9NV | 0.5 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) | ||

- | 1 Piece(s) | Quote | 12 | 15 | -10~60 | 0.07~1 | Standard (rod-end female thread) | M9PW | 3 | 2 pcs. | Through-Hole / Both Ends Tapped Common (Standard) | ||

- | 1 Piece(s) | Quote | 12 | 15 | -10~70 | 0.07~1 | Male rod end | Without auto switch (built-in magnet) | None | None | Through-Hole / Both Ends Tapped Common (Standard) |

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy